Electrical equipment not working

All equipment

If all electrical equipment does not work at the stove, then the reason is most likely that there is a violation in the supply of electricity. There may be no contact in the socket, the plug or wire may be damaged, the wiring inside the stove may be broken. First you need to check the health of the outlet by turning on another electrical appliance. If the outlet is working, then the stove must be disassembled. Using a tester, we check the health of the wiring. If mounting contacts are provided in the plate, then we check the presence of conductivity between the plug contact and the mounting contact. If there are no such contacts, then you will have to cut the wire, check it, then connect it back.

Unfortunately, errors occur periodically in articles, they are corrected, articles are supplemented, developed, new ones are being prepared. Subscribe to the news to stay informed.

Good day! I manage with one working capacitor 45 microfarads, I have 400 watts. Good sine wave, everything works, except for the refrigerator. Should I increase the power of the transformer to make the refrigerator work? Read the answer.

Good afternoon. I have such a problem. Stove BURNING, gas. I turn and press the knob of the stove to turn it on. The burner lights up. Everything here is no problem. Having endured a certain time, I release the on/off knob, and the burner goes out. This problem is only with one burner. Thanks in advance. Read the answer.

Good afternoon. When you turn on the oven, the whole stove began to heat up very strongly - handles, side walls, upper part - everything! There is no smell of gas. Gas stove, about 3-4 years old. What could be the reason and is it dangerous? Read the answer.

Tell me, please, where are the jets in the ARDO 640 oven. The kit comes with 6 jets for bottled gas for replacement, but the instructions describe the replacement on the table (the easiest), but there is nothing about the oven. Read the answer.

Hello, I have this question: stove: 'Kaiser'. When you put the pan on the burner (the biggest one), there is a strong smell of kerosene. Without a frying pan, it burns without smell. The rest of the burners light up normally. The smelling burner burns with yellow ends, with characteristic jerks. Thank you in advance for your response. Read the answer.

Hello. I have a BOSH gas hob with electric ignition. In operation 4 years. The power cable got very hot. What is the reason for this phenomenon? Read the answer.

There is a Datid gas hob, service life of 3 years. Recently, the following has begun, when igniting and holding the knob pressed for 5 seconds (as expected) or even more (up to 1 minute), the flame still goes out in most cases (you have to either hold it for a long time or try many times). What is the reason? Need a replacement thermocouple? Read the answer.

We salt the mackerel. Selection of fish, salting, marinating. How to salt mackerel. Salting tips. Classic salting recipe. Salting in .

How to cut laminated chipboard, chipboard without chips? How to repair chips. When making furniture, you have to saw chipboard. Chipboard does not like this very much -.

Close the joint of the bath + walls, tiles, tiles. Glue, stick, stick b. How to reliably and permanently close the junction of the bathtub and the wall? If the wall is made of panels, slabs.

How to make a bench and a table in the country with your own hands. Garden bench design. How to make a comfortable bench in the country with your own hands.

Knitting. Spider family. Drawings. Pattern schemes. How to knit the following patterns: A family of spiders. Detailed instructions with explanation.

One of the most common hob problems is when the burner does not work, while the appliances can be gas, electric or induction. This malfunction is not always easy to fix on your own, since intervention in the working system requires special skills.In this article, we will look at the main reasons why burners for electric stoves and other modifications do not function correctly. We will also analyze how you can fix some problems without professional help.

Both all and individual burners can stop functioning.

Gas burner service procedures

A gas burner, like any technique, needs service from time to time. However, today many technical work codes strictly prohibit independent intervention in the operation and repair of gas appliances and devices. Therefore, it is often necessary to resort to the services of professional specialists.

However, this fact cannot prevent us from considering some acceptable preventive procedures that can significantly increase the efficiency of your gas burner.

Firebox cleaning

Keep the interior of the furnace, burner and control equipment clean. Periodically vacuum the firebox and dust off the control equipment.

Vacuum both the column and the burner itself from dust. The jets are cleaned with a brush.

Engines with lubrication points should be lubricated with a small amount of oil.

Shutting off the gas line valve

Always at the end of the heating season, when the stove is no longer needed, turn off the gas line valve.

The handle of the closed tap must be perpendicular to the gas pipe. If your gas is in a cylinder, close the shut-off valve on it.

Search for leaks

Be sure to check pipes and equipment for gas leaks. The location of the leak can be found by smell. Special substances are added to the gas entering your home, which give it a characteristic pungent odor.

If there is a leak, turn off the gas valve and call the gas service immediately.

Examine the torches of flame

At the beginning of the heating season, when you start the stove, look at the appearance of the flame. It should be blue-green.

Check the color of the flame in the burner.

If something is wrong with the torch, call the master who will adjust the supply of the gas-air mixture correctly. The length of the pilot flame must be 13 mm. It can be adjusted with a screw.

Joint density

Be sure to check the tightness of the chimney joints and the presence of holes in it. Those sections in which there are holes need to be replaced.

Call a technician every few years to check the pressure regulator, main gas cock and safety valve. To find out the efficiency of the gas furnace, the master must also check the draft, the temperature of the exhaust gases and the level of carbon dioxide in them.

The burner does not turn on

|

Here is a selection of materials for you: VEverything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, firewood, electricity). Do-it-yourself ovens. Heat carrier, radiators, pipes, floor heating, circulation pumps. Chimney cleaning. Conditioning |

Lights do not light up, the turbine does not turn on. Causes:

Insufficient gas pressure at the entrance. The gas fittings are equipped with a pressure switch that blocks the burner from turning on if the inlet pressure is less than the set one. In this case, the burner does not show any signs of life at all, since this blocking is usually carried out by turning off the power. The most common cause of this malfunction is a closed gas cock. Having closed it in the spring, at the end of the heating season, in the fall they often forget to open it. Check it out. The gas line may be overloaded. This happens in some areas. If you have an autonomous gas supply, then liquefied gas could run out or freeze. Gas tanks provide reliable gas supply only at positive temperatures.To ensure it, they are buried in the ground (always plus at a depth) or heated. Within certain limits, the response threshold can be adjusted. But with a very low inlet pressure, the burner will not work with any adjustment.

No power supply. The burner needs power to operate. It is fed through the boiler. The boiler is equipped with a switch, a thermostat for maintaining the temperature of the coolant and an emergency thermostat. All of them must be turned on for the burner to turn on. The switch is displayed on the front panel. The temperature maintenance thermostat is also adjustable from the front panel. It turns on when the temperature of the coolant drops below the set value. By turning its knob in the direction of increasing temperature, you can check if it is turned off. The emergency thermostat turns off when the water temperature approaches 100 degrees. If it is turned off, then it will not turn on by itself. You need to press a special button on the boiler. But its operation indicates a malfunction in the control thermostat. So after such a trip, the boiler must be observed, to make sure that it does not overheat. In addition, the boiler itself may not be securely connected to the network.

The oven thermostat does not regulate the flame

This effect is often complained about by housewives who do not understand very well how the oven thermostat works. If you have a stove with a thermostat, then when you change the position of the regulator, the flame may not change immediately. The thermostat works like this: first, while the oven is cold, the gas is supplied at full power, no matter how the engine is installed. As it heats up to the desired temperature (it is it that is set on the regulator), the valve gradually closes, the flame decreases.

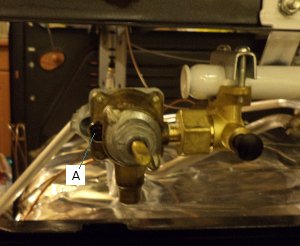

But two other malfunctions can be associated with the thermostat. Firstly, the flame may go out after the oven heats up. Secondly, the flame may burn too hot even though the oven is already hot. Both of these problems are caused by improper adjustment of the low fuel screw on the oven burner (Figure 3. A).

This screw needs to be turned out a little. Light the oven, close it. Set the adjuster to 140 degrees. Wait 10 minutes. Now, by adjusting the screw, you need to ensure that the flame is small (reeds about 4 mm), but burns steadily, does not go out. This is usually easy to do. But sometimes, even with the low flow screw fully turned, the flame is too large. The fact is that there is a small hole in the screw, which excludes the complete shutdown of the gas supply even with the screw screwed to the end. Why this hole is needed, I have not figured it out. But the fact remains. If the flame cannot be reduced to the desired level, then the screw must be unscrewed completely and replaced with a screw with a smaller hole, or the hole must be sealed with a poxypol (it is completely useless). Then we screw the screw again and adjust the flame.

All of the above applies to the oven with a thermostat. The burner with a tap is regulated similarly to the burners of the table. It is very easy to distinguish a thermostat from a faucet. Temperature values are written on the thermostat scale. On the scale of the crane are just numbers.

Advantages and disadvantages of this system

Like any technical element, the gas control system has its advantages and disadvantages. The former, as a rule, border on its functions and come down to the fact that gas control allows you to:

- automatic shutdown of the gas supply when the flame goes out on the burner or in the oven;

- getting rid of constant monitoring of the furnace during its operation;

- prevention of dangerous situations associated with fires and explosions.

Nobody relieved the gas control of the shortcomings. Inventors are working to eliminate them, but for now they are still there. These usually include:

- the need to keep the knob or button pressed while waiting for the thermocouple to warm up and send a signal to the solenoid valve;

- lack of stable operation of the burners and oven in the event of a system failure;

- difficult repairs (especially if you decide to do it yourself and do not have such skills in work).

Due to these shortcomings of the gas control system, many users resort to turning it off. To achieve this goal, it is necessary to adhere to the following algorithm of actions:

- turn off the gas supply from the gas pipeline;

- find where the gas control system is located in your case (in all models, its location is different);

- disconnect and remove the solenoid valve;

- pull out the spring, which is responsible for the flow and shutoff of gas;

- return the solenoid valve to its place.

The removal of the spring is just responsible for ridding the stove of the automatic restriction on the gas supply. In this case, the valve will always be in the open state, regardless of whether it receives a signal from the thermocouple or not.

Disabling gas control will not be difficult, however, any independent operations with gas household appliances can lead to an accident, so it is best to call a specialized craftsman for such work.

The master, turning off the system, at the end of the work makes the appropriate notes in the instrument operation log indicating the date and reason for the action (very often the gas control is turned off when it goes out and is out of order, so as not to waste money, time and effort on its repair).

Gas control ceases to function properly in the following cases:

- with severe contamination of the sensor elements;

- when the thermocouple is displaced (its rounded end must always be on the border with the flame);

- thermocouple obsolescence;

- solenoid valve wear;

- weakening the connection of elements.

Repairs related to the replacement of elements are best left to a specialized organization in order to protect yourself and avoid problems with the law. You can clean the thermocouple from contamination or tighten the connections yourself.

Why are induction hobs not working?

Very often, induction hotplates do not work due to the wrong switching sequence. For the correct operation of the hob, it is necessary:

- Activate panel.

- Select the desired burner.

- Set power.

Check all connections located between the power board, the control unit and the coils. If there is no damage, the entire control assembly will most likely need to be replaced. If this does not work either, the burner block is faulty.

Not all types of materials are suitable for induction cookers

To find out for what reason the burner on the hob does not work, the specialists of the TER-MARKET company will help. Depending on the type and brand of equipment, suitable spare parts will be selected. Call us, we will answer all your questions!

So I was in the kitchen, and at that time there was lunch in the dining room. And so our cooks (three women) turned to one of the full-time locksmiths with a complaint that their gas stove did not work well.

The locksmith came in, looked, lit all the burners in turn and made sure that one did not work at all. Then he lit all the burners at the same time and found that in this case the gas burns worse. He poked around there for about five minutes, after which he issued a verdict that the nozzles were covered and nothing could be done. You just need to change nozzles. I smiled and went to look for a paper clip.

Surely many of you have noticed that over time, the gas on the stove burns weaker than usual, or that with all the burners lit, the gas also burns worse. So, in most cases, the cause of these troubles lies in the contamination of the burner, and not in weak pressure or gas quality.

Today we are going to clean the burner. Of the tools for this procedure, we need only one paper clip and five minutes of time.

Looking inside, you should see something like the following picture.

Here in this small hole (and do not call it a “hole”) we insert our paper clip-stick.

There is no need to be afraid - you will not break anything with a paper clip. We deepen the paper clip as deep as possible. I have it completely immersed in the hole to be cleaned.

After repeating this procedure a couple of times, we assemble our burner back. Exactly according to the same principle, we clean all the other burners, put the grate in place, pick up matches, light it and enjoy the results of our labors. After that, we drag our wife to the kitchen to brag about what good fellows we are, and after that, with a sense of accomplishment, we go to the store for beer).

The burner burns weakly or goes out

The burner of the table or oven burns weakly when the tap is open at full tap and the oven is cold. If there are problems with only one burner (the rest are working normally), then the reason is that the jet of the corresponding burner is clogged. Repair is easy. It is necessary to clean the nozzle (jet, nozzle). This is done with a thin wire or needle. At first, you can try to clean the nozzle without removing it. The burner nozzles of the table are installed under the burners (fig. 1. A). The oven burner nozzle is installed on the side of the stove (fig. 2. A). Getting to the oven nozzle is not always easy. Then you need to remove the bottom wall of the oven, unscrew and remove the burner (it is attached there with one or two screws). The nozzle can be accessed from the oven.

If it is not possible to clean the nozzle without removing it, then it can be easily unscrewed with a suitable key.

If all burners burn poorly, then the reason is low gas pressure. The combustion of the burner of an oven with a thermostat must be checked when the oven is cold. Otherwise, the thermostat may reduce the gas supply when a certain temperature is reached. This is, in fact, its regular function.

Professional burner repair

|

Service

|

Price |

|

Departure of a specialist for the diagnosis of an inflatable burner up to 90 kW. |

1500 rub. |

|

Cleaning the boiler from the diesel burner |

from 5000 |

|

Diagnostics of automation and setting of one circuit |

1500 |

|

Adjustment of a gas inflatable burner up to 90 kW. with gas analyzer. |

6000 |

|

Adjustment of a diesel inflatable burner up to 90 kW. with gas analyzer. |

6000 |

|

Repair of inflatable (gas, diesel) burners up to 90 kW. Without spare parts for the burner. |

4500 |

|

Gas setting. modulating burner (Weishaupt type) |

11000 |

| Night work is on the rise |

In our company you can order the departure of an employee to the place of breakdown. And we will give you confidence that all work will be carried out by specialists, not amateurs. Our masters have many years of experience, and therefore they carry out repairs of diesel burners not only within an acceptable time frame, but also in such a way that you do not have to turn to professionals for help too often.

But someone might think that it will be easier to buy new equipment than to carry out repairs. But in reality it will be more difficult and costly. To buy this or that equipment, you need to find exactly the model that you need. And such searches can take a decent amount of time. So why waste it?..

And if a model similar to the previous one cannot be found, then someone decides to offer to buy completely different equipment. But it will be necessary to get used to using a new fuel boiler, which will also take time. So why break the habitual way of life, when instead it is possible to repair gas burners that have failed through specialists? ..

This will be a better solution that will save you a lot of time. In addition, in this way you will significantly reduce your costs. Yes, since a malfunction has already been discovered, it will be easier to fix it.But replacing the entire apparatus costs a lot of money, and compared to this, repairing the burners will be a very cheap pleasure.

One way or another, the work of specialists, as a result of which your fuel boiler will return to operation, will be justified. And modern equipment and the work of experienced craftsmen will convince you that the problem was not as global and terrible as it seemed at first. And everything to avoid the repetition of such a situation in the future is the timely maintenance inspection and the correct operation of the fuel boiler and burners. This will save you from unnecessary worries and costs. And our specialists, who carry out any necessary work with fuel boilers around the clock, will help you achieve the best and regular performance of the equipment.

Our experts will help you to select, mount, configure and start up equipment with high quality, which in the future will not cause a lot of trouble and problems in setting up and repairing. We work with boilers and burners Baxi, Vaillant, Viessman, Protherm, Buderus, DiDietrish, Ferolli, ACV, Weishaupt, Gierch, Hansa, Lamborghini, Oilon, Cuenod, Fbr, Ecoflam, etc.

The purpose of the home gas stove

A gas furnace with forced air supply (blast) to the burners drives air through the heat exchanger using a blower fan. The heat exchanger is heated by gas burners, and the warm air goes to the ducts, from where it enters the room.

Scheme of a typical gas stove for a private house. Essential elements:

- blower and automatic gas supply control system;

- panel for access to the burner;

- main gas valve;

- pilot burner;

- main burner;

- control cabinet;

- air filter;

- panel for access to the fan and motor;

- chimney;

- openings for supplying warm air;

- heat exchanger;

- fan motor and fan itself.

The main gas pipeline leading to the furnace has a valve that can be used to manually shut off the gas supply. If the tap handle is parallel to the gas pipe, then the valve is open. To shut off the gas, it must be installed perpendicular to the pipe.

Features of a standard manual gas valve:

- up goes the main gas line for the furnace;

- when the handle is perpendicular to the pipe, the gas supply stops;

- when the handle is parallel, gas is supplied without restrictions.

The level of gas supply is regulated by a gas reducer and an automatic regulator. The gas reducer automatically regulates the pressure and, depending on the situation, can increase or decrease it to the level required for operation. The automatic regulator is responsible for controlling the gas supply to the burner. In most modern stoves, these devices are combined into one common fuel consumption control unit. Do not even think about trying to regulate the gas pressure yourself. This should be done by specialists of the gas company.

Ceramic gas oven Master 450CR.

Service work on gas ovens and other gas-powered equipment is much more dangerous than similar work on, say, electrical appliances or oil-fired devices. After all, even the smallest gas leak can lead to irreparable consequences. If you have even the slightest doubt about the serviceability of a gas appliance, contact your gas company or the manufacturer of your equipment.

Free standing gas stoves heating fireplaces

Such gas stoves have a very similar appearance to wood stoves. The device of the chimney of both furnaces is also approximately the same. Modern models of gas ovens are highly efficient heating equipment that produces a large amount of heat.

Free-standing gas fireplace is a real decoration of any interior.

The burners in such stoves look like burning logs, which can be seen through a transparent door.When purchasing such an oven, you should also be provided with instructions for its installation, as well as an operating manual. The outlet pipe is led out in the same way as the pipe in wood stoves, i.e. into the existing brick chimney, fireplace chimney, wall and roof.

The gas heating fireplace fits in perfectly with the Victorian style.

For gas stoves, there are also established requirements for their location relative to the floor and walls of the room. Although wood and gas stoves have different requirements in the code, their smoke extraction systems are similar to those shown in the diagrams above.

A gas stove of this design can stand right in the middle of the room and will not bother anyone.

The free-standing gas stove is in perfect harmony with the white design of the room.

The wall-mounted gas fireplace, unique in its design, will not leave anyone indifferent.

Simple free-standing gas fireplaces with a minimalist design.

Free-standing gas ovens, similar to those used in , are equipped with a pilot burner and are ignited in a similar way. Accordingly, exactly the same safety rules apply to it.

However, in any case, follow the rules prescribed in the manufacturer's instructions. If the pilot burner does not ignite for more than five seconds during ignition of the stove, turn off the stove, vent it of accumulated gas and try again. If the second time you did not succeed, call the representative of the supplier.

For operation on natural or liquefied gas. Gas burners are produced in various technical categories, up to fully automatic microprocessor control. They have from one to several stages of operation and operate at different gas pressures in the pipeline. Low noise level, economical operation, automatic control are the main advantages of natural gas burner operation. Like all technical devices, a gas burner requires periodic maintenance and repair, which can be carried out based on the table below of the main malfunctions of gas burners.