5 General data on working drawings

5.1 General data on working drawings (GOST 21.101) of heating, ventilation and air conditioning systems include:

a) a list of working drawings of the main set;

b) a list of reference and attached documents;

c) a list of the main sets of working drawings;

d) symbols;

e) general instructions;

e) layout plan for the placement of system installations;

g) characteristics of systems;

i) the main indicators according to the working drawings of the OB grade.

5.2 List of working drawings of the main set (clause , listing a) are in form 1 GOST 21.101.

5.3 List of reference and attached documents (clause , listing b) are in form 2 GOST 21.101.

5.4 List of main sets of working drawings (clause , listing v) are compiled in the form 2 of GOST 21.101 in the presence of several main sets of working drawings of the OB grade and are given on the sheet of general data for each of these sets.

5.5 On the sheet of general data on the working drawings, symbols are given (clause , listing G), not established by state standards, the values \u200b\u200bof which are not indicated on other sheets of the main set of working drawings of the OV grade.

5.6 In general instructions (, listing d) lead:

— the basis for the development of working drawings of the OV grade (design assignment, approved feasibility study (project) for construction, approved (approved) justifications for investments in construction for technically simple objects);

– a record of the results of the check for patentability and patent purity of processes, equipment, devices, structures, materials and products for the first time used or developed in the project, as well as the numbers of copyright certificates and applications for which decisions were made to issue copyright certificates for inventions used in the working documentation ;

- a record that the working drawings are developed in accordance with applicable norms, rules and standards;

— information about who owns this intellectual property (if necessary);

— design parameters of outdoor and indoor air;

- data on the heat carrier, coolant (name, flow rate, parameters);

- references to the Construction Norms and Rules (SNiP) and other regulatory documents, according to which the calculation of heating, ventilation and air conditioning systems was made;

- requirements for the manufacture, installation, testing, anti-corrosion protection, thermal and fire insulation, fire-retardant coating of air ducts and pipelines, as well as the composition of insulating structures;

— special requirements for installations (explosion safety, acid resistance, etc.);

- a list of types of work for which it is necessary to draw up certificates of examination of hidden works.

In general instructions, one should not repeat the technical requirements placed on other sheets of the main set of working drawings of the OV grade, and describe the technical solutions adopted in the working drawings.

5.7 On the layout of system installations (p. , listing e) are applied:

- contour of the building (structure);

- the coordination axes of the building (structure) and the overall dimensions between the extreme coordination axes;

— system installations;

— coolant input;

- heating point.

The installations of the systems on the plan diagram are depicted by dots with a diameter of 1–2 mm indicating the designation of the installation on the shelf of the leader line and under the shelf - the number of the sheet on which the drawing of the installation is shown.

The name of the plan-scheme for placing installations of systems is indicated in abbreviated form - "Plan-scheme".

An example of the implementation of the layout plan for the placement of system installations is given in the appendix.

5.8 Characteristics of systems (clause , enumeration well) is performed in the form of a table in the form of . In the absence of certain types of equipment in the systems, the corresponding columns are excluded from the table.

If the table is divided into parts, then at the beginning of each subsequent part, the column "System designation" is placed.

In standard projects, the characteristics of air heaters and, if necessary, other equipment are indicated for the calculated outside air temperatures adopted by the project.

5.9 The main indicators according to the working drawings of the OB grade (p., listing and) is performed in the form of a table in the form of . If necessary, additional columns are included in the table (for example, specific heat consumption).

2 Normative references

Present

the standard uses references to

the following standards:

GOST

2.316-68

ESKD. Drawing rules

inscriptions, technical requirements and

tables

GOST

2.782-96

ESKD. Conditional graphic designations.

Hydraulic and pneumatic machines

GOST

2.785-70

ESKD. Conditional graphic designations.

Pipe fittings

GOST

21.101-97

SPDS. Basic requirements for the design

and working documentation

GOST

21.110-95

SPDS. Specification execution rules

equipment, products and materials

GOST

21.112-87

SPDS. Handling equipment.

Conditional images

GOST

21.114-95

SPDS. Rules for sketching

drawings of general views of non-standard products

GOST

21.205-93

SPDS. Symbols for elements

sanitary systems

GOST

21.206-93

SPDS. Symbols of pipelines

GOST

21.404-85

SPDS. Automation of technological

processes. Symbols for conventional devices

and automation tools in diagrams

GOST

21.501-93

SPDS. Execution rules

architectural and construction workers

drawings

GOST

3262-75

Pipes steel water and gas.

Specifications

3 Definitions

Present

The standard uses the following definitions:

3.1 system:

Complex

functionally related.

equipment, installations (blocks),

devices, products, pipelines and

(or) air ducts (for example, a system

supply P1, exhaust system V1, system

heating 1, heating system

installations P1 - P3).

3.2 drawing

systems: Drawing,

relative location

functionally related.

equipment, installations (blocks),

pipelines and (or) air ducts and

other parts of the designed systems.

3.3 installation:

Conditional

name of the complex of interconnected

equipment and (or) devices, and when

the need for pipelines (air ducts),

attached to the installation equipment

systems (for example, installation of a supply

systems P1, installation of an exhaust system

IN 1).

3.4 drawing

settings: Drawing,

containing a simplified image

installations that determine their design,

dimensions, relative position and

designation of installation elements and

other necessary data.

3.5 Applied in

this standard terms according to GOST

21.110 and

GOST

21.114

are given in Appendix A.

EEE

7 Entrance to the tunnel, combined with forced ventilation

|

. 4 |

mm |

|

|

l I I |

||

|

>rk |

i - |

8 Tunnel entrance combined with exhaust ventilation

——N-

9 Hatch on the tunnel

3 minutes

Note - Symbols on network plans are depicted on a scale in accordance with Table 2, but not less than the dimensions indicated in the "Designation" column.

12

GOST 21.705-2016

Annex B

(reference)

An example of the implementation of a heat network plan

13

GOST 21.705-2016

Annex B

(reference)

An example of a heat network scheme

14

Annex D

(reference)

GOST 21.705-2016

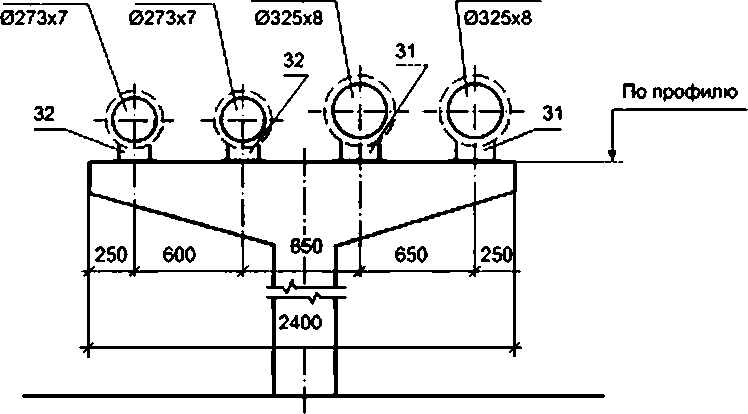

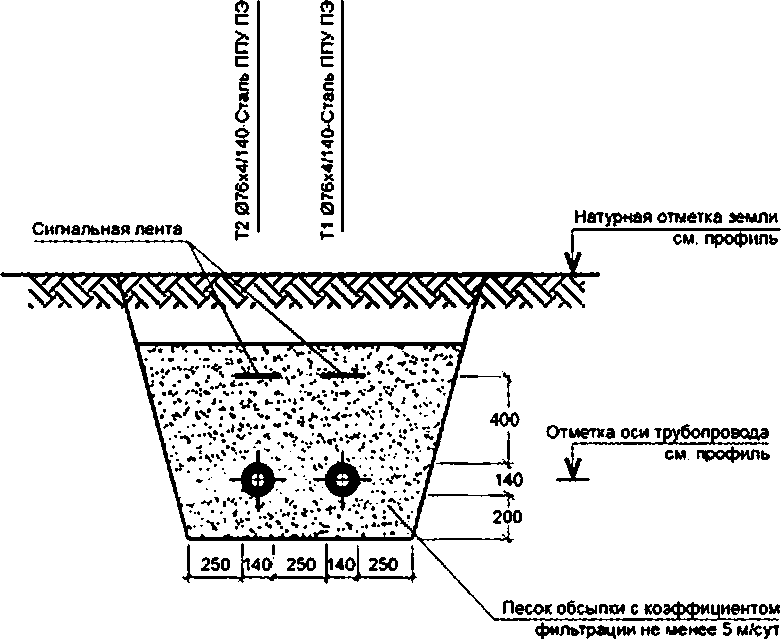

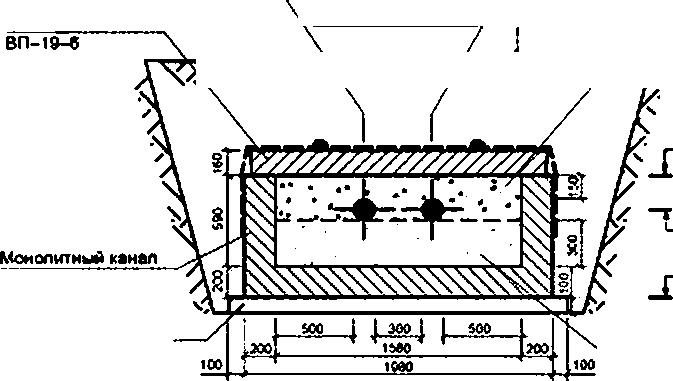

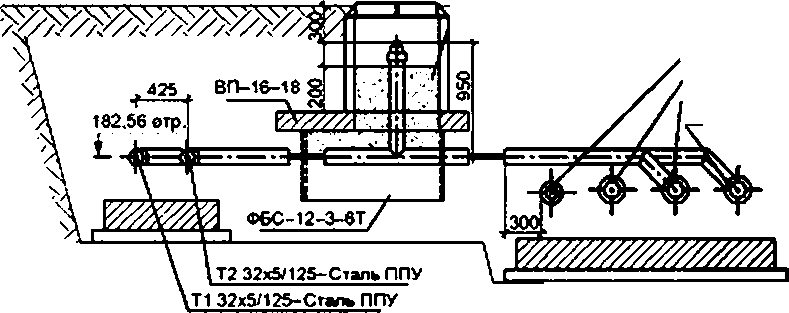

Examples of cross-sections of heating networks

1-1

Т4 ТЗ Т2 Т1 Тb Т5

Figure D.1 - Cross section for underground laying

3*3

T2 T1 Tb T5

Figure D.2 - Cross section for above-ground laying

1S

GOST 21.705-2016

Figure G.3 - Cross-section with no-cap laying in a trench

overlap ptta

1*2 076x4L4O-Stap PLU-LE

J1 076×4/140-PPU-PE steel natural ground mark

see profile

7V7J meadow L&G y.\ry-i

NNV; NN^NN^NN^ANCn V.VVTx filtration not less than 5 s/yut

Channel ceiling elevation

see profile

Elevation of the axis of the pipeline, see profile Elevation of the bottom of the channel

no pass concrete preparation

see profile

Base sand with a filtration coefficient of at least 5 m/day

Figure D.4 - Cross section when laying networks in the filling channel

16

GOST 21.705-2016

Т2 07bх4L4О-Stap PPU-LE

Figure D.5 - Cross section. Channelless laying and a trench for concrete preparation

17

5400

GOST 21.705-2016

Annex E

(reference)

Examples of executing a piping node plan

UTZ

Figure E.1 - Captivity of the pipeline node with underground channel laying

1v

GOST 21.705-2016

ТЗ 133х5/225-PPU steel T2 133×5/225-PPU steel

Figure E.2 - Plan of the pipeline assembly for channelless laying

Mixed sap with a filtration coefficient of at least S s / day

$183.61

T4Yu8k&«180-StapPPU TZ 133k5^225-PPU steel T2 133x5/225-PPU steel T1 133x5/225-PPU steel

r 182.28 1r. /

L 502 L S25 I 525 ]

Figure E.3 - Cross-section of a piping assembly for a trenchless laying

19

GOST 21.705-2016

UDC 697.34.002.5:002:006.354 MKS 01.100.30 Zh01

Key words: heat network, pipelines, pipeline elements, pipeline fittings, U-shaped compensators, network diagrams, elements of heat networks, channelless laying, non-linear channels, angles of rotation

Editor L.S. Bogachsnkova Tezhiesky editor 8.N. Prusakova Proofreader O-v. Lazareva Computer layout A.N. Zolotareva

Handed over to the set 21.122016. Signed and stamped 20.02.2017. Format 60»64^£ Headset Arial. Uel. oven l. 2.79 * acl 0.93. Uch.-iad. item 2.S2 * incl. 0.83. Circulation 48 zke. Per". 374. Based on the electronic version provided by the developer of the standard

Published and printed by FSUE kSTANDARTINFORM. 123885 Moscow. Garnet lane.. 4.

GOST 21.705-2016

Annex D

(reference)

Examples of execution of heat network profiles

Figure E.1 - An example of the design of a longitudinal profile for underground channel laying

Figure E.2 - An example of the shape of the longitudinal profile of the wireless gasket

GOST 21.705-2016