Step by step recipes for baking bread

There are many nuances that allow you to make the bread soft and airy inside, while having a golden crisp on the outside.

Starter preparation

Sourdough is considered to be a small piece of dough left over from a previous cooking. It contains bread bacteria that contribute to the active process of dough fermentation. The leaven is stored in a clay pot in a cool place. When there is a need to use it, the pot is placed in a warm place.

The starter is poured with warm water, stirred with a wooden stick until a homogeneous consistency. From above, the pot is dug up with rags and allowed to stand for about an hour in warmth. During this time, the dough will increase in size by 3-4 times, after which flour is poured, mixed well and the dough is sent to infuse for another 7-8 hours in heat.

If the starter has stopped bubbling, does not increase in size and emits an unpleasant odor, then it is not suitable for making bread.

Recipe for baking rye bread in a Russian oven

After the dough comes up, well-sifted flour and spices are added to it. Caraway seeds, sunflower seeds, sesame seeds, pumpkin seeds go well with rye bread. Knead a stiff dough, gradually mixing in the flour. This is best done on a wooden surface sprinkled with flour.

The prepared dough is laid out in molds. Each form is covered with a clean rag and sent to the back of the oven so that the dough disperses. After 1.5 hours, the dough will increase several times in size.

With the help of a shovel or a mold holder, the dough is sent to the oven. The barrier is closed and after 2 hours fragrant and tasty bread will appear on the table.

Important! Salt, sugar and other spices are recommended to be added in the process of kneading the dough, and not when preparing the sourdough. So that the top of the bread does not burn, it is smeared with vegetable oil or egg yolk, beaten with salt.

Rye bread from a Russian oven

Rye bread from a Russian oven

In the absence of forms, bread can be baked directly on the inner stone surface of the Russian oven. However, such a product will be flatter. The form allows the dough to rise upwards, while the form of hand-made bread depends entirely on the skills of the baker.

In ancient times, the exact dosages of ingredients were practically not used. They took as much flour as the dough would “take”, and the consistency of the leaven was determined by the density of sour cream.

Baking wheat bread

For making bread from wheat flour, it is recommended to use live yeast, which will reduce the time it takes to make bread. You will need to dilute them in a small amount of warm water, add a little sugar and flour. Using a spoon, knead the batter like for pancakes and let it stand warm for 2 hours.

When the dough has approached and noticeably increased in size, 2-3 parts of the prepared flour are introduced and the dough is well kneaded. It should be thick and elastic enough, easy to move away from the hands. Well-kneaded dough is laid out in pre-oiled forms, covered with rags and cleaned in heat for another 2 hours.

The dough should fill the form by 1/3, since during its increase in size, it can easily leave the borders of the form. The top of the dough is smeared with vegetable oil, which prevents cracking of the bread.

After the dough has risen, it is placed in the oven for 1 hour, closing the barrier. After the bread is ready, take out the form with bread and put it in a warm place for slow cooling. Only after that the finished product is taken out of the mold.

Cladding and design

The outer frame of the furnace was assembled from a metal profile 20 * 40, and sheathed with GVL for further lining. The cladding was made with antique Spanish clinker tiles.

Bakery oven doors are almost impossible to buy.There is a certain German company where you can buy a door for a bread machine, but its price will be comparable to the rest of the costs for the oven. Therefore, the doors were made on the spot. The opening principle is the same as for fireplace guillotine cassettes. Counterweights, equal in weight to the mass of the door, facilitate lifting and make it possible to fix the door in any position. Opening and closing can be done with one finger. Insulation of doors with vermiculite from the inside protects ferrous metal from excessive thermal loads. During the heating of the baking oven, such doors, of course, heat up, but it is no longer possible to burn yourself on them.

Immediately behind the doors there is an opening hatch for dumping ash into the box.

The doors are riveted and made in the style steam punk . In general, the stove is made in the style loft, under the general concept of the future decoration of the bakery.

After the opening of the bakery, the next post about delicious and healthy bread from our oven awaits you.

Subscribe, put likes. Mstislav Izotov was with you, see you).

DIY construction

Given the above requirements, manufacturers will improve designs, highlighting the most priority areas in them. You can become the owner of a bread machine not only by purchasing a finished model, but also by using a self-built brick structure.

It is almost impossible to make a gas oven, since any manipulations with gas equipment are fraught with an explosion or fire. All work must be coordinated with the supervisory services, so the easiest way is to build a wood-burning stove. It will have distinctive external features, due to which the temperature in the chamber will reach the required values.

The easiest way is to make an outdoor oven, as this requires a minimum of material and skill. At the first stage, a foundation should be erected, if a ready-made concrete slab is available, then it will fit perfectly as a base. Otherwise, you will have to fill a shallow foundation.

A brick base is laid out on top of the foundation, on which an arched entrance to the firebox is erected. It will be easier to make such an opening if you use a wooden template on which the bricks rest.

The spherical shape of the camera is elementary. A heap of sand is poured on the base, which is shaped into a hemisphere. From above, the sand is covered with wet newspapers, on top of which clay is applied. In order to better retain heat inside the chamber, thermal insulation can be made in the form of a layer of sawdust, which is again covered with clay. After the material has completely solidified, sand and newspaper should be removed from the firebox.

The resulting structure is quite fragile and requires careful handling. If you have a full-fledged foundation, instead of the inner layer of clay, you can use brickwork. Then the built oven for bread with your own hands will be very reliable. Note that pizza ovens are built using a similar technology.

But the example we have considered demonstrates the simplest construction. An important element in any model of a brick wood-burning oven for baking is a spherical dome. It is he who allows you to reach high temperatures. Radiation is repeatedly reflected from the walls of the vault and is not scattered in space, but is focused inside the chamber.

The disadvantage of such a simplified model is the lack of temperature control and the absence of a humidity control system. Ovens for baking large batches of bread have a complex device with the introduction of the necessary technologies and are comparable in size to a small house.

Dimensions

Baking ovens may vary in size and capacity. In this case, the choice should be guided primarily by their own financial capabilities, as well as the expected production volumes. Large ovens can produce up to one and a half tons of products per day. But, of course, they are quite expensive.So, for a large stove of domestic production, you will have to pay about 600 thousand rubles, German - 30 thousand euros.

A much more reasonable solution would be to install mini-equipment in the bakery at first. Finding, for example, a suitable stove for 500-2000 dollars of labor in our time will not be.

Showcases, racks, trays

When choosing a showcase, first of all, you need to pay attention to its capacity. You should also ask if it has heating or not.

When buying a freezer, you should decide on the required volume. The form of this equipment may be different. There are cameras in the form of a cabinet, cabinet or chest. In this case, the choice will depend on the layout of the bakery.

When buying additional baking sheets, you should, of course, take into account the size of the oven. The cheapest equipment is this type, made of stainless steel. Aluminum pans are more expensive.

Thus, when choosing equipment for a bakery, you should pay attention primarily to its design, brand and price. At first, it is worth buying models that are not too expensive and functional.

This will help to cut costs significantly. Later it will be possible to buy more modern and expensive equipment, perhaps even imported.

First steps

Almost all "professionals" are advised to start their business by registering and finding premises for a bakery. Forget about it. At best, your bakery will pay off for at least six months, at worst, you will go bankrupt.

Strange as it may sound, but you should start a baking business by looking for points of sale for finished products. If you manage to find and stake out a place with good traffic, you have already done half the work. Such outlets can be the following objects:

- Passing place in the market. It is desirable that it be located near the exit.

- Place (2x2 m) in a grocery store. It is better that the grocery store is not large (pay less rent), but located in a passing place.

- Point(s) in municipal offices and factories.

After you have agreed on a lease with the management of an enterprise or institution, you can start organizing bakery production.

The structure of baking ovens

- Working chamber. The volume of the chamber is of great importance for the baking device. The larger its size, the greater your opportunities. In the chamber, under the influence of high temperatures, the dough turns into ready-made bread. Before cooking, the oven chamber must be warmed up well to get good bread.

- A heating element. It is a special tube that is located under the very bottom of the bowl and covers the entire area intended for baking.

- Observation window. Necessary in order to observe and control the process of baking products.

- Work regulation system. Most modern hearths are equipped with sound signals that allow you to control the baking process more timely.

- Furnace conveyor. It is a device in the furnace, which serves to transport products.

- Steam humidifier. They contain steam headers with perforated pipes, which reduce the amount of scrap and improve product quality by eliminating condensate.

Basically, all bread machines are similar to each other, but different functions are laid inside the device. Therefore, before purchasing an electric mini bread oven for the home, you should first familiarize yourself with its individual features.

Bread oven manufacturers

After getting acquainted with the types of furnaces, their capabilities and operation, they proceed to the choice of the manufacturer.

The market for design developers is very wide, each of them tries to sell their product as profitably as possible, offering a wide variety of instrument functions.

But the suppliers below have managed to conquer the market due to the high quality and low energy consumption of the equipment:

- ASTerm is the most famous oven manufacturer in Europe. Devices differ in a ratio of low price and quality. Often used for baking pizza because of their dome type. The most powerful device of this company is capable of producing up to 195 products per hour.

- WERZ furnaces belong to the ecological class. With the 12 valve system, the baking speed is increased by 50%, which is a significant advantage.

- Apach products are equipped with mechanical control panels, which facilitates the operation process. They are renowned for their versatility and compact design. A great option designed for small bakeries or pastry shops.

- CASTELLI FORNI has been offering a wide range of modern Italian stoves for 35 years. Assembly of structures is carried out at one enterprise.

- Amborgi stoves came from the distant 1939. The manufacturer has preserved past traditions and modern technologies. Designs are made of special refractory materials. Used for pizzerias and restaurants.

Photo 4. Baking oven of the MEC 80 series from the manufacturer Amborgi with a dome made of vibro-compacted fireclay material.

- Ukrtechnofoods company. Equipment is most often found in large industries. The products of this manufacturer are intended both for the creation of confectionery products (puffs, cookies, bagels), and bakery products (lavash, tortillas).

The idea of outdoor baking in a wood-fired oven is a special romance. Famous natural builder Ziggy shares with us the secrets of building this budget-friendly clay oven.

Foundation.

Cinder blocks, some stones and empty bottles went to the foundation to create a work surface at a height of about 80 cm.

Refractory layer

Clay kiln dimensions

Creating an opening

Then we chose the sand from there and got such an opening.

Dome insulation

Which brick to choose

The quality of a bread oven largely depends on the materials used for the job. All types of bricks differ in their characteristics, which are taken into account when laying

It is important to purchase materials taking into account the battle, the reserve volume is about 5-7%. The main types of bricks that are used in construction are listed in the table:

| Name | Characteristic | Application in furnace construction |

| lode | The goods differ in quality, the correct forms of products and a wide palette of colors | Used for laying out the outer part |

| Vitebsk | Has smooth edges and conformity to the sizes | It is laid during the construction of furnaces on a thin seam |

| Trubny | Before using this material, it is recommended to pre-soak in water | Used for building the surface of chimneys |

| Resistant to internal and external factors | ||

| Facing | Differs in ease, which is especially important when lifting material to the roof of a building | Most often used for laying pipes above the level of the roof roof |

Classification

Baking requires a special type of oven with a bread chamber. Despite the same principle of making bread, ovens differ to a large extent from each other in a number of ways.

- According to the method of heating the surface of the furnace are divided into two types. With direct heat transfer, they are characterized by the fact that the surface is heated by the action of a flame. This type includes a baking oven on wood or on gas. Furnaces with indirect return use a certain medium as a heat carrier. Examples are electric ovens, convection ovens, oil ovens.

- Classification according to the type of thermal channel implies the existence of furnaces made of materials of high heat capacity and low heat capacity. The first type includes brick structures, and the second - mechanical.

In the distribution by type of fuel used, 4 groups are formed. Electric ovens are made in the form of compact devices in which 1-2 loaves of bread can be baked. Typically, such an oven is small and located in the kitchen in a house or apartment. Oil-fired ovens operate on a more global scale, they are massive and allow bread to be baked in large batches. This is a great option for small businesses. Wood or gas structures can act as an extension to the stove or fireplace, as well as as a separate unit.

According to the method of placing products in the chamber, each model can also be attributed to one of the groups. The storey method of placement is represented by several shelves located in the chamber at a certain height. In order for the bread to be baked throughout the entire volume without the formation of burnt areas, pallets located on different floors have to be interchanged. Tunnel models do not make it possible to move bread to zones with different temperatures, but they allow you to bake products in huge batches. Such specimens can be found at plants that meet the needs of an entire district of the city. The rotary type of ovens rotates pallets around a vertical axis. In the horizontal plane in the chamber, the heating temperature is slightly different, so this rotation ensures baking uniformity. The cradle oven is represented by pallets that can be moved vertically. Peculiar cradles allow you to place pastries in a zone with a higher or lower temperature, at the discretion of the technologist.

Hearth insulation

The crucible of the furnace is insulated from all sides, including from below. We use foam glass to insulate the hearth. This material is inert and resistant to high temperatures, but not fire resistant. Two rows of bricks are laid over the foam glass.

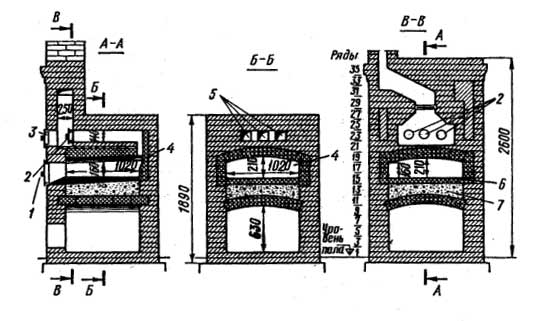

The working size of the hearth is 1.4x1.4m (2 m2) in each oven. From one heating, you can make 3-4 plantings of 36 loaves. for the continuity of the process, while one oven bakes bread, the second is heated.

Furnace furnaces are made of fireclay bricks from the Borovichi factory. The hearth, tuck and vault are made of sha-8, and the walls, to facilitate construction, are made of fireclay slabs sha-94. The side walls are almost not involved in baking, and the difference in thickness in this case is not very important. The main thing is to observe the equality of the thickness of the hearth and arch, for uniform heating of the baked product. Otherwise, one side of the bread may burn, while the other side will not be baked yet.The hearth has two rows: the first leveling, on which the frame is installed, is an essential element for baking ovens. Without it, such a furnace cannot be assembled, since the gentle vault strongly presses on the side walls and, without a frame, will push them apart and the vault will collapse.

Wood burning brick oven

Bread is a food product that has an incredibly long history, and each part of the world has its own recipe for baking it. Despite the peculiarities of dough preparation, baking, as well as the wide variety of modern ovens, it is the brick oven that remains the oldest device on which people in all parts of the world and at all times could create fragrant pastries.

- With the advent of stoves with ovens, many have stopped cooking in brick ovens. They took up too much space, and in a modern apartment its use is completely prohibited for safety reasons.

- Despite the great commitment of people to modern electrical appliances, many still prefer to install a good old brick structure in their yard, gazebo, or country house.

- This is explained quite simply, because baking created by mechanisms will never be able to surpass bread cooked in a wood-burning oven in terms of its taste characteristics.

Historical references

A brick oven, when it comes to conversation, everyone associates with ancient times. Such associations arise for a reason, since it was precisely such designs that served as an important kitchen appliance even among our distant ancestors.

- From the moment when people learned to grind cereals, and later use them as flour, it became necessary to use fire in the preparation of flour products.

- Scientists still do not know exactly when and how a person prepared bread. But it is obvious that subsequently such products were created on hot stones, and were cakes.

- According to the results of the study of the found remains of ancient cakes, it can be said with confidence that a person learned to bake more than 8 thousand years ago.

The ancient Egyptians learned how to make bread through fermentation. After that, this tradition was passed on to other peoples, and the cakes familiar to everyone took on a new form.

Thanks to such advanced civilizations as Egypt, Greece, the Roman Empire, stoves also began to change dramatically, and acquired a completely new look.

It was far from profitable and convenient for everyone to have a large stone structure in their house, therefore, bakeries began to meet more and more often, in which residents of large and small cities turned to buy fresh pastries.

And yet, everyone who wanted to cook delicious bread according to his own recipe strove to build brick stoves in his house. At the moment, such a structure cannot be called a necessity, but many people strive to build such an oven in their yard or in a country house in order to always enjoy hot goodies, regardless of weather conditions.

Features and Benefits

A do-it-yourself brick stove is very tempting. Many men think about this in order to please their ladies, and add one more reason to go out of town.

The modern technology market offers a huge range of ready-made bread ovens, but they are electric, and therefore directly dependent on the availability of power. Outside the city, the best device for baking will be a self-made pompeika or tonir.

The main advantages of such a device include the following characteristics:

- Fast warm-up saves a lot of time. Baking is quick and hassle-free.

- A properly designed fixture guarantees uniform baking of products of any shape.

- In addition to lean bread, you can cook pies with filling. Both vegetable and meat fillings are perfectly baked.

- Just one kindling is enough for long-term use of the stove.

- The furnace works in any conditions and at any temperatures.

- Ease of design and calculations.

- Inexpensive building materials. The price of a finished brick structure is much less than the price of electric ovens.

- Long service life.

Mini bakeries for baking bread

The oven is the most expensive equipment for a bakery and its cost varies greatly, depending on the capacity, quality and brand.

In general, prices vary greatly. Ovens come in many types, but the most popular for mini bread bakeries are rotary and deck ovens.

Ovens for mini bakeries

The most famous brands of mini-bakery equipment are German brands, such as Miwe, Winkler, WernerPfleiderer. A very good reputation among French mini-bakery equipment manufacturers.

Although there are very small ovens that produce a small amount of products, they can be bought for 500-2000 dollars.

Other mini bakery equipment

Approximate prices and characteristics for other equipment:

Dough mixer, used for kneading dough, $400 and up.

A boring cabinet, which is needed so that the dough is in it under a certain percentage of humidity and temperature.

This is done to improve the characteristics of the dough, its loosening due to the release of carbon dioxide. The dough, in simple terms, is suitable (the cost is 40 thousand rubles or more, depending on the brand).

Dough sheeter MRT-60M

A table for cutting dough, needed for cutting already rolled dough into pieces of various shapes, from 40 thousand rubles, a baking trolley - bread is placed on it in tiers in the oven, usually there are 15-18 tiers, it costs about 12 thousand rubles.

Flour sifter, used for thorough loosening, sifting and removing foreign particles from flour, bakery products, so they turn out more magnificent and tasty, costs about 15 thousand rubles. The dough sheeter is used for accurate, constant uniform rolling of dough (20-30 thousand rubles).

If you have funds, you can additionally purchase a dough-forming machine for forming dough pieces (about 30-60 thousand rubles), a rounder - quickly and accurately cuts the dough and rounds into shapes (from 100 thousand rubles), various trays, baking sheets, forms, scales.

The cost of equipment for a full cycle of work is much higher than the cost of equipment for a partial cycle. With an incomplete baking cycle, dough kneading is excluded. Therefore, the cost is much lower. With an incomplete cycle, you only need a bread machine, a freezer (about 15 thousand rubles) and a showcase for goods (about 30 thousand rubles).

You can buy all the equipment not only new, but also used to optimize costs, but of course you should look at the expiration date and condition of the used equipment.

Production technology in a confectionery mini-bakery

For production, you will need raw materials: this, of course, is flour, yeast, as well as sugar, salt, vegetable oil, margarine, various additives and flavorings.

The main aspect that you should keep in mind is that flour is a product with a very short shelf life and you should always buy it in small batches for baking.

Therefore, suppliers need to be looked for that meet these criteria.

The workflow goes like this. The most important person, on whom the quality of your products and, accordingly, profit, will depend, is the technologist.

Therefore, approach the choice of a technologist with responsibility. You will also need a cashier, a cleaner, and a baker.

Depending on the size of production, the number of people can increase. You will also need an accountant or you can use outsourcing services if your volumes are small and it is expensive to keep a person in a separate position.

Ovens baking gas firms Voskhod, Russia

Here the scale is already different - gas baking equipment is a rotary oven - a cabinet-sized structure into which a cart with baking sheets is rolled, on which dough blanks are laid out. During the heat treatment of products, the trolley rotates around its axis to achieve evenly baked products. So, the gas furnace "Musson-Rotor 55-01". Her characteristic:

- the ability to simultaneously bake 90 loaves in the form of L7, or 108 loaves, or 250 buns;

- 18 working levels 600 x 450mm in size;

- temperature range - from 100 to 300 °C;

- rated power - 2.4 kW;

- 101 baking programs;

- digital control;

- visualization of forward and reverse timer;

- display of the current situation in text and graphic form.

Such equipment costs today about 620,000 rubles. And about 10% of the cost will have to be paid to the representatives of the Saratov plant for the initial launch - otherwise they will be exempt from warranty obligations. Indeed, this is not a HPE bakery oven for you.

masonry stages

Foundation and order

The bell-type bread oven is built on a solid foundation so that in the future the structure does not warp or crack. The parameters of the depth, width and length of the base of the building depend, first of all, on the size of the future furnace. It is better to lay the foundation during the construction of the building, otherwise the complexity of the construction work increases several times. Construction stages:

A pit is dug, into which crushed stone and sand are poured, after tamping the mixture, cement mortar is poured.

Next, laying is carried out, all rows should be as even as possible, any deviations are leveled using the building level

Only solid bricks are used.

At this stage, it is important not to miss the moment with the dressing of the sutures. To protect the destruction of the structure by groundwater, a layer of roofing material is preliminarily laid until it dries completely, only after that brick ordering is performed.

Furnace design

- The walls are laid out with various types of bricks (silicate or clay), light blocks of concrete.

- The lower part of the firewood compartment and parts of the ash pan are mainly laid out from concrete blocks, while you should not forget that the ash pan itself needs to be re-filled with mortar and reinforced.

- The inner surface of the firebox is made of refractory material that can withstand high temperatures.

- Upon completion of the installation of the ash pan of the oven, they proceed to the formation of a cooking chamber for baking bread products.

- When the chamber is formed, they begin to fix the door and raise the blockwork to the upper level.

- If the masonry is completed and the concrete has dried out, work begins on the plastering of the outer walls.

- After completing the work, be patient and dry the Kuznetsov oven. Drying time - up to 2 weeks.

Chimney installation

Different types of ovens for baking bread are equipped with a chimney. This design has a number of advantages, including the fact that smoke freely exits the furnace through the chimney and does not enter the room.

Before starting work, it is important to carefully study the chimney construction scheme and build a rectangular foundation, which is formed from reinforcement or solid brick. The chimney itself is laid out of refractory red brick

The seams are important to form thin to ensure the strength of the structure.The walls are laid out evenly, and the corners remain straight.

Conclusion

The construction of such a furnace is not a quick matter, it requires considerable effort. However, lovers of fresh homemade pastries are ready to work hard and build such an oven. In addition, the design of such an original form can become a real decoration of the local area.

There is an opinion that the oven can successfully replace the wood stove. By wood-fired oven, I mean either a universal Russian oven or a Mediterranean-style culinary domed oven. This is the same as saying that a microwave oven can successfully replace an oven. Bread from a wood-fired oven is substantially better than from an oven or gas oven, for the same reasons pizza is. Soft, but powerful, infrared radiation from the mass of the oven allows the loaf or loaf to greatly increase in volume, starch caramelization to develop throughout the volume, both inside the crumb and on the crust. Another plus is that baking is much faster.

Method of preparation Dissolve yeast in warm water, add salt and sugar, mix. Sift flour into yeast mixture. Add sunflower oil. Knead an elastic, soft dough. Cover the dough with a paper towel and leave for one hour in a warm place. After an hour, knead the dough again, divide it into 2 parts, form balls from it and leave it in a warm place to rise again Put the balls on a floured shovel, make shallow cuts, and place in a preheated oven directly on the bottom (floor of the oven), which was previously cleaned of ashes with a brush. Read more about oven preparation below. Bake the bread for about 1 hour, checking doneness by the color of the crust. You can pierce the loaf with a wooden torch or a kebab skewer, making sure that there is no dough left on it, or tap its nieu with your fingers to hear an empty sound. Bon Appetit!

How to prepare an oven What is the difference between an oven and an oven? In the power of thermal radiation and its distribution in space. If we open the oven door to slowly put chicken or bread in there, the temperature inside will drop by 20-30 degrees, and then the oven will raise it to its previous level for 5-10 minutes, because it has cooled down, and because the product we put cold. The stove will not even notice this manipulation, its heat capacity (accumulated heat) is more than 100 times: the heated elements in the oven weigh 2-3 kg, while even in the smallest and lightest wood-burning stove, heated bricks or clay weigh 200-300 kg. At the same time, only the floor and ceiling actively radiate in the oven, because only behind them are heating elements, and in the oven there are also walls. Thus, the product in the culinary oven is immediately and from all sides exposed to powerful heat, while in the oven it is much slower and partially - there is not enough power. And we are not yet talking about the special aroma of wood-fired food, and we are not yet talking about the fact that for an oven 250 degrees is the ceiling, and for an oven even 400 is quite normal. Why such temperatures? Well, for example, pizza - it needs to be baked on the verge of burning, at 350 degrees, which oven will give it?

Whatever you say, baking bread in the oven takes practice. But you have to get up and do it. In the meantime, an important tip about humidity. It is very important for the formation of a crispy crust, caramelization, and the ability of bread to increase significantly in volume. In a dry atmosphere, the surface of the loaf quickly seizes with a crust, which prevents the development of the crumb in volume. Water vapor helps prevent this. To create steam (humidity) in a wood-burning stove, light a fire in it for at least an hour, bringing the temperature of the vault and hearth to 430 degrees, at which the entire inner surface of the stove will be cleaned of soot. Then completely remove the coals, sweep out the ashes, and leave the oven alone for about an hour, just about the time when the dough that you had in the refrigerator will warm up to room temperature.Depending on the type of bread you are going to bake, the temperature should drop to the range of 230-290 degrees. Wipe under a damp, but not wet, towel. Now you need to either put a baking sheet with wet rags in the oven, or spray it well with mist from a conventional spray bottle. If the oven is hot and you want a lot of steam, do both. Bread should be loaded when steam is visible in the oven. When the bread is loaded, you need to sprinkle water again, not on the bread, but on the roof of the oven. And again, you should be able to see the steam inside. Remember, without steam, the crisp will not turn out the way it should be, as the caramelization will be underdeveloped.

To keep the steam in the oven, it is important to keep the door closed. If you have a pizza oven and you use a damper, you need to lean it tightly against the muzzle, you can even press it with a brick