GVL is a gypsum-fiber sheet, which, like drywall, is used for interior decoration. These materials have a similar composition, but different properties and applications. In some cases they are interchangeable, and in others they successfully complement each other. Gypsum fiber has not become as widespread as GKL, but in terms of its individual characteristics it significantly surpasses it, so some craftsmen abandon the usual drywall in favor of Knauf GVL.

Specifications

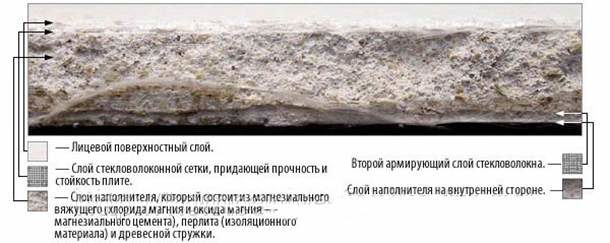

GVL: what is it and how does it differ from GKL? Gypsum fiber sheet got its name from the two materials from which it is produced - gypsum and cellulose fibers. As a result of pressing this mixture, a high-strength building material is obtained.

Characteristics of the GVL sheet:

- Strength, viscosity and density (withstands force up to 100 kg per 1 sq. cm).

- Excellent thermal insulation properties due to low thermal conductivity.

- Good soundproofing qualities, directly dependent on the thickness of the sheet.

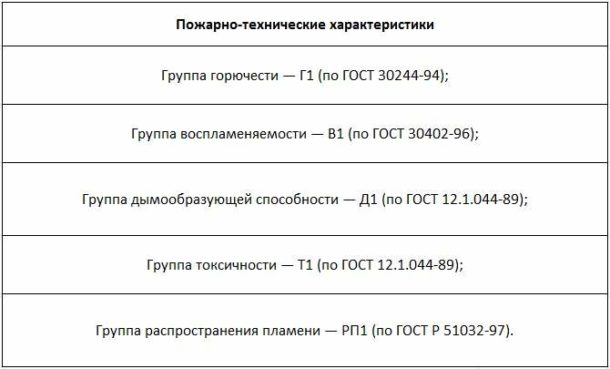

- Fire resistance. The material cannot ignite on its own and does not spread the flame, therefore, in accordance with GOST, it is often used for finishing industrial premises and for fire protection of structures.

- Frost resistance. Due to this quality, it can be used to finish an unheated loggia.

- Environmental friendliness. The material does not emit harmful substances, perfect for residential premises.

- Moisture resistant GVL sheet successfully used in the kitchen and bathrooms.

With high humidity in the room, gypsum fiber absorbs its excess, with a lack of moisture in the air, it can release it.

Several disadvantages of gypsum fiber sheets:

- The main disadvantage of the material is its weight. Compared to drywall, it is heavy. GVL 10 and 12.5 mm thick weigh 36 and 45 kg, respectively.

- Gypsum fiber cannot be bent, it cannot withstand such deformations.

- The material costs 2 times more than drywall.

Gypsum fiber sheets are produced by many foreign manufacturers, but Knauf products are the most common on the Russian market. It has two types of sizes corresponding to GOST:

- Standard sheet - 2.5 × 1.2 m, thickness 10 or 12.5 mm.

- Small-format sheet - 1.5 × 1 m, the thickness is the same.

Sheet sizes are selected based on the purpose for which they will be used.

In addition to ordinary sheets, Knauf produces elements for the Knauf-superpol dry floor screed, which have a size of 1.2 × 1.2 m and a thickness of 2 cm. They are plates obtained by gluing two GVLV sheets with an offset, for due to which folds 5 cm wide are formed from two adjacent sides of each element.

Technical characteristics of gypsum fiber sheets and production technology must comply with the requirements of GOST R 51829-2001. When buying material, you need to make sure that it is not a fake: it must have a certificate of conformity, each sheet must have a marking indicating the size, type of edge, GOST.

Difference from drywall

GVL has many advantages over drywall:

- Much more durable. Does not deform under the weight of a person standing on heels, in difference from GKL. Drywall can be broken by hand, with a gypsum fiber sheet this will not work.

- Does not crumble when cut like drywall.

- Moisture-resistant GVL resists moisture much better than GKL with similar properties.

- The noise and heat insulation properties of the GVL slab are higher than that of drywall, even without the use of additional materials.

- GVL painlessly tolerates 15 freezing cycles, GKL can begin to crack after 4 cycles.

- The fire resistance of gypsum fiber is also much higher than that of drywall.

The GVL slab has a more complex production technology than the GKL. Therefore, its price is much higher. But the high cost is justified by excellent performance.

wall application

GVL is used for walls in order to level the surface, sound and heat insulation. This material is mounted in two ways.

Frameless way

GVL is attached to the walls with special glue. Fixing Methods:

- With small surface flaws, gypsum glue is applied to the sheets and pressed against the wall.

- For large irregularities, special glue is applied to the sheets around the perimeter and in the center with dots every 30 cm. If shelves and cabinets are then hung on the GVL, then the entire surface is smeared with glue so that it can withstand the heavy weight of hinged structures.

- If the irregularities of the wall are more than 4 cm, then narrow strips of GVL are glued to it at a distance of 50–70 from each other, and a solid sheet is glued to them.

Before gluing the GVL sheet, the material is kept in the room for 2-3 days so that it adapts to the humidity and temperature in the room.

You can see the detailed gluing technology in the photo.

The size of the GVL is chosen based on the size of the room. Holes are cut in the plates for sockets and wiring.

Frame method

For this method, a metal frame is first assembled from durable galvanized profiles that can withstand a lot of weight. In this case, you can use glass wool or other material for insulation and soundproofing. GVL is attached to the profile with special self-tapping screws with a two-row thread. Stages of work:

- Surface preparation.

- Marking the wall with a level.

- Profile mounting.

- Sheet fastening.

The photo shows that it is necessary to start the installation of GVL from the corner of the room, from the bottom up. After installation is completed, all joints are covered with putty.

The GVL partition will turn out to be strong and solid. The technology of its manufacture is the same as for the partition of the plasterboard.

floor application

After installing the GVL on the walls, you can proceed to finish the floor.

Stages of work:

- The floor level is marked.

- A vapor barrier is being installed.

- A foam rubber edge tape is glued along the walls.

- Expanded clay backfill is laid on the prepared base, leveled.

- A rough floor is assembled from gypsum-fiber elements, the seams are smeared with glue, the elements are fastened with self-tapping screws through the folds.

- The joints are putty.

- After that, finishing material can be laid on the GVL - tiles or linoleum.

The manufacturer recommends, in the case of using a thin elastic coating, pour a leveling mixture over the gypsum-fiber coating with a layer of 2 mm or more.

A complex curved design design cannot be made from a gypsum-fiber sheet. But you can be sure that it will not break during installation and during operation.

Now you know what GVL is and how to mount it. Reviews of the masters say that this is a reliable material for wall decoration in apartments. GOST assumes the absence of toxic substances harmful to humans, so you don’t have to worry about your health. The only significant drawback is the heavy weight.