What breaks in an oil heater

The tank is filled with heat-resistant oil by 85 - 90 percent. An air gap is left to compensate for the thermal expansion of the oil - the corresponding accordion case configuration is selected. When refueling, choose transformer oil - you can not mix varieties. Now we know the possible elements of a breakdown - we proceed to repair.

The situation of a leaky tank is familiar: it worked, it worked, it leaked. In the morning there was oil on the floor, the tank was empty, the appliance turned off, the thermal fuse burned out. It is worth using cold welding. FastFix for metal keeps temperatures from minus to +120 degrees Celsius. Take it out in the cold with care, patched, you can use it at home. FastFix for metal contains magnetic iron filings - the fastest setting material in the range. The master will have three minutes - in an hour the material will dry.

FastFix holds temperature, sold as a stick: a polymerizing compound of the epoxy class of adhesives. The resin outer shell protects the inner hardener. Cut off the composition of the pencil in the right amount, knead with wet hands, apply in place. After hardening, trim the result with emery, grinder, better with a wet knife until completely solidified. There are many breakdown points - do not forget to wear rubber gloves. Wet your hands before use.

Broken oil heater

The place of breakdown before applying the patch should be cleaned of paint, rust, oil. Sand with fine sandpaper for a firm grip. If the hole is on the channel of the section, try to leave a little room for oil flow

According to the manufacturer, the patches hold pressure (important for the master), or check with the manufacturer. There are many brands of liquid paint, choose your own

FastFix, which does not require thinning, smearing on plastic with a spatula, is a good choice.

Sometimes there is a need to independently repair an oil heater with a burned-out heating element. Breakdown identification: ring both branches with the switches off, the plug is pulled out of the socket. If the resistance is tens of ohms, the integrity of the core is in order. A short circuit or a break indicates: a breakdown is here. The heating element is rolled inward - you have to pull it out. The new one should be similar to the previous one. The tube used is steel, not copper, to avoid electrochemical corrosion.

Before dismantling, turn the oil heater on its side: the hole must be higher to save the oil. When replacing, use cold welding in place. Before installation, check the insulation resistance of the heating element. At least 20 MΩ figure (according to the rules, they are measured by a voltage driver of 500 V). One contact of the tester is connected to the spiral, the second to the body. The operation is done twice, one per branch.

Understood the repair of an oil heater that did not turn on. In the absence of voltage on the heating element, the following are to blame:

- Emergency or working thermostats.

- Thermal fuse.

- Switch.

In the latter case, there will be no voltage on the only branch of the heating element. Constant clicks during operation are emitted by a working thermostat on a bimetallic plate with an adjustable screw. If the oil heater works before the emergency shutdown, try looking here.

Oil-filled electric heaters are popular units in everyday life, characterized by high durability, as they are produced under industrial conditions using modern technologies. However, these electrical appliances are not designed to withstand all emergency situations in everyday life and still fail.

The device of even the most modern unit allows in some cases to repair oil heaters on their own.

Consider this popular household heater from the perspective of assessing the possibility of its restoration after a failure, since it is necessary to repair an oil heater with a guarantee of the safety of its further operation.

Varieties of thermostats

There are three types of regulators:

- electronic;

- electromechanical;

- mechanical.

Below we will briefly discuss the characteristics of each of them.

Electronic regulators

The thermostat with electronic filling is composed of three components:

- temperature sensor;

- microprocessor responsible for processing and transmitting information;

- thermal relay, thanks to which the control switching is carried out.

Electronic thermostats are used not only in oil heaters, but also to organize the management of larger heating systems (for example, "smart home").

Electromechanical regulators

Relay-based electromechanical devices are much simpler than electronic devices. There are several types of electromechanical regulators:

- Devices of the first group include a group of contacts and a double metal plate. When the equipment is heated, the plate bends and, thus, opens the group of contacts. The consequence of the opening is to stop the supply of electricity to the heating plate. When the heater cools down, the plate returns to its starting point, and the electrical circuit starts to work in the previous mode, since the contacts are closed again. The cyclic operation allows you to maintain the temperature level at approximately the same level.

- Devices equipped with a relay operate on the principle of expansion of its elements as a result of heating. The relay is a cylindrical tube containing a heat-responsive substance. The pipe is in a container of water. When the temperature of the heater rises, the substance in the pipe expands. When the temperature reaches a certain value, the expanded content acts on the electrical circuit with the help of an actuator, resulting in the closing or opening of contacts. In this way, it is possible to avoid overheating of the equipment.

Mechanical

The most simple are mechanical regulators. Such thermostats are conventional shut-off valves. The design of the device includes a cylinder with a rod filled with a thermally sensitive substance. As a result of the expansion of the substance during heating, the rod partially or completely blocks the flow of the coolant in the system.

Malfunctions and repair of an oil heater

If a heater that worked properly yesterday stops heating today, then there is no need to immediately run to the workshop, or to the store for a new heating device.

Many malfunctions can be completely eliminated on your own, having basic skills in repairing electrical appliances.

An exception may be a faulty heating element, most often tightly rolled in the heater housing. It is quite possible to remove it, but it will not be possible to put it back in place. Even if the heater is equipped with a removable heating element, it will be difficult to achieve tightness of the device when replacing it.

Usually, the malfunctions that occur when the heater breaks down appear in more accessible places. The most vulnerable point of the device is the cord, so its integrity should be checked first. If the design of the plug allows it to be disassembled, then you need to check the connection points of the cord cores with the pins of the plug.

If the plug is in good condition, the next step should be to check the condition of the cord itself, as well as the place of its connection to the heater power supply. To do this, the decorative cover of the device panel is removed and the tester checks the serviceability of the cord. If it is damaged, the cable is replaced with a new one.

If the cable turns out to be serviceable, then the malfunction may be hidden in the state of the contacts of the power supply.Contacts may be carbonized and loosened.

In this case, the contacts are cleaned of carbon deposits with sandpaper, and the weakened contacts are carefully tightened.

The thermostat is located in the same place. If darkening is visible on its contacts, then they also need to be cleaned. In the thermostat, the bimetallic plates may be faulty. If their damage is detected, the thermostat is carefully disassembled, and the plates are replaced with new ones.

If the oil cooler belongs to the energy-saving category, then its design has a thermostat that turns the device on and off at the specified parameters.

In case of excessive heating of the heater, or low temperature, it must also be inspected. If a malfunction is detected, this part is replaced with a new thermostat with similar parameters.

If there is a fan in the design of the oil heater, it must also be checked. In this case, not only the contacts of the device are checked, but also the integrity of the winding of its motor. It may need to be replaced.

After completing the above checks and eliminating the observed malfunctions, the heater is assembled and then connected to the network. If the heating device still does not work, you will have to seek the advice of a specialist.

Most likely, he will advise you to purchase a new heater. Some types of repairs can be so expensive that it's easier to go to the store.

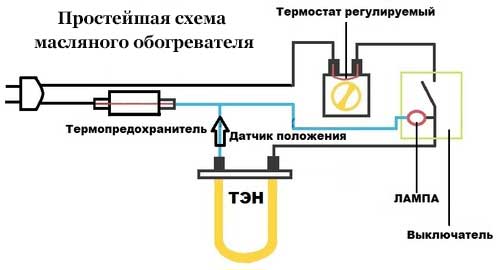

You will find the device and the electrical circuit of the oil cooler in the video:

Do-it-yourself instructions for repairing (replacing a heating element) an oil heater in the video:

Oil heater device

Temperature conditions and oil heater tank

The principle of operation of an oil heater is to transfer energy from a small area, the size of a heating element to oil, then through it to the surface of a steel tank. The amount of heat loss depends on the temperature difference on both sides of the plane, area. It is unprofitable to increase the first parameter - the spiral will burn out. If we increase the area, we will achieve the desired result. The calculation is such that it is impossible to burn yourself on the surface of the tank, but the temperature difference with the room must be significant for heat exchange.

Normal conditions: the room is 20 degrees Celsius. Citizens bring the temperature to 35, even higher - not good for health. Manufacturers have chosen the lesser of the evils - the surface of the oil heater heats up to 70 ºС.

We disassembled the oil heater to determine the modes:

- Emergency thermostat KSD 301 with a response temperature of 80 degrees Celsius.

- Left brand thermal fuse, set to 142 degrees Fahrenheit (61.5 degrees Celsius).

Emergency thermostats KSD 301 and thermal fuse

The first one stood as a sensitive platform on the channel of the radiator section closest to the electronic unit. The oil is in an accordion made up of sections. They are rolled to each other, the seams are tacked from the outside by spot welding (dashes in reality). The accordion-radiator is non-separable, it stands on a platform with wheels: it is attached with two steel wire brackets. From one side there is an accordion in the form of a heating radiator, from the other, the cover of the electronics block leaned against it (a loud name for a couple of resistors).

Each section is flat. Top and bottom channel cut. Vertically connected by veins: a small amount of oil oozes through. In the lower channel, with the base to the electronic unit, there is a heating element. Difference: there is no thermostat in the water heater. But the thermal fuse is screwed to the base. Low temperature - 61.5 degrees (although the element does not touch the working part of the heating element). The thermal fuse is wrapped with a rubber gasket, additionally protected by a heat-resistant cloth: when the oil boils, the temperature will be low.

A thermostat with a fixed response temperature of 80 degrees Celsius leaned with a metal side (on two screws) against the central vertical vein of the first section. No matter how you set the modes with the upper thermostat, or press the power buttons of the heater sections, the limit will not be exceeded.

Oil heater models

The myth about the hot surface of oil heaters is not true. The maximum is 80 degrees Celsius. Then there is an emergency shutdown with hysteresis (return on at 65 degrees Celsius).

Oil heater temperature control

We started with emergency modes for a reason. When repairing leaks, choosing cold welding, you need to know the temperature regime (operating conditions for a glued joint). Let's move on to the main characteristics of the oil heater. The heating element consists of two unequal branches: they are switched on together or separately. It will provide three temperature modes of operation, differing in heat transfer. Switching is provided by two buttons located at the top of the oil heater electronic unit.

There is a thermostat under the control panel. Does not control the emergency mode - it is represented by an adjustable bimetallic plate that sets the room temperature for heating with a heating element. The response temperature is not high, like the emergency one - 40 - 60 degrees Celsius, even lower. Due to the rotation of the screw, which changes the preload of the plate, the response temperature changes in the right direction:

- By pressing the buttons, we change the speed of heating the oil, heater, room.

- Twisting the thermostat, we achieve turning off the device at the right time.

Thermoregulators for infrared heaters

In recent years, heating devices using infrared radiation have become increasingly popular. Such heaters do not increase the temperature of the air, but of objects in their reach. For them, special designs of thermostats have been developed, somewhat different from the usual ones. Conventionally, they can be divided into two main categories - mechanical and programmable.

Mechanical

The mechanical thermostat will fit well into the interior of the room

Mechanical thermostats are produced by most companies involved in the production of products of this kind, but they all practically do not differ from each other, since their design is extremely simple and the difference can only be in the quality of the materials used for the manufacture. Almost all models of mechanical regulators are wall-mounted, separation is possible according to the principle of installation, into mortise and overhead devices, so that they can be connected to any type of wiring.

The standard temperature setting range that such regulators are able to support is in the range from +5 to + 30 degrees. In size, they are slightly larger than conventional sockets and switches, so they do not disturb the interior of the room. Mechanical regulators are controlled by a knob that sets the temperature level at which the heating system should start or stop its operation, as well as a button to turn the regulator on and off.

Programmable

If you are looking for maximum comfort, then you should definitely buy a programmable thermostat. Programmable thermostats are the most modern and easy-to-use types of devices of this type. They have a wider operating temperature range, which most often ranges from +5 to + 45 degrees, which makes their capabilities more flexible and somewhat expands the scope. Their main difference from all other types of regulators based on the mechanical principle of operation is the ability to set a complex heating program for several days or even weeks, depending on the model.

Moreover, for each day you can set a different sequence of changes and temperature control. They have two sensors for measuring temperature, one monitors the entire room, the second monitors the level of heating of the infrared devices themselves. In "smart home" systems, it is the programmable versions of thermostats that are used as the most convenient and comfortable.

The device can be programmed for hours, days and even weeks

When choosing a thermostat, you need to consider the following points:

- external climatic conditions;

- reliability of own thermal insulation of the room;

- the number of heating devices;

- types of heaters.

Several devices can be connected to all thermostats designed to work with infrared heating devices and systems, but their total power should not exceed 3-3.5 kW. If the total power of the heaters is higher than this value, then a magnetic starter must be built into the circuit, redistributing the load between the individual devices of the heating network.

All types of wall-mounted thermostats are installed at a height of about one and a half meters, in accordance with the rules for installing devices of this kind. The schemes for connecting them to the electrical network of the room are quite simple and do not fundamentally differ from the schemes for connecting sockets and switches, the main thing is to make sure that the cross section of the wires used matches the power of the heaters that they connect to the regulator.

In conclusion, we can say that installing thermostats on heating systems and heaters is a profitable and reasonable solution that will not only make life easier and more convenient, especially in regions with a cold climate, but will also help save on utilities without wasting electricity. It is also worth giving preference to well-known manufacturers, since the thermostat is always part of a complex system, and if it is of poor quality or defective, this can lead to an emergency in the room where it is installed.

When choosing a specific model, it is worth considering all the nuances of heating a room, starting from the number of heaters and ending with the power of each of them. If your own knowledge is not enough to calculate and select the desired model, you need to turn to electricians and heating specialists, and not choose the first one that comes across or seems to be the most suitable only at first glance.

Oil cooler device

Different models of heaters may have a different number of heating elements, thermostats and switching devices for connection and connection. They also have forced airflow systems to enhance convection and increase heat transfer.

The heating elements are housed in an oil-filled, sealed housing with ribs, covered with a durable dielectric powder coating. Switches are attached to the heater from the outside. All connections of heating devices and external control elements are connected through a hermetic coupling.

The oil heater circuit is designed as follows: a power cable with a plug is connected through switches and a thermal fuse to the heating elements. At the same time, the thermal fuse provides a break in the supply circuit in case of emergency overheating of the device. The latest models of oil heaters are also equipped with a position sensor that turns off the device in case of a fall or a critical deviation from the working condition.

What breaks in an oil heater

The tank is filled with heat-resistant oil by 85 - 90 percent. An air gap is left to compensate for the thermal expansion of the oil - the corresponding accordion case configuration is selected. When refueling, choose transformer oil - you can not mix varieties. Now we know the possible elements of a breakdown - we proceed to repair.

The situation of a leaky tank is familiar: it worked, it worked, it leaked. In the morning there was oil on the floor, the tank was empty, the appliance turned off, the thermal fuse burned out. It is worth using cold welding. FastFix for metal keeps temperatures from minus to +120 degrees Celsius. Take it out in the cold with care, patched, you can use it at home. FastFix for metal contains magnetic iron filings - the fastest setting material in the range. The master will have three minutes - in an hour the material will dry.

FastFix holds temperature, sold as a stick: a polymerizing compound of the epoxy class of adhesives. The resin outer shell protects the inner hardener. Cut off the composition of the pencil in the right amount, knead with wet hands, apply in place. After hardening, trim the result with emery, grinder, better with a wet knife until completely solidified. There are many breakdown points - do not forget to wear rubber gloves. Wet your hands before use.

Broken oil heater

The place of breakdown before applying the patch should be cleaned of paint, rust, oil. Sand with fine sandpaper for a firm grip. If the hole is on the channel of the section, try to leave a little room for oil flow

According to the manufacturer, the patches hold pressure (important for the master), or check with the manufacturer. There are many brands of liquid paint, choose your own

FastFix, which does not require thinning, smearing on plastic with a spatula, is a good choice.

Sometimes there is a need to independently repair an oil heater with a burned-out heating element. Breakdown identification: ring both branches with the switches off, the plug is pulled out of the socket. If the resistance is tens of ohms, the integrity of the core is in order. A short circuit or a break indicates: a breakdown is here. The heating element is rolled inward - you have to pull it out. The new one should be similar to the previous one. The tube used is steel, not copper, to avoid electrochemical corrosion.

Before dismantling, turn the oil heater on its side: the hole must be higher to save the oil. When replacing, use cold welding in place. Before installation, check the insulation resistance of the heating element. At least 20 MΩ figure (according to the rules, they are measured by a voltage driver of 500 V). One contact of the tester is connected to the spiral, the second to the body. The operation is done twice, one per branch.

Understood the repair of an oil heater that did not turn on. In the absence of voltage on the heating element, the following are to blame:

- Emergency or working thermostats.

- Thermal fuse.

- Switch.

In the latter case, there will be no voltage on the only branch of the heating element. Constant clicks during operation are emitted by a working thermostat on a bimetallic plate with an adjustable screw. If the oil heater works before the emergency shutdown, try looking here.

Electric oil heaters are common devices and have high reliability, but it happens that even such simple devices fail. In a situation where the heater does not turn on or heats poorly, you need to check for a warranty card. If the warranty is valid, it should be taken to a service center. But it often happens that there is no such possibility, and the repair of the oil heater will have to be done by hand. In this case, it is necessary to consider the possible causes of breakdowns and find out how to eliminate them.