Installation of drywall sheets is most often done on the frame. Drywall accessories - these are all the elements that are necessary for assembling the frame structure: the profiles that make up its basis, connecting elements, fasteners necessary for fixing the frame parts and mounting the plasterboard. It is important to choose the right drywall and accessories in order to create a reliable design.

Profile types

The skeleton of the frame for drywall is made up of profiles made of galvanized steel sheet. The frame turns out to be simple - racks fixed in guides. Structures are ceiling and partition, and for each of them the corresponding metal profiles are used. Depending on the methods of connecting the elements, different options for partitions, suspended ceilings, wall decoration, boxes and niches are created.

Existing types of profiles:

- PNP (UD) - ceiling guide or starting. Creates a base and aligns the frame, fastens around the perimeter of the room. Marking "Knauf" is indicated in brackets.

- PP (CD) - carrier (rack-mount) ceiling. Creates a complete frame structure. Also used for wall cladding. Racks are intended for installation of gypsum cardboard.

- PN (UW) - guide (starting) profile for partitions. It is the basis for the installation of the frame. It is attached to the ceiling and to the floor.

- PS (CW) - rack for partitions and wall cladding. It is selected in length according to the height of the room.

- PU (UA) - reinforced to create durable structures.

- PA (CD) - arched, for structures where there are bends. The profile is loosened for more flexibility.

- PU - corner profile, has a small thickness, increases the strength of the corners and aligns them.

The thickness of the metal is 0.4–0.8 mm. The necessary strength of the frame is achieved when using elements with a thickness of 0.55 mm. Too thin racks are characterized by insufficient rigidity and self-tapping screws do not hold well in them.

The length of the products is 2.75–4 m. The standard dimensions of the profiles make it possible to create frames for structures from gypsum boards with virtually no waste.

Additional elements

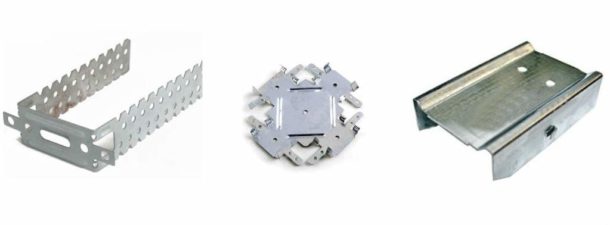

GKL accessories also include suspensions and a variety of connectors, screws and dowels. The following auxiliary elements apply.

- Direct hanger for CD. The part is attached to the ceiling or wall with self-tapping screws or dowels. The suspension is bent with the letter "P". The length of the product is 7.5, 12.5 and 30 cm.

- A two-level connector (“butterfly”) is used to attach a CD to each other crosswise. The part is bent with the letter "P" and fastened with metal screws to the profiles, one at the edges.

- Single-level connector ("crab") serves to fix profiles at the same level. With a load of up to 20 kg, no self-tapping screws are needed for fastening: just click on the connector.

- The longitudinal extension is used to build CD. It is inserted from the end inward and fastened with two self-tapping screws.

- The angle connector provides a T-shaped connection at the same level like a "crab".

Homemade hangers and connectors

From the remaining trim, you can make connecting elements that are not inferior and even superior in strength to standard fittings. You can do the manufacture of suspensions with your own hands from the ceiling profile as follows.

- "Boot". A piece of a suitable size is taken and the edges are cut from it on the side. It is folded at a right angle and cut through, getting a hard corner called a boot. If 2 such devices are installed close to each other on the ceiling, you get a very strong suspension for the PP.

- With a large distance from the overlap, the profile is bent, giving it a U-shape.The suspension is fixed with the sole to the ceiling, and with the lower ears - to the profile.

- A part of the back at the profile piece is cut out, after which the sides are bent and fastened to the ceiling with dowels, and the lower part to the PP.

The presented options for home-made suspensions are much more reliable than wire suspensions that hold the suspended ceiling with only two curved spring shelves. From the action of the load, the connection slips, and re-adjustment is often impossible, since the structures are non-separable.

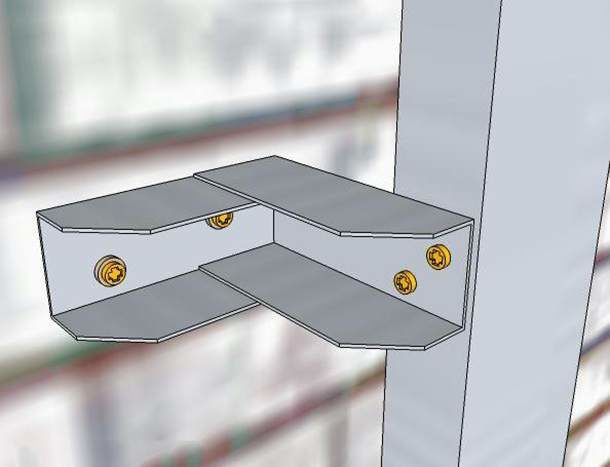

When the number of connections is small, there are not enough connectors, you can replace the crabs with a homemade design. To do this, the profile is taken 10 cm longer. Longitudinal slots are made in the bar, after which the edges are bent to the sides and attached to another profile with self-tapping screws. To facilitate the work, holes are pre-drilled in the bent strips.

To obtain long products, the profiles are built up by inserting pieces of PS inside and connecting them with self-tapping screws. To make them fit in size, you should slightly tighten the shelf.

If metal profiles and waste are optimally used, the price of materials will be reduced, and the quality of the structure will not deteriorate at all.

Fasteners for plasterboard

The frame elements are fastened together by drilling (LB) or piercing (LN) self-tapping screws for metal (“bugs”). The length of the shortest self-tapping screw is 9 mm. It is difficult to twist it, and the cap prevents the GKL from fitting to the profile.

Drywall is usually attached to the frame with TN self-tapping screws 25 mm long. A length of 35–40 mm is taken if the skin is made in several layers.

To fix the guides to the wall, nylon dowels with self-tapping screws, dowel-nails are used.

Manufacturers

The leader in the building materials market that manufactures drywall and components is the German company Knauf. In many cities of Russia, factories have been built that produce products using the Knauf technology: Knauf-profile and fittings for Knauf-profile. Recently, domestic products have appeared that are not inferior in quality to imported ones and win in terms of cost, for example, the Petrovich brand. Profile production has been mastered at almost all leading metallurgical enterprises in Russia.

A few tips for choosing accessories

When choosing a metal profile, you need to pay attention to the following points:

- The metal must be of sufficient thickness, the profile must have exact dimensions.

- The product must not show signs of rust.

- Abundant lubrication on the profile can mask a poor-quality coating.

- The elements of the future frame should not be deformed, they should not have burrs.

Conclusion

The strength, durability and appearance of the structure depend on how correctly the drywall and components are selected.