Putty is a material intended for the final alignment of walls and ceilings. The quality of the resulting surface equally depends on the experience of the master and on the characteristics of the material. To find out which putty is best for the ceiling, you need to take into account its condition and decide on the final result. There is no one “correct” putty mixture for the ceiling; the type of material is selected in accordance with specific conditions.

What should be putty for the ceiling?

The choice of putty for the ceiling must be taken with all responsibility, because the ceiling is an open space and all defects in the finish are immediately evident. Puttying shelves is more difficult than walls, but the right material will help make the job easier.

Requirements for putty mixture for the ceiling:

- homogeneity of the structure, the absence of individual large particles;

- not too high curing speed, allowing time to level the surface;

- softness and elasticity, providing ease of application;

- lack of tendency to cracking and shedding after solidification;

- strength and long service life.

Types of putty

Different putty mixtures differ from each other in their composition, purpose, operating conditions, fraction size.

Composition

Depending on the main component used in the manufacture of putty mixtures, gypsum, cement and acrylic putties are distinguished.

- Gypsum putty does a good job of filling cracks. It is suitable only for dry rooms, but it can be used to prepare the ceiling in the room for applying a smooth thin layer coating.

- Cement putty is suitable for the ceiling in the bathroom or in the toilet, because it is designed for wet rooms. It evens out large depressions well, but is difficult to sand, so it can be used as an intermediate layer before applying a textured decorative material.

- Polymer putty allows you to achieve a perfectly smooth surface, so experts recommend it for the final leveling of the ceiling. Since this type of material is applied in a very thin layer, it requires preliminary leveling of the ceiling with starting putty mixture. The advantage of the polymer composition is the low setting speed, which allows even an inexperienced home craftsman to work with it.

By appointment

Depending on the stage of work at which the putty mixture is used, it can be starting, finishing or universal.

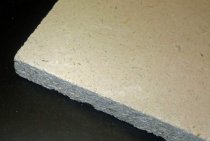

- Starting putty mixtures are used to pre-level the ceiling, which has significant irregularities (more than 0.5 cm). Can be cement or gypsum based. For good adhesion to the ceiling, the starting mixture should have larger fractions - up to 0.6 mm.

- Finishing putty mixtures have a fine-grained structure (fraction size - up to 0.3 mm) and a softer consistency, are easier to apply and lend themselves well to grinding. They well eliminate minor defects and fix the first layer.

- Universal putty mixtures combine the properties of starting and finishing compositions, or rather, they are somewhere in the middle between them. Apply to the surface without major flaws.

Dry and ready mixes

Putty is available in the form of a dry powder or a paste-like mixture, ready to use. The advantages of a dry putty mixture are a lower price and undemanding to the temperature regime during storage. For solution preparation dry material is poured into a container with water and stirred with a construction mixer.It is very important to strictly observe the proportions recommended by the manufacturer.

Ready-made putty is more expensive than a dry mix, but its price is justified by its excellent characteristics. It has high plasticity, slowly seizes, so it is well suited for beginners. The finished mixture is made on an acrylic or vinyl basis using extra fine fractions (less than 0.1 mm).

Attention! Ready putty mixtures do not tolerate transportation and storage at low temperatures.

Final goal

The choice of putty depends on the type of final coating under which the ceiling is leveled.

- Applying a putty mixture for painting is considered the most difficult option, since it requires obtaining an ideal surface. Under a layer of paint, any flaws will be clearly visible, so the material for leveling the ceiling must be of the highest quality. It is best to choose a finishing putty from a well-known manufacturer. The main requirements are softness and plasticity.

- Putty for wallpaper does not require a professional level of skill and is less demanding on the material. In this case, the main thing is to eliminate large irregularities; it is not necessary to achieve maximum smoothness.

- When preparing the ceiling decorative plaster, as well as under wallpaper, it is not necessary to achieve mirror smoothness, it is enough to make the surface as even as possible. Strong compositions based on cement or gypsum, starting and universal, are suitable.

Additional components

The quality and properties of the ceiling putty will also depend on the various additives present in the mixture in addition to the main binders. Therefore, before choosing a putty, carefully study the composition. Additives that improve the properties of the material include:

- plasticizers - provide plasticity and pliability of putty during work;

- mixture hardening and setting regulators;

- pigments - give the material a certain shade;

- oligomers provide moisture resistance, strength and high drying rate;

- water repellents - allow the use of the material in rooms with constant high humidity.

Proven putty brands

In stores you will find a huge number of putties of different brands. If you want to be sure of quality when buying a material, then it is better to choose products from well-known manufacturers who value their reputation. The price of such mixtures is higher, but they have a higher covering ability and are several times more durable than cheap counterparts.

Masters recommend time-tested putties from Knauf, Henkel (Ceresit trademark) and Weber-Vetonit. Brands such as PUFAS, Bolars, Volma and Osnovit have proven themselves well. Usually, the price of a putty mixture is directly proportional to its strength and durability, so saving when buying this material is not justified.