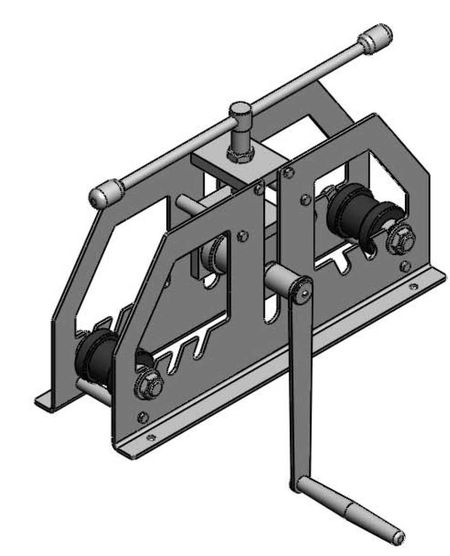

Tool

When rolling with your own hands, you will definitely need special tools, such as units for bending steel sheets or bending rolls. These tools are easy to use, versatile and highly accurate.

Ticks

There are many tools for rolling. They differ according to the features of the application:

- T-series tools are used to work with pipes with a small diameter (6-11 mm). The equipment allows you to set the depth of rolling;

- ST series tools are used to work with elements whose inner diameter is 6-11 mm behind the weld;

- Tools of the RT series are used to work with products with a small diameter (5.50 - 11.5 mm);

- Tools of the P series are used to work with products with a large diameter (12-40 mm);

- Tools of the SR series are used to work with products that are a structural element of thick tube sheets;

The 5P series tool is used to work with thin-walled pipes with a large diameter, made of stainless steel or titanium alloys.

How rolling is done

Do-it-yourself rolling is of several types. Work can be done with a cone, without eccentric and ratchet, with eccentric

When making a bend, it is very important to follow safety rules.

The general meaning of the work performed is to transfer the cold state to the ends of the pipes in the holes of the same designs. This method allows you to securely connect all the elements, to ensure the strength of the structure. So, let's consider the stages of rolling with our own hands (photos will allow us to more clearly present this complex work):

- The part is installed in the hole intended for this. In this case, a hole is usually formed between the walls of the product and the walls of the unit. Normally, it should not exceed 1 mm;

- The part is expanded. As a result, the gap should disappear. The part is firmly fixed in the hole;

- The outer surface, expanding, begins to exert pressure on the tubular drum, as a result of which its deformation occurs. At the end of the work, the pipe drum will return to its previous shape, which will create the necessary compression. This factor makes the connection so reliable.

This technology is suitable for both large diameter pipes and small diameter pipes.

It is very important to choose the right tool for rolling. Otherwise, excessive deformation of the metal of the drum may occur, which will lead to increased expansion and rupture of the part.

In order for rolling with your own hands to be done correctly, you need to know the specifics of the tools used, be able to use them correctly, study the technology of metal bending

It is important to study the relevant instructions, to know the features of working with a particular metal. In order to perform pipe rolling with high quality, we recommend that you view the relevant videos and photos, which show the work of professionals.

So you can see firsthand how to correctly deform metal sheets

It is important to remember that when rolling, it is required to follow not only the instructions for the correct conduct of work, but also safety rules.

How to flare a copper pipe at home

When installing copper piping systems, it often becomes necessary to expand the cut end of the pipe - for installing climate control systems or soldering heating and water supply pipelines.

I welcome our esteemed reader and offer an article about what flaring of copper pipes is, in what situations it is used and how to do it yourself.

What is it and why is flaring necessary?

Flaring - radial uniform expansion of the walls of a copper pipe. When expanding, only the end of the pipe can be conically expanded or a sufficiently long section can be expanded, in which a sleeve is formed - a section of a larger diameter.

The need for such deformation at home arises:

- When installing air conditioning systems.

- When repairing refrigerators, heat exchangers, cars, household appliances, heat pumps.

- When installing heating and water supply systems.

During installation by welding (soldering), the ends of copper pipes are expanded in the form of a coupling, inserted into a pipe of the original diameter and welded. Flaring is used less frequently than soldering with fittings, as this method is slightly less reliable, but sometimes fittings may be missing or not available for repairs.

The need for flaring arises if the necessary fittings are not at hand, it is not possible to purchase a copper tube of the required diameter, or a very precise adjustment of the tube size along the internal section is required. In practice, flaring is used in the installation of climate control equipment, in cars and during urgent repair work, when copper tubes available on the farm are used.

Flaring stages

To obtain a quality cone or expansion sleeve at the end of the pipe, it is necessary to follow the correct work order.

Flaring as a process of deformation of the ends of copper pipes includes the following steps:

- Cut off the tubular. Copper is a very soft material, so it is essential to use a quality pipe cutter designed for soft non-ferrous pipes.

- After cutting, even with a high-quality pipe cutter, the copper pipe is jammed, and its inner diameter decreases. Therefore, with the help of a special device - a rimmer - a chamfer is removed from the inside of the workpiece, the shape is restored.

- Clean the end of the tube from burrs, clean from copper chips, dust, dirt, grease.

- The workpiece is inserted into the flaring machine and rotated until a small socket is obtained with a wall angle of 45° to the pipe axis.

- They take out the product, try on whether it is suitable in size for further installation with a union nut. If the socket diameter is insufficient, then the flaring operation is repeated. Insufficient socket during installation forms an unreliable connection: water leakage is unpleasant, refrigerant leakage is dangerous, since it consists of toxic fluorocarbons.

- Then use the pipe for its intended purpose.

All the subtleties of expanding a copper tube can be seen in the video.

Tools and accessories for rolling

For high-quality expansion of the ends of the pipes, a special tool is used - mechanical or electrically driven. The use of cones or templates and manual expansion is used only for manual expansion of single pipes. If you have to carry out a heating system or plumbing, it makes sense to purchase a mechanical flare.

Expander

The expander is a simple roller with several template nozzles for processing pipes of different sizes.

It stretches the ends of the tubes quickly enough, the force is applied with the help of a lever, and flaring does not require much physical effort.

The quality of the flared products is not ideal - most likely, the deformation will be inhomogeneous, thinner sections of the walls will stretch, and the socket will have different thicknesses. Cracks and breaks may occur.

cone flaring machine

The cone tool is one of the simplest, provides an acceptable quality of the copper socket, but worse than other types of mechanical flaring.

The pipe is fixed in a vice, the cone is pressed into the workpiece several times, each time to a greater depth, then it is removed - and so on, until a socket of the desired size is obtained.

Such a device is used quite often because of its cheapness and simplicity.

Mechanical flare

The best quality of rolling is provided by a flaring machine, in which the processing of the pipe is carried out with several rollers made of alloyed tool steels. The tool is completed with a set of rollers for several diameters of pipes.

How to flare a copper pipe at home

Adjusting the diameters of pipes when connecting them is not an easy task. Either there is no workpiece of the required size, or the wall thickness in different parts of the part is different.

But the need to work with the diameters of products arises not only in industry, the expansion of structures for hermetic fastening of household communications is also often required.

We will learn what flaring of copper pipes is with our own hands, why it is carried out and how to act in order to get a good result.

How to flare a copper pipe with your own hands

When connecting copper pipes to each other or when joining them with working parts, for example, air conditioners, special preparation of their ends is necessary - the so-called flaring. The durability of the future system directly depends on how well it will be done, because the vast majority of problems with refrigerant (freon) leakage from air conditioners are associated precisely with poor-quality joints.

Most often, flaring of a copper pipe is required when installing an air conditioner yourself.

How to properly flare a copper pipe will be discussed in our article.

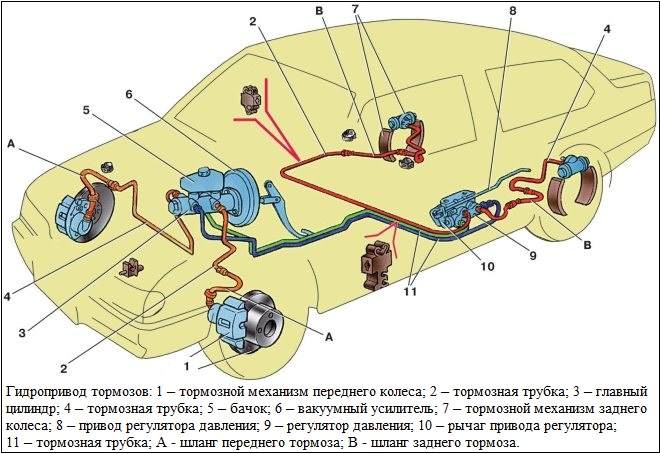

Functions of brake pipes

Brake pipes are an integral part of the braking system of any car, which is responsible for stopping it at the right time. To understand the importance of such tubes for the operation of the brake system as a whole, one should at least superficially get acquainted with the principle of its operation.

So, the process of stopping the car, for which the braking system is activated, consists of the following steps.

- If necessary, reduce the speed of the car or stop it completely, the driver presses the brake pedal.

- The master cylinder piston connected to the pedal is actuated and begins to act on the brake fluid.

- Under the high pressure communicated by the piston of the main cylinder, the liquid begins to flow through the tubes and hoses into the cylinders of each wheel, already acting on their pistons.

- The fluid pressurizes the pistons against the brake pads, which press against the brake discs, stopping the wheels from spinning.

Scheme of the brake system of the car

Obviously, the brake pipes play a crucial role in the operation of the entire brake system, and if they break, it completely fails. That is why the repair of these elements, to which and applies, should be approached with all responsibility.

How to perform flaring

So, after preparation, proceed directly to flaring:

- If necessary, put a return nut on the pipe in advance so that later there is no incident with the pipe fasteners, since it is no longer possible to put it on the flared end.

- The prepared pipe is clamped in the die, having previously selected a hole of a suitable diameter in it. It is necessary to clamp it so that the end of the pipe protrudes slightly above the surface of the die, and the pipe itself is securely fixed. The height of the protrusion depends on the diameter of the pipe and is selected according to the table below.

| Tube diameter | Height

protrusion (mm) |

Collapsing Diameter (mm) | |

| (mm) | (inch) | ||

| 6,35 | 1/4 | 1,0…1,3 | 8,3…8,7 |

| 9,52 | 3/8 | 0,8…1,0 | 12,0…12,4 |

| 12,70 | 1/2 | 0,5…0,8 | 15,4…15,8 |

| 15,88 | 5/8 | 0,5…0,8 | 18,6…19,0 |

| 19,05 | 3/4 | 0,1…0,5 | 22,9…23,3 |

- Next, the rolling element is moved to the desired hole and clamped. Usually there are special marks on the die for the correct fixation of the rolling element. When properly fixed, the top of the cone will coincide with the center of the pipe hole.

- The screw of the rolling element is rotated. In this case, the cone gradually enters the pipe, expanding its end. Rotation is performed until it stops.

- Unscrew the screw back, release the pipe from the die, check the result. The output should be an evenly flared symmetrical end without displacement to the side and without a bevel. In addition, it should be free of cracks, breaks and other damage. If there is something like this, the failed section is cut off and the procedure is performed again.

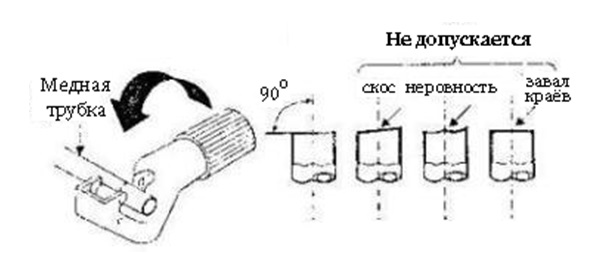

When expanding a copper pipe, the errors shown in the picture are not allowed

Take the quality of the flared pipe seriously, as it is important for the smooth functioning of the system in the future. A job well done will prevent unwanted agent leaks and equipment breakdowns.

- The flared area is processed again - burrs, possible chamfers and irregularities are removed. Here it is necessary to achieve a perfectly even and smooth surface in order to achieve further complete tightness of the joint.

You can visually familiarize yourself with the rules for flaring from the video below.

If you did everything correctly, then the flared pipe can be considered completely ready for further installation.

Thus, we described the stages of preparing a pipe for flaring, told which one is better and how to use an expander for a copper pipe, and presented instructions for doing flaring with our own hands.

Preparatory work

How to properly prepare the end of the pipe

Before proceeding directly to flaring, you need to prepare. Preparation begins at the stage of cutting the pipe, namely, make sure that after cutting the end of the pipe meets the following conditions:

- did not have bevels (must be made strictly at 90 degrees relative to the axis of the pipe);

- was even;

- did not have a blockage of the edges.

When cutting a copper pipe, the errors shown in the picture are not allowed

To do this, cutting is carried out according to the instructions below:

- A special pipe cutter for copper pipes is put on and fixed on the pipe section where the cut mark was previously applied.

- In a counterclockwise rotation, the pipe is slowly cut through.

- Check the end for the absence of irregularities and bevels.

- With the help of a file and / or sandpaper, possible bumps and burrs are removed from the end.

Flaring tool

To complete the task, you will also need a flare. This is a special die with template holes for different diameters of pipes, to which a rolling with a cone is attached. This tool can be purchased from a specialized store. As a rule, it is sold complete with a pipe cutter and accessories for processing the ends of pipes.

It looks like a tool for expanding copper pipes

When choosing an expander for copper pipes, make sure that the die has a hole for the diameter you need. In addition, the kit should include an example in the form of a pipe segment with a flared end, made with this particular tool.