Pump for wall-mounted boilers WILO NO 256 boiler version

Description

The pump is suitable for all European wall mounted boilers

(if WILO pump is inside)

CHECK YOUR PUMP IMPELLER SIZE BEFORE ORDERING

1) 72 mm then you need a pump NO 25/6

BAXI

PROTHERM

VAILLANT

VIESSMANN

BUDERUS

Bosch

etc.

The impeller and the pump housing have a special shape. Removal of the "native" snail from the boiler is not required.

Only the impeller with the rotor changes. The rest rarely fails.

WILO boiler pump

power 1 step—39 W

2 steps—62W

3 steps - 93 W

power 0.43A

revolutions 1950 rpm.

|

General characteristics |

A type

surface circulation

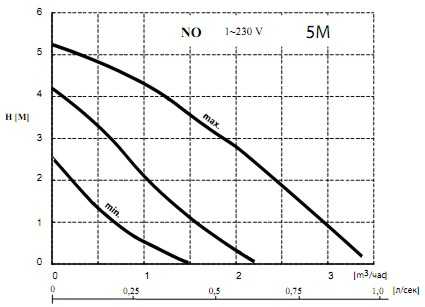

Max head

6 m

Bandwidth

3 cube m/hour

Mains voltage

220/230 V

Water

Water quality

clean

Permissible liquid temperature

-10°C to 110°C

Design

Rotor type

"wet"

Connection connector diameter

1.25″

Pump installation

vertical

Weight

2.6 kg

Peculiarities

Permissible ambient temperature

up to 40°C

General information about positive displacement pumps.

Volumetric

called a hydraulic machine, the working process

which is based on the alternating

filling the working chamber with liquid and

pushing it out of the working chamber. Under

working chamber of volumetric hydraulic machine

refers to limited space

inside the machine, periodically changing

its volume and alternately communicating

with fluid entry and exit points.

Volumetric hydraulic machine can have one

or several working chambers. According

so that hydraulic machines create a fluid flow

or use it, they are divided into

displacement pumps and hydraulic motors. V

positive displacement pump moving liquid

carried out by expelling it from

working chambers with displacers. Displacer

- the working body of the pump, making

displacement work (pistons, plungers,

gears, screws, plates, etc.). By

principle of action (nature of the process

liquid displacement), positive displacement pumps

share pa piston

(plunger)

and rotary.

V

piston -liquid

displaced from immobile chambers into

reciprocating

movement of displacers (pistons, plungers,

diaphragms). V

rotary

- liquid is displaced from the moving

working chambers as a result of rotational

or rotary-translational motion

displacers (gears, screws, plates,

pistons). According to the nature of the movement of the input

volumetric pumps are divided into

rotational (with rotational movement

input link) and direct acting (with

reciprocating motion

input link). To general properties

positive displacement pumps include the following:

1.

cyclicity

workflow and related

portioning and uneven delivery.

The supply of a volumetric pump is carried out

not in an even flow, but in portions,

each of which corresponds to the supply

one working chamber. 2.

tightness

pump, i.e. permanent separation

pressure pipeline from the suction

(vane pumps are not sealed

possess, but are flowing). 3.

Self-priming,

i.e. displacement pump capacity

create a vacuum in the suction

pipeline filled with air

sufficient to lift liquid into

suction pipe to the level

pump location. Suction height

there can be no more liquid

maximum allowable. Vane pumps

without special devices

are self-priming. 4.

Rigidity

characteristics (its steepness in the system

coordinates

(or)

on),

which means a small supply dependence

pump from the pressure it develops. Ideal

delivery is completely independent of pressure

pump (characteristics of vane pumps

usually gentle).5.

Pressure Independence,

created by a volumetric pump, from

movement speed of the working body

pump and fluid velocity. At work

on an incompressible fluid a positive displacement pump,

with a perfect seal

able to create arbitrarily high

load pressure at

arbitrarily low speed

displacers. To get high

pressure with a vane pump

high speeds required

wheels and high fluid velocities.

Expert answers

Alexei:

It is logical that you need to make a hydraulic arrow.

Untie the boiler-pump circuit of the boiler and the heating system with its own pumps with a hydraulic separator.

Vladimir Kolpakov:

the regular pump on the boiler is always in the return line. sequential operation of pumps is not desirable. but in general I’m interested in what the problem is, what makes me put additional. pump

Vladimir Petrov:

The Weiland boiler already has a pump and it is enough. And you don't need to add another pump. The boiler is designed for a certain heat flow and it is not necessary to increase it.

Fursov Yuri:

Can you remove the filter and clean it? and all on this and end

husky:

Better yet, have two pumps. and so that they work towards each other ... then you don’t have to break your head how to connect to a standard

Onotole Chake:

In the same place, it seems like there is a return line, which is enough with a head along with a regular pump. If in doubt, ask in some thematic site then

Semyon Arazaev:

There is no point at all in this, given that there is more than enough return flow there. Well, as some kind of rezev, in principle, the norms, but this should already be clarified with a specialist in these same boilers from s pechki

Yegorych:

Underfloor heating is not done this way, you need a thermostat and a separate pump, well, sort of like this

Grandfather Au:

The pump is usually placed on the return line.

Vladimir:

What is the question?

Dmitriy:

it all depends on the connection scheme, without knowing that you have useful advice, you will not hear ...

Rogue of the Seas:

Read the DHW consumption in the passport of your column, if you have more water than the column can heat, then your hot water will be cool

Alexey Lesyuk:

Vitaly, if the heating system was not installed correctly for you, installing an additional pump will not help you, but it will also harm you if the boiler is double-circuit. It is necessary to change the scheme for connecting the boiler to the heating system to install additional. nasoa

Do I need an additional pump for a double-circuit boiler Navien

After installing a condensing double-circuit boiler, many users are considering installing an additional pump in the heating system of a country house. The need to use an additional booster device is explained by the uneven heating of the living quarters of a two-story house with sufficient power of the boiler equipment.

Advice! If the temperature drops of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to a higher speed or get rid of air locks.

Installation of another pump is necessary in such cases:

- When installing the heating of a private house with an additional circuit, or in the case when the length of the pipes is more than 80 meters.

- For uniform supply of coolant through the heating system.

There is no need to install an additional pump if the heating is balanced with special valves. Therefore, before buying booster equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure test pump. If, after carrying out such procedures, the autonomous heating of a private house will work normally, then another pump will not be needed.

Why do you need a hydraulic gun

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or a hydraulic arrow must be included in the circuit.The specified device can be operated together with a single-circuit diesel boiler or a solid fuel unit. In the latter case, the device regulates the supply of coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Capturing dirt from coolant flows.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airing, and prevents the accumulation of dirt in pipelines. Such a device must be installed without fail in the presence of several booster units

Installation nuances

When installing heating on a turnkey basis, the master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise, its rotor rotates without lubrication. A coolant is used here as a coolant and lubricant. When installing pumping equipment, you need to consider the following nuances:

- The shaft of the device that injects pressure is placed horizontally with respect to the floor plane.

- Carry out the installation in such a way that the direction of the water coincides with the arrow on the device.

- Mount the instrument with the terminal box up to prevent water from entering the electronics.

Important! Experts recommend installing a pump on the return pipeline of the heating system of a one-story or multi-story residential building. Despite the fact that such equipment is designed to operate in hot water with temperatures up to 110 degrees, warmer liquid in the return pipeline will only extend the service life.

Installation of the unit is carried out only after draining the water from the system. In the event of a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, a strainer is installed in front of the inlet pipe to prevent scale and debris from entering the impeller. In addition, shut-off valves are provided at the inlet and outlet of the device for possible replacement and repair of the device.

As we can see, the installation of a circulation pump requires certain skills, so the installation of this equipment should be carried out by a professional. To order the service, you can leave a request on the website or call +7 (926) 966-78-68

Do I need a pump in the home heating circuit Does gas consumption decrease when using an athunder pump

In the Kuban, I encountered the fact that people are convinced without exception that it is necessary to put a pump in the circuit of the home heating system in order to reduce gas consumption (of course, when using a gas boiler for heating a house). Yesterday, gas workers from RostovGorGaz also mentioned this during preventive measures. In this regard, I would like to raise the question of whether the pump is really needed in the home heating circuit.

I have an old one-story house. In the heating system, natural circulation, i.e. The water heats up and moves on its own through pipes and radiators. The heating system works fine, since the relatives ate the dog in the design and installation of heat supply systems, heating, as well as setting up houses, from cottages to high-rise buildings. Including they often have to correct the mistakes of unfortunate specialists.

In a one-story house, forced circulation (using a pump) allows you to warm up the house faster. All this is due to the fact that warm water flows faster into cold rooms. But if you permanently live in the house, then there may not be much advantage in this at all.

If there is a decrease in gas consumption when using the pump, then it is insignificant. In this case, the pump consumes electricity. Let this be a maximum of 20-50 W, but with round-the-clock operation, electricity costs should not be neglected.

The pump in the heating system is really needed if natural circulation does not work. But even in a multi-storey building, it may be optional.

In one-story houses, with the exception of rare cases, there is a banal divorce for money, and not at all a concern for reducing gas consumption.

Update (26.01.2016 21:58) A correction has been made after the designer's comment: It is also not necessary to use a pump in high-rise buildings (approx. it is logical if the pressure in the line is already high).

What helps save gas:

- high-quality calculation of hydraulics,

proper selection of pipes and radiators,

well-tuned radiator fittings,

home insulation,

weather automatic,

temperature controllers on each appliance or in each room,

high efficiency boiler.

The post is about ONLY pump installation unlikely will not lead to gas savings.

Parallel and series connection of pumps

Notation

- \(L_{E}\quad\) Equivalent or total flow

- \(L_{1}\quad\) Conditional first pump flow

- \(L_{2}\quad\) Conditional second pump flow

- \(P_{E}\quad\) Equivalent pressure

- \(P_{1}\quad\) Conditional first pump pressure

- \(P_{2}\quad\) Conditional second pump pressure

On the joint operation of pumps in heating and cooling networks

In hydraulic circuits, it is quite common to find pumps connected in parallel and very rarely in series. Nevertheless, sometimes the pumps still work in series - although this scenario may not have been considered when creating the circuit.

Basically, the joint operation of pumps is found in redundant schemes - where one pump is the main one, the other is the backup one. Although more than two pumps can work together, for simplicity we will consider only two - the first and second. More precisely, in such schemes, each pump is both the main and the backup, while the load can be distributed by 50% for each pump. If one pump fails, the second provides at least half the load.

Pump characteristic

The characteristic of the pump is a curve of dependence of the flow rate on the developed pressure. This curve depends on the design of the pump and is determined during production and testing. In general, it looks like in the picture

Figure 1 General view of the pump characteristics

Parallel connection of pumps

If you connect two pumps in parallel - for example, as shown in the figure, then what will their overall characteristic look like? The general characteristic will be based on the following rule:

When pumps are connected in parallel, their flow rates are summed up at the same pressure value

The equivalent characteristic will look as shown in the figure.

Figure 2 Parallel Connection Diagram

Figure 3 Equivalent characteristic for parallel connection

serial connection

As already mentioned, it is the intentional serial connection of us that is very rare, let's say now this is not a common practice. Although the sequential operation of pumps can be found, for example, in multi-circuit diagrams. If the pumps are connected in series, then their equivalent characteristic is built as shown in the figure based on the rule:

When pumps are connected in series, their pressures are added at the same flow rate

Figure 4 Serial Connection Diagram

Figure 5 Equivalent characteristic in series connection

Tips & Tricks

Is it necessary to build an equivalent characteristic of pumps? If you take the design of hydraulic circuits seriously, and hydraulic circuits definitely deserve such an attitude, then the characteristic must be built, otherwise how will you know how the network will behave under various operating modes

Best Answers

Uncle from the Future...

It is not advisable to put two pumps in one system.. If you don’t have enough built-in parameters, it’s better to just put an external pump of the required power and turn off the built-in one or remove it from the boiler altogether ...

Dmitry E:

why, some kind of stupidity, if there is little power, change the boiler itself

Anatoly Bondar:

"Only in vain: a strong castle will not save you, You will not sleep peacefully in your house," - VSV

uncle Ivan:

Is there a pump in the boiler or not. In principle, you can put it on the return line, but it is better to have the same performance. There are a lot of pumps out there now. And what is not pushing the system for you? Raise the system temperature.