Additional recommendations for selection and installation

Fittings with caps must be mounted:

- where drains from washing machines and dishwashers will be connected;

- on the tie-ins of the internal pipeline into the risers;

- where several relatively small pipes are connected;

- as backup inlets for additional hoses.

Gate valves for flanges are not the only option. There is also a welded type of plugs and blanking caps for rubber sealing rings. In addition to these structures, meshes can be used to block the movement of solid waste, as well as pneumatic plugs mounted to disconnect risers from the entire system. The gate valve is designed to crush paper pulp, it is also installed at the outlets of systems that process heavy, strong waste. The larger cross section of the square outlet compared to the round inlet helps eliminate solids build-up in the valve and ensures non-stop blade movement.

Knife-type gate valves are most often installed horizontally, they are characterized by increased reliability, they can serve any pipe and a technically complex system. The index "Ch" or "C" denotes, respectively, the case made of cast iron or steel, and "CM" shows the manufacture of non-ferrous metals. The letter "F" in the marking shows that the body is lined. All these parameters allow us to state that gate valves are ideal for various branches of modern industry. Some of them are even equipped with an electric drive, because manual control is impractical and unreliable.

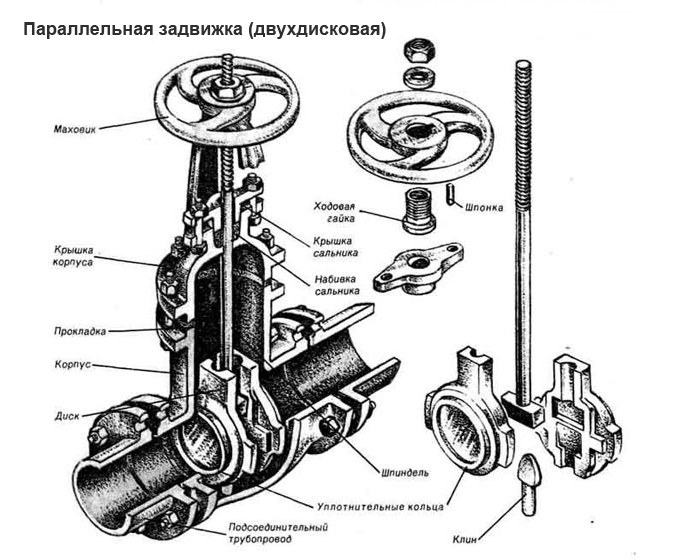

The cast iron gate valve, which is optimized for low pressure operation, is always flat. If medium pressure is to be tolerated, the shape is closer to an oval. But those devices that are designed for high loads are made in the form of a ball. It is also necessary to distinguish between parts according to the execution of the working unit, which may have a retractable or stationary spindle. All this applies to wedge gate valves, otherwise parallel-type systems are arranged.

The principle of their operation implies blocking the flow due to the sideways movement of successively fixed disks. They diverge because the wedge located in the gap goes down. The sealing rings both in the valve body and on the working disks are placed at an angle of 90 degrees to the apparatus axis. Parallel cast iron valves are designed for a nominal pressure of up to 10 bar, the design diameter can vary from 5 to 42 cm. It is necessary to choose valves equipped with an electric motor if remote control is needed (usually it is practiced when the device is mounted in a hard-to-reach place).

Not all electric actuators are equally efficient. Those equipped with a return spring react somewhat faster than usual to incoming signals. A parallel valve is better than a wedge valve because there is less risk of wedge sticking with infrequent use, and wear of the seal rings is also reduced. For your information, these negative points are less pronounced for wedges with a rubber sheath.

Other benefits of having it are:

- suitability for contact with liquids moving at speeds up to 4 m/s;

- reducing the effort to unlock and block the passage channel;

- increase in strength;

- increase in tightness;

- reduced torque and increased smoothness.

The hose format of the valve is so named because an elastic channel is placed inside (actually, a hose in some cases, a branch pipe in others). This channel may shrink or become less dense depending on the pressure exerted on it by the spindle. The elastic course made of rubber allows you to cover the metal elements of the valve from the transported liquids. The retractable spindle implies an external location.When the flywheel is spinning, the working part is screwed into it or goes out strictly to the size of the shutter. This solution is good because it facilitates the control of the health of the node and simplifies technical service.

In underground sewer passages, this advantage is not very significant, where spindles that do not move outward show themselves much better: they take up less space. At the same time, you have to put up with an increased intensity of wear. The running unit, sealed according to the stuffing box type, is considered the most reliable, the bellows one is somewhat worse, and the self-sealing one should be considered only as a last resort. It is recommended to use valves assembled by welding.

How to eliminate or prevent an unpleasant smell from the sewer, see the video below.

Types of ventilation

Properly arranged ventilation provides air circulation, while oxygen enters in sufficient quantities, and carbon monoxide and carbon dioxide are released into the atmosphere. After the end of the bath procedures, with good ventilation, the steam is actively removed outside the building, and the rooms in which there was previously high humidity dry out. If this aspect was not given sufficient attention, after a couple of years in the steam room, and then in other rooms, the lining rots, the smell of mustiness and sweat appears and gradually increases, and the wood turns into dust. Now, I hope, it is clear whether ventilation is needed in the bath ...

Heating and ventilation of the bath

Please note that the exhaust hole is located at a low height from the floor - usually not higher than 50 cm. With this scheme, exhaust steam is released into the atmosphere

Moreover, the floor in the steam room warms up well

Ventilation in the bath is not needed in only one case: if it is all built of wood and has not been insulated anywhere - neither inside nor outside. In this case, air exchange occurs due to the fact that the wood "breathes". Even in this case, they talk about the presence of natural ventilation in the bath: any wood has pores and cracks through which the outflow / inflow of air occurs, temperature and humidity are regulated. But if insulation or moisture / vapor insulation is arranged in a bathhouse made of rounded logs or timber, then the creation of additional ventilation holes is necessary.

There are three types of ventilation:

- mechanical ventilation. In this case, the inflow and outflow of air masses occurs due to artificially created air movement. Air parameters are controlled by technical means.

- Natural ventilation: circulation occurs due to the difference in pressure inside and outside the room. This method is possible only if there are "breathing" walls or thoughtfully arranged ventilation vents.

- Combined ventilation: the simultaneous use of the natural movement of air masses and technical devices (in the simplest case, fans).

The video below shows a variant of combined ventilation.

In a specific case, 100 micron aluminum foil was used in the construction of the ventilation duct.

Installation of door latches

For self-installation of a door valve, you will need the following tools and materials:

- screwdrivers or screwdriver;

-

electric drill;

- construction roulette;

- pencil;

-

hydraulic level.

Installation of overhead deadbolt

Installation includes several steps:

- Markup. On the door leaf, the optimal place for the location of the mechanism is selected. As a rule, the valve is placed at a height of 80–100 cm from the floor. With the help of a level, a horizontal line is drawn, along which the heck body is subsequently attached.

- Fixing the latch to the canvas. To do this, use wood screws (with a wide thread pitch). With a screwdriver or screwdriver, the case is attached to the surface of the door leaf.

-

Mounting the counterpart to the door frame. The seat must be exactly located in the axis of the valve.Skew will lead to jamming of the crossbar, which is unacceptable.

Installing a mortise latch

In the case of a mortise valve:

- The markup is carried out as in the first case.

-

A hole is drilled at the end of the door leaf. The diameter is selected based on the dimensions of the crossbar - it must move freely inside the channel.

- On the inner surface of the canvas, the location of the drive lamb is determined. A hole of the required size is drilled.

-

The latch body and the turntable are installed on the seat. On wooden doors, a piece of wood is selected from the end so that the body is in the same plane with the surface of the door.

- A hole is drilled in the frame along the crossbar diameter (with a gap of 1–1.5 mm). The depth is determined by the length of the protrusion of the bolt (plus 2–3 mm).

-

In the event that the door frame is made of wood, a striker is mounted on it. It is fixed with screws over the bolt hole. If the gap between the door leaf and the frame is small (less than 3 mm), the plank is recessed into the frame, deepening into the wood by a few millimeters.

Metal doors are equipped with both overhead and mortise latches. There may be several options. The overhead latch can be mounted on bolts previously welded to the door, or directly by welding. The latch is inserted in a manner similar to that described above for wooden doors.

A radio-controlled latch can block the door leaf in the most unexpected places for a burglar

Steam room ventilation schemes

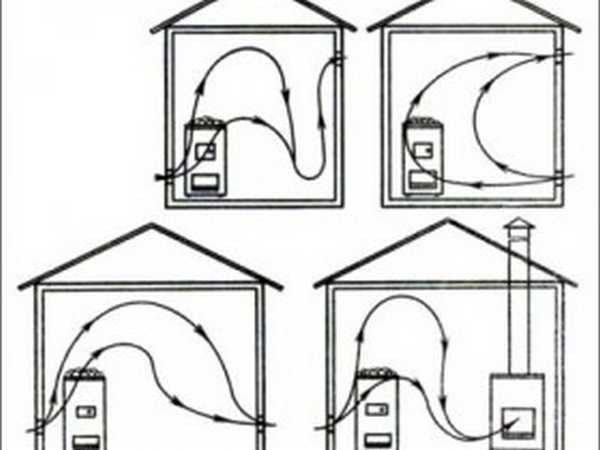

Consider some of the most common options for ventilation in the steam room:

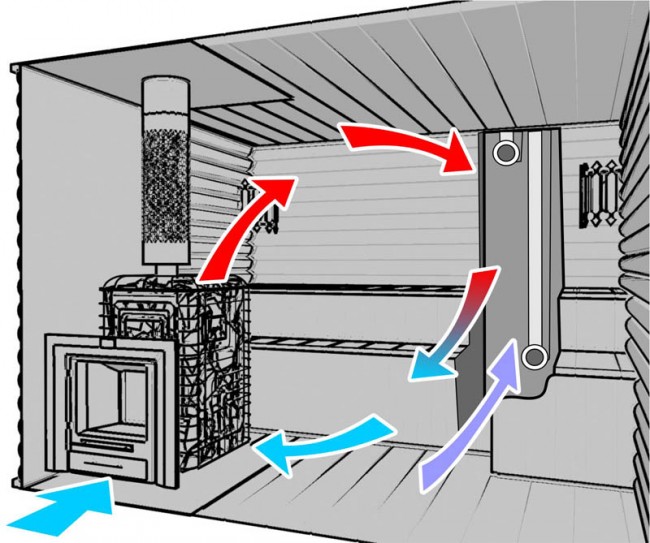

- This option can be considered a natural ventilation system. Ventilation vents are on opposite walls. Supply - at the bottom behind the heater, exhaust - at the top on the opposite wall. This option is not the most efficient: the air, passing near the furnace, heats up, rises and immediately exits through the exhaust vent. As a result, the movement of air masses is insufficient, oxygen saturation is weak, and drying of floors and walls after procedures is ineffective (it can be made more intensive by opening the door and a fan in the exhaust).

- A more efficient way to ventilate the steam room: the inlet is located below the stove, the exhaust is on the wall opposite, but not at the top, but at the bottom. In this case, the exhaust opening must be equipped with a fan. With this arrangement of vents in the steam room, cold air is heated from the stove, rises, cools there and falls down. It is removed due to the outgoing air flow created by the fan.

- Ventilation vents are located on one wall opposite the one where the stove is installed. This scheme is used in baths, in which only this wall faces the street. The air inlet is located at a level of 30 cm from the floor opposite the stove, the exhaust with a fan is 30 cm from the floor on the other side. In this case, cold air enters the steam room, hits the stove, heats up, rises, gradually cools down, goes down and is discharged through the exhaust hole.

- The exhaust superheated air is discharged through the furnace blower. With this method of organizing ventilation in the steam room, there is only one supply air vent near the stove. Such a scheme will only work when the stove is heated. There is another option using the blower of the furnace to remove the exhaust air: an inlet ventilation hole is made in the foundation, the furnace is positioned so that the blower is below the floor level.

Supply and exhaust ventilation schemes

These are the most commonly used ventilation schemes for steam rooms in the bath, there are many more variations and combinations. Based on these four options for organizing ventilation, you can develop a scheme for your steam room.

Brick and Turkish bath ventilation

When planning a ventilation system for a brick bath, it must be taken into account that its efficiency should be several times higher than that of a wooden one. Indeed, in this case, it will be necessary to dry not only the inner lining of the steam room / washing / locker room, but also the walls: brick is a very hygroscopic material. To remove all moisture, it is necessary that the inflow / outflow of air during drying be very active, and the vents should have reliable dampers that allow you to adjust the intensity of air movement.

When arranging the ventilation of a Turkish bath (“hammam”) with its 100% humidity, exhaust ventilation must also be very effective: it is necessary to provide six changes of air in the room per hour of operation. In addition, it is necessary to provide for the possibility of removing condensate, which forms during cooling in large quantities. There are two ways to solve this problem: install an air dryer in the pipe, which discharges condensate into the sewer system, or provide a channel for condensate drainage in the ventilation pipe (it also goes into the sewer).

Ventilation system opening parameters

The dimensions of the holes will depend on the parameters of each individual room:

- steam room;

- pre-bath;

- washing;

- recreation areas.

You must accurately calculate not only the parameters of these holes, but also the possibility of convenient access to them. The latter is necessary so that you can replace or repair them at any time. In order to be able to adjust the gaps in the ventilation openings, it is worth installing special gate valves and gratings on them.

It should also be immediately taken into account that with the huge dimensions of the ventilation holes it will be problematic to heat the room and bring the temperature regime to the desired level. And the more difficult it will be to maintain a constant temperature. As a result, you will get a huge waste of fuel materials and electricity. Or it will be difficult to regulate the cross section of the channels of the ventilation system. In other words, the distances that will have to be opened manually in each hole.

Important: the parameters of the window for ventilation are calculated based on such indicators - 24 cm2 x 1 m3 of the volume of the room that is ventilated. In order to ensure sufficient draft of fresh air mass from the outside, it is necessary to make the exhaust opening larger than the supply one.

If the area of openings for ventilation is not enough, then all indicators can rise to a dangerous level - temperature, carbon monoxide, humidity.

It is important to correctly calculate all the quantities

Valve selection

Gate valves for pipelines differ according to several criteria:

- area of use;

- control method;

- dimensions;

- fastening method.

For the correct selection of the device, a complete coincidence of all factors is necessary.

Where are valves used?

Gate valves are used:

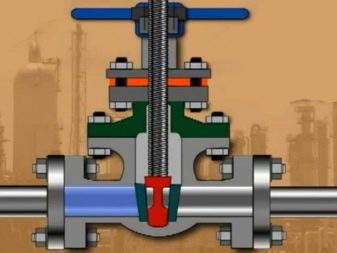

- in pipes that carry water. It can be both plumbing or heating systems, and sewer pipes. The plumbing valve consists of a disk that moves inside the body (picture above);

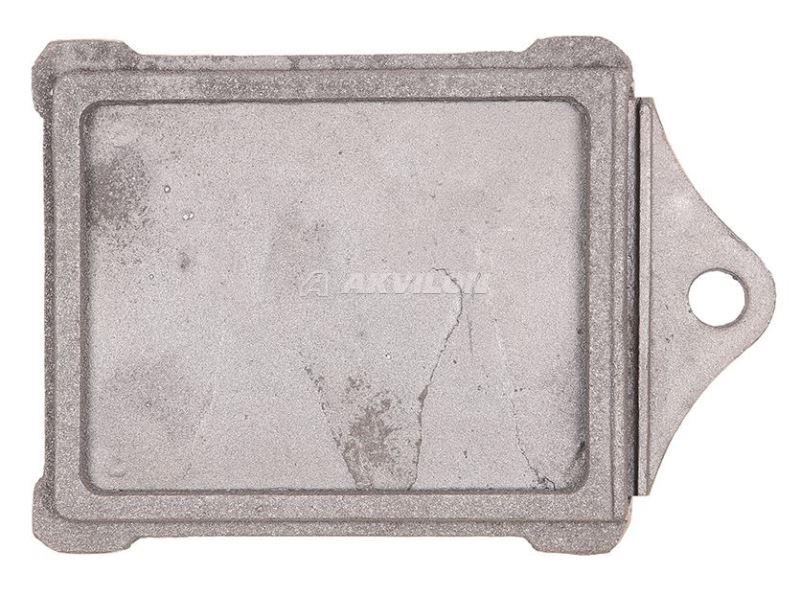

- in chimneys. The furnace valve is a metal plate that moves along the guide elements.

Chimney damper

Gate valves on a sewer or other pipe that conducts water can be:

wedge. The device is driven by the rotation of the flywheel, which moves the spindle with wedge-shaped locking discs. The tightness of the device is achieved by installing sealing gaskets on the disks that fully correspond to the shape of the locking element;

Internal device of the gate valve

parallel. The main distinguishing feature is the presence of two locking elements connected by a spring. When the water supply is shut off, the disks are tightly pressed against each other, not letting the passing flow through.

The device and principle of operation of a parallel valve

Parallel valves are more reliable, which allows the devices to be used in pipelines with an increased temperature of the passing fluid.

Valve control methods

Gate valves can be controlled:

- manually, by turning a handwheel or other control element. Such devices are mainly installed on stove, sewer and water pipes;

- with the help of automation. The predominant area of use of automatic valves is heating systems.

Sizing

In addition to the purpose, type and method of control of the valve, it is necessary to select according to the following factors:

- section shape;

- diameter.

Depending on the shape of the pipe, the valve can be:

- round section. Designed for standard pipes carrying fluid;

- square or rectangular section. Mostly gate valves in the chimney.

The diameter of the shut-off valves must fully correspond to the diameter of the pipes on which the device is to be installed. For example, a 110 pipe valve should be 110 mm in diameter.

Mounting methods

According to the method of fastening, the shut-off valves are divided into devices that are fixed:

threaded way;

Threaded gate valve

using connecting flanges;

Flanged gate valve

by welding.

Gate Valve Installing By Welding Method

Threaded gate valves are mainly installed on metal household pipelines. Flanged devices are placed on industrial pipelines, and fittings connected by welding are placed on pipelines made of PVC.

Design and principle of operation

All water supply valves consist of the following parts:

- Housing with a lid, inside which there are locking elements, the material of manufacture is stainless steel or cast iron.

- The locking unit (guide and lock) is integral with the body to ensure maximum reliability of the fixture and accuracy of movements, the material of manufacture is steel.

- The control assembly includes a valve, a handwheel and a threaded bushing that converts the rotating movements into directional movement of the valve inside the body.

- Yoke assembly, due to which the connection is placed outside the body, excluding its contact with the transported medium.

The control takes place by means of a mechanical rotation of the valve or by means of an electric drive.

The principle of operation of the entire mechanism lies in the verified actions of the constituent elements: the valve (flywheel) drives the stem through the threaded connection, and the shutter moves with it, which closes the internal cavity of the body. In order to open the passage, you just need to turn the valve in the opposite direction.

Locking devices in most cases cannot be repaired, therefore it is extremely important to use them exclusively for their intended purpose, until the pipe is completely blocked and the flow of fluid stops

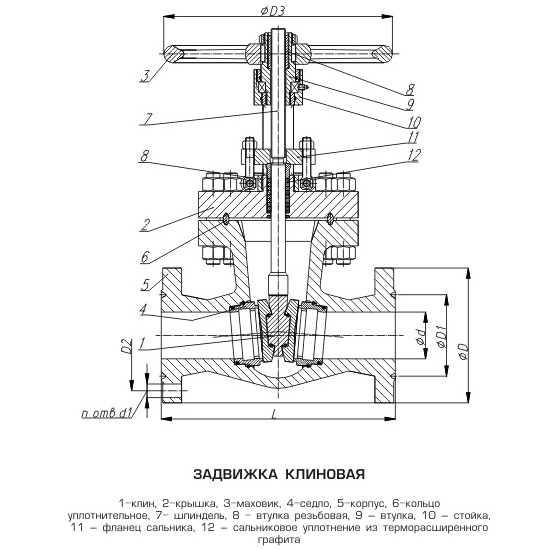

Varieties and their device

Wedge type fittings are made of cast iron. It is distinguished by its simplicity of device and operation: it is quite easy to block the flow of liquid. The wedge device works great even if the flow is moving fast. An example of such a device is the modification 30ch6br.

The quality of the design is such that it can be used not only in sewers, but also in:

- water pipes;

- steam pipelines;

- oil pipelines;

- gas pipelines.

Cast iron is chemically neutral in relation to the contents of the sewer. In addition to the simple cast-iron part, there are also rubber-coated products. Both versions fully comply with GOST standards, which allows you not to be afraid of a pipeline malfunction. The wedge gate valve has the advantage that its maintenance takes place without particularly complex operations.The locking block moves forward or backward at right angles to the fluid flow and blocks its movement or opens the way.

When mounting cast iron or other valves, it is required to check:

- their compliance with the technical parameters of the pressure in the pipe;

- installation of a filter (it will clean the working environment);

- whether the system is under pressure.

Types and classification of water valves

Locking mechanisms differ in the material of manufacture (steel, cast iron), the method of overlapping (with a retractable and non-retractable spindle), but the valves themselves are classified according to the type of locking element:

- Wedge - the mechanism is triggered by the entry of a moving element between the saddles located at an angle, as a result of which a rigid wedge is formed (most reliable, but most prone to jamming due to rust formation), a wedge with two disks (sufficient tightness is ensured, but due to the complexity of manufacturing increases price) or an elastic wedge (ensuring tightness with the simplest design).

- Parallel valves differ from wedge valves in the arrangement of seats - in this case, they lie parallel to each other, despite the simplicity of the design, a reliable overlap of the system is ensured.

- Hose valves lock the system by pinching the elastic hose in the element body.

- Gate valves are the most unreliable and are most often used in sewer systems, the design is one gate that replaces two seats, and a moving element.

- The Ludlo gate valve has been made exclusively from cast iron for over 150 years and consists of a parallel double disc device with a wedge.

More about 30ch6br

Cast iron structures are also distinguished by low hydraulic resistance. It is this circumstance that allows liquids to move as freely as possible. But it should be noted that it will not work to open or close the pipe in a short time. The cast iron gate valve is made in the form of a wedge with two discs and a retractable spindle. The reinforcing body is equipped with a cover holding the paronite gasket.

The spindle is delimited from the cover with a stuffed gland. This solution allows the unit to be sealed.

The locking block is formed:

- brass rings;

- expanding axis;

- compensating pads.

The entire product line can be installed in horizontal, vertical or inclined pipelines. There are only two basic positions: open and closed. Flow control is not possible. Parallel valve DN 50 can operate at a pressure of not more than 1 MPa. Similar properties make it possible to use 30ch6br even in very complex sewer systems. In production, the equipment is subjected to both hydraulic tests and checks for action in the air.

Why do you need ventilation in the bath

Ventilation in the bath

Ventilation in the bath is a system of ventilation holes through which fresh air enters the steam room and slowly leaves it outside. If you do not create ventilation holes in the bath, after a few years, the wood paneling of the steam room will begin to become moldy, and the boards themselves will emit an unpleasant odor (the smell of rotten wood and sweat).

To prevent all this from happening, it is necessary during the construction of the bath to pay enough attention to the ventilation scheme of the bath, which will allow you to remove stagnant air from the steam room, refreshing the room with oxygen.

Making a damper with your own hands

A damper of any kind can be made independently, but only from steel. Cast iron gate valves are made by forging.

The manufacture of a sliding valve is done in the following way:

- frames are cut out of two steel sheets, the internal dimensions of which are similar to the parameters of the chimney section;

You can also use steel wire or an angle profile to make the frame.

- the damper itself is cut out, in size 3 - 5 mm smaller than the frame;

The main components of the slide gate

- structure is welded.

The manufacture of a rotary valve is as follows:

- a circle with a diameter corresponding to the overall dimensions of the chimney is cut out of sheet steel;

damper manufacturing

- the axis of rotation is being prepared. For this element, it is recommended to use a small diameter pipe with an internal thread. The length of the workpiece must be 6 mm greater than the diameter of the damper;

- the axle is welded to the damper.

Adjusting the axis of rotation of the damper

The cost of finished dampers is not high, so it is recommended to engage in self-manufacturing only in exceptional cases.

Valve selection

The valve on the chimney pipe is selected depending on the following parameters:

- device type;

- material of manufacture;

- sizes.

Let's consider each of them in more detail.

Types of valves. Their advantages and disadvantages

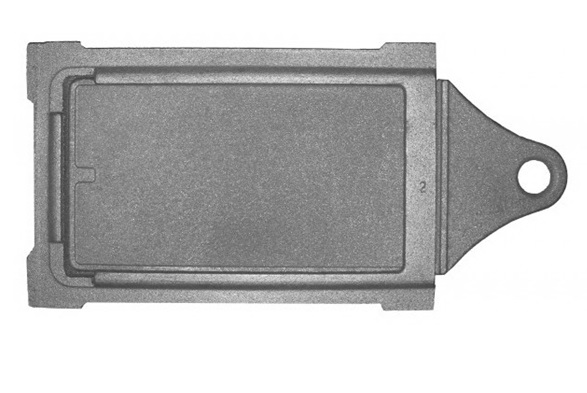

Depending on the design features, there are:

- retractable dampers (figure above), which are a piece of pipe with a moving plate. This type of gate is easy to install, low cost and the possibility of self-manufacturing;

- rotary (throttle) dampers. The smoke channel is opened by rotating the plate located on the guide in the center of the pipe cut. A rotary valve is less reliable than a retractable gate valve, but can be installed not only on the chimney, but also on flue pipes, for example, from a fireplace.

Butterfly valve for chimney

As a rule, retractable structures are installed on brick chimneys, and rotary structures on steel chimney pipes.

Choice of damper material and dimensions

In addition to the type of furnace valve, it is important to take into account such parameters as the material of manufacture and the dimensions of the device. The damper for the chimney can be made:

The damper for the chimney can be made:

from cast iron. This type of material is the most common in brick chimneys, as it has a high margin of safety and durability, and it is not affected by the negative effects of moisture, soot and other deposits. The only significant drawback is the large weight of the structure, which complicates the process of installing the device;

Gate made of cast iron

stainless steel. The lightest, but no less durable material with proper processing. Steel is easy to clean, not exposed to corrosion and high temperatures. As a rule, butterfly valves for steel chimneys are made of steel.

The dimensions of the gate are selected depending on the internal section of the pipe. The density of the chimney overlap can only be achieved if the specified parameters are fully met.