Shower faucets

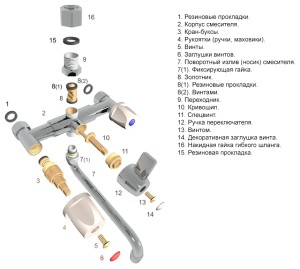

The device is made as a single-lever ball or in the form of two valve valves. The kit includes a replacement shower head with attached flexible hose and bath spout. The mixer is made hidden, bringing out only the valves for controlling the water temperature.

The classic option is a two-valve accessory with manual temperature control. Cold and hot water are mixed in a special chamber, and then flow into the shower hose or spout. The main elements of the device are two crane boxes with replaceable gaskets.

A single-lever device with convenient water regulation is becoming popular. The main element of the mixer is a replaceable cartridge. In case of failure, it can be easily removed and replaced with a new one.

With a built-in thermostat, adjustment is simplified. It is pre-configured, which guarantees the output of water at a given temperature. To do this, there is a thermostatic element in the housing that distributes the flows. The only drawback of such models is the high price.

ball or valve Find out what the essence of the choice is.

The choice of shut-off valves for residential use cannot be underestimated. It is hardly worth saying that not only the absence of problems, but also the comfort of operation fully depends on the reliability of the selected cranes. Below are the main recommendations for choosing taps for an apartment / cottage.

Cranes in the Stream Market today are presented in a wide range. We are talking about the fact that you can easily purchase valves from the world's leading manufacturers of sanitary equipment. Understanding the main selection criteria, you will protect yourself from problems with water supply and heating.

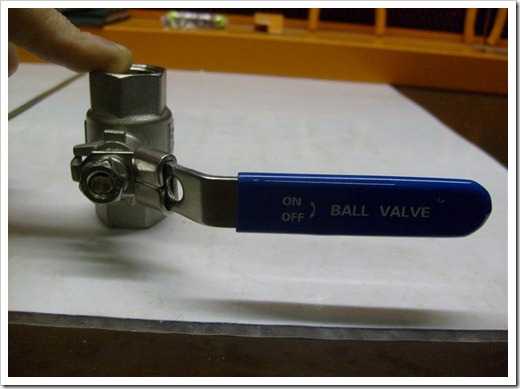

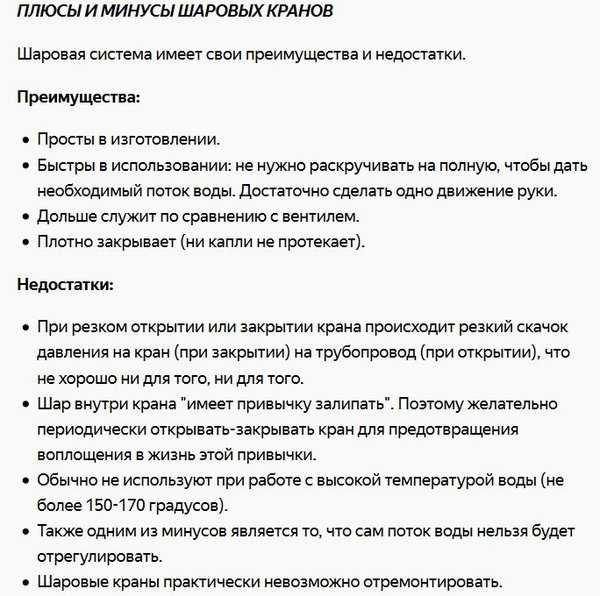

Benefits of using ball valves

Indeed, almost all specialists working in the field of organizing water supply networks or heating talk about the need to use ball valves.

This part of the water supply network has the following advantages:

However, the positive aspects mostly concern European manufacturers of valves. Note that maximum attention should be paid to the choice of alloy from which ball valves are made.

In addition, choosing combo solutions is not recommended. An example is the widespread Italian products, where the ball valve is connected by an integral connection with a coarse filter.

Thus, in case of failure of the shut-off valve itself, you immediately lose the filtration in the system.

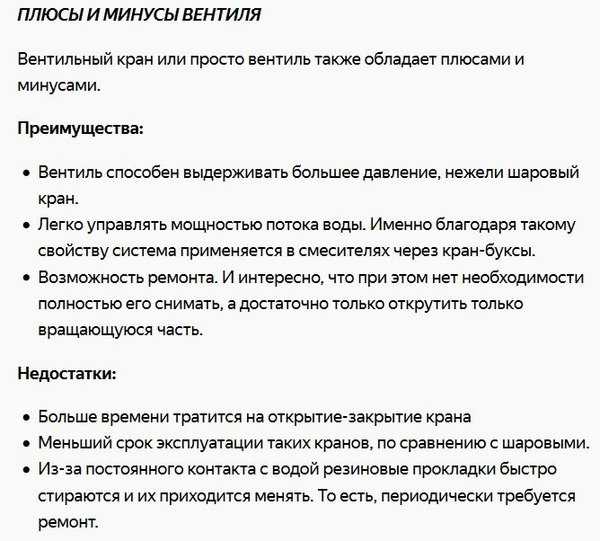

Why are they trying to get away from using valves

The design of plumbing valves is imperfect. To fully open it, you have to perform a large number of turns of the handle. While for a similar action, a ball valve will require only one movement with the hand.

The valve may "stick". It will be almost impossible to unscrew it by hand. However, when force is applied to the valve handle using an elongated lever, the threads “lick off” and the valves can no longer be used for their intended purpose.

Work has to be done to replace it.

The video will talk about which type of taps is better to prefer for heating radiators:

Based on materials: http://stream-market.com.ua/krany_sharovye_zapornaya_armatura

Tweet

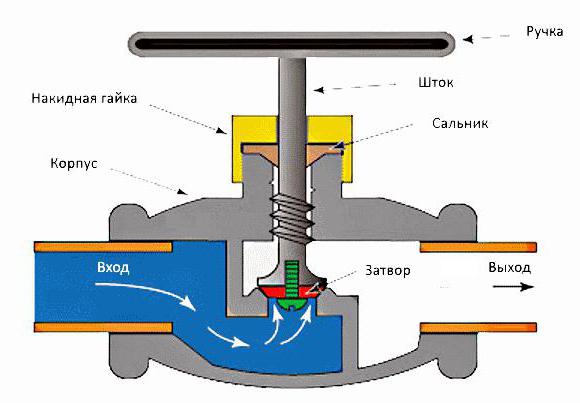

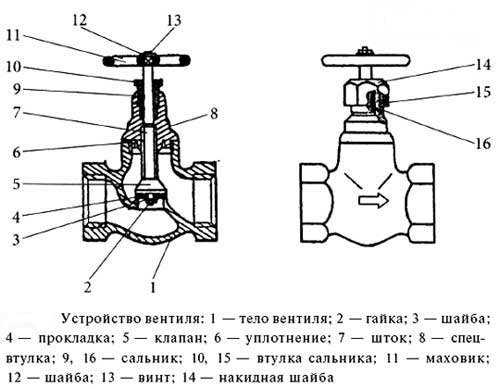

The device and operation of the valve valve

The most important working body of the valve is the seat with the valve manually moved by a spindle. The water valve valve, the device of which is given below, contains a thread in the body and on the stem, which has the property of braking. As a result, the valve disk is pressed tightly against the seat, shutting off the flow when the valve is closed.In the open state, the flow area remains unchanged during the movement of the water flow.

Usually, the body is not threaded, as it wears out quickly. To do this, a running nut is attached to it, into which the spindle is screwed. Then, instead of a worn-out node, you can install another one, while the body will remain. All parts are interchangeable with a water valve (GOST 12.2.063-81, GOST 5761-74).

The valve is opened by turning the handle. In this case, the spindle moves forward, freeing the passage for the liquid. If the rotation is reversed, the valve will close.

The device is connected to the pipeline through the inlet and outlet pipes. They can be distinguished from each other by the presence of an arrow indicating the direction of flow.

General characteristics of different types of valves

Shut-off valves are used in the construction of gas and sewer systems. It can be seen on general purpose pipelines, industrial type pipelines, industrial pipelines with special operating conditions, plumbing pipelines and many others. They are designed to block any water or gas flows.

For these purposes, a gate valve, tap, valve, valve, as well as other locking mechanisms are used. Household plumbing is not complete without such mechanisms, but few people understand how a faucet differs from a valve. Without this, it is simply impossible to connect household appliances, fix leaks, turn off the gas or change the faucet. Plumbing surrounds us all the time, and valves are an integral part of it.

But, based on their functional characteristics and scope, one or another type of device is selected. For the right choice, you should know how the principle of their work may differ, and what function each of them performs.

How to choose a ball valve for an apartment water supply system

Top

redevelopment

House catalog

Where to start repair

about the project

Advertising

Contacts

Facebook

Vkontakte

Odnoklassniki

Instagram

Design and decor

- Apartment

- Bedroom

- Kitchen

- Canteen

- Living room

- Bathroom, bathroom

- Hallway

- Children's

- Attic

- small rooms

- Workplace

- Wardrobe

- Library

- decoration

- Furniture

- Accessories

- Vacation home

- Landscape

- Storage systems

- Corridor

- Cleaning

Construction and repair

- Foundation

- Roof

- Walls

- Window

- Doors and partitions

- Ceiling

- Balconies and loggias

- Internal structures

- Floor

- Water supply and sewerage

- Heating

- Ventilation and air conditioning

- Gas and power supply

- Lighting

- Plumbing equipment

- Security and home automation

- Baths, saunas, swimming pools

- Construction Materials

- Decoration Materials

- Tools

- Technics

- Laws and finance

Best Answers

La Nochka:

For a faucet in the shower, ceramic half-turns are better, the so-called faucets, rather than one-handed with a cartridge.

Yoda:

Buy a mixer made in St. Petersburg. I have a valve in my kitchen and bathroom, it has been working for 5 years without a single leak, even the faucet does not flow when you switch to the shower. However, they are not very expensive.

the most worthy plumbing in its price range, while it is also Russian-made.

Vitaly Kononov:

For your taste! But They are not durable How to check the quality and who to trust is not known! I had both a ball and valves! But now he stopped at the valves!

merulius:

For your taste and color. I had a ball. He had a drawback - it is very difficult to adjust the comfortable temperature of the water, especially when the neighbors from below all abruptly go to wash. Constantly twisted back and forth. I installed a regular multi-turner. good luck.

Dmitry:

Almost no one produces ball mixers now. Single-handle faucets are now made on the basis of a cartridge with ceramic plates.

A single-lever mixer is undoubtedly more convenient than a valve one. But cheap Chinese single-lever faucets are short-lived, and high-quality Finnish or German ones are not very cheap (for a washbasin from 2500 rubles, for a bath and shower from 4000 rubles). If you are ready to pay such or a larger amount - take a single-lever, if not - then a valve is better.In any case, do not take Chinese!

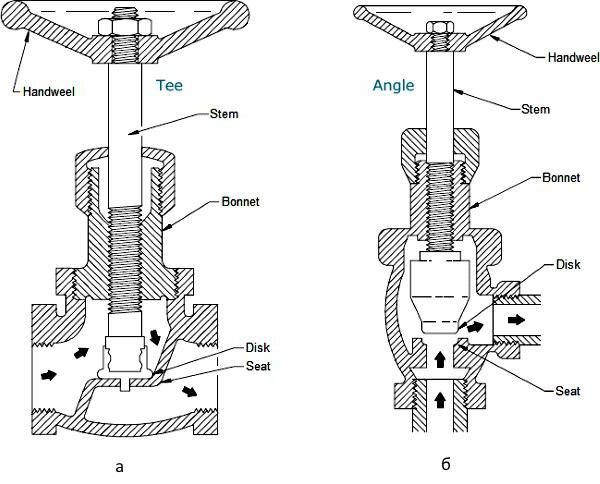

Angle valves

For a perpendicular change in the direction of fluid transfer with the possibility of overlapping and adjustment, an angled water valve is used (drawing below: a - through passage; b - angular).

The perpendicular arrangement of the inlet and outlet nozzles determines the purpose of the valve for pipelines that change direction by 90 °. The principle of its operation is the same as that of the through passage. The shutter stroke is made coaxially with the inlet pipe.

Scope of application of angle valves:

- When pipes are connected to a heating radiator, when it is blocked or regulated by a water supply valve (see photo below). Models made of high-temperature polypropylene are more convenient and cheaper than brass ones when connected to plastic pipes.

- Prevention of vibration and buildup of pipelines.

- Decreased fluid flow rate without high frequency noise.

- In operation in any position.

- Simplified installation of pipes by reducing the consumption of fittings.

Hot water faucet specifications

The use of this type of shut-off valves implies the possibility of complete blocking or opening of the flow of the working medium. The pressure in the system is not regulated using ball valves.

The main technical characteristics and operational properties of the equipment are as follows:

- body material – polypropylene, which simplifies the process of crane installation;

- the material of the ball for covering the working medium is high-quality brass;

- standard diameters for integration into plumbing systems (20, 25 and 32 mm).

The PPR body material makes it easy to connect the hot water ball valve to the piping system. The connection is made by welding on special equipment. This ensures quick installation and guarantees no leaks.

What is the difference between a valve and a ball valve

In modern times, the pipeline may have various options for fittings. Depending on its variety, they can be divided into the following types: regulating, driving, shut-off, safety options, etc. But before deciding on the distinguishing characteristics between a conventional faucet and a special valve, it is recommended to indicate what is meant by such concepts .

A crane is a kind of pipeline fittings of a special drive version. The rotation of the shutter body is carried out around its own axis. It is located in a perpendicular manner in the direction of a certain incoming flow. Often such a product consists of only a few basic elements. This should include both a rotating plug and a conventional fixed body - study the catalog of cranes https://giacom.market/truboprovodnaya-armatura/krany-sharovye/.

But the valve is presented under the guise of a type of actuator valve, where the valve body rotates in the direction of the flow itself. In other words, he sits, as they say, on the saddle. With all this, such a product as a valve is mainly intended for regulating, closing and, accordingly, opening a liquid.

The main distinguishing characteristic between a faucet and a valve lies precisely in the fact that the second version of the product allows regulation of the flow pressure, but using the first device such actions are unacceptable. In addition, it should be noted that the regulation of the flow using a crane is strictly prohibited in accordance with the current rules of use.

The crane is designed to perform only a few functions. This is due to the fact that it has only such provisions as "closed" and "open". But with the use of a valve, quite easy regulation of the pressure itself is possible.

In this situation, the situation is precisely in the design differences.In the valve, the shut-off organ present here, in any case, sits, as they say, on the saddle. The movement is carried out in the direction of the flow. In cranes, wrapping around its own axis is carried out. Additionally, valves are often presented under the guise of a ball version. In other words, as the ball rotates, the diameter of the hole itself also changes. But such a device as a valve is additionally equipped with a special bottom box. By twisting and unscrewing the stem of the bottom box, the valve is lowered, as well as the valve itself is raised. As a result, it is possible to close or open the hole itself, which is located in the saddle.

In any situation, taking into account all of the above, the following conclusions can be drawn:

- The crane has several positions. In other words, these are provisions such as "open" as well as "closed".

- The very design of such a device as a valve, in addition to the function of turning it off and on, at the same time allows you to regulate the pressure of the working flow.

- Visually, a tap can be distinguished from a valve in this way: if the handle is quite simple, and its tip itself is attached to the stem, then such a product is presented under the guise of a tap. In a situation where a “lamb” is used instead of a handle, then the product is called a valve.

What is better faucet or valve

Here it is impossible to say unequivocally that a valve or a ball valve is better. We only note that the faucet is easy to use: by turning the handle 90◦, it blocks the flow of water. While the shut-off valve (valve) must be wrapped in order to open or close the water supply.

The valve has valves with gaskets, which, when worn, can be easily replaced with new ones. At the same time, it will still be necessary to change the seal over time. Ball valves do not have this problem. Here it is only necessary to constantly care for the surface of the ball so that it is in perfect condition.

In general, if you have hard water, it is better to install a valve, because it is subject to partial repair. And if the valve is damaged, then it will need to be completely replaced.

And also a valve for a crane can be bought much cheaper than a ball product - from only 20 rubles. all diameters. Such a low cost is due to the simpler design of the shut-off valve (valve).

To change the flow rate of the transported media to a complete stop, a water pipe is used for water, which has the following properties:

- simplicity of design and operation;

- application at high pressure drops;

- small size and weight;

- possibility of installation on any section of the pipeline;

- a small shutter stroke ensures convenient maintenance.

Main advantages of Valtec valves

Among the many manufacturers of sanitary ware, Valtec stands out for its excellent value for money products. This is what attracts buyers in most cases. To date, the price for a shut-off valve for water ranges from 300 to 1600 rubles, depending on the diameter of the thread. At the same time, such products are distinguished by a long service life (can withstand up to 8 thousand cycles). In addition, all valves are maintainable, which will allow you to replace the desired element in the event of a breakdown, which is extremely rare.

Check and close the check valve. These valves are used to supply flow in one direction and open or close by themselves depending on the direction and pressure of the fluid. This valve has a seat with a spherical profile and in it the ball is adjusted and can work with pressure acting on it with a liquid, or with the help of a method when, with a turn of 90 °, it is placed in the direction of the pipe. A perforation made through a sphere, when rotated 90° again, the perforation also rotates, being perpendicular to the flow, closing the passage to the liquid.

Plumbing is an essential attribute of every home. Shut-off valves play an important role in ensuring its operation, allowing you to regulate the flow of water according to basic needs.

There are quite a few models of such structures that differ in quality and materials. You can find out more by visiting the friatec ag representative office in Russia, where you will be provided with complete information about a particular mechanism.

Air intake valve. Air push valves, as the name suggests, are used to release air accumulated in a pipe for both cold water and hot water, especially the latter. The use of valves in hydraulic installations is made in accordance with the following arrangements.

A faucet or key from the water company is installed when connected to the main supply. A sealing faucet or faucet is located next to the safety line of a building or home to provide a means to control the building's or home's water supply. A bypass valve is installed on each side of the water meter, either a gate valve, or a ball valve, or a butterfly valve.

Cranes main features

A faucet differs from a valve and a gate valve in that it is not necessary to rotate the spindle to start or stop the flow with a faucet.

They do not have a stem, and their shutter is made in the form of a ball, cone or cylinder with a hole for the passage of the flow and rotates perpendicular to the flow. If the axis of the valve opening coincides with the axis of the pipeline, then the valve is open, since the flow passes through the hole. If the valve is rotated 90°, the valve will be closed. A faucet differs from a valve and a gate valve in that it does not require the spindle to be rotated to start or stop flow with a faucet. To do this, just turn the shutter by 90 °. This is the difference between a faucet and a gate valve. It does not have a flywheel, so it is powered by a crank. The valve is in the open state if the handle is located along the pipeline, and if it is perpendicular, it is closed.

For cone cranes, the shutter is made according to the type of a truncated cone. It has a hole for the passage of flow in the form of a rectangle or circle. The tap body also has a conical surface. This is done so that the cork can tightly adjoin the saddle.

For tightness, it closes with a lubricant, which must fill all the micro-gaps between the body and the valve. At the same time, it reduces the effort required to turn. The cork is in a pressed state to the surface of the housing.

There are two ways to press the shutter, and therefore

Distinguish between stuffing box and tension valves.

In stuffing box valves, between the upper end of the plug and the valve cover, there is a stuffing box packing. This is an elastic element that presses the valve against the body with a constant force. Tension valves have a stem at the bottom of the plug, which passes through the body opening. The shutter is pressed by a spring. Such valves are more reliable, since they do not have stuffing box packing, the elastic properties of which are lost over time. Therefore, in such important industries as gas supply, tension cranes are used.

Cone valves are low cost, they are not difficult to revise, they have a simple design and relatively low hydraulic resistance. This is their advantage.

But such cranes also have disadvantages. It takes a lot of effort to turn the cork. Over time, the microgaps between the shutter and the body surface become covered with deposits. In this case, a large force is already required to turn the shutter, which can lead to breakage of the crane.

For the production of taps, a high-quality surface of the gate and body is required, so they are made of bronze and brass. In addition, these metals are less susceptible to corrosion, and this prolongs its service life.

Which valve is better valve or ball Myths and reality MMUP KX Kletskoye

You can find opinions on the net. Both right and wrong. How can an unprepared person, who decides to clarify for himself some question unknown to him, find the truth?

There are only two ways:

– Check any information from other sources and analyze;

- Follow the recommendations of those specialists whom you already know as professionals.

Let's try to use the first method and analyze one recently appeared article in Zen with a similar title.

Quoting from a screenshot:

What can be said here? Valves appeared long before the emergence of the USSR and are still very widely used in world practice.

Why don't they last long? This unsubstantiated statement of the author is given solely in order to make the transition to "some kind of replacement", which is offered as ball valves. Why they are more popular, the author is silent, but gives such a list of the pros and cons of ball valves:

In fact, simplicity is not so simple, ball valves became widespread only after the advent of sufficiently high-tech materials and production processes, before that their use was quite modest due to the inability to provide the necessary tightness of the seal of the ball plug with traditional materials and surface treatment methods.

Does it last longer than a valve? Complete nonsense, the standard service life of high-quality ball valves and valves is approximately equal and is about 30 years. The actual service life of the valves is many times longer.

The occurrence of water hammer during a sharp closing of a ball valve is not significant for small diameters of valves used in everyday life.

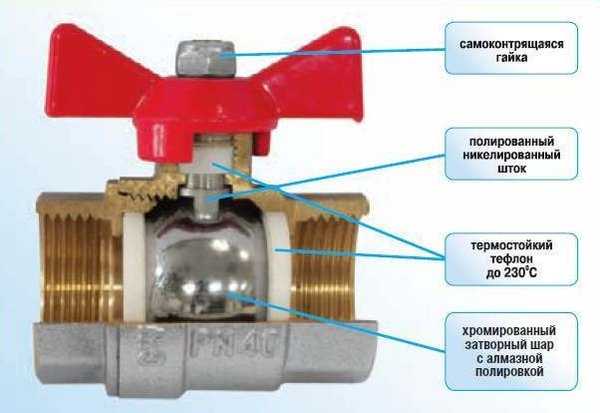

Ball valves are also used at higher temperatures, the difference is only in heat-resistant gaskets:

Ball valve for working with temperatures of the transported medium up to 230 degrees

Typically, ball valves are used as shut-off rather than control valves. But there are also special ball valves. It is enough to google to be convinced of this. But these are mainly industrial taps, if a regulation function is needed in everyday life, it is better to use a valve.

High-quality ball valves are maintainable:

Column 5 in the crane passport - maintainable, column 2 - standard service life - 30 years

The crane is easily disassembled and worn or damaged parts are replaced with new ones:

Let's move on to the valves. The author of the article in question offers us the following:

There are ball valves and valves for a variety of pressures.

Valves are indeed much easier to repair at home without the use of branded spare parts. Therefore, their repair is also cheaper.

There are valves with a ceramic locking mechanism (widely used in faucet boxes of mixers and taps). A valve with such a locking mechanism opens as quickly as a ball valve.

The rubber seals are abraded by rubbing against the faucet seat, not by contact with water. They cost a penny, the replacement is simple and within the power of almost anyone.

And now about the really important difference between ball valves and valves. The valve, due to its design features, creates greater pressure losses in the system than a ball valve

The valve, due to its design features, creates greater pressure losses in the system than a ball valve.

The diameter of the hole for the passage of the medium in the ball valve most often corresponds to the inner diameter of the pipeline on which the valve is installed (such a ball valve is called full bore). In the open position, the ball valve does not create resistance to the flow of the transported medium, and therefore does not "devour" the pressure in the system.

This is important for heating systems and gravitational water supply of country houses with limited pressure in the system. It was with full bore ball valves that I installed a gravity water supply system in my country house, which works perfectly at very low water pressure from a storage tank installed in the attic of the house

It was with full bore ball valves that I installed a gravity water supply system in my country house, which works perfectly at very low water pressure from a storage tank installed in the attic of the house.

You can read more about the design of my gravity water supply system at the link.

Varieties of cranes

Valves for water can be divided into several main types:

- Cone cranes. Such mechanisms are used quite rarely, since they wear out very quickly, which leads to their frequent replacement.

- Valve valves. Among the advantages of such designs, one should highlight the ability to work even in highly chlorinated water without losing technical features. Repair of such valves is relatively simple and often requires only replacement of the seal.

- Ball valves consist of a special body in which a ball with holes is placed. When turning it, this allows both blocking and opening the flow of water. Such systems are very often used in household systems and have a different design, which allows them to be matched to any type of interior.

It should be noted that water valves can have a different type of connection to the main pipe:

Safety and Maintenance Measures for Relief Valves

There are various safety valves for all equipment. Therefore, the installation of safety valves should be carried out only by those who understand this issue. Deploying the wrong valve that doesn't fit your piping and could result in poor installation quality, won't work properly

Therefore, it is worth mentioning that professional assistance in acquiring and installing the right equipment is essential.

- carving is used quite often. Such valves can be found everywhere in domestic use;

- flange connection is also used everywhere. Often this type of valve is used to block overall pipes.

When choosing a valve for water, you should pay attention to the quality of its performance, which will significantly extend their service life. Stainless steel valves have a long service life provided they are properly maintained and maintained

Despite low maintenance requirements, programmed inspections of these accessories are recommended to ensure that relief valves last longer and last longer. Safety valves must pass functional and resistance tests and meet the minimum requirements required for their manufacture.

Stainless steel valves have a long service life provided they are properly maintained and maintained. Despite low maintenance requirements, programmed inspections of these accessories are recommended to ensure that relief valves last longer and last longer. Safety valves must pass functional and resistance tests and meet the minimum requirements required for their manufacture.

Not all valves on the market are made with the correct components.

Therefore, it is important to find out where to buy safe and reliable valves. Reliable and reliable suppliers have good recommendations and affordable conditions for your purchase