Soundproofing drywall partitions step by step

Soundproofing under drywall is carried out as follows:

1. Markup

First you will need to use a pencil, marker and tape measure, as well as a laser level.

It is necessary to cut the material along the drawn lines, so carefully follow all measurements and marks, trying to make minimal gaps, but you can’t deviate from the horizontal and vertical

This is very important when attaching intermediate skeleton posts. Measure the entire perimeter and fix all dimensions on the sketch

2. Preparation of materials

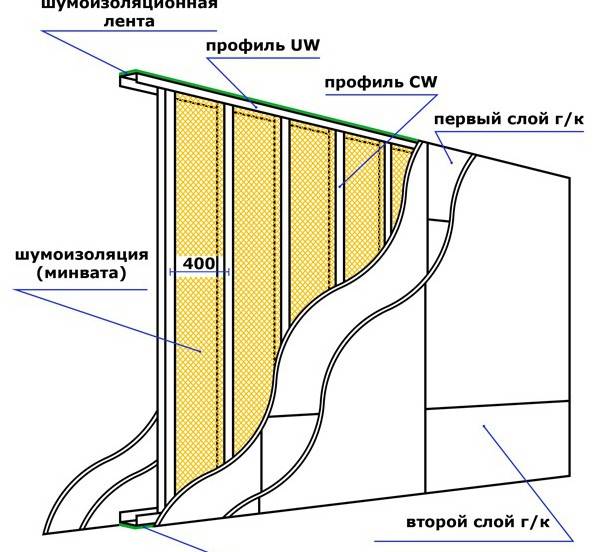

We take the UW profile and cut it to the dimensions obtained, we will mount it vertically on the walls, on the floor and ceiling. We will also need a CW profile, which we will mount vertically between the UW profiles. We also need a sealing tape, which will help to better strengthen the frame and prevent noise from appearing due to profile vibration. Make all metal-to-metal fastenings with a layer - a polymer gasket.

3. Frame fixing

We stick a self-adhesive sealing tape along the drawn lines on the floor, ceiling and walls, and fasten the UW starting profile from above with the so-called quick installation (dowels and driving screws), and metal dowels are used on the ceiling, not plastic ones. Now we take the CW profile and install it vertically, inserting it between the UW profile on the ceiling and on the floor, and fix it with self-tapping screws - fleas. Two fleas in each attachment point. CW profiles need to be fixed so that the distance between them is 40 or 60 cm. We recruit the door opening from the CW profile, into which the timber was previously driven. This profile should no longer be fixed with fleas, but with self-tapping screws.

4. Filling the frame

We have a finished metal structure. Now, on one side, it needs to be covered with plasterboard sheets twelve and a half millimeters thick in two layers. Now it is necessary to make electrical wiring and after that fill the entire space between the profiles with soundproofing material. In this case, it is necessary to clearly ensure that there are no voids, otherwise there will be a poor soundproofing effect. Now you need to fix the layer of the membrane on the profile.

5. Closing the frame

Now you need to tile the second side of the frame with drywall screws. It is also necessary to fix 2 layers of GKL. It should be remembered that the seams of the second layer should not coincide with the seams of the first layer. The optimal offset is half the width of the sheet. The number of self-tapping screws is approximately 35-50 pieces per sheet of plasterboard, 1200x2500 in size. Now you can, if desired, fill the drywall joints with the wall, floor and ceiling with sealant. After that, you can finish the drywall, the soundproofing work for drywall is over.

Back to content

What not to do

There are some nuances when assembling a false ceiling with sound insulation, which it is advisable to take into account during the acquisition of materials and installation of the structure.

- You should not buy cheap materials, especially vibration suspensions or unknown membranes. Otherwise, the system simply will not work.

- The whole process will have to be carried out "on top", which means it is desirable to have an assistant.

- Do not forget about such a factor as neighbors from above. Due to force majeure, your ceiling may be flooded, and mineral wool will lose all its sound-absorbing properties. To prevent this, it is better to lay a waterproofing sheet in the form of a film or membrane on the ceiling.

Soundproofing can also be arranged under a stretch ceiling, for which, for example, a plasterboard box is assembled around the perimeter of the room, soundproofing material is laid over the entire area and the canvas is stretched.

Choosing the best sound-absorbing material

Building sound-absorbing materials are divided into several groups:

- solid - products made on the basis of porous aggregates (vermiculite, pumice), as well as suspended or granulated mineral wool. They, as a rule, have a high mass - up to 400 kg / m³, the average sound absorption coefficient is 0.6;

- semi-rigid - plates with a cellular or fibrous structure. For the manufacture of such products, various foamed polymers or mineral wool are used. They have a slightly lower weight compared to solid counterparts - up to 140 kg / m³, sound absorption coefficient - 0.8 / 0.5;

- soft - products with a pronounced fibrous structure, where the fibers are arranged in a chaotic manner. This group includes: basalt and glass wool, felt, cotton wool. They have the highest noise absorption coefficient - 0.95 / 0.7, with a relatively small mass - up to 85 kg / m³.

- sprayed - a group of modern finishing products that are widely used in construction to reduce the noise level in rooms. The basis of the sprayer is cellulose fibers impregnated with a special adhesive compound. The product can be applied to any surface with a sprayer. With such processing, the thickness of the final sound-absorbing layer, if necessary, is easily adjusted.

In addition to the value of the noise absorption coefficient, when choosing a material, one should be guided by several more criteria that it must have:

- durability and strength;

- minimum thermal conductivity;

- ease of installation;

- minimum water absorption.

Selection of materials and design

For a normal comfortable pastime, especially during sleep, the total sound background should be about 30 dB. In the city, background noise is about 40-50 dB, or even more, depending on the location of the house.

Suitable design

At the planning stage of the repair, it is worth deciding what type of floor will be used. Indeed, when ensuring normal sound insulation, all details are important, including the design of the ceiling. In the apartment, you can use three types of floors with a different device:

- Suspended ceilings with soundproofing under plasterboard.

- Acoustic tensile structures.

- Combined systems.

The most common design option with soundproofing properties is a plasterboard suspended ceiling, and the soundproofing is located under the skin.

materials

Noise is vibrations in the air caused by certain activities. The entire soundproofing system works on two principles: reflection of these vibrations or absorption. With this in mind, suspended ceiling materials work as follows:

- drywall sheets act as a huge membrane, which is located on special suspensions and is able to dampen and reflect sound vibrations;

- fillers (mineral wool, felt, polystyrene and others) contribute to the absorption of vibrations.

Combining these properties of absorption and reflection, we get an excellent option for soundproofing a plasterboard ceiling. However, it is worth considering in more detail the various types of materials that will need to be purchased to assemble the structure.

Materials with a high sound absorption coefficient and the necessary tools

Noise isolation of frame systems is a complex task, for which the use of acoustic drywall is not enough. Despite its characteristics, its installation as the main coating is not able to completely neutralize the problem.

As a rule, an additional layer is formed in the interframe space to improve the insulating properties. To create it, various materials are used that are characterized by low thermal conductivity and sound transmission:

- Styrofoam;

- expanded polystyrene;

- mineral mats;

- glass wool slabs.

The use of such materials for soundproofing drywall partitions allows you to achieve a positive result. The combined use of acoustic sheets, drywall thermal insulation and special soundproof membranes can completely eliminate the problem. A partition made according to all the rules will have the insulating characteristics of a monolithic concrete slab, or even exceed them. Making a frame structure with your own hands is not so difficult. The first stage of its construction is the creation of a basic plan for a future plasterboard partition.

Plan and diagram with the dimensions of the plasterboard frame partition

Plan and diagram with the dimensions of the plasterboard frame partition

It includes the exact dimensions of the room, the ratio of surfaces and the magnitude of the angles. Based on the data obtained, the exact amount of material and fasteners is determined. The construction of the frame system begins with the collection of the necessary tools that will come in handy in the process. The minimum set of inventory that will be needed to create a partition is as follows:

- building level;

- roulette;

- plumb;

- pencil;

- Screwdriver Set;

- metal scissors;

- screwdriver;

- knife for cutting drywall.

The above list contains only the most necessary tools for drywall, which cannot be dispensed with in the process of erecting drywall structures. At the same time, depending on financial capabilities, it can be expanded or modified. For example, metal shears are successfully replaced by a grinder.

Watch the video: how to soundproof walls and interior partitions.

Sound propagation and absorption

The concept of "sound", as physicists define it, is mechanical vibrations propagated by some source in an elastic medium - air, wood, metal, etc. By emitting vibrations, the source creates pressure (reduced or increased), which spreads in all directions. The sound wave generated in this case enters the human hearing organs and transmits vibrations to the eardrum, the vibration of which is perceived by the brain as sound.

The parameters of sound propagation largely depend on the density of the medium and can vary significantly. So, meeting an obstacle, sound waves are reflected or refracted. If a porous substance is in their way, it absorbs the wave, scattering it inside itself. This physical property of materials is widely used in construction, for example, for soundproofing ceilings and plasterboard partitions.

The greatest dissipation of sound energy is due to an increase in the number of pores and voids present in the substance. The materials themselves, made taking into account these features, are called sound-absorbing or sound-proofing.

Types of materials for sound insulation

So, having studied a brief theoretical background, we can conclude: effective protection of the home from extraneous sounds is impossible without the use of additional materials. The modern market offers a huge number of solutions to achieve the required level of soundproofing of premises. Materials that are used in the fight against excessive household noise fall into two main categories:

- Sound-absorbing (picture 1). They are able to absorb sound waves, preventing their reflection and further propagation. They have a granular, fibrous or porous structure and are most suitable for protecting residential premises from extraneous noise due to easy installation, optimal performance and low cost. For example, they are widely used for soundproofing ceilings and plasterboard partitions.

- Soundproof (picture 2). They prevent the penetration of sound vibrations, reflecting them. Noise insulators are massive, since it is the thickness and mass that affects their sound transmission. The most common, reliable and high-quality materials that isolate sound are concrete, brick and drywall.

Note that only the joint, combined use of these materials allows you to achieve the desired effect when equipping a home with sound insulation.

Combined barrier device

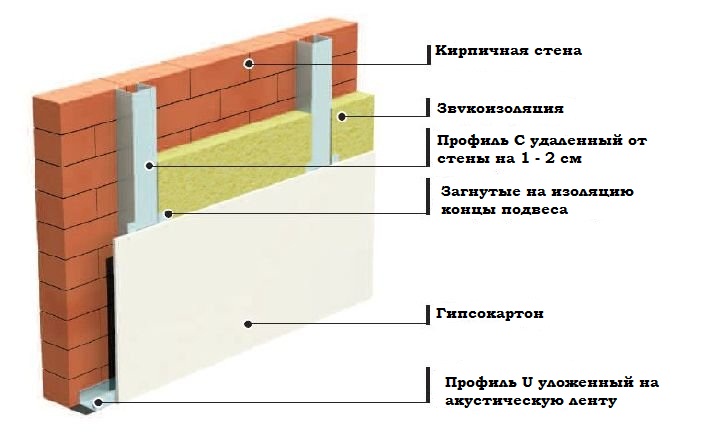

Combined wall insulation is mounted on a metal frame. To work, you will need tools:

- screwdriver;

- construction stapler.

Materials:

- drywall;

- cork panels;

- glass wool;

- polyethylene film;

- self-tapping screws;

- sealant.

They work in this order:

- Cork panels are laid in frame cells, fixing them.

- From above, the cork is covered with a waterproofing film, overlapping it and fastening it with a stapler.

- Glass wool is mounted on top of the film, which is then again covered with waterproofing.

- Drywall is installed on a layer of soundproofing materials using self-tapping screws.

- The gaps at the floor level are filled with sealant.

The right choice of sound-absorbing material and installation, made according to the technology, will reliably isolate the room from extraneous sounds. the insulation of walls made of plasterboard sheets will also increase the sound absorption in the apartment itself, which will not allow loud sounds to penetrate to the neighbors. The method of erecting plasterboard walls with a soundproofing layer is simple, so installation can be done on its own. The time and money spent on soundproofing is fully justified by the effect received from it.

Ceiling soundproofing technology

Soundproofing the ceiling in an apartment under drywall is installed quite simply. One has only to add some elements and the absorbing material itself. The work algorithm is as follows:

- Along the perimeter of the room, along the walls, you need to mark the lines along which the guide profiles will be laid. If the ceiling is planned to be one level, then this markup will determine its lower edge. Here it is worth considering that a sufficient distance should be retreated from the ceiling for the installation of sound insulation and wiring for lighting. The minimum level of the false ceiling must be 100 mm lower than the load-bearing floor.

- Before proceeding with the installation of guide profiles, a damper insulating tape is mounted on this markup. On top of this lining, a UD profile is installed, fixing it with dowels-nails in increments of 350-400 millimeters.

- The next step is to lay a soundproof membrane on the ceiling surface. The canvas is fixed to the ceiling using dowels - umbrellas.

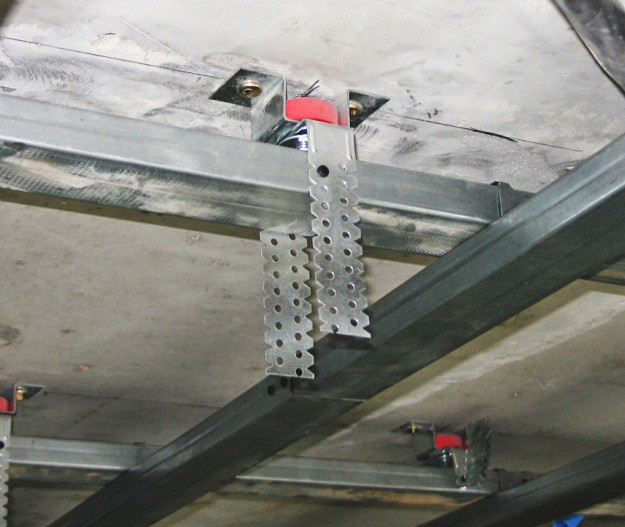

- Now lines are marked across the room where the main frame rails will be mounted. According to the marks, vibration suspensions are attached. The distance between them should be about 800 millimeters, and between the transverse profiles within 600 mm. Hangers are fastened with dowels - nails driven into the floor slab.

- Rack profiles are inserted into the guides and fixed with bedbugs to them and suspensions. And also transverse rails are made, which are also fixed with bugs on the frame.

- When the base crate is ready, you need to lay the main sound insulator. (mineral wool). After that, it is covered with a vapor barrier sheet and wiring is laid under the lighting fixtures.

- After that, the frame is sheathed with sheets of drywall using standard technology with the output of wiring for lighting. Drywall screws are screwed in at a distance of 200 mm from each other, the sheets are joined on the profiles.

If the height of the room does not allow the ceiling to be lowered too low, then it is better to use not spotlights for lighting, but pendant or overhead ones.Built-in "eyes" in a too tight space between the gypsum board and mineral wool can quickly fail due to constant overheating! See in the video the process of installing a soundproof false ceiling.

Soundproofing under drywall choice of filler

With the help of fillers - sound-absorbing plates, insulating membranes and sprayed coatings, it is possible to carry out high-quality sound insulation of plasterboard partitions.

The soundproofing membrane is a polymer-based material having a small thickness (2.5 to 12 mm). Such a surface does not transmit sound waves, is characterized by a high coefficient of sound insulation, resistance to various temperatures. One of the best is the Tecsound brand, which practically monopolized this area of the market. Membranes can also be used in combination with slabs to increase sound absorption.

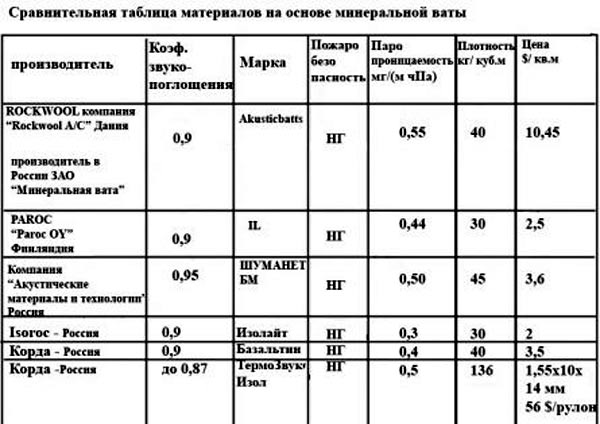

Sound-absorbing boards are also often used as a soundproofing material in plasterboard walls. Glass fiber materials from KNAUF insulation are considered to be of the highest quality, however, they are also the most expensive. These plates have high sound-absorbing properties, small thickness, increased air permeability. One of their main competitors is Rockwool. Insulation materials are produced on the basis of stone wool, they are fire-resistant, environmentally friendly, efficient and also have a lower cost.

In order to soundproof drywall walls, a good solution would be to use polyester boards as a filler, but it should be remembered that several varieties of these boards do not have the fire resistance we need. As for the foam, you should not use it as soundproofing.

The use of acoustic spray coatings is an innovative and completely uncomplicated solution. They can be applied both from any side of the drywall sheet, and as a "filling". The sprayed materials have excellent adhesion to the treated surface, while the number of layers and, consequently, the thickness of the insulation can be controlled. But for application you will need special tools. Sonaspray is considered a proven and reliable brand.

Back to content

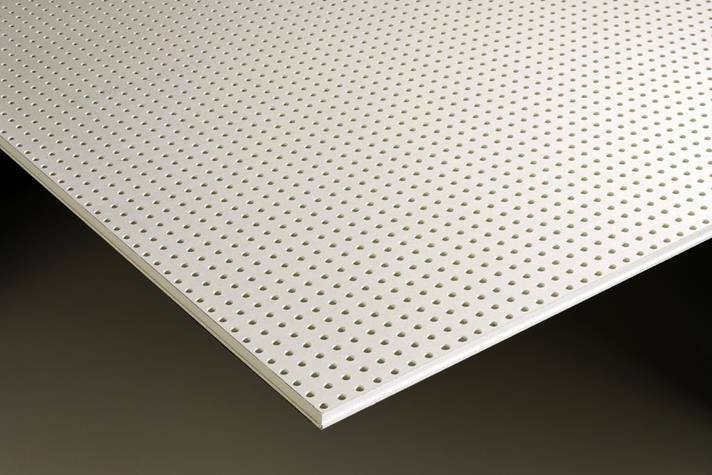

Acoustic drywall pros and cons

Acoustic drywall is a new material on the construction market. It has a lot of positive qualities, including excellent sound retention. But there is one very important nuance - it is not suitable for complex finishing, i.e. it cannot be pasted over with wallpaper, putty, plaster. Acoustic drywall can only be painted, and this is not always the best option, especially in relation to interior partitions, because it is not a fact that the painted perforated wall surface will go well with the existing interior. As an alternative to the external installation of acoustic gypsum plasterboards, the builders propose to mount them in the internal space of the frame with additional installation of mineral wool.

Advantages of Knauf Acoustic stoves

Main advantage

material is its ability to absorb various types of sounds and noises.

The soft basis most effectively captures sounds and absorbs them. Thin

fibers provide good air and steam permeability, which allows

apply insulation in rooms with high humidity. Flexible Structure

promotes warming and isolation of sounds of sewer drains. material

You can tightly wrap the pipe, thereby reducing the noise of the sewer.

You can use cotton wool for both apartments and private houses. Quite often knauf ceiling insulation,

It is used as a heater for roofs, attics and attics.

@Knauf

@Knauf

Talking about the benefits

It is impossible not to note the environmental friendliness of the material.The product is made from

natural raw materials, so there are no harmful elements and resins in its composition.

Knauf soundproofing

walls are odorless, so they are often used in soundproofing residential

buildings and public spaces.

With the material is easy and

convenient to work. Given the low weight of the material, it does not require special

equipment for loading and transportation. One package contains 16 tiles

size 1250*610*50 mm. This number of plates is enough to process

an area of twelve square meters. No need for slabs

special equipment or tools, laying technology is similar to those

which are used when installing basalt or mineral wool.

@Knauf

@Knauf

Knauf soundproofing of the ceiling is carried out using a construction made of

aluminum profile or wooden beams. Due to the parameters of the slabs, the frame

the base is built according to generally accepted dimensions with a step width of 60 centimeters. Such

the same width for the slabs, which makes it possible to use sound insulation practically

without waste.

Base frame assembly

Installation of the frame for plasterboard cladding is carried out according to an identical scheme, regardless of the design features of the partition. The sequence of steps for installing it is as follows:

- With the help of a level and a plumb line, the initial profile is set. It is on him that all subsequent racks will be guided. Therefore, it should be installed as evenly as possible in relation to all planes.

- A UW profile is attached to the floor and ceiling, which is necessary to ensure the rigidity of the structure. It is fixed with drywall screws, which are screwed in every 40-50 cm.

- The guide profile is filled with vertical posts, which are installed every 30 cm or 60 cm. They are fixed with metal screws or a special cutter.

- To increase the bearing capacity, vertical rack-mount CD profiles are fastened with horizontal guides. They provide the frame with greater rigidity and immobility.

The process of mounting the frame of the crate for drywall does not contain secrets and is carried out by hand in the shortest possible time. At the same time, the strength and appearance of the future partition will depend to the greatest extent on the quality of installation work.

Installation rules

The main soundproofing material is located between the supporting surfaces of the partition, which means that there can be several layers of it.

The most widespread are fibrous materials, which are supplied in rolls or sheets, depending on the specific density of the substance. The form of manufacture also imposes some specific requirements for installation.

In the case of mounting sheet noise-insulating materials, their precise molding may be necessary, which is important, first of all, with a low elasticity of the substance.

If there is an air gap behind the insulator layer, it is permissible to install plates on the frame to prevent the sheets from falling out of the gaps.

Some nuances may arise with the simultaneous installation of dissimilar noise and heat insulation layers. In this case, the heat-insulating layer is placed first, starting from the side of the sound source. As a rule, its width is selected in accordance with the width of the frame.

After that, a plastic film is laid and the sound insulation is installed, for which it is most convenient to use sheet materials. They are located in the frame of the other side of the partition or in the free gap between them, for which sometimes it may be necessary to install auxiliary fasteners.

Tips for achieving the best soundproofing result under drywall.

- The technique of layer-by-layer penetration of noise through the layers should be observed, and then the sound insulation of plasterboard partitions will justify itself.All fasteners and structural elements must be installed with soundproof gaskets.

- The soundproofing effect will be greater if two separate frames are mounted, on which the skin will subsequently be fixed.

- Sheathing should be selected taking into account the required absorption coefficient Rw - a conditional characteristic that reflects the ratio between the soundproofing parameters of materials and noise in an apartment or on the street. It is better to choose such a coefficient from 0.8 and higher.

- The soft layer material should not be less than 100 mm. As a percentage, it should not be less than 50% of the volume of the soundproof partition.

- Acoustic mineral wool can be placed between the GKL frames in order to create a damping effect. In this case, the sound insulation coefficient is increased by reducing the resonance effect in the partition.

It is necessary to achieve complete tightness of structures. Avoid any mechanical deformations, holes and cracks. Putty the joints using a shock-absorbing mesh. Use silicone sealant in places where electrical wiring and other communications are carried out. Mounting foam is not suitable due to its flammability.

A significant effect of soundproofing interior walls (approximately 30 dB) can be achieved using sound-absorbing membranes. Such elements are attached to the inside of the structure with glue. Soundproofing under drywall - there is no more ideal and justifiable way to protect against noise.

Instrument preparation and material collection

The preliminary stage of work is the preparation of a basic plan for the future wall. You can model it on a computer or just draw it with a pencil on a piece of paper. Its creation makes it possible to get a complete picture of the scope of future work and visualize the object.

The finished plan should contain aspect ratios, their geometric dimensions and angles. The only condition that is put forward to the project is the maximum detail. It is she who is the key to success and allows you to significantly simplify the process of installing the partition.

A suitable plan for partitions and plasterboard walls, showing the location of the profiles for mounting the GKL structure

A suitable plan for partitions and plasterboard walls, showing the location of the profiles for mounting the GKL structure

Obtaining a visual representation of the building marks the beginning of construction work. However, their implementation will be impossible without the preparation of a tool for working with GCR, the list of which is as follows:

- pencil;

- level;

- plumb;

- knife;

- spatulas of different sizes (narrow and wide);

- screwdriver;

- solution container;

- grout mesh.

Each of these tools must be prepared for work and complex in a specific place. At the same time, in order to understand the full structure of the process and assess the scale of construction, it is necessary to purchase a whole set of drywall components, the list of which is as follows:

- rack profile-CD and guide-UD;

- three types of self-tapping screws for the profile (25 mm, flea and 45 mm) and self-tapping screws for fixing drywall;

- mineral wool;

- perforated drywall (acoustic);

- soundproof membrane;

- reinforcing tape;

- plaster putty.

As you can see, the list of necessary material is quite extensive. However, each component in it is necessary and performs its specific function.

Watch the video: installation of a partition with sound insulation.

Pros and cons

Soundproofing Knauf Acoustic, like any building material, has its own advantages and disadvantages.

limitations. If we talk about the merits of the material, then there are a lot of them, and

they are as follows:

Non-combustible material belonging to the group "NG". Such characteristics

allow the use of insulating boards in rooms with increased

fire hazard.

The durability of the product makes it possible to operate insulating

plates for at least fifty years, while they do not lose their properties and

characteristics.

Due to the fibrous base of the panel, rodents, insects,

fungal growths and mold. These indicators make it possible

use insulating material under conditions of high humidity.

The composition of the plate does not include harmful components that have an unpleasant odor,

therefore they can be used even in rooms for allergy sufferers and children.

In the process of working with plates, cutting and installation, a lot of

dust, which clogs the treated room less and saves time on

cleaning.

The soft base does not cause discomfort during the laying of soundproofing.

The elastic base easily returns the original shape of the slab structure.

The product contains natural ingredients. The adhesive base consists

from tree resins that do not have a negative impact on health and

human well-being.

Affordable cost plates. Compared to analogue materials,

acoustic kunaf cost

soundproofing is suitable for an average family with an average

income

Using such sound insulation, you can not only effectively protect

house from noise, but also spend the minimum amount of time and money on it,

what is not less important.

@Knauf

@Knauf

Despite all

positive qualities of acoustics

knauf soundproofing, there is one minor minus, during installation

it is necessary to create a profile frame. This soundproofing takes

space in the room. More precisely, the average thickness

insulation will vary in the region of ten centimeters. Given that

the distance will be removed from each wall, the area of \u200b\u200bthe room to be processed is several

decrease. The insulating material simply has no other disadvantages, with which

due to its popularity among buyers.

Overview of soundproofing methods and characteristics of materials

There are two ways to insulate the ceiling:

- Lay the insulation in the space between the profiles;

- Use GKP - gypsum combined panels.

The gypsum combined panel is a building structure consisting of two layers, one of which is a sheet of drywall, and the second is a polystyrene foam board, securely glued to it. The panel is used not only in interior, but also in exterior decoration. It is glued with heavy-duty adhesive to the surface to be treated, which must be perfectly flat. The length of gypsum boards is from 30 cm to 2.5 m, width - 60 cm and 120 cm. Working conditions - temperature not lower than +5 degrees, normal humidity conditions.

Mineral wool

Acoustic boards are successfully used to provide good sound and heat insulation performance. Produced with or without synthetic binders. In mineral wool on a synthetic binder at a temperature of 300 degrees, harmful components are released into the surrounding space. During a material fire, being in the vicinity is hazardous to health.

From the point of view of environmental safety, it is better to use plates in which an inert polymer is used to bind the fibers.

It is important to choose exactly acoustic mineral wool based on the basalt component. Many domestic and foreign companies are engaged in its production.

The most famous are Acoustic Group, Knauf, Rockwool, TechnoNikol. Mineral plates with longer and thinner fibers are better.

Mineral wool is often used for soundproofing plasterboard partitions.

Soundproof membranes

The membranes provide a certain degree of noise absorption. They are used as a complement to mineral wool or by themselves. They are glued to the floor slabs, and sewn up with drywall on top. Some membranes have a self-adhesive surface, so the speed of their installation is as high as possible.The thickness of the mats is 4-20 mm, the cost is 800-1000 rubles per m2.

The noise level is reduced by 20-60 decibels according to manufacturers, which is most likely a marketing ploy, since the maximum noise reduction that multilayer structures can provide is 15-20 dB. Well-known names of membranes are “Zvukoizol”, “Teploizol”, “Shumanet”, “Teksound”.

The permissible noise level in the daytime should not exceed 45 decimal places. For a person, a value of 20-25 DC is comfortable, which can be achieved by using acoustic mineral wool. The best option is to stick the membrane on the base and then fill the space with basalt slabs.

Vibrosuspension as a way to improve sound insulation

Elastomer-based fasteners are a good way to completely isolate the ceiling structure from the supporting bases.

Each suspension has a rubber gasket, which it comes into contact with the ceiling. Its fixation is carried out in the same way as usual - with an anchor dowel-nail.