Setting up the boiler with your own hands

Proper adjustment of the gas boiler is needed for:

- saving resources;

- comfortable stay in the room;

- increase the service life of equipment.

First of all, it is necessary to correctly determine the power of the heating equipment

It is important to take into account the features of the room: the number and area of windows, doors, the quality of insulation, the material from which the walls are made. The minimum calculation is based on heat loss per unit of time

As you know, the heating power is directly dependent on the modulation of the gas burner. If you have an electronically controlled unit, then the thermostat is activated

which is connected to a room thermometer.

Adjustment is carried out in automatic mode: the thermometer measures the temperature in the room. As soon as its indicators become below comfortable, it gives a signal to start the burner or increase the strength of the flame.

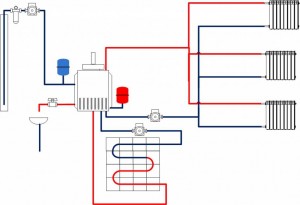

In normal mode, the thermometer controls the temperature in only one room. But if you mount valves

in front of each radiator, control will be in each room.

You can adjust the burner manually by acting on the gas valve. This is true for atmospheric boilers with an open combustion chamber. For example, in the Protherm Cheetah, Proterm Bear models, the valve is controlled by an electric motor. To change the settings, you must go to the service menu. Usually this work is performed by a specialist, and the user himself is already acting according to the instructions.

However, it is still necessary to know how to call up the hidden menu for adjustment. Let's look at a few examples.

Before going to the menu and setting up, you need to perform a sequence of actions:

- open taps on batteries;

- you need to set the maximum values;

- in the user settings, set the maximum temperature mode, which you usually set at the lowest possible temperature outside. The burner always turns off when the reading is 5°C higher than the set value. For example, at 75°C, shutdown will occur when 80°C is reached;

- coolant

should be cooled down to 30°C.

For Protherm Gepard

:

- You need to hold down the Mode key on the panel. As soon as you see zero on the display, set the value to 35 by pressing "+" and "-".

- Then press Mode to confirm;

when d.0 lights up on the screen, you must enter the line number in the menu. These manipulations are also performed by pressing "+" and "-" d. (number). In order to set the maximum burner power, select d.53, for the minimum - d.52.

In order to proceed to the parameter selection, Mode is also used, it changes “+” and “-“.

The installation receives an automatic confirmation.

Return to the original menu and hold Mode.

While making adjustments via the panel, monitor the flame change and temperature intensity.

Gas boiler display Proterm Panther

For a different procedure:

- Hold Mode for about seven seconds.

- Next, code 35 is entered.

- Input is confirmed.

- When d.00 appears on the left side of the screen, you must enter the number using two buttons.

- Then change the parameter on the right side of the screen using the 3 keys.

- After confirmation, click mode to exit the menu.

Setting, adjusting the power of a gas boiler when working on antifreeze

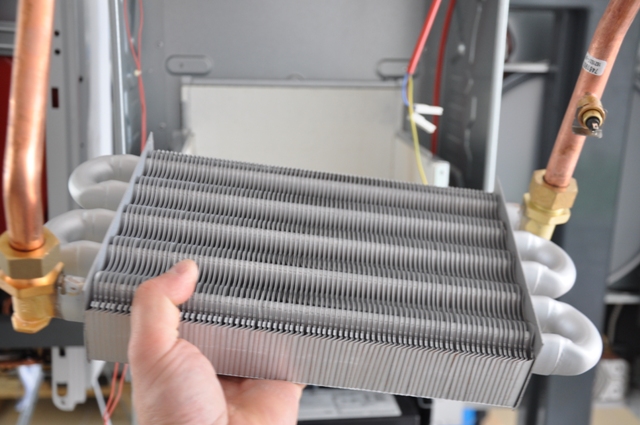

Traditional antifreezes based on ethylene glycol or propylene glycol have a higher viscosity than water. As a result, the movement of the coolant through the boiler heat exchanger slows down.In addition, antifreezes have a lower heat capacity. All this leads to the fact that the antifreeze in the boiler heat exchanger, which is designed for water, at maximum power instantly heats up to the boiling temperature and boils. Boiling of antifreeze, as a result of local overheating in the heat exchanger, manifests itself in the form of loud noise, a roar with gurgling.

When working on antifreeze, a gas boiler can only operate at a reduced power, lower than that indicated in the boiler instructions for water.

To slightly increase the power of a boiler running on antifreeze, it is recommended to dilute the antifreeze with water, as well as increase the pressure of the circulation pump.

So, for example, the manufacturer of antifreeze "DIXIS TOP" for heating systems with wall-mounted gas boilers recommends diluting the contents of the factory packaging with water in a ratio of 1: 1. As a result of diluting antifreeze, the crystallization onset temperature will increase from -30 °C

up to minus 10 °C

.

If the crystallization temperature of the diluted antifreeze does not suit you, then another antifreeze is selected.

In any case, to avoid overheating of the heat exchanger, in the settings of the service menu and the gas valve it is necessary to limit the boiler output in heating mode

(in lines d.00 and d.52 of the service menu), as well as set the maximum coolant temperature not higher than +70 °C (in line d.71 of the service menu). It is also recommended to increase the opening pressure of the bypass valve on the boiler (how? - read below).

The manufacturer of the boilers in the instruction manual usually gives its recommendations on the choice of antifreeze. So, for Protherm gas boilers, the instructions say: “It is not recommended to use non-freezing liquids in heating systems with Protherm equipment installed. The use of non-freezing liquids entails a decrease in heat transfer efficiency, higher temperatures on the surface on the walls of the heat exchanger and its rapid wear, an increase in the corrosion effect and viscosity, corrosion of gaskets and fittings, both in the boiler itself and in the heating system. Boiler failure due to the use of non-freezing fluids will void the warranty.”

BAXI gas boilers Baxi installation errors and how to avoid them

d.

Before alkalizing the boiler, it is necessary to inspect and flush the feed tanks, deaerators, feed and auxiliary pipelines.

The superheater, as a rule, is not subjected to alkali and is not filled with an alkaline solution; it is cleaned of oil contamination and rust by steam blowing.

Filling the boiler with water and subsequent make-up during alkalizing should be carried out with chemically treated feed water. Before filling the boiler with water, it is necessary to open the valve to remove air, and where there is none, lift one safety valve to remove air. The water level in the drum is brought to the lower limit, after which the filling of the boiler with water stops and is maintained throughout the alkalinization process.

Alkalinization is accompanied by boiler kindling and pressure rise.

To ensure the greatest efficiency during alkalization, the pressure in the boiler must be brought to 75–100% of the operating value, but not higher than 1.3 MPa (13 kgf/cm2) at a nominal pressure of 1.4 MPa (14 kgf/cm2) or 2.3 MPa (23 kgf/cm2) at a nominal pressure of 2.4 MPa (24 kgf/cm2).

When alkalizing, fire heating of the boiler should be carried out.

In the presence of steam heating of the lower drum, the combined initial heating of the boiler by fire and steam up to 0.4 MPa (4 kgf/cm2) is allowed. In the future, only fire heating should be carried out.

Reagents are introduced into the boiler separately, in the form of a solution through any fitting of the upper drum or by phosphate pumps. Entering them into the boiler and dry or not completely dissolved is not allowed. The following reagents are used: caustic soda, trisodium phos - fat and soda ash.Therefore, the maintenance personnel engaged in boiler alkalizing work must be provided with overalls, goggles, gloves and aprons. The boiler room must be well ventilated.

After the reagents are poured into it, samples of the boiler water are taken every 3 hours from the upper and lower drums and screen chambers in order to determine its alkalinity and contamination.

The initial small purges are performed 12-20 hours after the alkaline shake, and the most intense. sivnye - by the end of alkaline in order to remove accumulated dirt.

If severe contamination is detected, it is necessary to increase the blowdown from the lower points of the boiler at a pressure of 0.5–0.6 MPa (5–6 kgf/cm2). Alkalinization of the boiler, depending on the degree of contamination of the internal surfaces, lasts for 48-86 hours, it is stopped when the water sample taken is clean. The alkaline mode is selected depending on the contamination of the boiler.

If the gap between the end of alkalization and the start-up of the boiler exceeds 10 days, conservation should be carried out.

|

Table 3.6. The required amount of reagents per unit volume of boiler water for alkalizing boilers |

|

Quantity of reagents, kg/m3 |

|||

|

Boiler brand |

Sodium hydroxide (NaOH) 100% |

Soda ash (Na2CO„) |

Trisodium- Phosphate (Na3PO, X X121IaO) |

|

Boilers are new with a slight layer of rust |

|||

|

E-2.5-14R (KE-2.5-14C) |

|||

|

E-4-14R (KE-4-14C) |

|||

|

E-6.5-14R (KE-6.5-14C) |

|||

|

E-10-14R (KE-10-14C) |

|||

|

E-10-24R (KE-10-24C) |

|||

|

E-25-14R (KE-25-14C) |

|||

|

E-25-24R (KE-25-24C) |

|||

|

Boilers new with |

Large layer of rust |

||

|

E-2.5-14R (KE-2.5-14C) |

|||

|

E-4-14R (KE-4-14C) |

|||

|

E-6.5-14R (KE-6.5-14C) |

|||

|

E-10-14R (KE-10-14C) |

|||

|

E-10-24R (KE-10-24C) |

|||

|

E-25-14R (KE-25-14C) |

|||

|

E-25-24R (KE-25-24C) |

Lower the boiler or perform secondary alkalization before start-up.

Water from the boiler after alkaline merges with a temperature not higher than 50-60 ° C at atmospheric pressure. The pipes of the boilers are washed through the hose with hot water from the drum.

The required amount of reagents per unit volume of boiler water for alkalizing boilers is given in Table. 3.6.

After alkalizing and washing, an act is drawn up on the condition of the internal heating surfaces of the boiler. The boiler is then filled with softened water for vapor density testing.

During the first month of operation of the boiler, it is necessary to carry out its increased purging (approximately twice as much as the calculated one) to remove contaminants.

E-1/9-1M boilers operating on liquid fuel are equipped with AR-90 burners. To protect the boiler, the fuel supply is automatically stopped when the water level in the boiler drops below the permissible level, when the steam pressure rises to ...

In the manufacture, installation and repair of elements of boilers, superheaters and economizers, only butt joints should be used when welding shells, pipes (pipes) and welding convex bottoms, as well as tee and corner or ...

A. Baranov

—

CAUTION 1

егÑлиÑовка оÑлиÑаеÑÑÑ Ð¿ÑоÑÑоÑой и ÑоÑноÑÑÑÑ.

a

егÑлиÑовка Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ ¸Ð±Ð¾ велиÑÐ¸Ð½Ñ ÑÑги. ÐоÑÐμниÐμ в кР° жÐ'ой гоÑÐμÐ »ÐºÐμ ÑÐμгÑл иÑÑÐμÑÑÑ Ð¿Ð¾ ÑÐ ° ÑÐ ° кÑÐμÑÑ, вÐμÐ »Ð¸ÑинÐμ и ÑвÐμÑÑ ÑÐ ° кÐμл Ð °, Ð ° в ÑÐμÐ » ом на пеÑÑ - по анализам дÑмовÑÑ Ð³Ð°Ð·Ð¾Ð².

a

егÑлиÑовка оÑлиÑаеÑÑÑ Ð¿ÑоÑÑоÑой и ÑоÑноÑÑÑÑ.

a

егÑлиÑÐ¾Ð²ÐºÑ Ð¸ ÑÑги ÑекомендÑеÑÑÑ Ð°Ð²ÑомаÑизиÑоваÑÑ.

a

RÐ»Ñ treadmill нÑжно оÑвÐμÑнÑÑÑ ÐºÑÐμпÑÑиÐμ винÑÑ Ð¸Ð »Ð¸ Ð ± Ð ° ÑÐ ° Ñки, ÑнÑÑÑ Ð³Ð¾ÑÐμл ки и пÑовÐμÑиÑÑ Ð¸Ñ ÑоÑÑоÑниÐμ, ÑиÑÑоÑÑ Ð²Ð½ÑÑÑÐμннÐμй полоÑÑи.

a

Rз-за treadmill Ñðμð¼ð¿ðμðÐμμ½Ð½½Ð½Ð½ÐμðμÐðн½Ð½ÐðÐ'Ð'Ð'Ð'Ð'Ð'Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ñðμññð Ð ²

a

RESEARCH treadmill Ðμж Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð ° Ð Ð Ð ° Ð ° ÑвелиÑиваÑÑÑподаÑÑгаза, а заÑем подаÑÑÑодаÑÑÑгаза, а заÑем воздÑÑа. Runs Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° одаÑÑгаза. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð 'Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð' Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð 'Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð'ñññð¾¾¾ ± CLEARANCE SHUTTER

a

RESEARCH treadmill Ðμж Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð ° Ð Ð Ð ° Ð ° ÑвелиÑиваÑÑÑподаÑÑгаза, а заÑем подаÑÑÑодаÑÑÑгаза, а заÑем воздÑÑа. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð ° Ð °Ð·Ð°. ÐÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ·

a

rак видно из ÑиÑ. 5, из-за treadmill Ñðμð¼ð¿ðμðÐμμ½Ð½½Ð½Ð½ÐμðμÐðн½Ð½ÐðÐ'Ð'Ð'Ð'Ð'Ð'Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ñðμññð Ð ² ÐÑобо ÑледÑÐµÑ Ð¾ÑмеÑиÑÑ ÑледÑÑÑий ÑакÑ. Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð ² Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÑÑÑкак Ñепловой ÑдаÑ.

a

rак видно из ÑиÑ. 5, из-за treadmill ÑемпеÑаÑÑÑÐ½Ð°Ñ ÐÑобо ÑледÑÐµÑ Ð¾ÑмеÑиÑÑ ÑледÑÑÑий ÑакÑ. Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð ² Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÑÑÑкак Ñепловой ÑдаÑ.

a

|

Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ñð¹ññ² ñð¾¾² · a |

Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð δ Ð Ð Ð Ð Ð δ treadmill.

a

|

Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ñð¹ññ² ñð¾¾² · a |

Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² Ð Ð Ð Ð Ð δ Ð Ð Ð Ð δÐðÐ Ð Ð Ð ² на treadmill.

a

Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð · Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð · Ð Ð Ð Ð °Ð½Ð¸ÐºÐ¾Ð², treadmill.

a

The influence of power on the efficiency of the boiler

I would like to pay special attention to the selection and calculation of the boiler power. Here, a method like “the stock does not fix troubles” is unacceptable.

Therefore, if you do not deviate from the topic, then the essence is this: if you take a boiler that is too powerful, then it will turn on and off more often at shorter intervals.

Regarding the fact that a more powerful boiler “eats” more fuel than necessary, a lot of disputes arose on the specialized forums, however, in our opinion, if the boiler is too powerful, then it will less often work in the optimal mode, and the manufacturer declares the efficiency specifically for optimal mode.

If you pick up a boiler that is too weak, then it will work “for wear”, and the resource of such a boiler will be consumed faster

Therefore, for efficiency, it is important to choose a boiler of optimal power, and this is about 75% of the maximum power of the boiler (if another one is not prescribed for the selected boiler, then it is better to focus on this one). That is, we select the boiler, according to our parameters and leave it a reserve in the region of 30% of the power

Do not forget about the overall efficiency of the heating system.For example, for a house 4 by 5m, the design power of the boiler of a well-insulated house with double-glazed windows is almost 2 times less than a similar one but with poor insulation and ordinary glazing.

Manufacturers and efficiency of boilers

There are things that at first glance do not directly affect the efficiency of boilers. It seems like you take a passport to a boiler of some Ukrainian KAZ in one hand, you see there is not a bad declared efficiency (say 92%), and in the other passport from a German Bosch or an Italian brand boiler, where the declared efficiency is also 92% and you feel a catch, but you can't figure out where he is. Let's figure it out together.

We know very well the mentality of Ukrainians and Germans, and we know how they do it “with us” and how they do it “with them”. Therefore, despite the declared efficiency, the German boiler will in any case be more economical and more reliable than the Ukrainian one. This will be due to a number of indirect reasons - the screw did not last there, it was overtightened there. Here more heat flies into the chimney, the regime does not hold there, and so on. etc.

It is difficult to deduce how much more economical a German will be than a Ukrainian. Nevertheless, a gas boiler, like a car, is bought for a long time. And in the long term, with a constant increase in energy prices, even a difference of at least 5% is very noticeable.

How to lower the temperature on a gas boiler

Often, very often recently, on heating forums, a question has been asked about temperature drops in hot water systems with boilers or gas water heaters. People are panicking that they have some kind of technical problem. I will try to explain in simple terms some of the nuances of such situations.

So, you open a hot water tap, your heating unit turns on, and almost boiling water comes out of the tap. What is the problem? After all, you set the normal comfortable temperature.

Let's take a look at how your heaters work. If you use a column or a boiler, they work on the principle of FLOW heating. Here lies the whole simple secret of overheating. Most often, overheating occurs when you have already used it shortly before opening the hot water tap. What happened?

1. As soon as you closed the hot water tap, the water stopped flowing through the heat exchanger in which it is heated.

2. At the same moment, the automation closes the gas valve.

3. The flame in the burners begins to decrease, it takes some time until it is completely attenuated.

4. The metal of the heat exchanger continues to transfer heat to the non-moving water inside it.

5. During these few seconds, the water in the heat exchanger receives an excess of heat, which leads to its overheating.

6. Now, when you open the hot water tap again, that part of the water that was in the heat exchanger and was overheated moves inexorably towards the exit from the system and, flowing out of the tap, pleases you with its own temperature.

That is, it is almost impossible to reduce such an effect to zero. Of course it all depends on how fast the gas valve closes. If you have a gas water heater, you can personally check how quickly your valve works. Just watch through the igniter window how long it takes from closing the hot water tap until the burner is completely attenuated. If this time is less than 1 second, you are fine and will not get better. And if the burner goes out for more than 1 second, this may indicate that you need to clean and lubricate the valve stem or check its tightness. Only a huge request - DO NOT DO THIS YOURSELF, gas fittings are not jokes, it's better to ask a specialist.

In gas boilers with a bithermic heat exchanger, this problem of overheating is further exacerbated. Why? All because of the heat exchanger device. Such a heat exchanger is a pipe in a pipe. Your water flows through the inner pipe to the DHW system (the one with which you wash dishes, bathe.), And the coolant from the heating system circulates through the outer pipe.The coolant is usually very hot, about 80-90 degrees. As soon as you close the hot water tap, it stops flowing in the heat exchanger, but the coolant continues to transfer its heat to it. Thus, the water is heated even more than in the columns. In addition, it remains hot longer than in columns, because it is located inside the heat exchanger and is surrounded by another pipe with a coolant.

I understand that no one likes to be scalded, but this effect can only be completely leveled in systems with storage tanks. How to fight? Just let that water drain.

By the way, I once happened to observe a Czech column of Soviet times, in which the paint in front of the burner melted precisely because of the poor operation of the gas valve. The water was closed, the gas continued to burn, the heat exchanger overheated and there was so much heat that it was transferred to the column body in such a large volume. Therefore, do not forget to check gas appliances in time, demand timely maintenance from servicemen.

Note: The most interesting and beautiful places on the planet on the tourism blog resource, descriptions and comments from travelers and tourists from all over the country.

Economic mode of operation of the gas boiler

There is such a thing as an economical mode of operation of a gas boiler, that is, a mode in which the boiler saves fuel. Let's try to figure out what it is, what it is eaten with and how to achieve it. As we wrote above, the boiler should basically “plow” at about 70-75% of the maximum power (in the optimal mode). Plus, most boilers, as a rule, are guided by the temperature of the coolant to which it is heated. That is, you set the temperature of the coolant that the boiler must keep (rough description) - this is the normal mode of operation of the boiler.

But what to do if the sun comes out on the street, then the wind blows? In fact, the house becomes either warmer or cooler. Not much, but still. So, if you additionally install a feedback system with the boiler - temperature sensors, a programmer (room thermostat) - and use automation to set up automatic adjustment of the mode (in some boilers, such a system comes immediately with the boiler, but you can buy and install it separately - no problem), then the boiler will respond more adequately to temperature fluctuations in the street and turn on less often at times when it is already warm in the house, despite the fact that the temperature of the coolant has already fallen below the bar. In addition to the above, you need to set the lower temperature for the night - this will be the economical mode of operation of the gas boiler.

Such a system - a programmer plus sensors in a well-insulated house will help save up to 20% of energy resources.

Maintenance of gas equipment

Properly selected and adjusted gas equipment can malfunction from time to time. In order for this to happen as rarely as possible, it is necessary to adjust the system settings in time and carry out preventive work provided for by equipment passports.

To exclude accidents associated with gas leaks and damage to property and human health, the installation of gas equipment must be carried out by authorized organizations (oblgaz, rygaz, gorgaz) through enterprises licensed to carry out such work.

This is interesting: Do-it-yourself pyrolysis boiler - step by step instructions

Possible malfunctions when starting the boiler and methods for their elimination

Igniter does not turn on

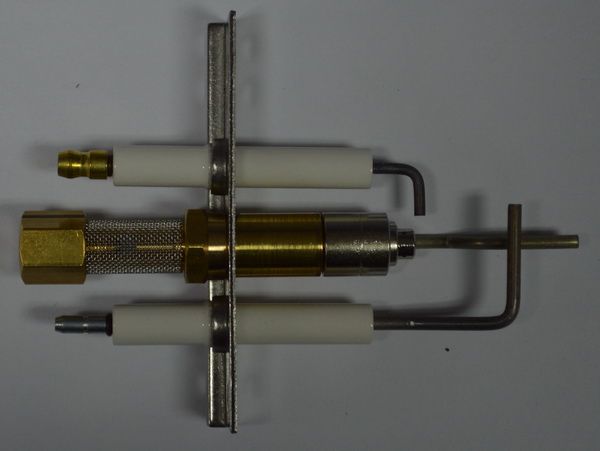

Sometimes a soot deposit forms inside the combustion chamber between the candle and the boiler body, soot is carbon, which is a conductor and prevents the creation of a spark. Such a malfunction is eliminated by lightly tapping on the pipeline supplying gas to the burner.

Water does not heat up

"Boiler clocking"

When choosing a boiler with too high power, a phenomenon called “boiler clocking” may occur.

Knowing how to set up a gas boiler in such a case is very important. After all, when the boiler is “clocked”, gas consumption increases, frequent operation of automation leads to premature wear

To eliminate this unpleasant phenomenon, it is enough to reduce the gas supply to the burners. Carefully studying the instructions, we find the gas valve, the adjustment method and reduce the gas supply to the burners.

Heating gas burner self-tuning, adjustment, conversion to another gas natural household methane

Adjustment of the gas heating turbo-burner. How to transfer to another type of gas. (10+)

Installation and connection of a gas burner for heating - Continued

‘);

Contents :: Search

In some cases, there may be a gas supply regulator at start. The fact is that the gas-air mixture burns well only at a certain ratio of gas and air in it. Moreover, at the time of launch, for reliable ignition of the gas, there must be more than during the rest of the combustion. Additional gas supply at start-up is just regulated by this regulator. It also needs to be set to the maximum feed.

We will install air supply and flame length regulators based on the required power. The position of these regulators depending on the required power is given in the burner manual.

Turn on the switch on the dashboard of the boiler. The burner turbine should turn on. After purging, a spark should appear (usually, although not always, its crackling is quite audible from outside the boiler). Next, the gas supply opens.It should light up. This may not happen the first time. After installation, air remains in the gas pipes of the burner, which can interfere with ignition. If the burner did not catch fire the first time, but blocked, then it must be unlocked in accordance with the instructions and try to turn it on again. Usually from the second or third time it lights up. If this does not happen, then there is some kind of malfunction. Link to an overview of burner faults at the beginning of the article.

|

Here is a selection of materials for you: Veverything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, firewood, electricity). Do-it-yourself ovens. Heat carrier, radiators, pipes, floor heating, circulation pumps. Chimney cleaning. Conditioning |

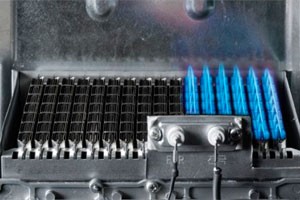

The burner turned on, there is a flame, but it cannot be operated in this form. The combustion is incomplete, the flame is orange, smokes and smokes. You need to make fine adjustments.

The choice of gas equipment is the main criteria

You need to decide on the settings of a gas boiler even before buying it. We advise you to start with the power of the equipment. The features of your home matter a lot. The main condition for the normal and uninterrupted operation of such a unit is the presence of a centralized gas supply. Naturally, you can try to use imported gas cylinders, but this will significantly increase costs. In some cases, it is even cheaper to purchase electrical equipment for heating a building than to buy gas cylinders.

Heating boilers are single-circuit and double-circuit. In the first case, we recommend purchasing an additional indirect heating boiler. Only then can the unit be used to heat domestic water. The best option is to buy a double-circuit boiler, which has all the necessary functions for heating the building and water. Its key feature is to transfer the priority of operating mode control to hot water supply. In other words, after opening the hot water supply system, the heat supply to the main circuit, which also includes the heating system, stops.

There are some features of choosing a floor and wall boiler. Wall-mounted equipment is less powerful, so it will not be enough to heat rooms with a total area of over 300 square meters. In this case, you will either need to purchase another boiler, or install a floor-standing gas boiler. In stores you can buy outdoor units of any capacity.

How the autoblock works

Manufacturers make control units that include all of the above devices. Even if they differ in appearance, their principle of operation still remains the same.

Automation from the Italian manufacturer EuroSIT is very popular. The 630 brand can be noted, which has many functions, reliability and long service life. Consider the device of an automatic block of such a model.

The EuroSIT 630 automatic block consists of the following elements:

- Casing, which consists of a pressure regulator module, a spring valve and a shut-off valve. Thanks to this, its device is facilitated.

- Gas is supplied through a pipe connected to the body.

- Cables from sensors and other elements are connected to the body.

Gas boiler adjustment

Consider the most popular problems that you can fix yourself:

- “The boiler warmed wonderfully in autumn, but it was cold in the house in winter.” This, in fact, is not a breakdown, but only the need to regulate the heating temperature. In the body of any gas boiler there is a thermostat.It may look like a rotary knob with a scale, buttons with a temperature screen, a scale with a slider on it. It is enough to set a higher heating value, as the house will immediately become warmer.

- “When igniting, the solenoid valve does not work, no matter how much you press on the handle.” The most common failure requiring valve replacement.

- “The boiler burns normally, but after a while there is a bang and everything turns off.” As a rule, here we are dealing with the operation of automation. But what is the reason for the “cotton” will have to be clarified. It is best to invite experts.

Transfer to another type of gas

Some common burners require replacement of the gas train for conversion to another type of gas, others will require replacement of the orifice and/or gas manifold. There are also universal burners, the transfer of which to another type of fuel is carried out by reconfiguring the gas train without replacing any parts.

It is best to immediately buy a burner for a suitable type of gas or a universal one, but if this was not possible, then you can try to transfer it to the desired type of gas.

For proper combustion, it is necessary to ensure the mixing of gas and air in the optimal proportion. For natural gas (methane) and for bottled liquefied gas, this proportion is different. But the ramp allows you to regulate the gas supply within a fairly wide range. As a result, it is often possible to make a burner designed for a certain type of gas work on another type of gas without changing anything, even if this is strongly recommended in the instructions. Nothing can be guaranteed here. But more than once I managed to adjust the methane burner to propane or vice versa without replacing parts so that the gas analyzer showed the optimal mode of operation. To do this, we supply the desired type of gas and carry out fine adjustments, as described above. When switching from propane to methane, you will first have to slightly increase the main gas supply and the gas supply at the time of start, so that the gas simply catches fire (without such an increase, a methane burner set to propane simply will not light up). A burner set to methane on propane will smoke as if it was first started with maximum gas supply. It just needs to be adjusted, gradually reducing the feed.

What exactly can not be done without replacing parts? The specific heat of combustion of propane is one and a half times greater than that of natural household gas, which mainly consists of methane. So the interval for adjusting the power of the burner when transferring it from methane to propane will shift upwards and vice versa during the reverse transition. So a methane burner of 10–30 kW on propane without replacing parts can (if it can, guarantees cannot be given) operate in the range of 15–45 kW. But at a power above 30 kW, it may overheat. So the safe interval of its adjustments on propane will be 15 - 30 kW. The adjustment range of a 10-30 kW propane burner, converted to methane without replacing the recommended parts, will be 7-20 kW. But at a power below 10 kW, most likely, optimal gas combustion will not occur, so 10–20 kW can be considered the operating range.

(read more…) :: (to the beginning of the article)

Contents :: Search

Unfortunately, errors occur periodically in articles, they are corrected, articles are supplemented, developed, new ones are being prepared. Subscribe to the news to stay informed.

If something is not clear, be sure to ask! Ask a question.

Conclusions and useful video on the topic

On the presented video you will find a brief instruction for installing a gas boiler equipped with an automatic Eurosit system.

A modern gas boiler is a rather complex design, which provides for many useful functions. Automation of most models greatly facilitates their operation, takes over the management of mechanisms and control over their work.

.

This significantly increases the level of safety during the operation of the heating system, and also increases its efficiency by selecting the optimal mode.

Do you need to adjust the automation of your gas boiler? Do you want to solve this problem yourself and want to clarify some points? Feel free to ask your questions under this article, and our experts will try to help you.

Gas equipment is ubiquitous in apartments and country houses. You independently regulate the equipment, setting a comfortable temperature in the room. So you are not dependent on utilities, you can save fuel as you see fit. But for the operation to be really economical, the correct setting of the gas boiler is important.