Recommendations for choosing a new generation mini-automatic machine

In addition to the characteristics discussed, it is worth paying attention to some more features:

- Power - is calculated individually for each type of boiler. It depends on the power whether the heating of the room will be sufficient.

- Efficiency - for electric boilers, the efficiency is high - 95–98%.

- Power adjustment - can be stepped or smooth. In models with an independent heating element, stepwise adjustment is used. Smooth is possible only in devices with a rheostat.

- Price - depends on many indicators: type of electric boiler (heating element, ionic), power, manufacturer, additional functions.

Reference! Particular attention should also be paid to the dimensions, weight of the electric boiler, efficiency, type of room that it will heat.

Carrying out service maintenance

It is worth noting that. like any other heating device, electric boilers require maintenance of some components. And all these works must be carried out both at the beginning of the heating season and at its completion.

The schedule of necessary technical work includes, first of all:

- Shutdown of the main electrical module;

- After that, it is worth cleaning the module from dust and other contaminants;

- Conduct a visual inspection of all module piping to ensure that there are no possible leaks;

- Next, dismantle the protective plugs and check the quality of fastening of the working contacts, if a loose connection of the contacts is detected, tighten them.

That's practically all that concerns service maintenance. You can install plugs in their regular places, connect the power supply of the main module, and start the system. It is also worth saying that for the most part these works are carried out by specialized organizations that sell and install these units. But as it can be assessed as a whole, this procedure does not have any subtleties, and it can be completely done independently.

As for the current repair, its regulations will be as follows:

- The first thing to do is to de-energize the module;

- Carry out work to clean it from dirt and dust;

- Close the ball valves of the system;

- Unscrew the polyamide nuts with the fastening of the electrodes;

- Clean the electrodes and the inside of the module from scale and clogging;

- Inspect the fastening of the contacts and, if necessary, dismantle them, clean them and install them in a regular place;

- Assess the condition of the temperature sensor;

- The final stage of the work will be the sequential reassembly of all nodes and the installation of all plugs and protections in place. Next, you need to open the taps of the system to provide power and start the system.

Very important: to maintain the unit in working condition and prevent premature breakdowns, maintenance of the unit must be carried out at least once a year

Ventilation

For the normal functioning of a solid fuel, diesel and gas boiler house, a constant supply of air is required, which ensures not only the combustion process, but also the removal of smoke and gases. For a low-power boiler, natural ventilation at home is usually enough. To do this, a hole is punched in the lower part of the door at a height of 30-40 cm from the floor and a plastic pipe with a diameter of 100 mm is inserted into it. To protect the channel from debris and meet the requirements for the operation of a gas boiler, they put on a fine mesh made of metal or stainless steel. A non-return valve is installed from the inside, the exhaust hole is closed from the outside with a visor to protect it from precipitation.

The natural ventilation of the boiler room depends on weather conditions, it cannot be regulated, therefore, an artificial system scheme is often planned in the house, which you can do yourself. This design involves the installation of supply and exhaust fans. This is a requirement for rooms with a gas boiler. It is recommended to mount devices in aluminum housings capable of withstanding high temperatures.

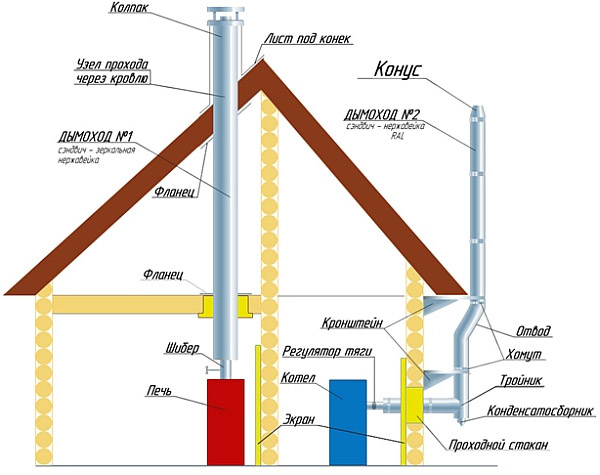

Chimney

In the arrangement of this element, there are also certain nuances that are no less important for the safe operation of the boiler room:

- The chimney is made of metal, there is a gap for cleaning.

- The height of the pipe does not protrude beyond the roof ridge by more than 4 m.

- Umbrellas are not allowed.

- The chimney is made with three bends, has a cylindrical shape.

- The opening of the pipe coincides with the outlet of the boiler.

- The entire area has the same diameter.

- The inside of the chimney is plastered and insulated to prevent combustion products from entering the house.

Requirements for boilers on different fuels

Depending on the type of combustible material for the operation of the equipment, the basic conditions for use are determined:

1. Electric boiler.

This model is considered the safest, so the construction of a separate building in this case is not necessary. A mini boiler room in the basement of a private house is quite suitable. Since the coolant is heated without the release of by-products, ventilation is not needed. But this option is dependent on the supply of electricity, it cannot be called economical. The equipment has a fairly high cost, for a house of 100 m2 you will need a model with a capacity of 10 kW.

2. Solid fuel boiler.

This type is not explosive. The requirements for the heating system include an installation diagram with convenient access for loading fuel. The distance between the unit and the wall is about 15 cm. In order to ensure fire safety, all surfaces are sheathed with steel sheets with an asbestos backing, so it is more expedient to locate an autonomous boiler room in a separate building. A metal sheet is also laid in front of the firebox. Installation of ventilation is required, preferably forced. Lighting devices are required for a coal-fired boiler, electrical wiring must be placed in a special fire-resistant box. The area of such a boiler room is at least 10 m2. For 1 kW of power, 10 cm2 of glazing is needed.

3. Diesel equipment.

The scheme of operation of such a unit is to ensure timely refueling. At the same time, fuel tanks are located outside the premises. Depending on the quality of the material, its consumption is determined. On average, you need 1 liter per 10 kW of power. This model also requires ventilation. The rules for installing a chimney in this mini boiler room do not differ from the standard procedure.

4. Gas.

This option is considered the most common, although it requires permits. In this case, the owner will have to coordinate the entry point of the gas pipeline and the performance of the ventilation system. Elements can be put into operation after verification and approval by special services. For placement, you need to know how many sq.m. there should be a gas boiler in the house.

Price

You can prepare an individual turnkey boiler room yourself, but it is better to do this with electrical equipment. As for gas and solid fuel, it is worth asking for help from specialists. The price for their services depends on the power of the boiler, the size of the room and additional appliances, which can be seen in the table:

| House area, m2 | Boiler (type of fuel) | Boiler capacity, l | Number of boiler circuits | Chimney | Turnkey cost, rubles |

| 100-150 | Gas

Electricity Coal or firewood Diesel |

100 |

2

3 3 2 |

Sandwich

Not Coaxial Sandwich |

700 000

300 000 500 000 600 000 |

| 200-250 | Gas

Electricity Coal or firewood Diesel |

150 |

3

2 3 2 |

Sandwich

Not Coaxial Sandwich |

750 000

400 000 550 000 650 000 |

| 300-400 | Gas

Electricity Coal or firewood Diesel |

200 | 3

3 3 2 |

Sandwich

Not Coaxial Sandwich |

900 000

500 000 700 000 800 000 |

Electric heating boilers GALAX

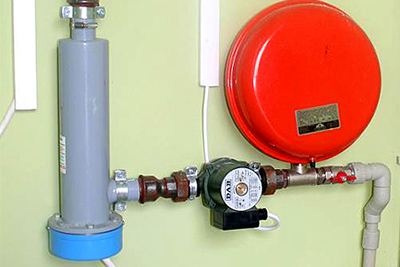

Hydraulic connection - heat-stabilized (working temperature 95 ° C) pipe and fittings Heisskraft ClimatFaser

Circulation pump Unipump 25×60 130 (5 year warranty)

Automation and protection - pressure gauge, safety valve, air vent and thermal fuse KSDI 90

Control and heater manufactured by Firma GALAN JSC (24 months warranty)

The climatic company "Termomir" offers a wide range of electric boilers of various capacities. Read the information or call our consultants to select the right boiler model.

Electric boilers are designed for heating private house, dacha, apartment (including for apartment heating), various administrative, commercial and industrial facilities ranging from 30 to several thousand square meters. m. Electric heating is optimal where there is no main gas or strict requirements for the environmental friendliness of heating devices. Also, an electric boiler is often used as a backup heating option, in case of problems with the main boiler, for example, gas.

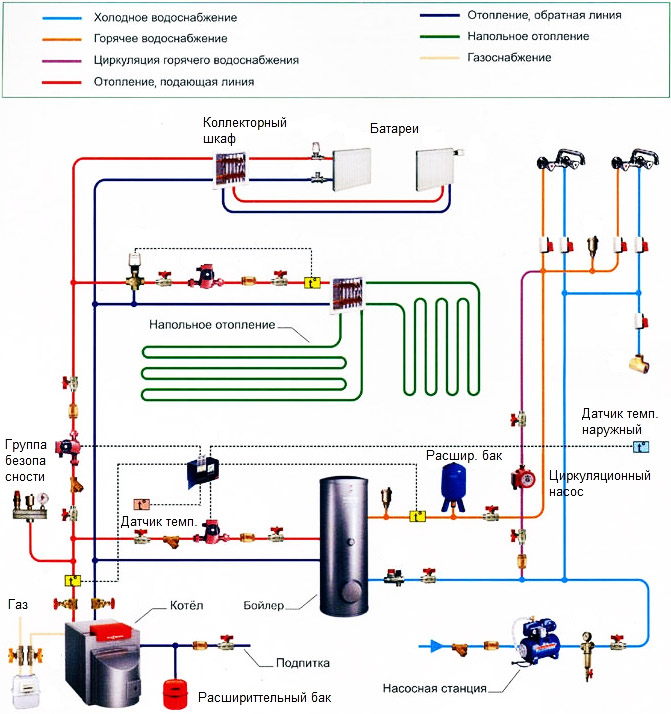

The electric heating boiler consists of a heat exchanger, a block of heating elements, a control unit and control and safety devices. Some electric boilers are equipped with a circulation pump, expansion tank, safety valve and filter. The coolant heated by electricity circulates through a system of pipes and radiators, providing space heating, as well as heating water in the boiler. An electric double-circuit boiler is used for heating and hot water supply, a single-circuit boiler is used only for heating a house, as well as for underfloor heating.

pros: Compared to boilers using other fuels, electric boilers are cheaper, more compact, safer and quieter. Connecting electric boilers is much simpler and less expensive than other types of boilers. Due to their compact size and light weight, electric boilers are wall-mounted, do not require a separate boiler room, and installation is allowed in utility or utility rooms, pantries, kitchens, basements, and even living rooms. Electric boilers are easy to operate and do not create harmful emissions and foreign odors, do not need constant maintenance, expensive cleaning and regular purchase of fuel.

Minuses:Dependence on the stable availability of electricity and high demands on the quality and reliability of electrical wiring. The relatively high cost of electricity should also be taken into account. For an informed decision on the purchase of an electric boiler, it is recommended to make a preliminary calculation of the cost of electricity.

The boiler will be used in the Russian climate from September to April inclusive, i.e. only 8, not 12 months of the year. In autumn and spring, the use of the boiler will be carried out at a minimum, in winter - at full capacity. Thanks to the built-in automation, the operation of the boiler will not be continuous, on average - about 8 hours a day, so the approximate electricity costs for the year can be calculated using the following formula:

240 days X 8 hours a day X boiler capacity X cost of 1 kW of electricity

Electric boilers with a power of up to 12 kW are produced single-phase (power supply 220 V) and three-phase (power supply 380 V), and boilers with a power of more than 12 kW - only three-phase. Most electric boilers with a power of more than 6 kW allow multi-stage power adjustment.

To save energy without sacrificing comfort, various remote programmers that can maintain the temperature in the room according to a user-defined schedule help.

To select an electric boiler, you need to find out the power of the device. Basic calculation - 1 kW of boiler power is enough to heat 10 m2 of a well-insulated room with a ceiling height of up to 3 m. To select a specific model of an electric boiler, you can contact the consultants of the Thermomir company. Remember that in addition to the boiler itself, it is necessary to purchase other elements of a complete heating and water supply system (radiators, pipes, pumps, thermostats, a boiler, and much more), so it is better to entrust the selection of equipment and its complete set to professionals.

At the moment, the assortment of our company includes both the best electric boilers from European manufacturers, and good inexpensive Russian electric boilers.

Need help choosing or haven't found the right model? Call!

Why do you need a turbine

Heating boilers, as a rule, have rather large dimensions. This is due to the need to obtain a large amount of oxygen needed for fuel combustion. Accordingly, to increase power, it is required to expand the combustion chamber and air ducts. However, a turbocharged double-circuit wall-mounted gas boiler takes up quite a bit of space and is content with a very small combustion chamber. What is his secret?

In such a design, air does not enter the combustion chamber naturally, but is forced under pressure. As a means of supplying air and removing exhaust gases, floor and wall-mounted gas double-circuit turbo boilers use powerful fans (turbines). At the same time, the combustion chamber itself remains closed and does not communicate with the room in which the boiler is installed. Thanks to this, turbocharged boilers not only have great power, but are also absolutely safe.

Boilers with a closed combustion chamber must be installed close enough to an external wall to provide the necessary air flow. If this is not possible, large-diameter air pipes are used, but they should not be long. Experts point out that the optimal length of the duct is up to 3 meters.

Important! When installing a turbocharged boiler, it is necessary to provide high-quality protection against wind, which can significantly change the characteristics of the air flow inside the combustion chamber. In addition, it is desirable to prevent moisture from the ambient air from entering the combustion chamber.

Advantages of buying electric boilers

So an electric boiler for heating a house 220v is characterized by:

- High efficiency. As a rule, this figure exceeds 95%.

- Ease of installation. There is no need to create a boiler room. This greatly simplifies the installation process and reduces financial costs.

- Noiselessness. During operation, the unit practically does not make any noise.

- Reliability in use.

- Easy to operate. The unit does not require constant maintenance. Therefore, problems such as the need for regular cleaning or replacement of nozzles do not arise.

- Minimum operating costs. Since electric boilers for heating a private house 220 volts do not require the cost of delivery and storage of fuel.

- Ability to work in reserve. Electric boilers can work together with other heating equipment. Therefore, they can be used as a spare heat source.

- Compactness. Many wall-mounted boiler options are small in size. Floor models are also quite compact. Therefore, it is not necessary to allocate a separate room for the placement of a heat generator.

- Safety and environmental friendliness. During operation, the 220v electric heating boiler does not emit harmful combustion products. Therefore, a chimney is not needed.

- The presence of additional features.Some models are equipped with the option of step power control. There are options with remote GSM control.

- High level of automation. The device is able to maintain the optimum level of temperature in the house without outside interference. All that is needed is to set the device to a certain mode of operation.

- Affordability in terms of cost: the price of an electric boiler for heating a 220v house is acceptable.

True, electric boilers also have some disadvantages, for example:

- Consumption of a large amount of electricity. Therefore, by installing such a device, electricity costs will increase.

- In areas with frequent power outages, power surges, it is not recommended to install boilers. Of course, you can install a voltage stabilizer and an uninterruptible power supply. But these are additional costs.

- TEN models differ in some complexity in operation. Scale builds up on heating elements over time. Because of this, the device begins to consume more resources.

But, despite this, the pros of electric boilers still outweigh the cons, and to a large extent. Of course, the price of electric boilers for heating a 220v apartment is considerable. But this disadvantage is gradually compensated by the increasing cost of solid fuel and gas.

The principle of operation of the electrode boiler

The design of the boiler provides for connection to a closed heating system. And the whole cycle of its work is controlled by built-in automation. It is the automatic controllers that regulate the temperature regime of the system, which can be kept between 20 and 90 degrees.

Also, the magnetic starter, which is built into the boiler controller system, monitors the drop in operating temperature and, if necessary, turns on the heating on its own. After that, it will also independently turn off the system if it reaches the desired temperature range. In turn, the electrical network will also be protected from possible overloads that occur during the switching on of the boiler, accompanied by increased loads. And in this boiler, the automatic switch will help, it is he who, in the event of critical loads on the network, will turn off the boiler until it is completely stabilized. Also in the boiler system, coarse filters are also provided, which will save the electric boiler device from pollution and further out of operation.

Electric boiler miniautomatic new generation

principle of operation

- It is worth saying that these units (electric mini-boilers) can be used to heat residential buildings, industrial warehouses, all kinds of industrial premises, country houses, and even greenhouses.

- It is also worth noting that these devices can work with heating systems, both with natural circulation of the working fluid, and with forced circulation.

- In addition, Electric boilers can be used for the preparation of hot water with the participation of indirect heating boilers.

- Electric boilers can also be used in the design of thermal curtains, for working with "warm floors", for drying wood, in systems with combined water and electricity supply (wind generators, solar panels, centralized water supply, autonomous well with an electric pump).

Mini electric heating boiler VEN-4.5 kW

One of the advantages of electric boilers is that these units can be installed in already working heating systems, in parallel with another heating device already installed (gas boilers, solid fuel boilers). In order to achieve the maximum effect of this device on large areas, it is necessary to install several such devices, thereby reducing the load on each unit individually, and raising its service life.

Types of electric mini-boilers

In fact, an electric boiler is installed wherever there is electricity.

It is important that the electric boiler is connected to existing heating systems (gas, solid fuel), reducing the load on them.

Installation does not require special permission. Mini-electric boilers are divided into two types according to the type of modification.

heating elements

Heating of system water is carried out by means of a heating element of an electric boiler: TENA. Inside it is a spiral of tungsten or nichrome wire, which heats up and transfers heat to the environment. The shell is made of steel, titanium or aluminium. A dielectric is placed between the sheath and the helix. More often this role is played by quartz sand.

The main elements of the heating element miniautomatic device:

- heating element;

- heat exchanger;

- insulation;

- Control block;

- circulation pump.

Important! It is better to use distilled water in the heating system to prevent scale formation. This is the main "disease" of heating elements boilers

The device has an automatic switch that turns off the device when the desired temperature is reached or in case of overheating.

Photo 1. TENovy mini electric boiler for a heating system with an automatic switch from the manufacturer Galan.

- The power is constant and adjustable.

- The temperature of the liquid does not affect the heating element.

- If there are several heating elements, then if one device breaks down, the device will work.

- Various liquids are used as a heat carrier: water, antifreeze, antifreeze.

- In case of failure, the heating element is replaced.

- The formation of scale on the heating element is the main disadvantage of this device. Because of this, the boiler fails or heats up poorly.

Attention! During operation, the heating element must be covered with water, otherwise it will burn out!

Ionic

The principle of operation of new generation ionic electric boilers is different. They do not have a heating element, and the conductor of energy is water or a special liquid.

Electrodes are placed here, passing through which the current heats the liquid. Ion boilers are also called electrode boilers. They heat up quickly, unlike heating elements.

The ion electric boiler has the following elements:

- frame;

- electrodes;

- body insulation;

- Control block;

- heat conductor.

In some models of the electric boiler, a temperature sensor is installed.

The system has a built-in electronic control: when it cools down, the boiler will turn on by itself, and when the desired temperature is reached, it will turn off. Works even with unstable voltage without shutting down. Compared to a heating element boiler, an ion boiler uses half the electricity.

- reliability;

- fast heating;

- compactness;

- economy.

Photo 2. Ionic small electronically controlled boilers from the manufacturer Galan consume a minimum of electricity.

- For filling, you need a special liquid or prepared water.

- Maintain continuous fluid circulation.

Installation schemes for a turbocharged double-circuit boiler

Depending on the size and design features, a gas double-circuit turbo boiler can be installed both on the floor and on the wall, or even in pieces of furniture. This becomes possible due to the relatively small size of powerful turbine heating units, as well as the presence of a closed combustion chamber that does not create a fire hazard. Consider the features of the main installation options for a turbocharged boiler.

Floor boilers

Vaillant atmoVIT

The boilers, which are intended for installation on the floor, have a fairly large size, and, consequently, high power. Often this power is excessive for a small house or apartment. That is why, in most cases, floor-standing double-circuit boilers are used in enterprises or in large private houses with a height of 2 floors or more.

In addition to high power, the advantage of such models is ease of connection.All structural elements of the floor boiler are located outside, which allows it to be connected to the gas pipeline and water supply system, as well as included in the heating circuit. At the same time, workers without special skills can perform the installation of such a boiler. However, for the supply of gas, it is still necessary to use the services of a specialist.

The main disadvantage of large and powerful floor boilers, of course, is their high cost. In addition, they have a large weight, which does not allow them to be placed in apartment buildings. And, of course, more power means more fuel consumption, which can be excessive for a small room.

Wall and built-in boilers

wall boiler

This category includes small heaters of low and medium power, designed for heating private houses and apartments. Unlike floor models, they are quite light in weight and have a mounting system that allows them to be placed on a wall or in furniture. Wall-mounted gas double-circuit turbo boilers are the ideal solution for those cases when the installation of the heating system must be carried out in a limited space.

Of course, such boilers consume less fuel and require lower costs. In addition, they can be installed hidden - that is, built into certain interior items. Built-in boilers can be located in various parts of the apartment or house - in the kitchen, bathroom or even the pantry.

There is only one drawback that a turbocharged double-circuit wall-mounted gas boiler has. This is his power. As a rule, the heat produced by such models is enough for heating 180-200 sq.m. However, this indicator is quite enough to heat a large apartment or a medium-sized house.

Heating boilers

All these requirements are met by the products of the Czech manufacturer Protherm. The range of its boilers is made in the range from 6 to 36 kW. It is noteworthy that models with a power of 6 and 9 kW require connection not only to 380 V, but also to 220 V. Another foreign brand that is actively promoted in the domestic market is the Polish Kospel. This manufacturer starts with devices with a power of 2 kW, but does not imply an expansion tank in its case. Each electric boiler is energy-saving due to the features of the control unit. Automatic mode provides smooth power modulation with a uniform load on the series circuit of heating elements. It is also envisaged to connect weekly programmers that control temperature amplitudes according to a predetermined scheme without involving a person. The unit has outputs to sensors that react promptly to weather changes and issue appropriate commands to increase or decrease electrical energy consumption.