Main characteristics of circulation pumps

The main characteristics by which the choice of the circulation pump is made:

-

pressure

, showing the ability of the device to raise water to a certain height; -

performance and consumption

, showing how much fluid the supercharger delivers per unit of time.

These parameters are key in the calculation of the heating system. The head will allow you to understand whether the supercharger is able to serve the pipeline network with a certain height difference. And the flow rate is calculated according to the requirements of the heating boiler for the planned volume of coolant.

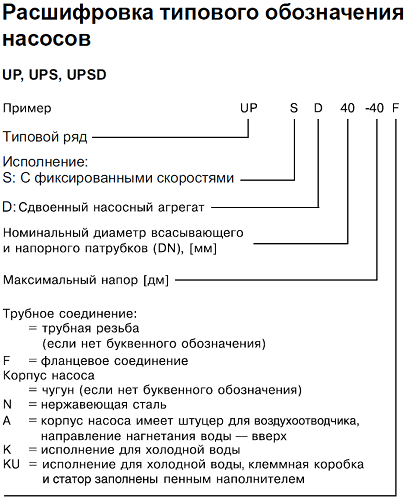

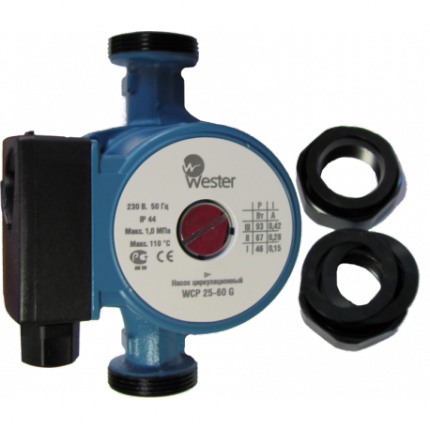

All data required by the user is contained markings on the front

. The numbers on the circulation pump mean:

- type of device (most often it is UP - circulation);

- type of speed control (not specified - single-speed, S - step switching, E - smooth frequency control);

- nozzle diameter (indicated in millimeters, means the internal dimension of the pipe);

- head in decimeters or meters (may vary from manufacturer to manufacturer);

- mounting dimension.

The marking of the pump contains information about the types of connections of the inlet and outlet pipes. The complete coding scheme and word order looks like this:

Responsible manufacturers always follow standard labeling rules. However, individual companies may not indicate some of the data, for example, the installation dimension. You need to learn it directly from the documentation for the device.

The choice of a circulation pump is always made after a careful calculation, which takes into account the type of heating equipment, the volume of the coolant, elevation changes, and the minimum required blower performance.

Advice! You can not buy products of unknown companies that copy the products of reliable and popular brands. Such a pump is an inefficient investment. The use of low-quality materials, impellers, turbines with a limited motor resource leads to a quick breakdown of the supercharger. On specialized forums, you can find many scary stories in photographs about what kind of technological nihilism the cases of Chinese “no-name” products contain.

Therefore, it is worth choosing a pump only from trusted brands.

. Reliable devices are also presented in the middle price category

And if you need the highest quality and there is an opportunity to pay one and a half to two times more - you should pay attention to the products of the brands GRUNDOFS, WILO

Pump installation steps and nuances during installation

The first thing to do is to drain all the liquid from the heating system. Then, if necessary, you need to clean the pipeline. In accordance with the connection diagram, work must be carried out to install equipment and fittings. When the installation of the heating system is completed, water is poured. then remove excess air from the pump. This is done by opening the central screw

Please note that before each turning on the unit, it is necessary to carry out work to remove air.

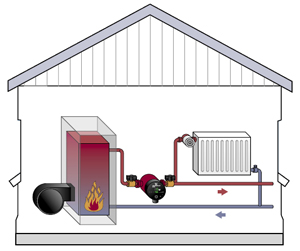

When a circulation pump for heating is purchased, it is necessary to determine the place where it will be installed. Experts recommend installing this equipment on the return line in front of the boiler. The thing is that air can collect at the top of the boiler during operation if the pump is installed on the supply. This can cause him to pull it out of the boiler, which will create a vacuum, causing that part of the boiler to boil.

If the pump is installed in front of the boiler, then water will be pushed into the heating installation. The consequence of this will be the appearance of air space, and the installation will be completely filled.In addition, with this installation option, the pump will operate at lower temperatures, which will positively affect its service life.

Having chosen the site for the installation of pumping equipment, then create a bypass or outlet. The need for it is due to the fact that in the event of a breakdown or when the electricity is turned off, thanks to it, the operation of the entire heating system will not stop and it will be possible for the coolant to pass through the main pipeline thanks to an open tap. When installing a bypass, it must be remembered that the diameter of the pipe must be smaller than the diameter of the main pipeline. When the bypass is ready, they proceed to the main stage of work on installing the unit.

The shaft of the pump for heating must be completely in the water. If it is only partially immersed in the coolant, this will lead to a decrease in equipment productivity by 30%. In the worst case, the work area will become faulty.

In addition, the installation also provides for the installation of a terminal box with a top location.

In addition, ball valves are installed on both sides of the pump. During the operation of the equipment, they will be required to carry out maintenance of the pump and its dismantling, if necessary.

The system must also include a filter. It will protect the unit from mechanical particles. Once inside its structure, they can adversely affect the operation of the pump.

A manual or automatic valve must be mounted on top of the bypass piping. It is necessary to release air congestion at regular intervals.

Purpose of circulation pumps

The principle of operation of a standard closed-type heating system is quite simple. The boiler heats the water that passes through the radiators, giving off the accumulated heat

In the case of natural circulation, it is very important to be accurate in the design, maintaining a certain angle of inclination of the pipeline. However, due to the low speed of the coolant, it cools down quickly, and cold liquid returns to the boiler, forcing it to constantly work at full load.

To eliminate this disadvantage, different types of circulation pumps are used. Their purpose is to create a coolant pressure necessary to ensure uniform distribution of heat between all elements of the system. First of all, it helps to reduce the requirements for compliance with slopes and cross-section of the pipeline. At the same time, the difference in the temperature of the liquid at the outlet and inlet of the boiler is only a few degrees, which significantly reduces the load on the heating equipment and reduces energy costs.

Design of pumps for heating systems

Depending on the design, all pumping units of heating systems are divided into two types:

- dry circulation pumps;

- wet rotor pumps.

Both types of devices are quite effective in heating pipelines and have both advantages and disadvantages.

Dry type pumps

In such units, the rotor does not come into contact with the working fluid, since all elements of the electric motor are separated from the working chamber of the device by a sealing system of a special type. It consists of polished, carefully fitted metal rings. To eliminate friction, a thin film of liquid is constantly present between the sealing elements, which acts as a lubricant. It is she who prevents damage to the seal rings.

Depending on the location of individual structural elements, dry pumps of heating systems can be divided into three types:

- console type pumps;

- vertical centrifugal pumps;

- block pumps.

The suction pipe of cantilever circulation pumps is located on the outer edge of the volute, while the discharge part is moved to the opposite side. A feature of the units of the second type is the location of the electric motor in a vertical plane, which can significantly increase the performance of the devices.

Dry rotor pumps have numerous advantages:

- long service life;

- high performance;

- Efficiency is close to 80%;

- the ability to work with a coolant leak;

- high maintainability;

- relatively low cost;

- reliability;

- Possibility of mounting in any position.

At the same time, the increased noise level of units of this type does not allow them to be installed in residential premises. The disadvantages also include the requirements for the cleanliness of the coolant and the need for periodic maintenance and lubrication of the movable seal.

Glandless circulation pumps

The rotor and impeller of this type of pumps are in the pumped coolant, which does an excellent job not only with its main function, but also with cooling the parts of the electric motor. The pump motor stator is separated from the rotor by a hermetic cup made of non-magnetic steel or carbon fiber. Wet-type units are designed to operate in systems with a stable, rarely changing fluid flow. The presence of a control unit allows you to vary the number of connected windings, and accordingly, change the pump performance. The choice of the optimal operating mode has a positive effect on the efficiency of the unit.

The advantages of "wet" type units include:

- low noise level;

- no need for lubrication;

- efficient cooling method;

- ease of maintenance and installation;

- relatively low price of the unit and spare parts;

- long service life.

Pumps with a wet rotor are not without disadvantages in the form of low efficiency (a little more than 30%), the inability of the unit to work without a coolant, and the requirements for the horizontal orientation of the rotor shaft during operation.

Design features by connection method

In the pipelines of municipal and industrial highways, circulating pumps with a dry rotor are most often used, as more productive and powerful devices. Their connection is carried out mainly by flange connection, and both a common support frame and a specially equipped foundation can be used for installation. At the same time, manufacturers also produce devices designed for embedding in autonomous heating systems. As a rule, they all have increased power and performance, and their installation does not require special fastening.

Coupling connections of circulation pumps are typical for low-power wet-type units with direct-flow movement of the coolant, which can be built directly into the pipeline. Such devices are represented by a wide range of household centrifugal pumps, while powerful industrial units with a flanged connection require additional fastening of the pipeline using a console and foundation.

Overview of popular models

It is impossible to give a clear name of the model of the best among superchargers without a clear segmentation according to their operating conditions. Therefore, the rating of circulation pumps for heating represents the competition of brands and the key features of the equipment they offer.

1 Grundfos UPS

One of the most popular and high quality

types of pumps.The company with roots in Denmark has ensured maximum reliability using stainless sleeves, ceramic bearings, turbine wheels made of composite materials. Glandless pumps are distinguished by the following features:

- low power consumption, from 45 to 220 W;

- very low noise level (up to 43 dB) and vibrations - to understand that the pump is working, you can only put your hand on it;

- wide temperature range from 2 (-20 for some models) to 110 degrees Celsius;

- simple installation;

- unpretentiousness, lack of service;

- durability, the service life is at least 10 years.

Grundfos UPS pumps are very compact and lightweight. Their disadvantages include high price

up to 2 times higher than competitors. However, the popularity of products of this brand suggests that their characteristics justify the price tag.

Pump Grundfos UPS 25/40

Products of this brand are considered the most reliable. Only proven and simple solutions are used in their design and electronic circuits. The pumps are characterized by:

- economy;

- simple power adjustment;

- reliability, durability - cast-iron body, turbine wheel made of polypropylene, metal graphite bearings, stainless shafts;

- operating temperature from -10 to 110 degrees Celsius;

- protection against surges and surges;

- ease of installation.

Wilo Star-RS pumps are compact, lightweight, maintenance-free

. Their price is also higher than competitors, but lower than that of the leader of the rating. Users note that at the highest speed, the pump starts to make noise over time.

Pump Wilo STAR-RS25/4-130

The Compass Series is a smart choice, a solid mid-ranger with attractive features and value. Pumps are distinguished by:

- profitability;

- simple speed switching circuit;

- small dimensions;

- sufficiently low noise level up to 65 dB;

- rich equipment and easy installation;

- fault tolerance due to the lack of complex technical solutions and the use of reliable materials;

- low price.

The manufacturing company has an extensive service network, however, users note that the pumps of the Gileks "Compass" series break very rarely.

Pump Gileks "Compass" 25/60

4. DAB VA

A series of pumps from an Italian manufacturer is optimal balance of performance and price.

They are not able to offer record performance, but they are reliable and adapted to the realities of domestic power grids. Devices are characterized by:

- three-stage speed control;

- easy installation using quick coupling;

- two types of mounting dimensions of 130 and 180 mm;

- noise level up to 70 dB;

- affordable cost.

Circulation pump DAB VB 55/120

How to choose a heating circulation pump

In order not to spend extra money and purchase a good pump, it is necessary to calculate the power of the equipment. which will be enough for your home. When performing them, the following parameters are important:

- pipe diameter;

- coolant temperature;

- coolant pressure level;

- boiler performance;

- throughput.

You also need to know about the number of liters of water that can pass through the heating system in one minute. You should also calculate the amount of water that is necessary for the operation of the radiator and the rings of the heating system in normal mode.

The length of the pipeline is also an important factor on which the power of the circulation pump depends. Typically, 10 meters of pipeline requires half a meter of pumping head.

To calculate the flow rate of the coolant, it is necessary to equate its parameters to the boiler power. For example, if the power of the installation is 25 kW, then in this case the coolant flow will be at the level of 25 liters per minute. If the heating system has a battery capacity of 15 kW, then 15 liters of water per minute will be required for their normal operation. With a decrease in the diameter of the pipeline, the resistance that occurs when the coolant moves increases.

Calculation of the flow rate of the circulation pump for heating

Any circulation pumping equipment has a number of indicators by which the performance of the installation is determined. The main parameter is the pressure flow. It is reflected by the equipment manufacturer in the technical data sheet.

When calculating the flow rate of the heating pump, use the following formula:

where N is the power of the boiler;

t1,t2 - temperature leaving the heat source and located in the return pipeline.

In a similar way, the head of the heating pump is calculated. Based on European standards, then 100 watts of equipment power is needed per 1 square meter of a private building.

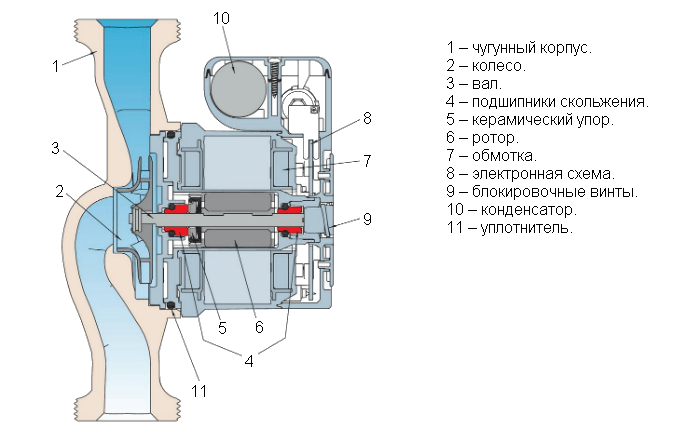

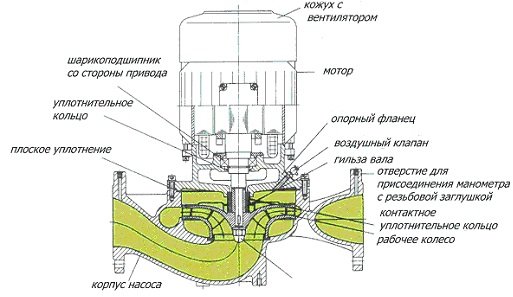

Design features of wet rotor pumps

Models with a "wet" rotor are distinguished by a low level of generated noise. They are of interest from the point of view of domestic use. They are widely used in the arrangement of autonomous heating systems in private buildings or in small administrative, industrial premises. The pump rotor is directly in the liquid.

They are attractive because they are easy to repair at home. But in order to eliminate the malfunction, it is necessary to know the features of the design. Therefore, let us consider in more detail how the circulation pump with a “wet” rotor is arranged.

For the manufacture of the body of models for heating, as a rule, cast iron is used, although products are produced in which the body is made of stainless steel (non-ferrous metals, aluminum, bronze, brass). They are used for hot water and cold water systems. The rotor is placed in a special glass and is rigidly connected to the impeller (impeller).

This achieves its isolation from the stator. The peculiarity of the technology is that the shaft can be either metal or ceramic. It is fixed in plain bearings (graphite or ceramic). The volute, on which the inlet and outlet pipes are located, is attached to the body using bolts, which are unscrewed with a special key (hexagon) supplied with the product.

On the front (end) part of the pump there is a plug, unscrewing which, you can bleed excess air. Although it is also provided for its automatic removal during operation. For this, an air vent is located in the upper part. There is a box for electrical connection with an operating mode regulator.

When the plug is completely turned out, access to the shaft opens, on the end part of which there is a slot for a screwdriver. Thus, it is possible to manually scroll if the pump does not start after a long "idle" (for example, due to salt deposits). Perhaps the only drawback of such pumps is their low efficiency. If for "dry" models it is within 70 - 80%, then for "wet" models it does not exceed 55%.

But at the same time, such a circulation pump scheme has a number of undeniable advantages:

- the liquid that it pumps at the same time cools and lubricates the parts;

- products at start-up automatically remove the air that has got inside;

- pumps are assembled according to the modular principle. Therefore, when repairing, it is enough to replace the faulty part;

- due to low power, they consume little electricity;

- switching of operating modes is provided, which allows you to choose the most optimal;

- the ability to automatically control the process of starting and stopping when using a temperature sensor, which also reduces energy consumption;

- absolute noiselessness in work;

- does not require maintenance.

The latest models of "wet" pumps are available shaftless. The impeller (it is also the rotor) rotates on ceramic bearings under the influence of the electromagnetic field created by the stator winding. This greatly simplified the design (there are no shaft and seals) and increased reliability and durability. Even the ingress of small fractions along with the liquid will not affect the operation of the pump.

How to choose a circulation pump

Each circulation pump has a set of technical characteristics. They are selected for the parameters of each system individually.

We select technical characteristics

Let's start with the selection of technical characteristics. There are a lot of formulas for professional calculation, but to select a pump for the heating system of a private house or apartment, you can get by with averaged norms:

Choosing a circulation pump for heating following these rules is easy. Calculations are elementary. But I must say that these figures are average. If your house at some point is very different from the "average", you need to make adjustments either upward or downward technical characteristics. For example, you have well insulated the house, the capacity of the previously purchased boiler turned out to be excessive. In this case, it makes sense to take a pump with a lower capacity. In the opposite situation - it is chilly in the house in extreme cold - you can put a more productive circulator. It will temporarily solve the problem (in the future it is necessary either to insulate or change the boiler).

Model selection

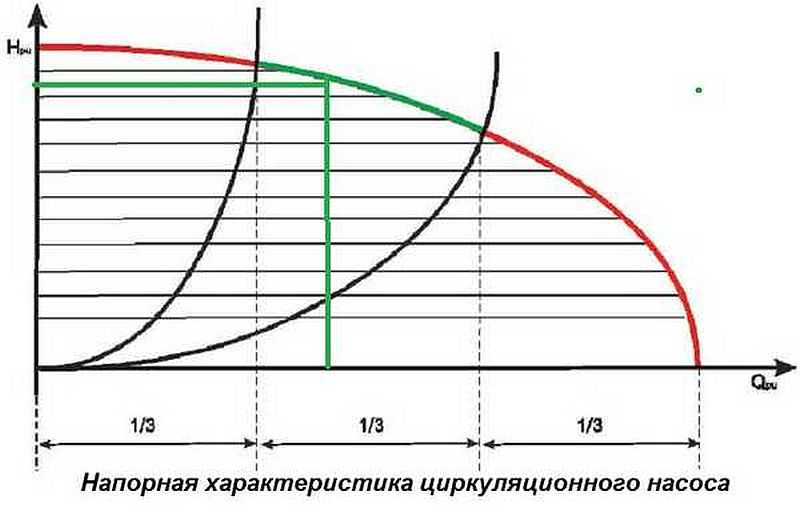

When choosing a specific model, pay attention to the graph with the pressure characteristic of the pump. On the graph, you need to find the point at which the values \u200b\u200bof pressure and productivity intersect

It should be in the middle third of the curve. If it does not fall on one of the curves (usually there are several of them, characterizing different models), they take the model whose graph is closer. If the point is in the middle, take the less productive one (the one located below).

What else to pay attention to

In the technical characteristics of circulation pumps, there are several more positions that you should pay attention to. The first is the allowable temperature of the pumped medium

That is, the temperature of the coolant. In quality products, this indicator is in the range from +110°C to +130°C. In cheap ones, it can be lower - up to 90 ° C (and in fact 70-80 ° C). If your system is designed as a low-temperature system, this is not scary, but if there is a solid fuel boiler, the temperature to which the coolant can be heated is very important.

It is worth paying attention to the maximum pressure at which the pump can operate. In the heating system of a private house, it is rarely higher than 3-4 atm (this is for a two-story house), but normally it is 1.5-2 atm

But still, pay attention to this indicator.

What else to pay attention to is the material from which the case is made. Optimal - cast iron, cheaper - from special heat-resistant plastic

Connection type and size. The circulation pump can be threaded or flanged. The thread can be external and internal - appropriate adapters are selected for it. Connecting sizes can be: G1, G2, G3/4.

It is also worth paying attention to the presence of protection. Can be dry run protected

In circulation pumps with a wet rotor, it is very desirable, since the cooling of the motor occurs due to the medium being moved. If there is no water, the motor overheats and fails.

Another type of protection is overheating protection. If the motor heats up to a critical value, the thermal relay turns off the power, the pump stops.These two features will extend the life of the equipment.

Design

The pump device is a cast-iron housing in which an electric motor rotates a composite wheel mounted on a shaft. The wheel consists of two disks, between which curved blades are located radially. The coolant enters the wheel through a hole in the lower disc.

In wet running models, all moving parts (including the motor rotor) come into contact with the coolant, which will act as a lubricant / coolant for ceramic (graphite) end bearings and the rotor itself. In this case, the stator is isolated from the coolant using a metal partition with sealing gaskets.

The device of "wet" pumps is more complicated than the design of pumps with a dry rotor, so their cost, with equal characteristics, will always be higher.

Note! As a rule, circulation pumps have 3 speeds, which are switched by turning the knob to one of the three speeds. At the same time, at the minimum speed, the pump consumes about 2 times less electricity compared to the maximum speed.

Why is it necessary

The heating circuit with a circulation pump eliminates some of the problems that are characteristic of the natural type of movement of the coolant. After all, if the water at the outlet of the radiator is cold, when it also reaches the extreme radiators, it is also barely warm, then the cold water entering through the return line makes the boiler work at the maximum of its capabilities. At the slightest design miscalculations, installation errors, the distortion in temperature becomes even more noticeable, especially when it is necessary to warm up the room quickly, or when the system is first started, which can be seen from the operation of the boiler, from distant registers.

The use of a circulation pump eliminates these disadvantages. First of all, the requirements for compliance with pipe slopes, their flow area are reduced, all plugs caused by temperature differences are eliminated. The heat transfer occurs evenly, the temperature of the coolant at the inlet / outlet of each radiator is almost the same, and the difference between the coolant before entering the system and returning it to the boiler is several degrees, within ten.

The pump greatly simplifies the design of the piping system.

What does it give? Stabilizes the boiler. If the difference is several degrees, then a smaller volume of gas is spent on heating, the duty cycle is reduced. For example, we need a coolant temperature of 70. Initially, when the water is cold, the boiler operates at maximum power, but as it warms up over time, the picture changes.

The coolant returns in one pass through the system, having lost only 5 °, its temperature is 65 °, while it is the same in the rooms, the heat is distributed evenly over all radiators, and the automation turns off the burner according to the programmed indicators.

The next switch on will occur when the temperature drops. This is an economical mode of operation, in which there is no constant heating, but only the maintenance of the required temperature parameters. If thermostats are installed on all radiators, then by setting the necessary temperature parameters on each register, for example, in the kitchen, in a warm room on the south side, by lowering them, we will get additional savings.