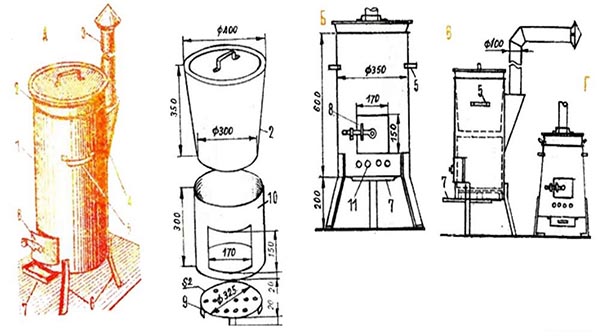

Varieties of stoves depending on the location of the vertical model

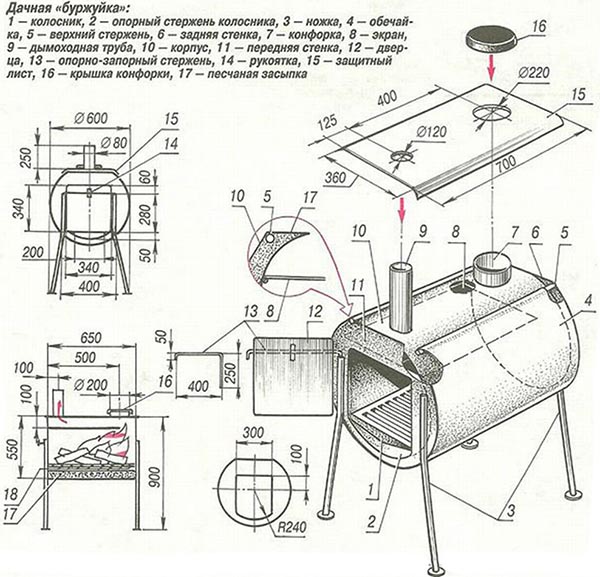

Depending on the plane in which the metal tank will be located, two types of home-made bourgeois stoves are distinguished: vertical and horizontal. Each of these types of heating devices has its own advantages and disadvantages.

The furnace from a vertical type barrel is not installed on the floor, but on legs. To complete the door, you will need to cut the side of the tank and provide it with hinges

It is important to remember that the hinges must be fixed to the barrel and the door not from the inside, but from its outer part.

A mandatory element of this design is a perforated metal plate, which is called a grate. To fix such a lattice, you can use the usual corners. In order to make a blower, you will need to prepare a metal pipe with a slide gate. The wall thickness of the metal must be sufficient, otherwise the structure will quickly burn out.

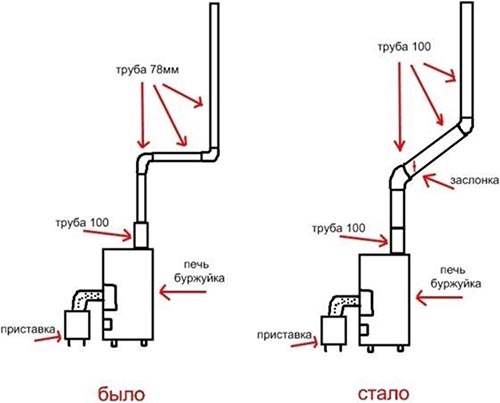

The damper for a long-burning wood-burning stove located in a vertical plane is fixed on special bolts. When igniting the fuel inside the tank, the blower should be opened to the limit.

In the upper part of the canister, it is necessary to make a hole in the shape of a circle. It will be needed in order to connect a chimney structure to a homemade stove. Docking of a pipe with a metal surface is carried out using welding equipment.

The function of the grate is to protect the bottom of the canister from burning out, as well as to retain thermal energy. Thus, this element is necessary when installing a home-made long-burning stove.

Design features are determined depending on the purpose of the device and the place where it will be located. If you wish, you can download a ready-made drawing of a potbelly stove on the Internet. However, in this case, it is necessary not to make a mistake with its volume.

The vertical variety of a home-made heating device is easy to assemble. You can find application for such a unit both in a private house and in the country. The firewood used to kindle a heating device of this type is selected depending on the dimensions of the firebox.

The principle of operation of a potbelly stove from a barrel

A potbelly stove from barrels is very similar to the type of potbelly stoves that we imagine perfectly well. However, it does not have mass production. Such a structure is purely the creation of self-taught masters. Among other things, the modernized stove has a round shape and looks like a metal stove "Slobozhanka".

The main difference between them is the option of fuel combustion. Wood sawdust is used as it for the following reasons:

- if you heat a potbelly stove with this fuel, then it will be quite economical due to the low cost of this type of fuel;

- Sawdust, which was previously compressed, burns out for quite a long time. One load may be enough for 6-10 hours for such a design.

It is quite obvious that a potbelly stove from a 200-liter barrel looks good. Such a stove usually has a diameter of 600 mm. A hexagon, which has sides of 314 mm, can easily fit into this circle. This makes it practically no different in technology from conventional furnace appliances. The efficiency in such stoves, as a rule, does not exceed 15% (We have already written and recommended adding the article to bookmarks.). If a screen is used to increase it, then such a stove does not last long and goes out of service after about one season.

Read the article about it and get answers to your questions.

The main reason for this efficiency comes not only from a fairly thin metal, but mainly from the height of the barrel of 850 mm. Approximately 1.3-1.5 times less than the depth, the height of the firebox in potbelly stoves made from a barrel should be located. In the case when the blower is made high and the grate rises, then the lower part, as practice shows, will take the heat and give it to the air, thereby violating all the correct gas dynamics. In this case, there are only two options:

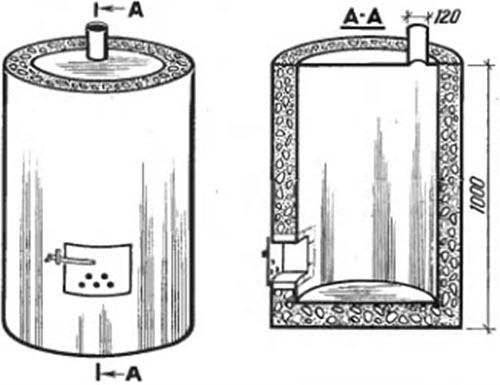

You can wall up the barrel to the middle of the height in a brick. This can be seen in photo 3.

It is also possible to equip a refractory-lined oven at the top of the oven. And run a chimney through it.

In both cases, the work will become more complicated. The service life of this furnace does not exceed five years, but the efficiency cannot be raised above 20%.

Rules for installing a potbelly stove

In order for you to have no problems with the stove and all sorts of troubles, it should be installed, adhering to certain safety rules:

- The oven should only be installed on a fire-resistant surface. It is possible to make it yourself using tile tiles or using bricks. The walls located in the vicinity of the stove must also be protected from overheating. The best effect can be achieved when using specialized drywall, as well as any other non-combustible material;

- In no case should flammable materials be placed near the firebox;

- You should also equip an excellent ventilation system in the room in which the stove will be located. This is a very important factor, since the concentration of carbon monoxide in the room must be reduced to zero;

- In order to make a potbelly stove, you need to use only high-quality material.

Video: do-it-yourself potbelly stove from a barrel

Making a potbelly stove is absolutely simple, as you have seen. For such a thing, you only need improvised materials, which are often found in the garage or in the country house of almost every person. A potbelly stove will delight the eye if all the details are thought out to the smallest detail and made very carefully.

Homemade stove from a metal 200 liter barrel: drawings, stove diagram, photo and video. A barrel stove can be used to heat garages, workrooms, greenhouses and other premises.

A standard metal 200 liter barrel has a height of 860 mm, a diameter of 590 mm and a weight of 20-26 kg.

The dimensions of the barrel are almost ideal for making a stove from it, the only caveat is the thin walls of the barrel 1 - 1.5 mm, which will quickly burn out from the high temperature. Alternatively, the firebox can be lined with refractory bricks from the inside.

To make an oven you will need:

- Two 200 liter barrels.

- Door for oven.

- Grids.

- Sheet metal, corners and rods.

- Chimney pipe.

- Refractory brick.

Tools:

- Bulgarian with a cutting wheel.

- Welding machine.

- Electric drill.

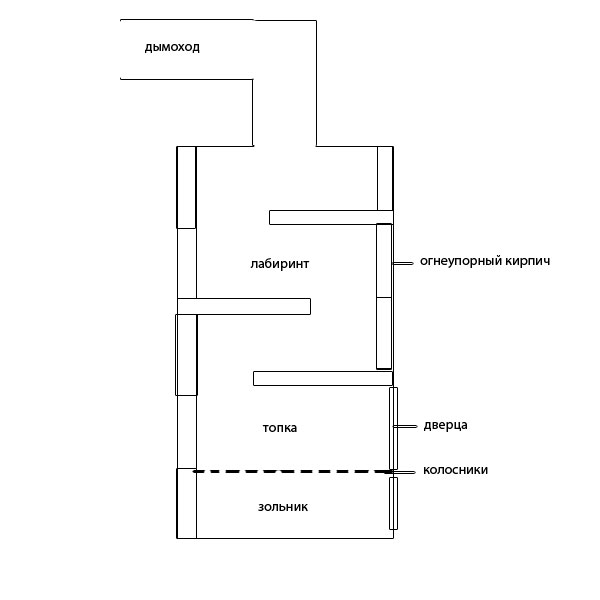

Stove from a 200 liter barrel: scheme.

We cut off the top of the barrel with a grinder and cut out a side opening under the furnace door.

We weld the furnace door to the barrel with a welding machine. At a height of 20 cm from the bottom of the barrel, we install grates for ash.

Under the ash pan, you can make a separate door, slightly opening it, you can adjust the traction force in the oven.

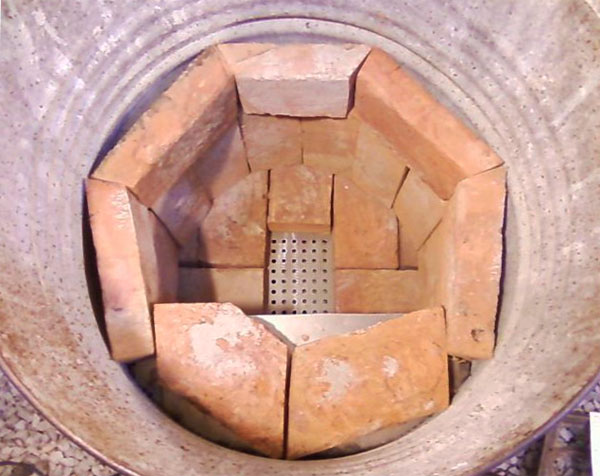

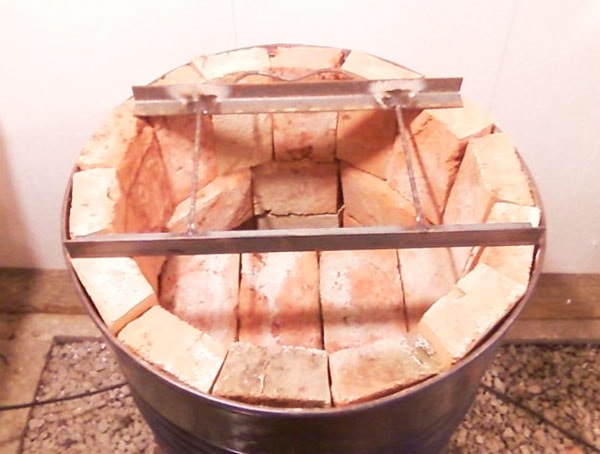

So that the metal walls of the barrel do not burn out over time, you need to lay out the inner surface of the firebox with refractory bricks. To fit the bricks more tightly, we file them with a grinder.

For laying the labyrinth of the chimney, it is necessary to weld from the corners of the crossbar under the bricks.

Bricks are laid out on the furnace mortar. The composition of the furnace solution is 1 part clay to 2 parts sand, the mixture is kneaded with a minimum amount of water to a very thick consistency.

The thickness of the joints for masonry should not exceed 5 mm.

Blower size 50 by 300 mm. Firebox 300 x 300 mm. It is necessary to take into account the difference in the heights of the drums and the height of the base, which will be placed in the outer drum;

3.A 100-liter barrel is brewed on top with a steel sheet;

4. A hole for the chimney is cut in the steel sheet, the diameter of the existing pipe is taken into account;

5. A pedestal is laid out at the installation site of a brick potbelly stove;

6. In 200-lit. a barrel with a mixture of crushed stone and clay, using a brick, the base for a 100-liter barrel is laid out;

7. The base is carefully compacted;

8. A 100-liter barrel is installed on a finished base;

9. The openings of the furnace and the blower of the barrels are combined and brewed;

10. A door is cut out of a steel sheet;

11. A deadbolt is made from a steel sheet cut into a plate.

12. One end of the plate is bent in the form of the letter "O" for the handle.

13. Hinges from a metal sheet plate in the form of the letter “P” are welded onto the door and the bourgeois wall, with legs on the walls. There are 2 pieces on the door - a bolt will slide along them. On the wall of the barrel 1. It will hold the door when the bolt is inserted;

14. Door hinges are welded;

15. The furnace door is welded;

16. The pipe for the chimney is cut to the required length. The longer, the stronger the pull.

17. The chimney pipe is welded. Welding without gaps is necessary so that the smoke only escapes into the chimney.

18. The free space between the barrels is filled with a mixture of clay and gravel.

19. The folded edges of the 200 liter drum are welded to the edges of the 100 liter drum.

When cutting holes and parts, it must be taken into account that the metal expands when heated. Therefore, the gaps of the door and other parts must be left sufficient for normal operation.

Between the blower and the firebox, to facilitate the removal of ash, you can put a grate assembled from metal corners.

Making a potbelly stove

When a certain moment comes, many people wonder how a potbelly stove should be made from a barrel with their own hands. And in general, how to make a potbelly stove from a barrel of 200 liters.

Potbelly stove is created in different sizes and shapes. It can be round and square, vertical and horizontal. It all depends on your imagination.

Horizontal stoves are considered simpler than stoves made vertically. In such a stove, a part of the bottom is attached to the place of the door, which is cut out. She sits on the loops. A hole was made at the opposite end of the barrel, to which a metal pipe should be attached, which will be a chimney for such a stove. Then a grate should be placed in the middle of the barrel. It plays an important role, as it will help retain heat for a longer time, and also protect the so-called bottom from burning out. If there is a great desire to create a hob, then you just have to weld a thick steel wire.

Do you want to build? See detailed instructions on our website!

Before you get to work, you will need to prepare some tools. To begin with, it is best to stock up on a welding machine, as well as a complete set of clothes for working with it, a grinder, circles for grinding and cutting metal, a hammer, a metal brush, pliers, a tape measure and a drill.

At the required level in the barrel, you should first mark and then cut out two rectangular holes that will serve for the ash pan and the firebox.

The parts that remain after cutting should not be thrown away, as they can later be used to make a door. In order for the door to be finished, metal strips are attached to it, and then a special latch with a handle is placed.

Then, on the inside of the barrel, just below the firebox, no more than 10 cm, angle-type brackets are attached, which will later serve to lay the grate.

For the manufacture of the grate, ordinary fittings are used. It needs to be cooked on its own.

It is best to weld the legs to the bottom of the barrel, but in the upper part you need to cut a hole for the future chimney and weld a pipe into it.

On the hinges that have already been attached in advance, the door is installed. Only after installing the door is a hook for the lock attached.

If you want to achieve a more aesthetic look for your stove, then it is worth carefully cleaning all the welds. Heat-resistant paint is suitable for painting, after applying which your potbelly stove will be almost indistinguishable from the factory one.

After the completion of all work, the potbelly stove is connected directly to the chimney, which has already been brought out into the street.

The principle of operation of a potbelly stove from a barrel what you need to know

Before starting the self-assembly of such a device, you need to understand how it functions. Understanding the principle of operation makes it possible to simplify the manufacturing process of such an impromptu furnace.

Sawdust or firewood is used as fuel for a homemade potbelly stove from a metal tank. Compressed sawdust is different in that it takes quite a long time to process inside a homemade oven. Among other things, the cost of such fuel is minimal, so it is widely used.

The diameter of a 200 liter drum is 600 mm. If desired, you can perform a fairly functional design, which will also have an attractive appearance. The dimensions of the tank with a volume of 200 liters allow you to place a hexagon inside it, the sides of which will be equal to 314 mm. In this case, according to the manufacturing technology, the devices resemble traditional furnace units.

It is worth noting that the finished device has a not very high efficiency - only 15%. To increase efficiency, one more component is often added to a home-made design - a screen. The reflective shield, of course, contributes to an increase in efficiency, but this solution also has a negative side. The use of a screen that reflects heat leads to the fact that the operational life of a homemade stove is reduced.

It is worth noting that if the grate in the unit rises due to the high location of the blower, then the efficiency of the device drops. This is due to the fact that heat in such a design is dissipated into the air through its lower part. To solve this problem, it is necessary to hide the lower part of the stove from the barrel in the brickwork. Not only instructions, but also educational photo and video materials will help to complete such a unit with your own hands.

The service life of potbelly stoves made of metal barrels averages 3-4 years under normal operation. To raise the efficiency, many tricks are used. However, it is worth saying that with all the desire to get more than 20% of the return on a home-made unit, it will not work.

The technical characteristics of the future heater and its efficiency depend on the choice of the barrel. In order to assemble a potbelly stove on your own, it is necessary to prepare a metal tank, the recommended volume of which is 200 liters. Of course, the stove can also be made from a smaller capacity, however, in this case, the efficiency of the heater decreases, which is already quite low.

To assemble a potbelly stove with your own hands, you can use any metal barrels made of steel material. Steel has good resistance to high temperatures, so its use for assembling a heating unit is more than justified. For the same purpose, you can use barrels that were used for storage:

oils;

- paints;

- fuel;

- bitumen;

- liquid glass;

- sand.

All containers produced and used for storing various compositions are divided into types according to several criteria. First of all, they can be with or without a closed top. And also such tanks differ from each other in the thickness of the bottom and the open cylindrical structural element (shell). Regardless of the variety, for the production of a metal furnace with your own hands, it is necessary to pre-clean the tank.

The operational life of such a stove in any case depends on the thickness of the walls of the barrel.Based on this, it is not recommended to use tanks that have a wall thickness of less than 2 mm for assembling the heating unit. The shelf life of the device is also affected by the frequency of its use.

Before proceeding with the assembly of the unit, it is necessary to draw a long-burning furnace. The more detailed it is, the less likely it is to make mistakes during the design of the heater.

Rules for installing a homemade potbelly stove

Before installing the stove, you need to familiarize yourself with some rules. This will ensure maximum safety when working with the unit. First of all, it is worth remembering that the potbelly stove should be located only on the surface that is resistant to fires.

A fire-resistant surface can be arranged on your own. To do this, you need to prepare a brick or ceramic tile. A platform is laid out from any suitable facing material. It is also recommended to protect the walls from the high temperature that the wood-burning stove produces.

Another way to protect work surfaces from heat is to use special refractory drywall.

It is important to remember that there should not be any flammable materials in the immediate vicinity of the potbelly stove.

If desired, you can make a potbelly stove with a water circuit. This heating option is more complex from a constructive point of view. It requires the organization of a heat exchanger, as well as pipe wiring.

For the manufacture of potbelly stoves, it is worth using only high-quality, reliable materials. Before starting work, it is recommended to study the video on this topic. Photos of stoves also help to understand the intricacies of the assembly. The unit, which was executed correctly, is able to last more than one year.

Thus, in order to make a stove from a metal barrel, you do not need to have any special knowledge. Strict observance of the instructions, as well as an understanding of the principles of operation of this device - this is all you need to know in order to make a reliable unit.

Everyone has an idea of a potbelly stove as an iron box in the shape of a rectangle, on which there is a door for laying firewood, as well as a chimney, often attached to the top of the box itself. Before, everything was like that. The hardest fuel burned in such a design very quickly, while almost all the heat that it emitted went out into the pipe. While the heating part, a pipe was used, which, as a rule, was laid through the entire room. However, time does not stand still and significant changes have taken place in this matter.