5 Manifold system the best choice for large areas

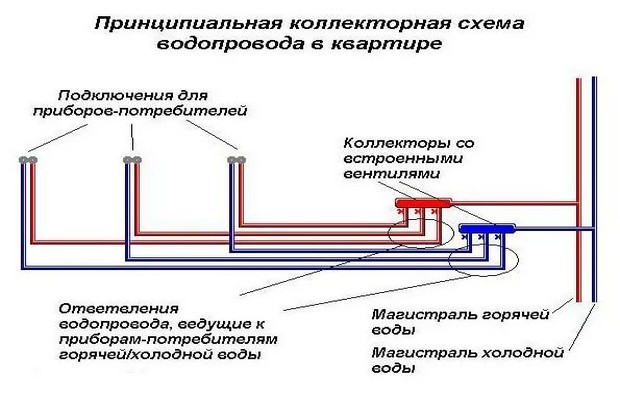

For large apartments with a large number of plumbing fixtures, a collector wiring diagram for plumbing is most suitable. This wiring is the best option for systems with variable pressure. It makes it possible to ensure an uninterrupted supply of water with the ability to control the strength of the flow and turn off some branches in case of repair work. A feature of the collector circuit is the presence of a collector. From the common riser, water first enters a special container, and then is distributed to individual branches. The capacity of the collector depends on the volume of the tank and the diameter of the inlet pipe. Each appliance or bathroom has a separate supply, equipped with a control valve, thanks to which you can turn off the water supply.

For the manufacture of collectors, stainless steel, brass, polypropylene, polyethylene and other materials are used. When choosing a collector, you should consider the method of installation. Metal products have a traditional threaded connection. The cost of collector-type water supply is higher, but the system is reliable, convenient and provides uniform distribution of water. The pressure does not depend on the distance at which the consumer is located, and the number of devices.

The advantage of the collector circuit is the ability to turn off one device for repairs without shutting off the general water supply. This allows you to personalize the characteristics of an individual device. Between the collector and the sanitary device, you can install filters, rectors, which allow you to purify water, saturate it with useful substances. The installation of control devices makes it possible to reduce or increase the flow of water.

Collector wiring diagram

The disadvantage of the collector circuit is the high cost of investment for its creation. It will take more appliances, fittings, taps and pipes than for a tee wiring. The connection begins with the installation of a collector for cold and separately for hot water, if centralized water supply is provided. You need to choose the right place. Stopcocks should be installed between the collectors and the central riser to completely shut off hot or cold water if necessary.

After installing the collectors, piping is carried out to each device and bathroom. Both hot and cold water are supplied to the bathroom, washbasin and shower. Only cold water is supplied to the automatic washing machine and the toilet bowl. Hot water is connected to the heated towel rail. Some plumbing systems use combined wiring diagrams. Branches with a serial connection have the disadvantages of a tee system, but the combined scheme makes it possible to save on the installation of a water supply system and optimally design a piping scheme in residential premises.

1 Why you need to change the plumbing main reasons

Consider the main reasons why the plumbing system is changing. Steel pipes are installed in old communications, on which deposits, sand, scale and other contaminants accumulate inside. Over time, they become clogged, their patency is disturbed, traffic jams occur, so they need to be replaced. You can get by with less losses if you regularly clean the pipes with a steel cable. But you can completely get rid of the problem only by completely replacing the water supply.

One reason for replacement is leakage. It occurs when using products of a suture type. You can fix the leak by welding. But this is a temporary way out of the situation, over time it is better to replace the pipeline.The unaesthetic appearance of old pipes (peeling paint, traces of rust) also requires their replacement with modern plastic counterparts that fit well into the interior. During a major overhaul, all communications are usually updated: plumbing, sewerage, heating. Replacing the plumbing may be necessary if the wiring was incorrectly done.

3 Taps for water supply which to choose

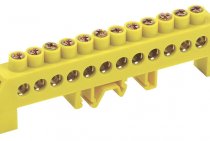

The plumbing system includes not only pipes, but also fittings, water taps, meters and mixing devices. The main purpose of the cranes is to block the movement of the carrier through the pipes. It is possible to install a valve at the entrance to the main, but in this case, during the repair, it will not be possible to use the entire pipeline. It is more expedient to install taps on logical branches or on separate bathrooms, which will make it possible to turn off the water at any time in a certain segment.

Any faucet consists of a body, a valve, seals and a locking element. Cranes differ in the type of locking mechanism. It can be spherical or in the form of a valve. In a ball valve, water can only flow in one direction, if the valve is turned, the flow is completely blocked. In the ball mechanism, it is undesirable to install the valve in an intermediate position, as it wears out quickly. The faucet can be either open or closed. It is better to choose a product with a handle in the form of a butterfly. The handle-lever can break at the most inopportune moment.

According to their functional purpose, cranes are divided into the following types:

- standard;

- corner;

- tees;

- water-folding mechanisms and valves.

Standard shut-off valves use a ball mechanism, so they serve to shut off water in certain sectors. They include straight fittings. Angle faucets differ from standard ones in that their body is bent at a right angle. The tee has three outlets, serves to redirect the flow of water. Water folding mechanisms are valves with a regulator valve that are installed on pipes to control the flow force. For metal pipes, you need to select taps made of metal, for plastic - from plastic.

Which ball valves are the best

So, in a store or in the market, you were offered several ball valves to choose from. Do not rush to buy what is more expensive, because a high price does not always indicate the quality of the product. The best ball valve can be selected according to the following characteristics:

Manufacturing material. Modern faucets are most often made of brass. However, you may come across a fake from silumin. It is cheap and usually of poor quality. It is an order of magnitude lighter than brass, so a fake is most often determined by weight.

Appearance

When buying, be sure to pay attention to the locking element. Quality ball shines and looks smooth

At the same time, a fake often has a dull sheen, fairly noticeable defects and even a matte finish. However, even if outwardly the crane looks decent, this does not mean that it is the best. Take an ordinary magnet and check the faucet. Often the ball is made of steel, which quickly rusts in a humid environment. The magnet will tell you exactly what material you are dealing with.

Maximum allowable pressure . The best ball valve is a valve with a high allowable pressure. For cold water, this figure is 10 kg / cm 2, for hot - from 20 kg / cm 2. However, experts always advise buying valves with a large allowable pressure. This will help to avoid problems that often occur with strong water hammer.

6 Do-it-yourself new plumbing installation instructions

Before installation, the design of the piping should be carried out. The project can be conditionally divided into three stages: drawing up a wiring diagram, determining connection points, calculating the amount of materials needed. Immediately you need to decide on the method of laying pipes: open or closed.

The diagram should indicate:

- how the pipes will be laid, indicating the turns, diameter and length of the pipes;

- entry points;

- places for connecting devices and assemblies;

- the dimensions of the premises and appliances to which water will be supplied;

- number, size and type of fittings to be installed, etc.

Metal-plastic pipe connections

Connection points are places where water supply is needed: a faucet in the kitchen, a faucet and a shower in the bathroom, a toilet bowl. If there is a washing machine and dishwasher, they should also be connected to the water supply. According to the scheme, you need to accurately calculate the amount of materials needed. The dismantling of the old system should be carried out after drawing up the scheme and purchasing all the necessary materials. Next, we proceed to the installation of the plumbing.

- 1. Before starting work, we turn off the water, dismantle the old riser and install a stopcock on it. We open the water supply through the riser to the neighbors and begin the installation of the water pipe inside the apartment.

- 2. To improve the quality of water coming from the central water supply, we install a coarse filter at the beginning of the system. After the filter there are water meters. For each type of water - a separate meter.

- 3. If necessary, install a fine filter after the counter. We equip the main line with a water reducer if the pressure in the line exceeds the norm. The reducer must be equipped with a pressure gauge, according to which the value in atmospheres is set.

- 4. Then we install either a manifold with the required number of outlets, or a tee if a serial wiring diagram is used.

- 5. Next, the pipes are laid out and the devices are connected according to the diagram.

Connections of metal-plastic pipes are carried out in two ways: press connections and pressure fittings. The second method cannot be used for hidden pipe laying. When using the method of compression fittings, first cut off the pipe of the desired size. We remove the chamfer from the pipe with a chamfer calibrator. We take a nut from the fitting kit and put it on the pipe, and then insert the ring, fitting and crimp it with open-end wrenches. This connection is of the open-end type, which means that leaks are possible, so once a year the connections must be checked for leaks and tightened if necessary.

We also start connecting with press fittings with the preparation of pipes of the desired size. Then we perform calibration. Next, we insert the pipe into the fitting and press it with a hand press. This connection is strong, withstanding sudden changes in temperature, but it is not separable. If polypropylene pipes are used for water supply, then pipes with a diameter of 25 mm and a wall thickness of 2.8 mm are taken for cold water, and pipes with reinforcement of the same diameter and a wall thickness of 3.2 mm are taken for hot water. Holding the special scissors at a right angle, we cut the pipes of the required length. At the ends of the pipes, we mark the depth of welding, depending on the depth of the fitting. Using a trimmer, we remove the middle layer of the pipe to a depth of 1–2 mm.

Turning on the welding machine, we start welding. We connect the pipes or fitting and the pipe, and then push them onto the nozzles of the welding machine. After seven seconds, we remove the pipes from the apparatus. Next, carefully connect the pipes without rotational movements. You need to act quickly and accurately. Keep the pipes connected until they cool. After installation, you need to check the quality of the connections, the operability of the system, the correct connection of devices and components. After checking the strength of pipes and connections with high pressure, water can be connected.

2 How to find the right pipes steel, stainless steel or polypropylene

An important stage in the construction of a water supply system is the choice of pipes. For plumbing, they can be metal or from various polymeric materials. Products differ in their characteristics and cost, which affects their choice. One of the old options is galvanized steel pipes. Their main qualities: strength and resistance to mechanical stress.Service life exceeds 25 years. The disadvantages of metal products are instability to corrosive processes, the appearance of growths inside pipes, which makes it difficult for water to move and reduces its quality. In addition, mounting difficulties arise due to the need for threading and twisting with each other. This work requires great precision, compliance with dimensions to the millimeter.

Stainless steel pipes are not afraid of corrosion. Their service life exceeds 50 years. The advantage is the high assembly speed, good maintainability. The disadvantage is the high cost of products and fittings. Most often they are used as heated towel rails. A universal version of the pipeline is copper pipes. They are not afraid of corrosion, ultraviolet, durable, smooth, able to withstand high pressure, not afraid of impurities. They have the longest service life - up to 70 years. But the cost of copper analogues is the highest.

Stainless steel pipes are not afraid of corrosion

The lowest cost is for metal-plastic pipes, the price of fittings is in the middle price category. The service life is 20-30 years. Metal-plastic is easily bent, mounted, does not rust, deposits do not accumulate on the walls. Disadvantages: places with fittings cannot be bent, they do not tolerate high temperatures. Polypropylene pipes are becoming increasingly popular due to the following advantages:

- affordable cost;

- the ability to hide in the wall, as they do not require regular checks;

- high strength;

- universality;

- durability - the service life exceeds 50 years.

Marking

Ball valves for heating systems have a digital and letter designation:

- KSh - ball valve.

- Letter designations: M (coupling), F (flange), Sh (fitting), P (through).

- Letter designation: E (electric drive), Pn (pneumatic drive), if there is no designation - manual control.

- DN XXX is the diameter of the passage. For example, DN 1 (1/2) in.

- PN XXX - working pressure.

- XX - characterizes the model in terms of resistance to the working and environment.

After reading the marking, you can easily choose the required option.

When buying, you should pay attention to the following indicators:

- Passage diameter. The peculiarity lies in the fact that on the cranes there is a designation of the internal size. If the parameter is 1 (1/2) inch, then a pipe with a passage of 40 mm or an outer diameter of 46 mm will fit it.

- Operating pressure. For heating systems, a parameter with a margin is always selected. Recommended value from 20 bar.

- Manufacturer. It is recommended to give preference to Russian or European manufacturers. Chinese production uses silumin for such devices, which is not reliable and resistant to aggressive environments.

- Body material. Brass products are considered the most reliable. They are recommended for heating systems. There are many fakes on the market, so you should request a product certificate. And also to study the appearance of the product. If it has sagging and other visible defects, this should alert.

- In the inner space, consider the locking ball. If it has a smooth mirror surface without defects, then this is a guarantee of a long service life.

- Price. Ball valves for heating, the price of which is much lower than the market average, most likely will also turn out to be a poor-quality fake. Their cost starts from 500 rubles.

- Handle material. It is advisable to choose metal. Plastic is brittle and degrades over time.

- Check locking mechanism. It should open and close without much effort.

When it happens in the house, it is necessary to turn off the water as soon as possible. In the old days, for this it was necessary to run to the basement and block the entire riser, and only a house management locksmith could do this. And all the while, while he was slowly getting ready and going to eliminate the accident, the “victims” had to fight the water flows on their own, risking flooding the neighbors.

In order to avoid such situations, it is necessary that in each apartment there are valves on the outlets from the main risers, which allow you to instantly shut off cold and hot water at any moment. What shut-off valve should be used for this?

Where to buy a ball valve

If we talk about the Bugatti brand, you will definitely not find these products in the market near the house. Real ball valves from an Italian manufacturer are sold only in specialized stores.

There is nothing worse than paying a lot of money for a supposedly real Bugatti crane, bought at a local market or in a nearby shop. The chance of buying a counterfeit there is very high. After a breakdown, you are unlikely to be able to return the money back - as a rule, neither checks nor certificates are provided on the market.

We conclude: regardless of the brand chosen, it is better to buy valves in a certified store or at least in construction hypermarkets. To dispel all doubts, do not be too lazy to ask for a certificate confirming the quality of the chosen model.

Selection tips: what to look for when buying?

In addition to certificates, you can simply pick up the crane and inspect it visually. If you have a genuine Bugatti or an original ball valve from any other well-known company, it definitely should not have incomprehensible sags and bumps. The applied marking should have even letters that are easy to read and distinguish.

Brass marking is another point that you should pay attention to at the time of purchase. For example, Bugatti make their products from brass material marking CW617N

Be sure to look inside and find a ball there. If it is mirror-like and polished to a shine, this is a good sign of quality. Feel free to scratch the case a little - the yellow metal will indicate brass. Fakes are most often made from silumin or steel.

Finally, a few more tips:

Take Bugatti "reinforced" type cranes. They have a 6xx serial number and a PN 40 stamp. This figure indicates a valve operating pressure of 40 atm (a very good indicator).

Reliable faucets have higher cleanliness, thicker walls at the threads, and more weight.

Try to avoid buying faucets that have plastic handles. The slightest effort will break the spitz, the handle will begin to scroll. Most often, such "pseudo-faucets" are placed on a washing machine, a toilet bowl and an eyeliner to a mixer.

The crane, even when buying, should spin freely enough (with minimal effort). If you managed to scroll only with a gas key, and at the same time you also rested your feet against the wall, it is better to refuse to buy

The thing is that the ball valve is never lubricated.

Pay attention to the size of the ball itself. The size of the "hole" in it must match the size of the attached pipe.

Features of buying a ball valve made of polypropylene

Before purchasing a polypropylene faucet, it is necessary to carefully inspect it; there should be no damage on its surface. When rotating the stem, you need to make sure that it turns with little effort.

And yet, it does not make sense to purchase a ball valve in markets or obscure stores. Practice shows that it is really possible to save money there, but there are no guarantees of quality and cannot be.

A valve made by a serious manufacturer is sold only through specialized outlets.

When choosing a faucet made of polypropylene, you need to remember a few simple things:

the thread on the valve body must match the thread on the nozzle;

the purchase of a used valve can lead to leaks, with all the ensuing consequences, in the form of flooded neighbors.

brand is important. The fact is that many European manufacturers transfer their production to third world countries, but do not always perform quality control.For the installation of the crane, it is advisable to invite specialists - plumbers

Self-installation of valves can end sadly. It must be remembered that the working pressure is up to 8 MPa

For the installation of the crane, it is advisable to invite specialists - plumbers. Self-installation of valves can end sadly. It must be remembered that the working pressure is up to 8 MPa.