Types of combustion chambers for gas boilers

According to this classification parameter, gas boilers are divided into boilers:

- With an open (natural, passive) combustion chamber. These types of boilers consume oxygen directly from the room where the boiler is installed. Exemption from combustion products is also carried out indoors. Therefore, for them it is necessary to equip special chimneys indoors and provide high-quality air ventilation. Boilers of this type are usually installed in non-residential premises or in specially equipped boiler rooms. Similar design features are most often found in floor-standing boilers with a power above 35 kW. For example, Lemax boilers, the technical characteristics of which make it possible to provide heat to residential premises up to 500 sq.m.

— With a closed combustion chamber. The combustion process is provided by air coming from the street through a special coaxial chimney. Structurally, a coaxial chimney is a system consisting of two pipes, one of which is located inside the other. Thanks to this design, air enters the boiler through one pipe, and the combustion products are forcibly removed through the inner opening of the chimney to the street due to the installed fans. Due to the coaxial chimney, a closed system is provided, which avoids the installation of additional ventilation of the room. Active draft combustion chambers are most often equipped with wall models of gas boilers, the power of which does not exceed 35 kW. (See also: Voltage stabilizers for gas boilers)

Combined boilers

The essence of this type of boiler is clear from the name. This is a lifesaver that can keep the heat in the house when one of the types of fuel is turned off or in short supply. There can be all sorts of combinations - for example, Finnish boilers are completely “omnivorous” and can easily switch from gas to electricity, from electricity to diesel, and from diesel to solid fuel.

Acceptable for our conditions is a combination - electric + solid fuel boiler. During the off-season, when the temperature "overboard" is not so low, you can connect to electric heating from time to time, and in cold weather, use the solid fuel function. Users of such boilers share their experience: sometimes in winter it is enough to put coal into the furnace once a day, and then maintain the temperature with electricity.

However, combined boilers also have opponents: some believe - perhaps not without reason - that such a “diversely developed” technique is by default inferior in reliability to a device that runs on only one type of fuel. In addition, such boilers are more difficult to install, repair and maintain.

What could be more important than warmth? Mental - from the fact that near relatives and loved ones - and physical, which will give you a well-equipped heating system. Take care of it in advance - and warmth, coziness and comfort will always reign in your house.

Basic terms and definitions

V

boiler technology use the following

Terms and Definitions:

Boiler- device,

in which to produce steam or heat

water with pressure above atmospheric,

consumed outside this device,

using the heat released during

combustion of fossil fuels, and

heat of exhaust gases. The boiler consists

from the furnace, heating surfaces, frame,

brickwork. The boiler may also include:

superheater, surface

economizer and air heater.

Boiler room

installation

- the combination of the boiler and auxiliary

equipment, including: draft

machines, prefabricated flues, chimney,

air ducts, pumps, heat exchangers

devices, automation, water treatment

equipment.

Firebox(furnace

camera)

- a device for

chemical energy conversion

fuel into physical heat

high-temperature gases, followed by

heat transfer of these gases to the surfaces

heating (working fluid).

Surface

heating- element

boiler to transfer heat from the flare and

combustion products to the coolant (water,

steam, air).

radiation

surface

– heating surface of the boiler, receiving

heat mainly by radiation.

convective

surface

– heating surface of the boiler, receiving

heat mainly by convection.

Screens

– boiler heating surfaces located

on the walls of the furnace and gas ducts and enclosing

these walls from exposure to high

temperatures.

Festoon

– evaporative heating surface,

located in the outlet window of the furnace and

usually made up of pipes

rear screen, divorced on

considerable distances through the formation

multi-row bundles. Purpose of the festoon

is to organize free

exit from the flue gas furnace

rotary horizontal flue.

Drum

- the device in which

collection and distribution of the working environment, ensuring

water supply in the boiler, separation of the steam-water

steam and water mixtures. For this purpose

are used placed in it

steam separators.

boiler room

beam –

convective heating surface of the boiler,

which is a group of pipes,

connected by common collectors or

drums.

Superheaterb

– a device for increasing the temperature

steam above saturation temperature,

corresponding to the pressure in the boiler.

Economizer

- device for preliminary

heating water with combustion products up to

feeding it into the boiler drum.

Air heaterb

– device for heating air

combustion products before it is fed into

burners.

Solid fuel boilers

This is the cheapest way to heat. Coal, which is the main energy carrier, is inexpensive and very accessible. Cars of every possible size, filled to the brim with coal, stand at all exits from the city, and there are more than enough advertisements in the newspapers. Nevertheless, this category of boilers has its own subtleties.

Solid fuel boilers are divided into two main categories: classic and long burning.

Everything is clear with the “classic” - we melt it ourselves, throw in coal, and clean it from ash. There is no automation, but on the other hand, minimal energy dependence, that is, when the electricity is turned off, the boiler will continue to work. But the temperature in the room will have to be set manually.

Long-burning solid fuel boilers are often stuffed with all kinds of automated stuff, which significantly reduces your labor costs. These “guys” are able to flood themselves, it is possible to automatically regulate the temperature, and they work “from load to load” longer and more economically.

Pros. Fuel is cheap and readily available (it will cost only one and a half to two thousand a month per 100 sq. M), you will not encounter the problem that, for example, there is nowhere to get coal from (but it is still better to always have a weekly supply).

Minuses. The classic solid fuel type of boiler needs constant monitoring - sometimes you have to throw up fuel several times a day. In addition, depending on the degree of fuel combustion until the next bookmark, the temperature in the house can vary within five degrees, which is more than noticeable in Siberian frosts. They are reliable, do not depend on electricity (unless they are equipped with a fair amount of automation), and their shortcomings can be partially smoothed out with the help of thermal bulbs and heat accumulators - this will reduce the number of fuel loads and avoid temperature fluctuations.

Long-burning boilers have fewer such problems, but their price is strikingly different from the "classics". And again, coal in them, although less often, but still need to fall asleep. And if you didn’t think over this point during the construction of the boiler house, then you will have to periodically engage in coal-bucket fitness.

Other types of heating boilers

In addition to gas, there are other types of boilers:

- electric;

- solid fuel;

- liquid fuel (diesel);

- combined.

electric boiler

The electric heating boiler is easy to operate, does not require fuel for its operation, this type of boiler has a high degree of safety. It is installed if the cottage, country house or apartment is located in a protected natural area where emissions of harmful substances are prohibited. Before choosing this type of boiler, you should think about the high cost of electricity. For comparison: 200 m² of area will require about 50 kW of power.

Liquid fuel (diesel)

Such boilers are not used for heating apartments. Diesel fuel is used as a heat source (it is considered an expensive type of fuel, and it is constantly consumed to maintain heat). The disadvantages include the characteristic smell of fuel, for this reason, liquid fuel boilers, as a rule, are placed in a separate building.

solid fuel

Such boilers are not installed in apartments for private use. In the modern world, solid fuel is used very rarely: it is difficult to imagine that a cottage will be heated with coal. However, now in stores you can find a heating boiler in which firewood, a special combustible product, coal, and wood waste are used as fuel. In terms of power, such boilers hardly reach 60 kW.

Combined

Allows the use of multiple fuels, such as gas and coal. Easy to use, especially in country houses and cottages.

Classification of domestic heating boilers

The direct purpose of household boilers is to heat small rooms: individual houses, summer cottages, cottages or even just apartments. As an additional service - getting hot water for household needs.

All household boilers are water-heating, low-temperature (temperature less than 100 ° C) and belong to the class of low-power boilers (heating capacity from 4 kW to 65 kW).

Household boilers are used wherever there is no central heating network nearby or connection to it is too expensive. Due to the high demand for domestic heating boilers, there is also a large supply. Therefore, a significant number of large companies are engaged in the production of boilers of this class. Hence the large number of brands and modifications of domestic boilers.

However, all these brands and modifications can be divided according to a number of parameters that determine the efficiency of using boilers in various circumstances.

The main parameters by which domestic heating boilers are classified:

- according to the type of fuel used.

- according to the material of the heat exchanger,

- according to the installation method,

– the possibility of obtaining hot water for household needs,

Possibility to get hot water

Depending on the method of heating hot water in heating equipment, boilers are divided into single-circuit and double-circuit. As a rule, such a division primarily refers to gas heating boilers.

Single-circuit boilers are designed only for space heating and do not have a system that provides hot water to the house. True, with the connection of a water heat exchanger of a remote boiler, they can also perform the function of heating water. This type of boiler equipment is cheaper than double-circuit analogues and is used in small private houses.

Double-circuit boilers perform two functions: heating the house and heating water.The boilers got this name because they have two circuits in their design: one is responsible for heating, the second for heating running water.

The most widespread are gas double-circuit boilers that run on natural or liquefied gas. Usually they have a capacity of 20 to 30 kW, while providing the house with about 10-14 lira of water.

To increase the amount of hot water, the boiler can be equipped with a boiler.

2. Classification of boilers

By

type of heat carrier produced

boiler plants are divided into steam

and water heaters. Depending on destination

they are divided into energy,

production, production and heating

and heating. Energy

boiler plants

produce steam for steam turbines

thermal power plants. Such boiler houses

usually equipped with boilers

large and medium power, which

produce steam with increased parameters.

Production

and

production and heating boiler houses

installations (usually

steam) produce saturated or

slightly superheated steam (up to 4 MPa and 450 ºC),

which is used in technological

processes of various industries (drying,

boiling, rectification, concentration

solutions, etc.), as well as to ensure

heat of heating and ventilation systems

and hot water supply. Heating

boiler plants

(mostly hot water, but they can

be steam) are intended for

maintenance of heating systems, hot

water supply and ventilation of industrial

and residential premises.

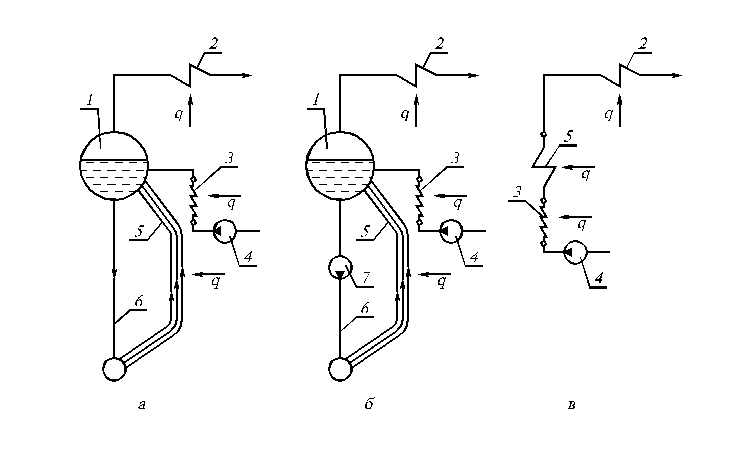

By the nature of the movement of water, steam

mixture and steam boilers are subdivided

on drums with natural circulation,

drums with repeated forced

circulation and direct-flow (Fig. 4.1). V

drum boilers with natural

circulation movement of the steam-water mixture

in lifting (heated) pipes and

liquids in lowering (unheated)

pipes is due to the difference

their densities. In boilers with multiple

forced circulation movement

water and steam-water mixture is carried out

using a circulation pump. V

once-through boilers do not have circulation

circuit, no multiple circulation

water, no drum, water

pumped by feed pump

through the economizer, evaporative

surfaces and superheater,

connected in series.

By moving products

combustion and water boilers are divided into

gas-tube (fire-tube and with smoke-fired

pipes) in which gases move inside

pipes, water pipes, in which water or

steam-water mixture move inside the pipes

and water and gas pipes.

By design features

distinguish between cylindrical boilers,

horizontal water pipe,

vertical water pipe.

Depending on the

steam capacity distinguish boilers

small (up to 20 - 25 t / h), medium (from 35 - 50 to

160 – 220 t/h) and high steam output

(from 220 - 250 t/h and above).

|

|

|

Rice. a |

According to the pressure level of superheated steam

distinguish between boilers with low (below 4 MPa),

medium (from 4 to 11 MPa), high (more

11 MPa) and supercritical pressure

(above 25 MPa).

According to the pressure level in the gas

tract distinguish boilers with natural,

balanced traction and supercharged.

It is also possible to classify

combusted fuel, ash removal method

etc.

Boiler power for home

The operation of residential heating systems directly depends on the operation of the boilers. The issue of choice must be approached responsibly, because the boiler plays one of the most important roles in the heating system of the house.

Scheme of operation of a double-circuit gas boiler.

Power is the most important parameter that you need to pay attention to when purchasing a boiler. Properly selected power is a guarantee not only of a comfortable temperature, but also of minimal energy costs.

Determining the required power is quite simple. For example, for high-quality insulation of a room with ceilings, the height of which is about 3 meters, and the area is 10 m², you need 1 kW (kilowatt) of power. For a larger area of \u200b\u200bthe room, more kilowatts will be consumed. By this analogy, calculations can be made, taking into account the size of any room, but the result will be preliminary.

To calculate the required amount of power, it is necessary to carry out a heat engineering calculation, taking into account many parameters:

- the thickness of the walls and the material from which they are made;

- floor thickness;

- size and number of windows;

- the presence of heated floors;

- the presence of a fireplace;

- functional purpose of individual rooms of the house.

It is almost impossible to make such a calculation without special education, and only experienced engineers and designers can perform it correctly.

Conditional gas pressure is approximately 13-20 mbar (millibar), but the pressure in gas networks is 10 mbar or even less. Therefore, the boiler will not work at full capacity, but only at 2/3.

Classification of boilers according to the material of the heat exchanger

The heat exchanger is the heart of the boiler, the most important element in which the coolant is heated. According to the material of the heat exchanger, boilers are divided into boilers with a cast-iron heat exchanger and with a steel one.

Consider their comparative advantages and disadvantages.

Cast iron boilers.

The service life of cast iron boilers is about 25-35 years, steel boilers are about 15-25 years.

Cast iron has a higher corrosion resistance than steel. On the other hand, cast iron is a material that is quite brittle and afraid of impacts. This circumstance is essential during transportation, where it is quite difficult to avoid shocks during loading and unloading.

Cast iron has a high thermal inertia, i.e. after heating, heat is retained for a long time, has increased corrosion resistance to chemically active media, sludge.

Cast iron is a brittle material, does not bend and stretch, and is extremely capricious in terms of deposition to temperature irregularities, incl. to fluctuations in wall temperature. Hence, there are stringent thermal requirements for the operation of cast-iron boilers.

As a rule, they require guaranteed forced cooling of the boiler (using a circulation pump).

Cast iron boilers compared to steel boilers have a higher weight and larger dimensions.

Cast iron boilers are afraid of the temperature difference between the inlet and outlet (i.e. cast iron boilers cannot be supplied with too cold coolant). Therefore, when using cast iron boilers, a unit for mixing hot water with water at the inlet is required. The heat exchanger of cast iron boilers always consists of separate sections. Due to their mass, cast iron boilers have a high thermal inertia.

Cast iron boilers are most often designed to burn coal or wood, but it is easy to convert it to burning liquid fuels or gas. For this, the front plate is changed and the corresponding burner is installed.

Boilers of this class are usually universal, i.e. when installing a suitable gas burner, e.g. burners equipped with automatic SABC. operate on low pressure natural gas. An example of a cast-iron household boiler is a Russian solid fuel boiler. KChM-5 .

Steel boiler.

Steel is a ductile material, works well both in compression - stretching, and in bending, so it can easily cope with large temperature differences. A steel kettle is not as brittle as cast iron and has good impact resistance, making it safer to transport.

Steel boilers are an all-welded structure with a resource of 15-25 years.

Steel boilers have a more aesthetic appearance, which is important when heating summer cottages. As for the cost, according to some sources, cast-iron boilers are more expensive than steel ones, and vice versa according to others.

Apparently it all depends on the particular brand of boiler

As for the cost, according to some sources, cast-iron boilers are more expensive than steel ones, and vice versa according to others. Apparently it all depends on the specific brand of the boiler.

Example of a steel heating boiler - Czech solid fuel boiler OPOP .

Recently, copper heat exchangers have also appeared. For such heat exchangers, the temperature distribution along the walls of the heat exchanger is almost uniform (due to the high thermal conductivity of copper) and the water is heated without local overheating. Thus, the formation of calcium deposits in the heat exchanger is minimal.

Copper heat exchangers are lightweight and corrosion resistant. In this regard, the entire design of the boiler becomes lighter. A boiler with a heat exchanger of small volume and weight is safer, the heating system with such a boiler responds faster to automation commands. In small-capacity heat exchangers, the coolant moves at a higher speed when heated, which prevents the formation of scale on the walls of the heat exchanger.

These boilers have another obvious plus - a very high efficiency, the impossibility of corrosion and ductility. But there is a big drawback of such boilers - they are very expensive.

Oil boilers

This type of boilers in terms of heat transfer is close to gas boilers - with the only difference being that it works on diesel fuel.

Pros. Minimum labor costs when using. No need to clean, refuel, kindle, everything is done automatically. In addition, the installation of a diesel boiler does not require permits. The price of the boiler itself is relatively inexpensive.

Minuses. In addition to the boiler, it is necessary to purchase a fuel storage tank (approximately 2–5 tons), which should be located in close proximity to the “heart of the system”, and this makes the question of the area where you can place all this urgent. Liquid fuel boilers are not environmentally friendly, they smoke and require a separate room with a good exhaust, otherwise there is a risk of carbon monoxide poisoning. Again, you need to initially think about how diesel fuel gets into the tank, because carrying canisters is not the best way to spend your leisure time. Well, the price of diesel fuel is already prohibitive and is clearly not going to stop there.

Electric boilers

Minuses. The main problem that owners of this type of boilers face is the high heating costs. This is an expensive type of fuel (on average, from 8 to 15 thousand rubles per 100 sq. m. per month). And if there are power outages in the area where your country house is located, you risk being left not only without light, but also without heating. This type of boiler requires careful attention to the heating element (electric heater), because of the formation of scale, it can quickly fail.

Thus, if the financial issue does not bother you and the amount of electricity allocated to you is enough to warm up the volume of your mansion in severe frost, then purchasing an electric boiler is your option. Otherwise, it makes sense to consider it only as a safety net to the main one.

How to choose a boiler for your home, given the dependence of the gas boiler on electricity

For gas boilers, the dependence of automation on electricity is also important. There are various problems with electricity, ranging from simple interruptions to its complete absence.Most of the gas boilers with atmospheric burners manufactured in Russia operate regardless of the availability of power.

In Western countries, there are no such problems with electricity, so the question arises whether there are imported boilers that operate autonomously from electricity. Yes, there are.

There are two ways to achieve autonomous operation of a gas boiler:

- For boilers from domestic manufacturers, you can come to independence from electricity by simplifying the control system due to the small presence of automation.

- The most effective way is to use a heat generator, which converts heat into electricity required for boiler automation.

Both floor and liquid fuel boilers can be of three types:

- single-circuit - suitable only for heating. An indirect heating boiler can be connected to any such boiler (water is heated by the boiler coolant or from an electric heating element). In country houses, boilers of 100-300 liters are most often used, but models with a volume of up to 1000 liters can be found;

- double-circuit. They carry the task of providing heating and hot water. They can be of two types: with a built-in coil or boiler;

- double-circuit boilers turbo. This type of boiler, in addition to the main functions, includes the removal of gases.

Power of gas boiler equipment

This characteristic is the most significant in order to meet the needs of the premises in which it is going to be used. The calculation of power should be carried out by a specialist, since it is necessary to take into account various factors, including the design features of buildings, their area, material of execution and the temperature difference between the external and internal temperatures. But you can also approximately calculate this indicator yourself using the formula:

where Q is the power, k is the heat transfer coefficient for the building, V is the total internal volume of the room.

In this case, it is recommended to choose a boiler with a power of 1.5 times more than the result obtained. If the gas boiler is double-circuit, i.e. is also used for hot water supply, then the power must be additionally increased by 10-40% based on the planned consumption of hot water. (See also: How to clean a gas boiler)

The power of the equipment during operation is influenced by:

- seasonal loads on the highway, due to which the working gas pressure in the network decreases;

- long-term absence of preventive cleaning of equipment;

- salinity of water in the heating circuit, which leads to the formation of scale inside the heat exchanger;

- frequent use of hot water.

gas boilers

Pros. According to the installation methods, gas boilers can be both floor-standing and wall-mounted. The wall-mounted gas boiler is an extremely compact device that can be installed in almost any room. Floor gas boilers have more power. Modern boilers have a high efficiency (over 93%) and are equipped with an automatic control system that ensures safe operation. Boiler automation allows for weather-dependent regulation, setting a heating schedule, hourly program heating specifically for each day of the week, which can significantly reduce gas consumption. The advantages of the gas type of boilers include its environmental friendliness, the absence of combustion products, the need to refuel once or twice a year. The complete autonomy of gas equipment is confirmed by the possibility of using a gas household generator in the system, which will provide electricity to a gas boiler and electrical appliances in the house.

Minuses. Perhaps the most basic disadvantage in installing gas boilers is the large initial investment for the purchase of a gas tank and the installation of a gas pipeline.