Do-it-yourself Lachinyanka oven production stages

Marking holes in the furnace body.

The Lachinyanka oven is made in a certain sequence:

- a case with a lid is made, as well as a tank for ash;

- all necessary holes are made;

- grooves are being prepared, into which river sand will then be poured;

- gas outlets and grates are made;

- two taps are mounted, which serve to supply oxygen;

- then you can proceed to the manufacture of the air intake;

- the whole structure is installed on the frame and the arm for the pallet is mounted;

- a chimney with a tank for collecting condensate is installed.

In conclusion, all fittings (fasteners, handles, clamps) are hung on the Lachinyanka oven. If required, ribs are welded onto the body to increase the heat exchange area and, accordingly, the power of the unit. The ash tray lever is only needed if the diagram does not provide for the ash tray to be hinged to the body. In the latter case, installation will be much more difficult.

For a body with a drip tray and a lid, a pipe with the same diameter is used. You should not take a thin-walled pipe, since metal is needed a little stronger to work in high-temperature conditions. The drawing of the Lachinyanka furnace is made with the expectation of a pipe with a wall thickness of 5 to 8 mm. When making edges (grooves) for sand from two plates welded in a circle, the inner part should be welded first. This must be done so that the seam lies in the groove itself.

In the manufacture of grates for the Lachinyan furnace, steel bars should be used and cast iron should be avoided. When choosing faucets for air supply, it should be borne in mind that they will have to work at elevated temperatures, therefore, they must be completely metal, without plastic elements. A one and a half inch water tap with rubber seals will do. Rubber is quite efficient in these conditions. A pipe with the same diameter is used for a body with a pallet and a lid.

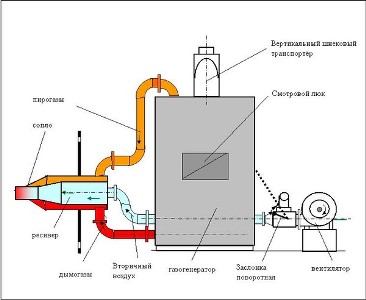

Schematic layout for installing gas outlets

You should not take a thin-walled pipe, since metal is needed a little stronger to work in high-temperature conditions. The drawing of the Lachinyanka furnace is made with the expectation of a pipe with a wall thickness of 5 to 8 mm. When making edges (grooves) for sand from two plates welded in a circle, the inner part should be welded first. This must be done so that the seam lies in the groove itself.

To avoid the formation of condensate, the chimney must be insulated or, if possible, located in a warm room. The flue pipe must not be horizontal. It is necessary to give a slight slope towards the heater so that the condensate flows first into the condensate collector, and then into the Lachinyan furnace.

Types of pyrolysis ovens

A high-quality long-burning furnace must meet several conditions:

• to maintain the maximum combustion temperature and long-term operation, have enough large loading chamber ;

• in order to prevent parasitic draft and excessive air intake, the boiler must be as tight as possible ; the doors on it should adjoin the body as tightly as possible;

• since the combustion of gases occurs partially in the chimney, in order to increase the efficiency of the furnace, its horizontal section at the junction with the boiler is better extend up to 1 m and additionally insulate with mineral wool;

• in order to reduce the number of bookmarks of fuel, it should be laid as tightly as possible, without gaps - so it will smolder much longer; it is advisable to cover large logs with wood chips or sawdust; in some models (for example, such as "Stropuva" or "Bubofanya", which we will discuss below), additional fuel compress ;

• presence in the boiler of the minimum amount heat exchangers (pipes with water to remove heat into the room) - since when heat is transferred to the pipes, the temperature in the furnace will drop sharply, and gases, without burning, simply evaporate into the pipe; In this case, the efficiency of the furnace, of course, will drop sharply;

• to avoid smoke in the premises humidity raw materials used should be as low as possible (up to 20%);

• Since these boilers require frequent cleaning, the chimney connection must be collapsible ;

• when the temperature in the boiler drops, it often forms water condensate ; to drain it at the bottom of the chimney, a drain valve should be provided.

Important! The performance of such furnaces directly depends on the volume of its working chamber. The shape of the boiler itself can be any

According to the method of fuel combustion, pyrolysis boilers are divided into:

• shaft type. air supply to solid fuel chamber carried out from below, through a blower (a hole in the lower part of the furnace), while, of course, the fuel begins to burn also from below;

• top burning. air enters the first chamber from above through a special pipe.

According to the methods of air supply, all pyrolysis boilers are divided into:

• working on natural draft (oxygen enters them naturally through special holes);

• Forced draft: air dosage is carried out using deflector (chimney). located on the chimney, this mechanical device has several inclined planes; when the air goes around such obstacles, a pressure difference is formed in the channel, while the thrust increases; it is possible to significantly increase traction with the help of electrical devices with turbine operating principle .

According to the type of fuel, long-burning stoves can be divided into:

• working on waste oil; • firewood; • coal.

Advantages and disadvantages of the pyrolysis oven

It should start with the fact that the mini gas generator, which is located in all devices of this type from a gas cylinder, has a very advantageous position. thanks to its principle of operation. Its efficiency exceeds 80 percent! Due to this factor, the operation of the stove is very economical (which cannot be said about fireplaces): it is rational to use fuel at no extra cost and adjust the process, as well as the degree of combustion on their own;

The second advantage of pyrolysis stoves from a gas cylinder is that the stove will work on any fuel. For fuel, you can use a variety of waste from the woodworking industry. It can be firewood, chips, sawdust, small branches and so on.

It is permissible to operate the unit on small household waste, in the form of plastic or small rubber products;

The third positive feature is that pyrolysis gas is environmentally friendly, which means that there is no harm to nature;

Very important is the “clean” operation of the stove from a gas cylinder (which cannot be said about fireplaces). During the operation of the device, such dirty substances as, for example, soot or ash do not appear, thanks to the principle of operation of the gas generator

This factor greatly facilitates the use of the design: you will not need to spend a lot of time cleaning the oven and eliminating various dirt from its external and internal surfaces.

The advantages of a long-burning pyrolysis furnace from a gas cylinder do not end there, for a better acquaintance with all the advantages, you can watch the necessary videos, but we will limit ourselves to this and proceed to listing the disadvantages of the device:

The first thing you need to pay attention to is the high cost of a pyrolysis oven for a bath or at home. Most often, this is what stops buyers

Unlike fireplaces, the cheapest model for a bath will cost at least 10,000 rubles.and if you want a more modern and improved sample, you will have to pay approximately 17,000 rubles. On the other hand, the high prices for pyrolysis stoves for a bath are fully paid off by their good quality and versatility: nothing will warm up your house as well as a pyrolysis stove;

The second disadvantage of devices from gas cylinders of this type is the need for a constant power supply. This is necessary to keep the oven running. The costs for the constant use of electricity are also very high, which cannot be said about fireplaces. To date, there are some models of pyrolysis stoves from gas cylinders that do not need a constant supply of electricity. however, due to some circumstances, they are not very popular.

If you don't want to spend a lot of money to buy a pyrolysis oven or fireplace, there is a great solution - you can make it yourself according to drawings and videos on the Internet. In order to make such a design with your own hands, you do not need to fully know the principle of operation of the boiler and gas generator - it is enough to understand the basics that were listed above.

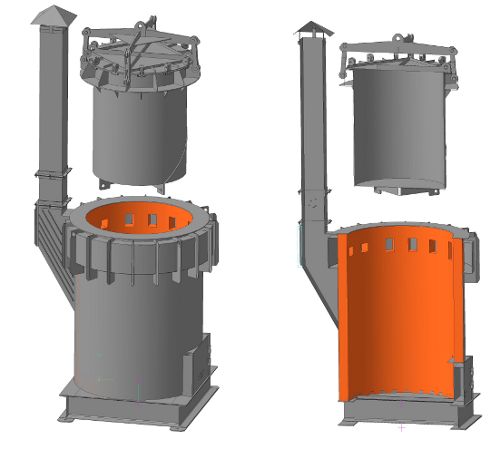

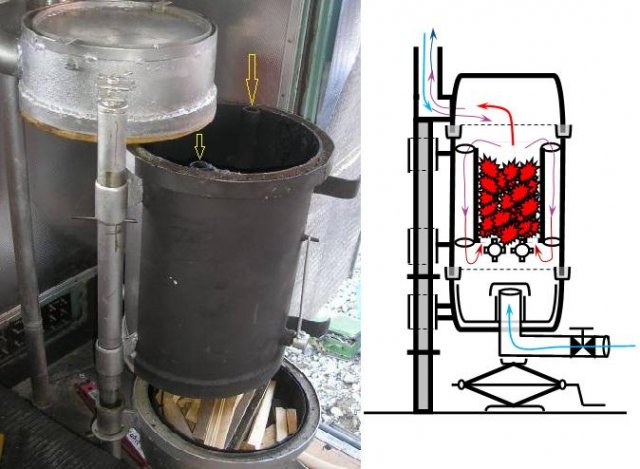

Do-it-yourself Lachinyanka oven

This boiler is a rather controversial (and little tested) model, powered by coal, wood, peat or pellets. At its core, it is a reduced copy of the industrial furnace "Energy TT". According to the author, his "Lachinyanka" is also able to work without interruption for a long time - a whole week. At the same time, the fuel loading rate is only 20 kg, and this boiler forms a minimum amount of soot. You can also use it as a regular potbelly stove.

Unlike other pyrolysis ovens, "Lachinyanka" is equipped with tank. installed on the chimney pipe, in which condensate collects. which is then fed into the combustion chamber. Such is the waste-free production. Even soot mixed with condensate burns to the ground.

Important! In order to obtain a sufficient amount of condensate, the temperature in such an oven should not be too high. Lachinyan S.S.

in order to popularize his offspring, he also gives a detailed scheme for its manufacture (the scheme is both freely available on the Internet and on the official website of the author). Therefore, if you wish, you can try to design such a stove yourself. But there are not enough reviews about her work, both positive and negative.

Lachinyan S.S. in order to popularize his offspring, he also gives a detailed scheme for its manufacture (the scheme is both freely available on the Internet and on the official website of the author). Therefore, if you wish, you can try to design such a stove yourself. But there are not enough reviews about her work, both positive and negative.

Video: do-it-yourself pyrolysis oven

Scheme of assembly and installation of a stove for a bath or home

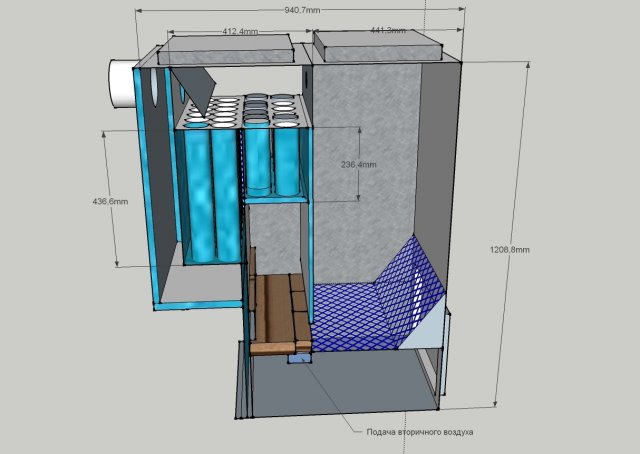

If, nevertheless, you decide to create a pyrolysis oven for heating a house, bath or sauna, as well as any other premises, then you will need the following tools and materials:

Note to Samodelkin

- Steel sheet measuring 6 by 1.5 m. Its thickness must be at least 4 mm.

- Ceramic and fireclay bricks.

- Fan with a power of at least 300 watts.

- 2 doors for blower and furnace.

- Cast iron grates - about 3 pcs.

- Lever thermostat.

- Electric drill.

- Welding machine.

- Bulgarians with 2 different circles - small and medium.

- Pipes with a diameter of 3.2 / 5.7 / 15.9 mm.

- Professional pipes with a diameter of 80x40.

- Temperature sensor.

- Electrodes for welding.

Depending on the purpose of the stove - for a bath, for a special heater, for the home, etc. – the dimensions and quantity of materials may vary, but the average parameters remain the same.

To make a pyrolysis oven for a bath, you need to be able to use, first of all, construction tools, in particular, a welding machine, and you must have an assembly drawing, where:

- A - boiler circuit controller;

- B - loading door;

- C - ash pan door;

- D - smoke exhauster;

- E - coupling for temperature sensor;

- F - branch pipe of the emergency line;

- G - supply line;

- H - cold water connection;

- K - hot water of the heat exchanger;

- L - boiler circuit return;

- M - expansion tank.

The sequence of work is as follows:

- First of all, you need to draw up a diagram of the future design of the stove for a bath or any other room.

- Next, the perimeter of the furnace must be laid out of ceramic bricks.

- Fireclay bricks are used for finishing and construction of external partitions.

- It is necessary to weld special pipes that will increase the tightness.

- Install a partition between the gas and secondary combustion chambers.

- The supply is mounted in the upper part, and the return is mounted in the lower part.

- Doors are made and installed from heat-resistant steel. Doors are needed to clean the oven and adjust the air supply. For a bath, they are reinforced with a metal corner. Next, the doors are equipped with locking handles.

- Attach a smoke pipe.

- Connect a fan that will blow air into the gas-oxygen mixing chamber.

Advice from the master!

However, before starting work, it is necessary to sensibly assess your strengths. If there is no certainty, then it is better not to take risks and use the services of professional companies and firms involved in the assembly and installation of such systems.

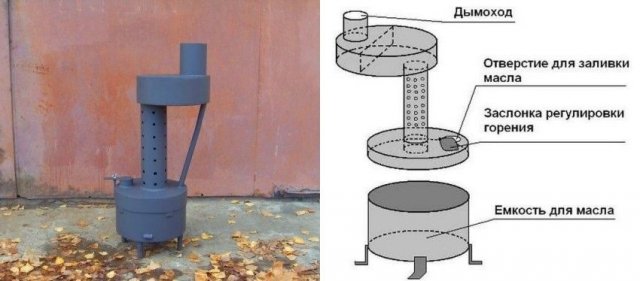

Do-it-yourself ovens

The most versatile and widely used oven mine type with a fairly high efficiency (up to 75%) is Buleryan. On the sides of such a boiler there are 6-8 pipes. Their lower ends “suck in” cold air from below. Pipes tightly encircling the stove quickly take in heat and throw it up into the room. On our website there is a very detailed description of the principle of operation of Buleryan.

The economical furnace for working out has also proven itself well. Its design is as simple as possible, and making such a boiler yourself does not present any particular problems.

Very original (and, most importantly), quite effective design top burning and high efficiency is the Bubofanya furnace. The widely advertised Stropuva model was taken as its basis. But, unlike the industrial model, the design of the Bubofani is extremely simple, and any novice welder can do it. You can get acquainted with the principle of its work and the stages of its creation by following this link.

Job Requirements

The principle of operation described above is the basis. However, in addition to all this, there are also additional requirements that are necessary for the full and high-quality work of pyrolysis. With proper assembly, such a boiler can be used for heating and for supplying hot water to the bath. In order for the process to proceed smoothly, without sharp jumps in temperature and pressure, certain conditions must be observed. Here are some of them:

Homemade heater from an aluminum bucket

- For self-manufacturing of the boiler, only high-quality materials are needed.

- First of all, the metal from which the frame and casing of the boiler are made must be of high quality. For this, alloy steel is perfect, which meets all the required parameters and building codes.

- You need to be able to use a welding machine, without which it will be impossible to assemble the entire system. In addition, you need to be able to understand the drawings of units and their structural parts.

- It requires electronics to monitor the operation of the boiler, which can be expensive.

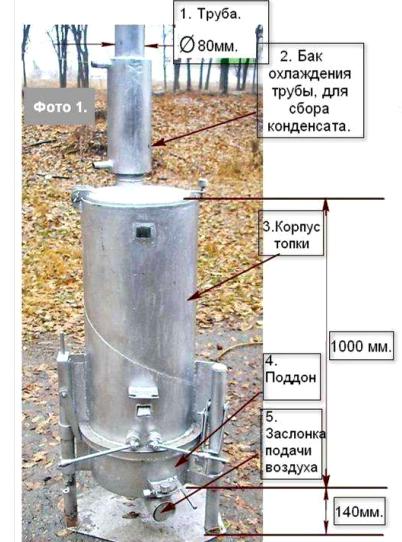

Operation of the Lachinyanka furnace

After you already have a Lachinyanka pyrolysis oven, you need to know how to handle it. The user manual is divided into several sections:

- installation rules;

- how to properly fire up the stove;

- application features;

- preventive maintenance.

Lachinyan's pyrolysis oven is placed on a flat surface, it should not stagger. Since the design has many movable elements (pallet, fasteners, etc.), there should be enough space around the unit. In addition, the furnace body can heat up to high temperatures, so you need to make indents from the walls. It is better, of course, that the latter be covered with some kind of heat-insulating material, or equipped with a thermal screen.

The design of the Lachinyan furnace is impossible without a chimney. It is subject to the same requirements as for chimneys of other gas or solid fuel heating appliances.

It is also extremely important to correctly calculate the diameter of the chimney. It must be no less than the cross section of the pipe in the furnace, while there should be no narrowing in any places, otherwise the draft will disappear

To kindle the Lachinyan furnace, coarse coal is poured into the furnace, without dust. A fire is built in the pallet. It is necessary to open both taps for air supply, and close the pan loosely. After the coal flares up, the tray can be hermetically closed, and more coal can be poured into the furnace. After an hour, the stove can be switched to pyrolysis mode. To do this, the lower valve is completely blocked and the upper valve is almost completely blocked.

During operation, it is necessary to remove ash and periodically clean the boiler and chimney. The frequency of cleaning depends on the quality of the coal. The higher it is, the less often you need to carry out the cleaning procedure. In addition, periodically you need to change the sand in the grooves for sealing. It is necessary to use clean, dry river sand, not too fine fraction. You can add fuel by simply opening the top cover, for this you do not need to stop the combustion process. published by econet.ru

SUBSCRIBE to OUR youtube channel Econet.ru, which allows you to watch online, download from YouTube for free a video about healing, rejuvenation of a person. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing - econet.ru.

Put LIKE, share with FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -

pyrolysis process

First of all, you need to understand what pyrolysis is and what is the principle of its operation. The process of burning fuel takes place with a lack of oxygen. Only after combustion, oxygen begins to react. If we talk about this process in more detail, then it happens like this:

- In the presence of a high temperature, the combustion of fuel is accompanied by the release of gas from it.

- Gas is released, as already described, with a lack of oxygen inside the furnace.

- The combustion temperatures for each fuel are different: for example, for petroleum products, the combustion temperature should be at the level of 800-900°C, and for wood, 400-500°C will be sufficient.

- When wood is burned, additional products appear: charcoal, resin, methyl alcohol, acetic acid, acetone, etc. Some of these products are used in the secondary and tertiary fuel combustion process.

Bath or house with a pyrolysis boiler advantages and disadvantages

Vertical oven model

People who plan to install such boilers in their home or bathhouse need to be aware of the advantages and disadvantages of pyrolysis.

The benefits include:

- Economical fuel consumption for the furnace. The efficiency of this boiler is given by the fact that almost everything can be used as fuel for it, up to used engine oil. Now it will not need to be drained anywhere, but to be used for useful purposes.

- Soot production is practically reduced to zero. The constant emission of smoke from the chimney can certainly disturb the neighbors, in which direction the wind is blowing. In addition, it harms the environment, that is, the environment. Now, with such a fuel combustion system, you can forget about it.Due to the fact that there is a secondary, and sometimes tertiary processing of combustion residues, soot, soot and smoke simply do not exist for natural reasons.

- High heat dissipation. When operating such a boiler, the efficiency level can reach up to 80%. At the maximum load of the boiler, the temperature of the room, even without the installation of heating radiators and additional pipelines, can reach such a limit that in winter it will be hot in one T-shirt. That is why people use this heating method.

- Easy to operate. Even a small child could control the operation of the pyrolysis boiler system. All that is required is periodically (not as often as in a conventional furnace) to fill in the fuel for combustion and select the required work power, otherwise the system is completely autonomous. Such systems are perfect for a bath, since it is there that autonomy of work is required.

- Possibility of safe disposal of almost any chemically produced substances: rubber, wood industry waste, polymeric substances, etc. In addition to the fact that this method is absolutely safe for the environment, it provides an opportunity to save financial costs for fuel. Efficiency, durability, etc. are easily adjusted.

Despite such a long list of advantages, the pyrolysis heating system has its drawbacks. Here are the main ones:

- The high cost of the finished boiler. However, you can solve this issue by making the oven yourself.

- High humidity fuel must not be used.

- A permanent connection to the mains is required.