Connecting the underfloor heating to the heating system

Heating of residential premises today is a whole set of very different options, each of which is technologically advanced, cost-effective and efficient. In most cases, residents of city apartments are content with centralized heating services. Only in recent years has the process of an individual approach to the heating of residential premises in apartment buildings begun. The main emphasis is on the installation of autonomous heating systems in new buildings, followed by the connection of heating radiators. In many households today you can find combined options, underfloor heating along with radiator heating.

As an additional method of heating, it is becoming fashionable to use water floors. For a private house and a city apartment with autonomous heating, such a heating scheme is quite real. Another thing is centralized heating in old apartment buildings. In this case, equipping a warm floor in an apartment is a problematic task. However, there are ways to connect underfloor heating as an additional source of heating in a city apartment. Consider what options exist in this case, how you can install a warm floor at home.

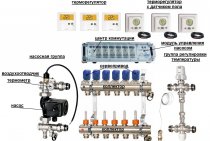

Module for connecting underfloor heating to the heating system

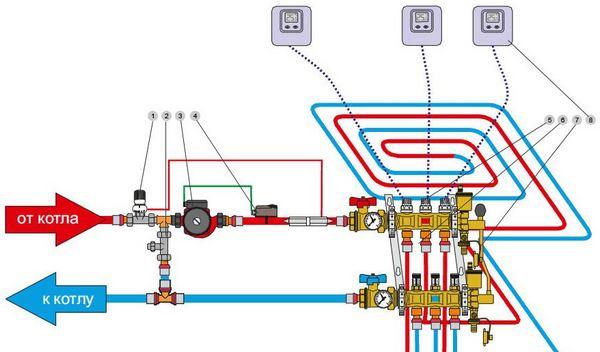

Now let's talk about the operation and device of the module for connecting the underfloor heating circuit. The underfloor heating adjustment module works according to all the laws of the underfloor heating system. That is the module, due to the thermal head, turns off or turns on the supply of coolant to the underfloor heating circuit. In this case, the module is mounted on the return line. For this purpose, an air vent machine is mounted in the module. To expel air from the underfloor heating circuit.

The module is assembled in a plastic box with a lid and is used for flush mounting inside the wall. The lid has a hole through which the thermostatic head protrudes to measure the room temperature. And, therefore, the resumption or termination of the circulation of the coolant in the circuit of the warm floor.

The thermal head is mounted on a cut-off valve under the thermal head. The valve, in turn, is connected to a tee, into which an air bleeder is screwed. All this is located inside the box.

Installation of the underfloor heating circuit begins with the installation of the underfloor heating module. To do this, you need to choose a place inside the room near the door. It is from the side of its opening. At a height of not more than 1000 mm. Make a recess in a brick wall or a frame in a drywall wall. It is also necessary to make a groove from the recess to the floor measuring 50x50 mm.

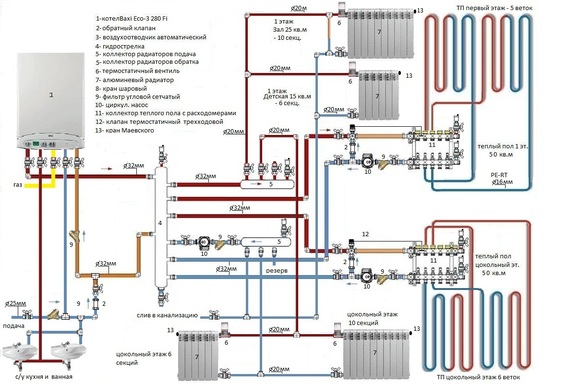

Now we mount the underfloor heating adjustment module. We mount a warm floor cake according to all the laws of the genre (details here) and connect the pipes of the underfloor heating circuit to the radiator heating system, following this scheme.

But not everything is so smooth in our time. Modules for connecting the underfloor heating circuit are expensive and not always available. In this case, the module for the circuit can be made with your own hands.

To do this, take, for example, a shield for installing electricity. The shield or junction box can be plastic or metal. The same applies to distribution boxes. In this case, we choose the size of 200x300 mm. 300 mm exactly in height. Now we take a direct radiator valve under the thermal head. Set the direction up. From below we fasten a fitting for connection of pipes. Maybe press or TM. From above we wind the outlet ½ inch with internal and external threads. We wind a ½ inch tee onto the outlet. We screw the air vent machine on top. From below a fitting for connection of pipes. Maybe press or TM. Now, using metal clamps on a hairpin, we mount this structure in a shield.

We connect a warm circuit to the module and enjoy its work and a warm floor.

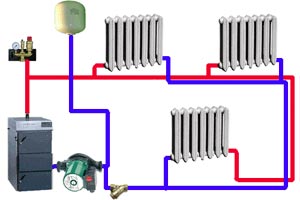

Heating system Leningradka

Leningradka, that is, the most economical of the existing heating systems, appeared several decades ago in the Soviet Union. This one-pipe system is very easy to implement, it is not difficult to mount it with your own hands. We will understand the intricacies of the design.

It all starts with calculation

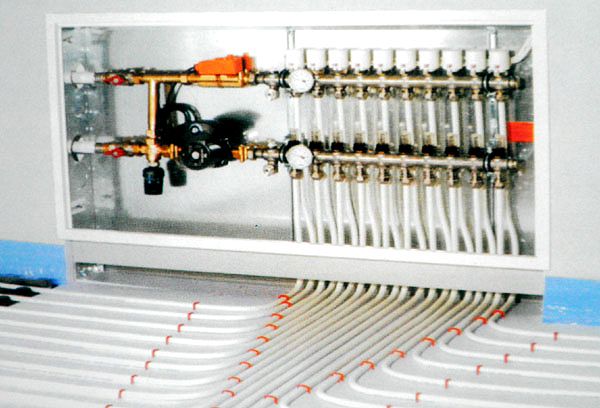

In the device of a warm floor, two main components can be distinguished: the floor itself, on which pipes with the heat carrier are laid, and the distribution unit, through which the connection to the heating system is made.

The efficiency of the underfloor heating as a heating system depends on its heat transfer, which in turn is determined by the amount of heat energy coming from the boiler. Here the relationship is simple: the longer the pipes, the more heat they will transfer to the surface of the concrete floor.

You can determine the optimal length of the pipes using the calculation. The easiest way is to use a special online calculator to calculate the underfloor heating. If underfloor heating is used as an auxiliary heating system, an online calculator may be sufficient. If we are talking about the main heating, the calculations will have to be done with specialists. Having decided on the length of the pipes, you can proceed to preparing the floor surface for installation work.

What are the nuances to pay attention to

The main differences include the temperature regime of the coolant, the operating temperature of which ranges from 32°C to 39°C. At the same time, in radiator devices, this figure is about 82 ° C

If we take into account the main method of heating the surface of the warm floor and the method of arrangement, then you should pay attention to such important nuances:

- When using porcelain stoneware or tiles as a floor covering, you will need a screed, the layer of which will reach 5.5 cm. In this case, the step between the installed pipes should be 10-15 cm.

- Before laying the top coat, a very thin layer of screed (no more than a few centimeters) is made. At the same time, to reinforce it, a reinforced mesh is used, the installation of which is carried out on top of the pipes.

- Reduces the heat output under the laminate used layer of insulation, so the use, in this case, is not recommended.

- Fittings are used to connect and fix the floor contours to the collectors, regardless of the chosen method and installation scheme of the device.

Central heating

That is, pipes with a circulating coolant coming from a local thermal power plant or another type of station that prepares a coolant for heating a home are brought into the house.

Regardless of the distribution system inside the house - radiator, underfloor heating or something else - there is either one or two pipelines that supply the hot coolant and take the cooled one - the return line. Thus, the supply of a heat source to the house is carried out centrally, without independent efforts, which makes the power supply system more stable, reliable and removes a lot of worries from the residents.

Rules for mounting system elements

Steel pipe connection

Metal pipes for heating systems are connected in the following ways:

- carving,

- gas-flame / electric arc welding.

It is welding as a connection that is in greatest demand due to the high strength of the connection. Before welding, the joined parts are cleaned with a file, a chamfering machine, a grinder, after which they are washed and degreased. How solid fuel boilers are installed, you can read in our article.

Gas welding is carried out using a filler wire forming a seam. When arc welding in a pipe, “+” is connected to the “-” electrode. The connection is inseparable.

Threaded connections make it easy to repair the heating system (mounting / dismantling). For connection, various steel and cast iron fittings are used that comply with GOST, as well as seals (linen and asbestos strands with impregnations). Installation is carried out with pipe wrenches after cleaning the threaded connections from dust and dirt particles.

Cutting metal pipes is best done with reciprocating saws.

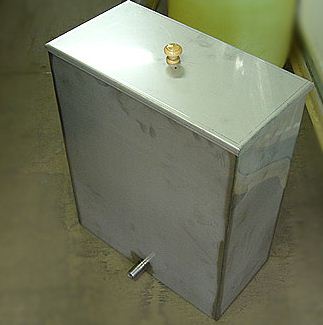

Expansion tank

An open type tank is a container with a threaded connection at the bottom, through which the connection is made.

Expansion tank open type

The closed tank is similar to a sealed capsule. It is usually connected before the pump in the return pipeline. For installation, a gas wrench is used, adjustable, a step may be useful. The tank is installed in a place where access for commissioning and repair work is not difficult. Installation is carried out strictly at positive air temperature.

Before installing the membrane tank, adjustment is carried out. The plastic plug is removed, the nipple is unscrewed. A car pump is connected to pump air up to the 1.1 kPa mark. In the heating circuit, the pressure must necessarily be > 0.2 kPa than in the tank.

A fitting cuts into the main heating pipeline - a branch. A pipeline and an “American” tap are connected to it, which will allow in the future to carry out repair work without draining the coolant from the system. The threaded connection of the "American" and the tank is sealed with linen strands.

The container itself is attached to the wall with dowels. For fastening, special holes are provided in the case or a metal clamp is used.

Tank attachment example

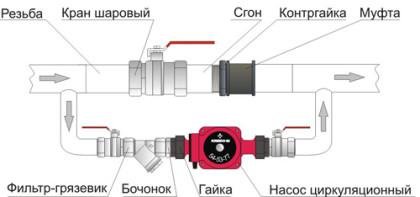

Circulation pumps for heating

The system can be equipped with a "dry" or "wet" pump. The rotor of the first device does not come into contact with the coolant, the efficiency is about 80%, a lot of noise is generated during operation.

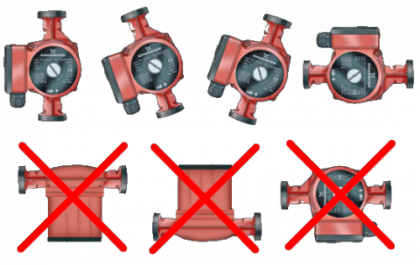

"Wet" devices are less noisy and demanding, but the efficiency is not more than 50%. Installation is carried out according to the diagram below. The pump shaft must be horizontal.

In order to further facilitate possible repair work, it is recommended to install a polypropylene ball valve on both sides of the pump. Having blocked them, it is permissible to dismantle the pump without draining the coolant from the system.

After assembling the fittings, the pump cuts into the main pipeline (on the return line, closer to the boiler) with the obligatory installation of a bypass.

Connecting a warm floor to individual heating

To connect the structure to the individual heating system in a private house or apartment, it is necessary to correctly design the structure contour, take into account the distance between the turns and the distance from the boiler, as well as the estimated location of furniture or other decorative and interior elements. It is recommended to locate the circuit under an open, unoccupied floor surface.

In a private house, the laying of this type of heating usually occurs during a major overhaul, when the floors are reinforced and poured with cement mortar. On a wooden floor, laying a water heating structure is also possible if there is a frame made of additional logs and a new coating. It should be noted that installation on a wooden base provides for effective thermal insulation on the underside of the structure. Also, laying on a wooden frame should ensure a uniform distribution of the generated heat, for which recesses can be equipped in the logs for the location of the pipeline.

A two-pipe heating scheme is considered the most optimal for connecting and operating underfloor heating. The two-pipe radiator heating system provides for separate pipelines for the return and hot water supply connected to the main boiler.In this case, you can connect the underfloor heating system in one place on the open part using the mixer module or conventional ball valves, which will provide the necessary water flow through them.

Important! The two-pipe type of connection can ensure the normal functioning of the underfloor heating circuit, the length of which does not exceed 50 m. The gravity scheme provides for the natural circulation of water through the pipeline

The water floor heating circuit must be connected to such a circuit, taking into account the slope of the line. You need to connect the system at one end of the room, and output the return line at the other. Do-it-yourself installation and connection to such a system is a very time-consuming process that requires special knowledge.

The gravity scheme provides for the natural circulation of water through the main pipeline. The water floor heating circuit must be connected to such a circuit, taking into account the slope of the line. You need to connect the system at one end of the room, and output the return line at the other. Do-it-yourself installation and connection to such a system is a very time-consuming process that requires special knowledge.

You should also choose the right pipe diameter for both battery connection and underfloor heating. The size of the pipes of the main line connected to the boiler must be at least 32 mm.

The layout of the pipeline can be made according to the principle:

The diameter of the pipe for laying a warm floor, when a single-pipe or two-pipe heating circuit is installed, should not exceed 18 mm.

You can connect a water heated floor with your own hands, while observing the basic requirements for the installation of such structures. Using this method of heating will allow you to abandon the open radiator heating scheme, which is also acceptable in a private wooden house. In case of insufficient external insulation of the building or an uninsulated wooden base, it is recommended to use the two heating principles together, depending on the efficiency of the boiler. The installation algorithm that determines how to make a warm floor from heating should include testing the operation with an open system that is not filled with cement screed. The final formation of the flooring in the house is possible after a certain period of time, making sure that the structure is intact and there are no leaks.

(No ratings yet)

Electric floor heating

During the construction of a cottage, such equipment can be installed as the main type of heating and save on an alternative device.

Necessary conditions to make the main heating with electric underfloor heating:

- Uninterrupted power supply;

- Stable voltage in the mains;

- Availability of reliable electrical wiring.

In winter, force majeure situations are possible, for example, heavy snowfall or a blizzard, when power outages occur. In this case, the house will remain without heating. It follows from this that such equipment can be used as the main, but not the only source of heat.

Electric floor device technology:

Electric floor device technology:

- Preparatory work, shtrobovka walls for wiring and thermostat, leveling and cleaning the surface;

- Laying thermal insulation;

- Mounting guides;

- The heating cable is laid along the guides. You can use heating mats where the cable is already fixed on the base;

- Connecting a thermostat;

- Filling with cement-sand screed;

- Clear flooring.

It is possible to heat a house using only a floor based on a heat cable instead of radiators, but such a scheme is unstable and expensive.

Infrared film underfloor heating

Modern technology of IR floors provides for laying infrared film not only on the floor, but also on the ceiling.Sometimes IR film is also placed on walls. A house without heating batteries is equipped with infrared flooring from below and above.

Considering that the energy source for the infrared film is electricity, which in some cases may disappear, it is rational to equip the house with an alternative way to heat the room.

Rod heating system without the use of radiators

Rod flooring is mats made of carbon rods. Heating is carried out by infrared radiation. The floor is powered by the mains, so it is not recommended to equip the house with only rod IR flooring. In the event of a power outage, there must be an alternative source of heat.

Floor plan:

- Rough surface;

- Thermal insulation;

- IR rod decking;

- Screed;

- Clean surface.

The scheme may vary depending on the type of flooring. Due to the fact that the rods are immersed in the screed, this system can be laid under the tiles.

It is important to equip a house or apartment with a heating system that will provide comfort and savings, taking into account the pros and cons of various types of underfloor heating. Water heated floor is the best choice if it is used as the main source of heat

Other types of floor heating, when properly calculated and installed, are able to fully provide a comfortable indoor climate, but they depend on an uninterrupted supply of electricity.

Characteristics of the warm floor

Underfloor heating can be called the most economical option in the presence of central heating

In order to carry out its installation, it is necessary to take into account a number of aspects. The essence of such horizontal heating is the endless circulation of hot water from the central heating battery along a special floor circuit.

The floor can be single or double. The circuit itself is a curved pipe through which hot water passes. In the process of circulation, the pipe heats up and intensively gives off heat to the floor covering.

In order for circulation to occur correctly and productively, a special pump is needed. If the heating batteries do not have it, then it will be necessary to purchase it. Some homeowners decide to do without it by creating a slope in the contour with their own hands, but this process is too laborious and, in essence, impractical, because you can just buy a pump.

A system with a slope in the circuit implies circulation under the action of physics, namely gravity. In this case, the movement of water will not have the required speed, and heating due to the slope will be uneven.

An important aspect is the calculation of the length of the contours. It depends directly on the area of the room. If the room is small, then one pipe will be enough. Its length should not exceed 30 meters.

If the quadrature exceeds 17 sq.m., then two pipes will be required. In this case, the length of the circuit should not exceed 50 meters. You can separate the contours if the length of the pipes is more than 30 and 50 meters, respectively, but they must be laid in parallel.

How does underfloor heating work from a heating boiler

The range of work that needs to be done to power the warm floor from the heating boiler is no different from that when crashing into a centralized route

You only need to pay attention to the following factors:

- Presence of a security group. If it is absent in the design of the boiler, then the group will need to be installed in accordance with the design standards for heating networks.

- Insertion of the collector node. This element will allow you to distribute the coolant flow between the radiators and the underfloor heating in the required proportion.

- Installing a circulation pump. If it is not built into the boiler, then you will have to spend some money on the purchase, which guarantees the efficiency of heat supply and its uniform distribution throughout all rooms of the building.

Nuance - any modifications carried out on central heating must be agreed and accompanied by a certain set of documents, one of which is an approved and agreed design solution. Buying a boiler will be an expensive pleasure, but it will allow you to avoid many troubles with licensing authorities.

Expert answers

Boss Heat:

Underfloor heating in an apartment is comfortable and safe if everything is done correctly. It should work from an individual heat generator - a boiler. It cannot be connected to central heating: 1. you will leave all other residents without heat2. the temperature of the heat carrier of the warm floor is up to 45 degrees, in batteries up to 70 degrees.3. at the beginning of the season, air is removed from the central heating batteries, if it gets into your underfloor heating system, you are trying to expel it from there.

Boyan77:

I don't think it's worth it.

Corum:

not worth it if you have little money))) you can.

VIK:

You can connect, but it's redundant.

Natalie:

And then it will explode, they will make the floors gouge to eliminate the impulse. And in winter you will complain about poor heating in the apartment due to connection to the central one (okay, your neighbors can complain), there will be no pressure, the parameters will be low.

Natalia V.:

and how will the neighbors from below react to this (they will have additional heating through the ceiling), and it will be hot for you ...

Alexandra:

It makes no sense, because the warm floor is good in winter, and at this time the batteries are heating, and if everything is done correctly, it will be warm and cozy. We do just that, the water is hot in the batteries - that's what it heats. Why waste energy...

ArkPol:

The power supply system from the central heating must be done through a filter and a comb, but this reduces the hydraulics of the existing house (entrance) heating system, which threatens with scandals or complaints. That is, if you really want a warm floor, then it’s better from your own heat generator, which is not always acceptable either. because there is an emission of combustion products into the air, and this is actually to the neighbors through the windows

There is an option with a chimney boiler. In your version, you need to look at the specific layout, take into account the “wind rose” and, importantly, what are the requirements for permitting services. T

That is, theoretically, all this is real, practically every little thing can become a stumbling block. There is an alternative option - these are electrically heated floors. BUT keep in mind that underfloor heating is not recommended in rooms with long stays of people. It is harmful to breathing, lungs, because a fine dust suspension rises up from the floor with an air flow. It is especially harmful for children prone to asthma and allergies. Warm floors can be installed in bathrooms, bathrooms, kitchens, dining rooms, corridors, hallways, living rooms.

Olga:

It seems to me that this is a whim. Central heating is quite enough. If your feet are cold, buy a woolen carpet.

Dunno:

And I think it's possible. Insert taps into one pipe at a distance of 50-80 cm, then a sump, thermal head, pump, check valve, manifold assembly with air vents, etc. Penofol is thicker, so that the neighbors from the bottom can heat the ceiling less. Dare.

Anatoly Bondar:

Central heating works only with vertical batteries connected in series (floor-by-floor) to the return line. Giving off heat, the water becomes heavier and drains down, sucks in hot water, the system works like a pump in a separate riser. Other devices slow down the flow and can generally stop the circulation of water in a separate riser. And yet - metals corrode from central heating water, and you may have to survive an accident and flooding. This is best done with an individual boiler and pump.

Victor:

Theoretically yes, practically very difficult, too much automation.

Paul:

I know my friend made from central heating in the kitchen. I know I drilled holes in the floor into the basement (he lives on the 1st floor) I put the pipes in, I don’t know how I hooked them up.covered with expanded clay and laid tiles on top. It's probably been 5 years already. cool floor is always warm even in the burnout.

Grandfather Au:

it is advisable to throw a separate thread, since the floor should be at a temperature of no more than 45C, well, try to put it on the return line in series, by the way, there should be control valves on the convectors to set the balance of the system

Alexander:

Do you have neighbors downstairs? Ask them... I don't think they can advise you... make the floor with electric heating ...

errare humanum est:

The floor will be cold if the battery is connected. The water must be hot for the floor.

Tolik Panarin:

This must be counted. And indeed, this idea is prohibited. The warm floor is made on the basis of electric heating, not water.

kiril deh:

I have a similar situation. advised to put a pump on the supply line and then there will be normal circulation. By the way, it’s a very small room, I have 9m for the toilet. sq. took about 40 meters

Yuri Dubov:

Connect the convector to the return line, everything will be fine.

Oleg:

Wow, Katherine! Beauty will save not only the world, but also you in winter... What dawned on you... But since you understand everything so well, put the pump on. You have no way out.

System elements

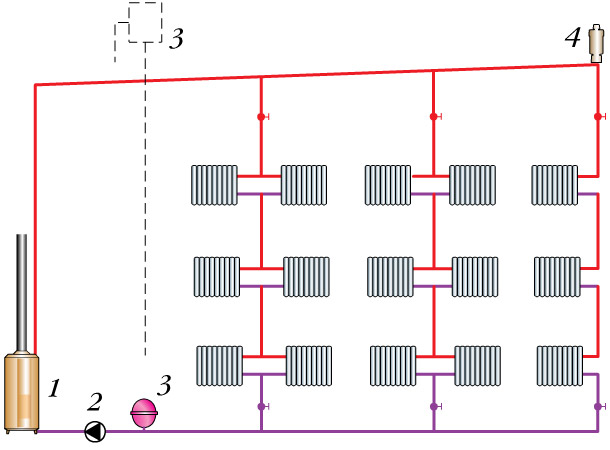

Leningradka consists of the following elements:

- heating boiler, which is usually installed in the utility room (boiler room);

- pipes for riser and piping;

- expansion tank (membrane or not sealed);

- heating radiators.

To increase efficiency, the system can be supplemented with the following components:

- Mayevsky cranes for bleeding air from the system;

- hydraulic pump. Improves circulation, but makes the system volatile. Installed on the return pipeline;

- bypasses with needle valves, allowing smooth regulation of the coolant flow;

A bypass in a heating system is a small piece of pipeline that is installed parallel to valves, shut-off and control valves.

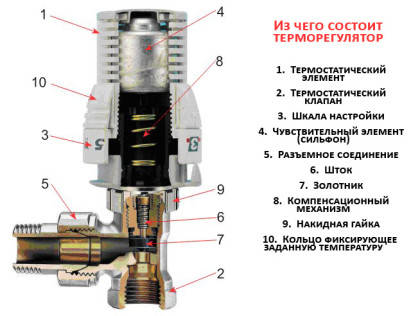

Temperature controllers for batteries

Ball valves on radiators

Preparatory work

A water heating system can be durable and extremely wear-resistant if installed in accordance with all the rules. First of all, it is necessary to prepare the surface for drawing the contour.

- It is necessary to free the floor from the floor covering with your own hands, if any. The subfloor must be "bare".

- The water floor system can only be installed on a flat surface. If there are cracks or other flaws on the surface, they must be eliminated with cement. The presence of distortions can be seen using the level.

- If the irregularities are insignificant, then it will be enough to fill the perimeter with an even layer of sand. Some experts recommend using quartz sand. Since this is an additional thermal insulation of the layer.

- The use of a damper tape is an integral stage of work. It is glued to the wall around the entire perimeter of the room, as well as at the junction of the contours. This material absorbs vibrations and provides additional thermal insulation. The process of rapid heating and cooling, thanks to the damper, will not promise the destruction of the screed. For the convenience and speed of this procedure, it is recommended to purchase rolls with an adhesive side. The tape is attached to the concrete with dowel-nails.

The preparatory work for the water floor is completed on this, then you need to think about installing thermal insulation with your own hands.

How it works

The heated coolant from the boiler, expanding, moves through the pipelines. As it moves through pipes and radiators, the water (or antifreeze) gives off heat and cools down, returning back to the boiler. The system must have a damper that compensates and equalizes hydraulic pressure. The expansion tank is installed at the top of the system. Thus, a continuous circulation is produced.Also in the system there is a branch pipe with a tap for draining from the coolant system. The system is filled from the central water supply through a tie-in to the return pipeline.

The system is closed (Closed one-pipe heating system). Radiators on the entire floor are located on the same level. Since the temperature of the coolant is gradually decreasing, radiators with the maximum number of sections are installed in the farthest rooms to equalize the temperature regime in the rooms.

Pipes are laid in two ways:

- over the finish flooring, along the walls. This installation method is quite simple. For better circulation, the supply pipes and the return pipe are mounted with a slight slope;

- inside the floor cavity. This flush-mounting method involves the use of rolled insulating materials to prevent heat loss.

Laying heating pipes in the floor

You can regulate the temperature in the rooms by installing thermostats or taps that block the access of the coolant to one or another radiator connected in series. This allows you to save on fuel without wasting it.

Leningradka with a warm floor