Types of mirrored ceilings

Whole mirror. This type was and still remains the most difficult system for installation. At the same time, a ceiling with a similar finish will look very impressive. Without special training and experience, it is better not to install a solid mirror yourself. In any case, you will need an assistant for installation.

If we consider this type of suspended structure from the point of view of economy, then it is completely unprofitable.

Mirrored ceiling panels. Inexpensive and fairly simple option. Polystyrene is covered with a protective polyethylene film. This view allows you to create a mirrored and tinted surface. You can buy both individual panels and a whole mirror roll, which will save a lot on costs. The disadvantage of this design lies in the fact that it does not allow you to create the correct reflection. The surface of the panels will distort the space and give a fuzzy image. It should also be added that this ceiling is sewn together, and the joints will be visible, which means that the magical effect will already be lost. But you can consider it from the other side. So, mirror tiles will create an interesting play of light, thanks to the effect of a cut picture.

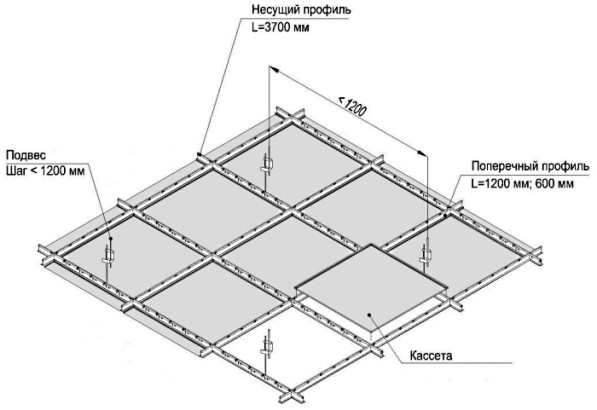

Installation of panels on the ceiling is carried out using the same technology as the Armstrong ceiling:

- make markings on the surface to be designed;

- then the cellular frame of the structure is assembled;

- plates are laid on the grate.

Ceiling scheme "Amstrong"

PVC panels. The material gives the surface depth and a mirror finish. Panels can be lacquered or painted in gold or silver. With their help, the ceiling can be visually lifted and expanded the room, which is very important for the kitchen or bathroom. Installation of PVC panels is not difficult. On the reverse side of the product have a sticky layer. Some types of plates are sold without it, therefore, for their installation, an adhesive composition based on PVA is used. Before you start attaching PVC panels to the ceiling, please note that this surface does not provide for the presence of high-power built-in lighting devices. The reason is that plastic can only be heated to a certain temperature to prevent it from deforming.

You can create a mirror ceiling without using glass directly. It will also be possible to achieve a reflective surface with the help of polyvinyl chloride.

About the benefits

- It's no secret that interior mirrors are a great way to play with space. Mirror ceilings visually expand the boundaries, make the room brighter, create a special mysterious atmosphere.

- Even a mirror surface does not exclude the possibility of choosing the perfect shade for a particular interior.

- Mirror tiles hide uneven floors.

- Due to the high moisture resistance, the mirror ceiling is often used in bathrooms.

- With this design solution, aluminum, glass and cassette covers can be combined. Mirror plastic - more practical, but less moisture resistant.

- Ease of maintenance. It is enough to wipe the mirror ceiling as it gets dirty with a rag and a special solution for glass surfaces.

Features of the use of mirror ceiling structures

The production of such ceilings is carried out by companies that produce material for cassette and tension systems. Even PVC panels have a reflective surface.

Installation of mirror panels provides for the presence of a T-shaped suspended structure.

The design for mirror panels consists of transverse and power profiles, suspensions that can be adjusted and wall corners.This suspension system is easy to install and dismantle, which makes it very practical to use. Behind the mirror panels, you can place any communications and build additional lighting zones. The result is a combined ceiling.

"Armstrong" is most often used for finishing floors of public buildings. Elements of mirror suspended ceilings have different sizes (from 30x30 to 70x70 centimeters). At the same time, the panels can be with shades of silver, gold or bronze. As for the shape of the mirror elements, it can be rectangular and square, with a cut of the outer corner and straight. In addition to glass, plexiglass is also used in the production of panels. This makes the ceiling lighter, making it easier to install the suspended structure.

The panels can be given a special color by applying a special film to their surface. Another way to decorate a suspended glass structure is a stained glass composition.

Advantages and disadvantages of glass ceilings

If you decide to glue mirror panels on the ceiling in the bathroom, then you should first study the pros and cons of such a finish.

The benefits of mirror coating include the following:

These products can be called universal because they are suitable for use in premises of any purpose. And we are talking not only about the rooms in the apartment, but also about public places.

Mirror surfaces visually increase the height of the room and expand the space, which is ideal for low-rise small rooms.

Due to the good light reflection and refraction of the light flux, the ceiling structure improves the illumination of the room and makes it brighter.

When installing using frame technology, engineering communications are laid behind the ceiling surface, hiding defects in the base and building structures. In addition, the base surface does not need special preparation and alignment.

Strength and moisture resistance are the main advantages of such coatings. They are not afraid of direct contact with water, withstand high humidity. They are not afraid of mechanical damage, fungus and rot.

The coating does not attract dust, does not accumulate static electricity, is considered environmentally friendly and harmless.

Behind the suspended ceiling, soundproofing materials and heaters are laid. The plates themselves, due to their dense structure, dampen external noise.

Hidden lighting can be installed behind the glass ceiling, which can serve as the main source of lighting in the room.

Installation of a mirror ceiling with a glue frameless method is simple

It is only important to level the base well. A step-by-step video on how to glue mirror tiles on the ceiling will help you complete all the work quickly and correctly.

The surface is unpretentious in care

It is washed using non-abrasive detergents.

The price of a mirror ceiling tile is quite acceptable and is $ 2-3 / m².

The disadvantages of mirror ceiling coatings include the following:

- Installation of a mirror ceiling in a bathroom or other room is done very carefully. This is especially true for cutting and drilling material. Due to the fragile structure, the likelihood of chips and cracks increases.

- If the plates are made of silicate glass, then the weight of the whole structure will be impressive. This will not have the best effect on the bearing capacity of dilapidated floors.

- Another disadvantage is the risk of injury when breaking glass. That is why it is better to additionally protect the surface with a translucent self-adhesive film, which will protect small fragments from falling.

Advantages and disadvantages of a mirror ceiling

If we talk about the pros, then there are several of them:

- Universal decor is used in residential, non-residential premises, offices, social and public facilities.

- Ease of installation.Collections are produced ready-made, already equipped with decor elements, hardware. In addition, depending on the height of the walls, you can apply different laying technologies without detracting from the size of the space.

- Diversity. Elements can be laid on flat, curved structures, form zones with different color, texture solutions, make backlight and safely use in children's rooms.

- Strength. Thanks to a special hardening process, mirror ceiling tiles, the price of which starts from $ 2 (150 rubles) per 1 m2, easily withstand accidental mechanical stress.

- Originality. The mirror can be cut, make curly compositions, laid out in the form of a mosaic or stained glass window.

- Water resistance and resistance to temperature influences.

- The ability to hide wires, communications, insulating materials under the finish.

- Lighting. If you make a backlit plexiglass ceiling with your own hands, then it will serve as the main lighting or become a good addition to the auxiliary type. Due to the reflective and light transmission ability, the ceilings will be appropriate in rooms with poor sunlight, visually expand the volume of the premises.

- Ease of installation is achieved by the stability of the shape of the parts and the absence of preliminary leveling work on the base surface. The time for laying out the decor depends on the complexity of the chosen design.

- Ease of care. To restore shine and cleanliness to the tiles, it is enough to use ordinary detergents with soap or ammonia.

There are few drawbacks to the finish:

- when cutting elements, you need to be careful not to damage the structure of the part;

- the massiveness of the elements dictates its own strength rules for fasteners and the frame.

natural glass

For a long time, the only way to produce a material on an industrial scale with the ability to reflect light cleanly and without distortion was to apply amalgam to glass.

The mirror has 100% reflective properties, but there are also disadvantages:

- Fragility. When broken, it shatters into fragments with sharp edges, which is why there is a risk of injury. In modern workshops, glass after cutting is pasted over with a protective film that prevents fragments from flying apart when broken.

- Big weight. The mirror structure of a large area is very heavy. The load on the fasteners is high, and many profile systems are not designed for such a mass.

- To cut or drill glass, you need professional equipment and a highly skilled craftsman.

- Expensive and difficult installation. Natural mirror ceiling is classified as an elite type of finish because of its cost.

Today they produce ready-made modules with dimensions for the Armstrong system. The mirror is available with a smooth edge or faceted.

For design projects, a mirror is ordered according to individual sizes. In the workshop, employees will cut out a panel of any shape, engraving if desired.

Features of the use of mirror ceilings

Mirror panels are produced by the same companies that produce material for tension and cassette ceiling structures such as Armstrong. The creation of a shiny reflective surface is provided even by manufacturers of PVC panels.

The installation of a mirror ceiling requires a T-shaped suspension system, which includes power and transverse profiles, adjustable suspensions and wall corners.

Installation of mirror panels

The power profile is joined at the locks with the transverse one in one plane. Their fastening to the ceiling is carried out by adjustable suspensions, with the help of which the suspension system is lowered to the desired level. Decorative tiles are embedded in the profile, which is why this design is considered very easy to install.And this is one of its advantages.

In addition, the design, if necessary, can be easily disassembled, and behind it you can place any engineering systems or create lighting zones. The result is not just a mirror, but a combined ceiling.

The Armstrong system is used mainly in public buildings and institutions.

Mirror-type suspended ceilings are made from elements of different sizes - from 30x30 cm to 70x70 cm. They are used for various suspension systems, and the panels themselves are made with shades of bronze, silver or gold. In shape, they are square and rectangular, with a facet (cutting the outer front corner) or straight. Moreover, now they produce not only glass mirrors, but also made of plexiglass. These panels are lightweight and therefore easy to install.

In glossy stretch ceilings you can look like in a mirror

In addition to various shades obtained both directly during manufacture and by applying a film or an appropriate composition to them, mirrored ceiling panels can be decorated with fancy matte patterns or stained glass compositions.

Stretch ceilings can not be performed using a mirror. Glossy PVC canvases do an excellent job with its function. Their surface is so smooth and reflects so much light that you can look at them like in a mirror.

Glossy film can also be chosen to match the interior, or you can stop at some neutral color - for example, blue-gray or black. The ceiling under such a glossy coating will even more resemble a mirror. The installation of this type of mirrored ceilings is carried out according to standard technology.

Another material that can give the ceiling a mirror finish and depth is PVC ceiling panels, painted in silver or gold and varnished.

PVC ceiling panels painted in silver and lacquered

Their use for decorating the ceiling will allow not only to visually “raise” it. Longitudinal strips of PVC panels will help visually expand the room. The latter is especially true for small spaces, such as a bathroom or kitchen.

As a rule, such panels are very easy to mount. A sticky layer has already been applied on their reverse side under the protective film. If plates without a self-adhesive layer were purchased, then a composition based on PVA is used for installation.

If you are going to make a ceiling from PVC panels, you should take into account that in this case you cannot use lighting systems with high power lamps, since plastic can only be heated to a certain temperature.

As you can see, the choice of ceilings "under the mirror" is not limited to mirror panels. So you can always find the most suitable option for you.

05.10.2013