Design features and principle of operation

Wood-burning boilers can be used for heating a house, for heating cold water, and also for both heating and hot water at the same time. Since a heating boiler that uses wood as fuel is exposed to open fire and condensate that causes corrosion, it is necessary to use special grades of steel or cast iron for the manufacture of its furnace and water jacket.

Heating on wood in a private house can be created using the following types of heating equipment:

- pyrolysis heating devices;

- long burning boilers;

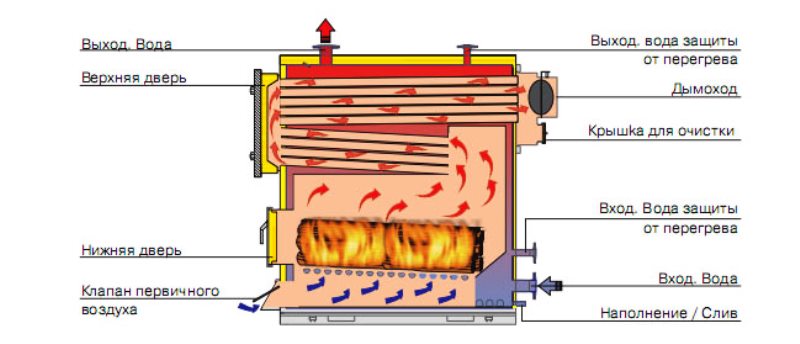

The pyrolysis heating device on wood consists of two combustion chambers. In one of them, the primary combustion of firewood is carried out, during which flue gases are released. In the second chamber, these flue gases are completely burned, releasing additional heat. This heat generation technology can significantly reduce the consumption of fuel materials.

The hot water boiler of long burning has a high efficiency. It is able to provide uniform heating of the coolant and low fuel consumption at high heat transfer rates. How long will one firewood bookmark burn? As a rule, one bookmark of firewood is enough to operate a hot water boiler for 24-48 hours.

Wood-fired hot water heating equipment is a closed vessel. The wood loaded into the furnace burns out and releases thermal energy, which heats up the coolant in the water circuit. Further, water from the heat exchanger enters under pressure into the heating system of the house, heating all its premises.

Use of electric boilers

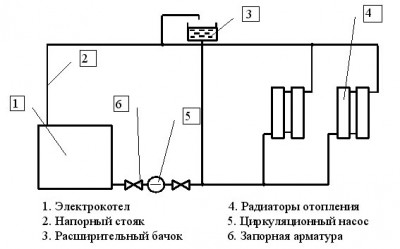

Scheme of installing an electric boiler in the heating system.

In order to heat all housing with electricity, a boiler is installed that heats water to a certain temperature, and then it circulates through the heating system through a coolant. Many believe that the installation and use of such boilers is an uneconomical option for a private mansion.

In this case, gas, compared to electricity, is much more practical, but this is if there is access to the gas main. Although the installation of gas equipment and service maintenance of gas boilers pay off for a very long time.

The main advantages of using electric boilers:

- convenience in the operation of equipment;

- fast heating of the house;

- temperature control;

- installation of equipment at any time of the year.

The principle of operation of an electric boiler is practically the same as a gas heating system. The difference lies in the fact that the heating of water occurs through heating elements, and not gas. At the same time, heat throughout the living space occurs in the same way as with gas heating, that is, in the pipeline using a coolant.

How to choose a wood-fired boiler for a private house

When choosing a heating boiler for a private house, several points are taken into account regarding design features and performance:

- Heated area - approximate performance calculations are carried out according to the formula 1 kW = 10 m². When connecting the second circuit for hot water supply, add another 15-20% to the result.

- Types of heating boilers - as already noted, there are classic units, as well as those that use the principle of pyrolysis combustion. The latter are considered the most economical wood-fired boilers for individual heating of private suburban households. The first are 3-4 times cheaper.

- Type of heat exchanger - there are two types. It differs in the type of materials used and construction.Steel boilers are cheaper, but serve an average of 10-15 years less. The units are not afraid of shocks and mechanical damage, easy to repair and maintain. Cast iron boilers, on average, last about 35 years, have the best thermal performance. They are afraid of mechanical damage. The repair will require the replacement of an entire section. Another disadvantage of cast iron is the large weight of the boiler. The pyrolysis unit, which has two combustion chambers, easily reaches a mass of 5 centners.

- Design features of the combustion chamber - manufacturers produce boilers with side loading of firewood. The design is used in most units, both classical and pyrolysis type. Boilers with top loading deserve special attention. This design is used in gas generating units. The main advantage of the solution is the possibility of preliminary drying of firewood, which increases the heating efficiency.

- The presence of additional functions - automation, the presence of a backup power source, a built-in storage boiler, a remote control system - all this increases the comfort of operation and is available as an additional package.

In addition to technical parameters, you will need to decide on the brand of wood-burning boiler and select a heat generator that is suitable for the price category.

Which boiler to choose

If funds allow, it is better to put a German or Czech-made wood-burning boiler. Somewhat worse in terms of performance, Polish and domestic units. Among foreign and domestic manufacturing companies, the leaders are:

- German wood-fired boilers - represented by Buderus companies. Viessmann. Lopper. All equipment has a high degree of safety and reliability, and a long service life. The disadvantage of models is whimsicality to the quality and grade of firewood, high cost.

- Czech-made wood-burning boilers - the products of OPOR companies deserve attention. Viadrus. and ATMOS. In terms of quality and automation, the models are in no way inferior to their German counterparts, but have an average cost of 10% less.

- Russian-made boilers - TT units are produced by almost every manufacturer of heating equipment. The boilers are adapted to domestic conditions, unpretentious in terms of fuel quality and the heat carrier used. The products of the following plants are the most popular: ZOTA. Teplodar.

- Polish wood-burning boilers - several dozen modifications are offered on the domestic market. Models are in demand: Defro, SAS, DREWMET, ORLAN. The range includes both conventional wood-fired heat generators and pyrolysis combustion boilers.

Most manufacturers, in addition to classic heating boilers that work exclusively on wood, offer universal or multi-fuel heat generators.

The cost of wood-burning boilers for country houses

Several factors affect the cost of the unit:

- Type of heat exchanger - a cast-iron boiler will cost 1.5-2 times more than a steel counterpart.

- Manufacturer.

- The principle of operation - the cost of a wood-burning gas-generating boiler of a domestic manufacturer will cost 35-40 thousand rubles. and the price of a boiler of classical design will drop to approximately 20 thousand rubles.

- Additional equipment.

Registration of documents for putting the boiler into operation, subject to their registration with Rostekhnadzor, is not required.

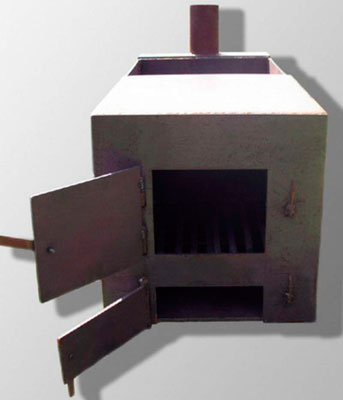

Making a wood-burning boiler with your own hands

Is it difficult to make a wood-burning boiler for the house with your own hands? The main condition for this design is the thickness and grade of steel used. In factory models, the outer case is made of heat-resistant steel with a thickness of 1.5 mm. For a heat exchanger, these parameters should be greater - from 2 mm.

The best option is to create a welded structure, which will be similar in shape to factory models.However, if we calculate the labor intensity of work and the cost of materials, the difference between buying and self-manufacturing will be low. Therefore, as an alternative to wood-burning stoves for a house with water heating, simple steel barrels are often used. The main condition is the thickness of their wall - from 1.5 mm.

For manufacturing, a capacity of about 200 liters is required. It is cut lengthwise and a partition is installed inside. Its length should be less than the length of the barrel. This is necessary for the installation of grates.

Then holes are cut on the front side for mounting doors. They should be selected in advance so as not to be mistaken with the sizes. To remove carbon monoxide, a chimney is cut into the back of the structure. Its diameter can be from 50 to 100mm.

However, judging by the reviews of such a wood-burning heating boiler, the following disadvantages can be noted:

- Low efficiency;

- Heating of the body, which can cause burns when touched;

- Short service life.

Similar designs are used for heating small utility rooms - a garage, a warehouse, etc. For the home, it is best to purchase a factory-made quality model. It will comply with modern wood heating schemes.

Before making a homemade wood-burning boiler for a heating system, it is necessary to calculate the optimal dimensions of the furnace.

System inertia

Another disadvantage of a solid fuel boiler is hidden in the cyclical nature of its operation and the inability to replenish fuel reserves on its own. Because of this, either a high heat capacity of the house structure itself is required, or deaf insulation, close to a passive house, or a way to store a supply of heat for the cooling period of the system.

Since the volume of the heat exchanger itself in the boiler is small, the displacement of the system can be increased mainly by increasing the diameter of the pipes. Another alternative of this kind can be called the installation of a heat accumulator. With the right approach, you can realize the accumulation of heat only after heating the main system, which will help speed up the warming up of the house and solve the problem with condensate.

Underfloor heating systems have their own high inertia, which grows with the thickness of the storage screed. In the presence of a thermal cutoff under the floor, this can be a truly long-term source of heat. With a sufficiently thick layer, even the use of water at a higher temperature will not cause discomfort and thermal zebra, but along with the inertia of the system, the time it takes to reach the regime increases. On the other hand, connecting a warm floor to a wood-burning boiler requires a rather complicated piping, which excludes overheating of both the boiler and the pipes in the floor.

Equipment power

Ultimately, for the boiler, it is not so much the details of its internal structure that are important, but the main performance indicators that have been achieved using a number of engineering innovations. The most important and defining parameter of the boiler is its nominal instantaneous power. The heat capacity of different types of fuel is different, as is the case with different types of firewood, the manufacturer cannot accurately predict it and calculate the rated power in a particular operating mode.

Power is determined by two indicators. By the volume of the furnace, one can judge the mass of the bookmark. On average, it is believed that for every kilowatt of wood-burning boiler power, there are 2.5-3 liters of combustion chamber volume. Having obtained the instantaneous value of the power released during combustion, it is possible to predict which part of it can be absorbed by the heat exchanger under different temperature operating conditions. Usually, absorption is deliberately made higher than the calculated heat release under combustion conditions close to optimal, but this approach is fraught with trouble.

The fact is that all wood-burning boilers suffer from a common disease - the formation of tar due to the high humidity of the burned wood.Condensation occurs only at a sufficiently high temperature difference. Thus, the formation of build-ups on the economizer or secondary heat exchanger may stop when the coolant is heated to 40-45 ºС. The bottom line here is that if you load the boiler halfway, its power will not be enough for the normal heating of the walls and heat exchangers, because of which the equipment will simply “leak”.

Specifications

Most of the wood-fired hot water boilers on the market today have the following performance characteristics:

- Power. This indicator depends on the volume of the heat exchanger, the volume of the combustion chamber and the material from which the furnace walls are made. Also, the power consumption of the boiler is directly affected by the consumption of fuel material. The more firewood is loaded, the more heat energy will be released during their combustion. How many kilowatts are needed to heat a private house? To find out how much power is required to heat a particular room, you must use the following ratio: 1 kW of thermal energy is required to heat 10 m² of a room.

- Efficiency. To calculate the efficiency of the device, you need to know the circulation rate of the coolant, the amount of heat given off by firewood during combustion, and also take into account the method of fuel combustion. The efficiency of long-burning heating equipment and pyrolysis systems can reach up to 85-95%.

- Coolant. Water is used as a heat carrier in wood-fired heating systems. Alternatively, any non-freezing fluid may be used.

- Purpose. In winter, the boiler can be used for both heating and water heating. In summer, the main purpose of a wood-burning boiler is to prepare hot water.

Advantages and disadvantages

Heating on wood is characterized by a number of undeniable advantages, the main of which are the following indicators:

- Low weight of heating equipment. For wood-burning boilers, unlike their counterparts that operate on other types of fuel, there are no strict requirements regarding their design and installation location. Therefore, a self-made boiler can be installed in any part of a country house, although allocating a separate room for a furnace would be the most correct solution.

- Automatic control system. The minimum number of ACS components of an industrial boiler allows not only efficient consumption of fuel material, but also reduces the likelihood of failure in the event of failure of one of the control devices.

- Versatility. In wood-burning heating boilers, not only wood, but also any other kind of solid fuel can be used as fuel.

- Long service life. A wood-burning boiler will serve its owner for more than one winter. How many years will an industrial boiler last? Manufacturers of this type of heating equipment guarantee at least 15 years of trouble-free operation.

- Ease of maintenance. In the course of performing work related to the maintenance of the heating boiler of a private house, it is only necessary to clean the ash pan and chimney once a year.

- Acceptable price. How much should I pay when buying a boiler? The price of each specific model depends on the number of options present in this equipment. It can be noted with full confidence that every owner of a private house can purchase a wood-burning heating boiler without serious damage to the family budget.

Unfortunately, wood-fired hot water boilers are not without certain disadvantages. These shortcomings apply only to wood-fired boilers made in a handicraft way.One of them is that it is impossible to automate the control process in a home-made wood-burning boiler, so the owner of such equipment needs to load fuel into the combustion chamber manually.

The second drawback is the "gluttony" of a self-made water boiler. In order for the operation of this equipment in the winter to provide comfortable living conditions, it is necessary to create a large supply of firewood. How much firewood do you need to have enough for the whole winter? Fuel consumption for each specific case is individual. The amount of firewood stored depends on the power of the heating device and the area of \u200b\u200bthe heated premises of a private house.

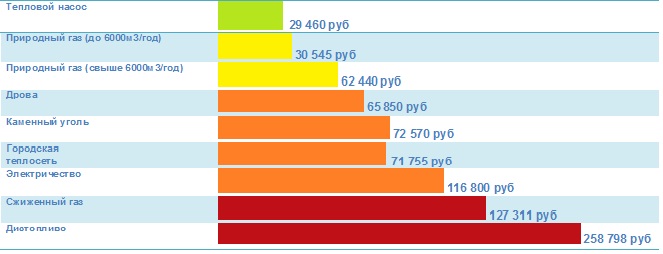

Other types of heating a country house or cottage

Using a heat pump

With the new alternative of the heat pump, space heating without gas and wood has become more affordable for everyone. This method is really the best type of heating a country house or cottage. The plant generates heat from natural resources: land, sea, lakes and even air. But the heat pump is not very popular among consumers due to the high cost of equipment and installation work.

The use of liquid fuel units

The main fuel for liquid fuel boilers is diesel fuel, and the equipment itself used to heat the room is called diesel. Instead of diesel fuel, kerosene or rapeseed oil is sometimes used. But due to the high efficiency, liquid fuel boilers are rarely installed in private homes, but they are very effective for heating large buildings.

Use of solar collectors

Recently, owners of private mansions have increasingly begun to use solar collectors, in which solar energy is converted into heat. It is most practical to install such collectors on the roof of the house so that it is possible to receive as much solar energy as possible. The main disadvantage of such an installation is a direct dependence on the weather and the number of sunny days.

Today, efficient types of heating used to heat a country house or cottage are electric heating installations and solid fuel boilers. It is these two types of fuel that are excellent substitutes for gas and firewood, and are considered the most affordable for consumers, both in the installation of equipment and in connecting the heating system. The remaining options, which provide heating and heat to housing, are applied directly as an additional method to existing installations.

Varieties

The consumer has a choice among several solutions, each of which has its pros and cons. In any case, heating systems of a residential building must be reliable, and also meet the requirements of thermal power (living area, intensity of operation, length of the cold season in the region, etc.).

Boiler classic

This design is the simplest and most understandable of all that exist on the market today.

Peculiarities:

- similar to an ordinary stove - equipped with a firebox, chimney and ash pan;

- operation does not require complex knowledge;

- runs on fuel with low efficiency;

- consumes a lot of wood.

If it is planned to install carrier wiring at your facility, classic boilers will not suit you.

Pyrolysis boiler

Design features:

- relative novelty on the market (therefore, reviews are still few and it is premature to draw global conclusions);

- it is possible to develop a high efficiency;

- with high efficiency, significant savings in fuel consumption are achieved;

- exhaust gases during the combustion process move into the pipe;

- from the pipe, pyrolysis gases transfer their temperature to the heat exchanger;

- Judging by the foregoing, I would like to call this design ideal. However, it has a significant drawback - a strict selection of fuel.

Long burning boilers

Peculiarities:

- such boilers with a water circuit are able to work for long hours on one wood-burning bookmark (the figure of 3-5 days speaks for itself, and the good reviews of grateful users only enhance the reputation of these products);

- such long-burning stoves can operate on different types of fuel (and are easily rebuilt from one to another).

Alas, to buy one for little money is simply unrealistic. Comfortable pleasure costs a lot of money and, as they say, will cost a pretty penny.

Safety requirements

It should be remembered that boilers with a water circuit require attention from a safety point of view. It is not only about ignition risks, but also about full-fledged air-gas circulation.

Fire hazard.

- The most important are the following points:

- availability of free space for storing fuel - firewood cannot be stored directly at the stove, since the risk of ignition increases;

- it is necessary to provide exhaust ventilation in the room, especially if you purchased a high-capacity boiler to heat the house;

Without sufficient ventilation, the unit will not cope with the amount of gases emitted during combustion. But among them there is carbon monoxide.

- it is strictly necessary to ensure the remoteness of the boiler from the walls and from the ceiling at a distance of at least 1 m;

- the size of the room must be at least 8 square meters. meters;

- the base must be non-flammable. For this purpose, the site is concreted. Another option is to cover the existing pedestal with tiles or iron, if it is, for example, wooden.

Chimney

The safety of the whole house and residents also depends on:

flue material - stainless steel. Only this material will protect the structure from the deposition of greasy soot and resinous substances. Stainless steel has a high slip coefficient, that is, microparticles repel rather than “stick”;

Simple iron pipes are very difficult to clean due to the abundance of tar and soot deposits.

- make sure that the chimney passes through the wall of the house at a certain angle, and ideally, you need to make a hole in the roof. This measure will ensure the full release of combustion products to the outside;

- Be sure to place the upper edge of the pipe about 1 m above the roof ridge. Otherwise, there will not be sufficient traction.

Automation and piping of wood boilers

As already mentioned, the power of the boiler can be regulated only by changing the amount of oxygen supplied. This system works most efficiently and accurately in pyrolysis-type mine boilers on wood or briquettes.

The main automation complex includes an electronic control unit, a fan, an electrically driven draft regulator and a thermocouple tightly wound to the supply pipe. All these components are sold both individually and in kits for a specific boiler model. On average, all automation costs about 4-5 thousand rubles.

Separately, we mention the importance of having protection against falling dampers and sealing grooves on loading and inspection hatches, a chimney, and a draft stabilization system.

For solid fuel boilers, a number of other types of protective devices are provided, installed in the hydraulic piping. Of course, this is a circulation pump and protection of the furnace from overheating - a safety group for relieving excess pressure

Please note that the outlet of the reset valve must be turned towards the wall or provided with a hose so as not to injure people present when it is activated. Safety requirements may provide for the installation of a chimney pressure relief valve to stabilize draft and combustion, it is mounted immediately at the outlet of the boiler or directly in front of the final vertical section

Connection diagram of a solid fuel boiler with a heat accumulator: 1 - chimney; 2 - thermostat; 3 - security group; 4 - air separator; 5 - circulation pump; 6 - thermal accumulator; 7 - three-way mixer; 8 - weather-dependent automation; 9 - heating radiator; 10 - circulation pump; 11 - check valve; 12 - expansion tank; 13 - protection against dry running; 14 - make-up valve; 15 — overhead temperature sensor; 16 - solid fuel boiler

Connection diagram of a solid fuel boiler with a heat accumulator: 1 - chimney; 2 - thermostat; 3 - security group; 4 - air separator; 5 - circulation pump; 6 - thermal accumulator; 7 - three-way mixer; 8 - weather-dependent automation; 9 - heating radiator; 10 - circulation pump; 11 - check valve; 12 - expansion tank; 13 - protection against dry running; 14 - make-up valve; 15 — overhead temperature sensor; 16 - solid fuel boiler

For cast iron boilers, it is practiced to install a two-way valve that mixes water from the hot outlet to prevent cold water from entering the heated furnace. When installing a heat accumulator, a three-way electric valve is added, which starts the supply of heat to the tank only after the main composition has warmed up. The control is carried out according to the return temperature, the additional circuit is switched on 7-10 ºС before the cut-off temperature is reached. In this aspect, control units with a PID controller are most preferred.