Ceramic gas outlet

This is the most versatile design that can be used with all types of boilers. The material is resistant to aggressive products formed during combustion. It is necessary to take into account the highest temperature for which the products are designed. For solid fuels, models are needed that can withstand 600 °, for gas-fired boilers, 450 ° is enough. First of all, they provide for the adaptation of a condensate trap.

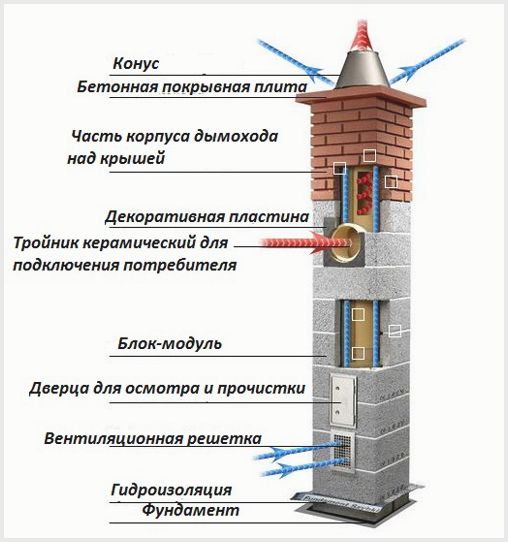

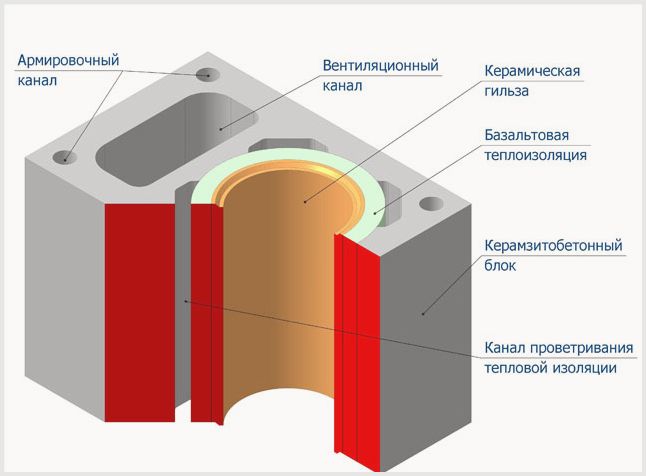

Ceramic pipes are installed mainly in brick construction or hollow cinder blocks. If they have two holes, one of them is used for ventilation or oxygen supply for a burner with a closed fuel chamber. Pipes are insulated with mineral wool to reduce the appearance of moisture, to increase traction. Models in the steel case are realized. They can be placed in the middle of the house without the construction of specialized channels.

The flue duct consists of individual elements 0.5–1 m long. On the upper part there is a sleeve into which the next section is placed. Various product options are available:

- 1. Round for installation in concrete blocks. They have a cavity where the pipe and asbestos sealant are placed. For connecting components, fittings are placed in the holes.

- 2. With right angles for installation in brickwork. Their size is 20x20 cm.

- 3. With steel body. Pipes are connected with clamps.

- 4. One piece design with sleeve. It has ventilation channels, holes are provided for installing fittings during installation.

The use of ceramic pipes for gas exhaust without enclosure and thermal insulation is not possible. They strongly absorb moisture, due to which the shell on the outside is required.

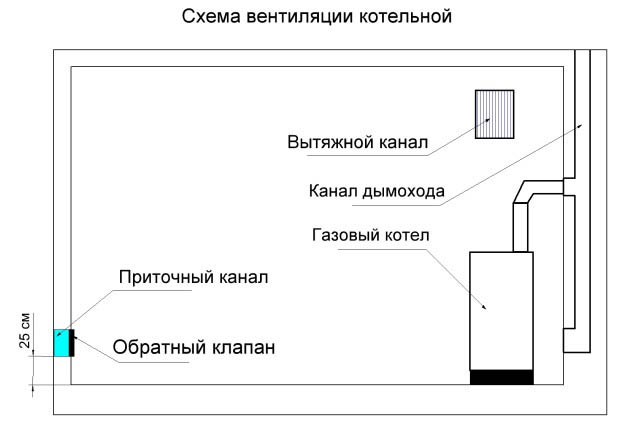

Ventilation system in a private house with gas heating

Supply ventilation for a gas boiler in a private house is considered highly efficient. According to the rules, the ventilation system is selected and planned at the stage of drawing up a project for a house. But even with a building already in operation, it is never too late to equip ventilation. In private houses, the most popular are aeration (natural air exchange), supply and supply and exhaust ventilation. With any scheme, there are certain technical factors.

Exhaust valve increases draft

Exhaust valve increases draft

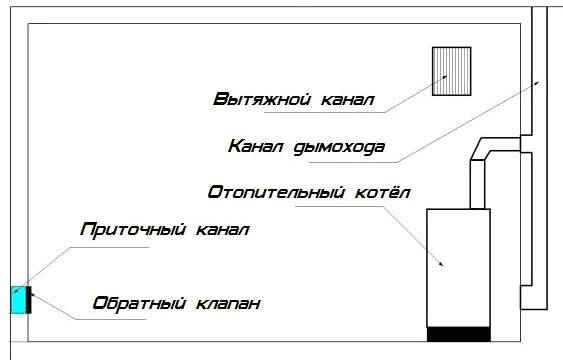

- Wall-mounted boilers, according to the rules, are mounted on load-bearing walls. Each of the models has its own system for the disposal of combustion products (natural, mechanical).

- The floor-mounted boiler equipment is placed only on the floor without the use of any supports. Combustion products are removed from it through special longitudinally or vertically installed exhaust pipes.

- Home improvement with plastic structures on window openings and balconies makes natural air exchange inefficient: both inflow and exhaust are completely blocked. In addition, the laws of physics stop working in the summer, because. temperature air flows inside and outside the building are aligned. Therefore, supply and supply and exhaust ventilation of a gas boiler in a private house are the best options for organizing air exchange. Here you need to act within the boundaries of reasonable sufficiency.

- The operation of the fan for inflow is suitable for medium-sized houses (up to 300 sq.m.). In cottages and suburban residential buildings with an area much larger than 300 m2, one discharge function of the ventilation system will not be enough, so it is better to use the supply and exhaust method of exchange.

Types of ventilation of gas boilers

There are two ways to ventilate a gas boiler room - natural and artificial.

To ensure natural ventilation, it is necessary to make a hole in the wall opposite the boiler and lay an air duct with a diameter of 15 cm or more through the hole, in accordance with the size and power of the installation. The flow of air masses is regulated by a valve in the pipe. Due to the natural flow of air from the street to the gas boiler, the combustion process is supported. However, the air in the room itself is not updated.

Supply ventilation in the boiler room is the easiest to install and use, but it has significant disadvantages:

- The system can only be used for low power boilers;

- The process of air intake cannot be controlled;

- Additional ventilation is required in a room with a gas boiler - gaps between the doors and the wall, windows, etc.

A more functional option for powerful gas boilers is forced ventilation, which is distinguished by the installation of artificial air exhaust. To do this, one or more fans are installed inside the chimney pipe, depending on the power of the gas boiler, the number of pipe turns and its diameter.

Exhaust pipe made of stainless steel

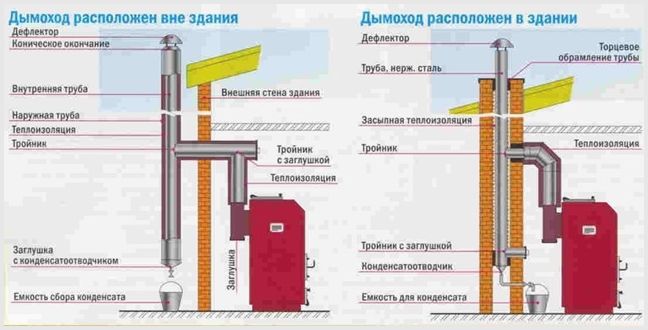

Steel chimneys are available in different versions. A single-wall pipe is placed in a brickwork. A similar scheme is also used for the restoration of a channel that worked with a solid fuel boiler. It is assembled from ready-made factory sections, any of them consists of an outer shell and an inner one. The space between them is filled with material for thermal insulation. Such structures are intended for installation in the house or from the outside. Specialized building channels are not needed.

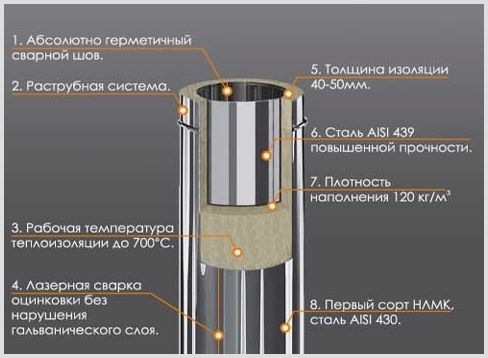

To protect the structure from the destructive processes of acid, which appears from the sulfur contained in the exhaust gases, a special stainless metal is used. The cost of similar structures is higher than brick and ceramic, but they have significant good qualities. They are mounted from some modules, the walls are perfectly even and smooth, easy to clean, not prone to the accumulation of condensate. Light weight does not require a base device. To clean the channels that are inside, it is disassembled into component parts.

The material is not flammable, will withstand the temperature of the outgoing smoke. The factory equipment takes into account the expected purchase of tees, elbows, which makes it possible to create any configuration at the required angle. To make a chimney in an already built house does not require serious alterations, even if it is not expected by the project. Can be attached to the wall. The diameter of the inner channel is selected to match the size of the hole for the outlet of the gas boiler.

The external placement of a single-wall structure leads to a very high formation of condensate, which interferes with normal draft. To avoid bad consequences, it is placed in a brick channel or a sandwich model with thermal insulation is used. In order to reduce the cost of such products, along with stainless steel, zinc coated steel is used. The inner tube is 0.5–0.6 mm thick. Two-stage devices are more economical than other metal hoods due to good thermal insulation, they do not require the construction of an external brick channel.

The ventilation pole accumulates in this order:

- start from the lower segment, installing one pipe into another;

- suggest a large number of stealth hatches;

- holders for wall mounting are installed after 1.5 m;

- the length of horizontal sections cannot be more than 1 meter without mechanical ventilation.

When buying a double-circuit model, attention is paid to the material of the pipes. For the inside, only stainless steel is allowed, galvanized metal is not suitable

At a temperature of just over 400 °, it begins to oxidize, toxic fumes appear. High humidity exacerbates the situation.A similar design is very easy to make with your own hands. For insulation, basalt-based cotton wool, expanded clay sand, polyurethane are used.

Boiler hood installation

Exhaust pipes for gas boilers can be installed independently. In this case, special care must be taken and the tightness of the connections must be carefully checked. To install exhaust ventilation you will need:

- fan with check valve;

- lattice;

- duct of suitable diameter.

Using a perforator, holes are made at the point where the pipe enters the wall. Then expand it to the desired size and insert the pipe. A fan is installed in it. All seams and cracks are blown with mounting foam. Lattice is installed last to give the structure a finished look.

Supply ventilation is mounted according to a similar principle, only the fan must work in the opposite direction. The test is carried out in a closed room using a piece of paper which is applied to the inlet of the ventilation duct. With good traction, it should touch the grate. If there is a blockage or installation was performed incorrectly, a sheet of paper will fall to the ground.

Installation of a chimney for a gas boiler and turnkey ventilation in a frame house.

Watch this video on YouTube

Necessary calculations

Accurate and competent calculation of ventilation is an important stage in the design of a heating system. Professional engineering calculations take into account the dimensions of the furnace room, technical characteristics and the installation location of the equipment. Designing a boiler room of a private house is easier. You need to define the following parameters:

- The geometric dimensions of the room (length, width, height).

- Air flow rate. It should not be less than 1 m/s.

- The coefficient of air exchange amplification, due to the difference between the allowable height of the room (6 m) and its actual value.

Having determined them, it is possible to calculate the optimal diameter of the supply and exhaust ducts of the ventilation system. For a room with dimensions of 4 × 3 × 2.8 m (length, width, height), the calculations look like this.

- By multiplying the parameters of the room, its volume is calculated. It is equal to 33.6 m3.

- The coefficient of increase in the air exchange of the boiler room is determined: (6 - 2.8) * 0.25 + 3 = 3.8.

- The volume of air that must be replaced within an hour is found: V \u003d 3.8 × 33.6 \u003d 128 m³.

- The cross-sectional area of the channel, which must have exhaust ventilation in the boiler room of the cottage, is calculated by the formula: F = 128/3600 = 0.035 m2.

- The resulting area value is converted into a diameter, since in practice circular ventilation pipes are more often used: D = 2 sqrt (S / π) = 211 mm.

DIY installation

A competent arrangement of the ventilation system of a boiler room includes three mandatory stages: preparation of a technical project, installation of equipment and performance testing. When planning, the performance of the ventilation unit, the length of the air ducts and the heat output of the boiler are taken into account. When installing air ducts, it must be remembered that their location depends on the type of air exchange used. Horizontal pipes should only be installed in forced-air systems. Moreover, their length is related to the capacity of the installed equipment. In any case, the channels should be straight, without bends or turns. Natural systems are allowed to be equipped only with vertical air views, the length of which cannot be less than 3 m.

Having completed the installation of the ventilation and heating system of a private house, it is necessary to check the performance of all its functional elements. It is required to make sure that there are no coolant leaks, reverse thrust and heat losses, measure the boiler efficiency and the concentration of carbon monoxide in the furnace. To ensure the reliability of measurements, they should be carried out only 24 hours after the start of heating and air exchange.In order to increase the safety of the boiler house and to effectively remove combustion products from it, it is useful to additionally use fire ventilation and a special smoke control system.

Prices

When installing turnkey ventilation, the cost of qualified preparation of project documentation for a boiler room and installation work depends on the size of the house, the type and characteristics of the heating equipment used, the type of air exchange, automation, and so on. The implementation of the first service averages 55 rubles per 1 m2, and the direct installation in a building with an area of 100-800 m2 will cost 25,000 - 33,000.

Main technical characteristics and prices of the most popular air handling units:

| Model name | Max. air consumption, m³/h | Heater power, kW | Dimensions, mm | Price, rubles |

| GlobalVent Economy-300 | 400 | 2,7 | 220x640x435 | 35 300 |

| 2vv Alfa-C-20VS-DP-2 | 2000 | 32,8 | 618x468x1200 | 172 300 |

| A-Clima ARL BOX 2,5 | 1970 | 34 | 1500x800x370 | 106 200 |

| GlobalVent Economy-1500 | 1900 | 11,1 | 390x770x635 | 63 900 |

| A-Clima Arl Box 1,5 | 1635 | 28 | 1270x670x370 | 103 900 |

| DVS OTA 160/5000 | 376 | 5 | 490x1000x490 | 42 500 |

Basic requirements for ventilation

Most often, boilers for heating systems of cottages are installed in separate rooms - boiler rooms. Sometimes special extensions are created for them. In addition to fire safety standards, ventilation requirements must be met in order to ensure the flow of fresh air to the furnace and remove combustion products in a timely manner. The procedure for air exchange in rooms with various types of organic fuel is regulated by state norms and rules (SNiP). In case of non-compliance, the supervisory authorities will not give permission to operate.

Not surprisingly, the requirements for ventilation of a gas boiler house in a residential building are the most stringent. In this case, for residents, the danger is not only harmful combustion products, but also the fuel itself - gas. Softer conditions are put forward for the installation of low-power gas boilers (up to 30 kW). For them, it is not necessary to allocate a separate room, they can be installed in a residential area, for example, in the kitchen. The standards relevant for gas equipment are fully suitable for boilers using other types of fuel.

When installing ventilation, follow the rules:

1. The height of the ceilings in the room for heating equipment is not allowed to be lower than 6 m. Since it is literally difficult to fulfill this requirement in private households, it is possible to solve the problem by increasing the ventilation intensity of the boiler room. Each missing meter of height must be compensated by an increase in air exchange by 25%.

2. In addition, according to SNiP, ventilation should be provided in boiler rooms to ensure the complete replacement of three volumes of air in the room within 1 hour. This does not take into account the volume required to ensure the combustion of the boiler.

3. If natural ventilation cannot cope with the replacement of air in the boiler room, then it will be necessary to install a forced-type system.

Types of exhaust ducts for gas-fired boilers

A classic brick chimney has a decent mass; first of all, a strong foundation is arranged under it. It is better to calculate this at the stage of building a house, but sometimes you have to equip old buildings with them. Surfaces inside are smooth.

Stainless steel exhaust structure resists chemical and mechanical attack. It is arranged according to the principle of a sandwich: a smaller one is placed in a larger diameter pipe. The space between them is filled with non-combustible material - stone wool. Manufacturers recommend a variety of device models.

Ceramic chimney consists of some blocks that are mounted in a concrete frame. The system is equipped with thermal insulation, which is why it is not afraid of temperature fluctuations. It is strong, not afraid of fire and moisture. During installation, it is required to connect the modules with high quality.

GAS connection and Chimney. film - 22

In a coaxial hood, the smaller ventilation duct is placed in the middle of the larger one. One at a time, the air necessary to maintain the combustion process is supplied, and the products of combustion are removed in another way. The system has good characteristics of safety, environmental friendliness, increases the efficiency of the equipment workflow.

The selection of the flue pipe depends on the specific situation. Any exhaust pipe for a gas boiler must comply with SNiP standards. They must be observed from design to installation, due to the fact that an incorrectly delivered design threatens the safety of people. Products are subject to the following requirements:

- good traction, providing complete removal of exhaust gases;

- high temperature resistance;

- impermeability of the joints of individual elements;

- the presence of a condensate collector for removing liquid.

In structures with turns, hatches are installed in such places for inspection and cleaning. Branches to the side should not be longer than 1 meter, and the maximum number of turns is three. Jointing of individual elements is not allowed in the place of the floor passage. A gap of 5 cm is left between the pipe and a non-flammable surface, and if it is a fire hazard - 25 cm or more. The chimney must rise above the roof ridge for good draft. The hood provides natural ventilation of the room.

To install a forced system, a duct fan is used. It consumes electrical energy, so to save it, it is installed exclusively on the exhaust or inflow. Bars are placed from the two ends of the pipe to block the way for rodents and third-party objects. Automation will make it possible to turn on the device along with the start of the boiler.

Types of exhaust pipes and their characteristics

The calculation of the diameter and height of the hood is carried out taking into account the following factors:

- power of a geyser or boiler;

- temperature difference between outdoor air and exhaust gases;

- the amount of exhaust gases to be removed;

- technological features of gas heating equipment.

In addition, the material from which pipes are made for extracting a gas boiler or column is important.

They can be:

- stainless steel grades 304, 310S, 316, and 316L;

- steel with enamel coating;

- aluminum.

For the manufacture of the hood, special steel is used, and heat-resistant enamel is applied as a coating, which does not crack during operation when exposed to high temperatures. The main disadvantage of metal chimneys is the formation of condensate with a significant temperature difference between the inside and outside of the structure, so they are insulated with heaters.

Thermal insulation materials must be resistant to fire, so the best option is to use mineral wool.

A steel gas ventilation pipe can also be with internal insulation made in the factory. Such products are characterized by high strength and long service life.

Another option for removing fuel combustion products during the operation of gas equipment is a coaxial chimney, which is a two-pipe structure. One of them serves to remove exhaust gases and is located inside the other, designed to intake and move air masses to the burner. They come from the street, so gas heating equipment with a coaxial chimney can be installed in any room.

For a geyser, the choice of pipes for ventilation is not limited to rigid structures. A corrugated chimney is not inferior in technical characteristics to a rigid one, provides the necessary draft and effectively removes exhaust gases. In addition, it is flexible, which avoids transitions and the use of connecting elements.

The corrugated hood for the geyser is lightweight, easy to install and resistant to condensate. It is made of laminated multilayer foil and steel wire, which serves as a frame. If necessary, the corrugated pipe is extended to the desired length.