The principle of operation of a diesel boiler

Wall-mounted diesel boiler or floor-standing - all installations of this type work on the same principle. And the owner of the house must at least in general terms know the principle of operation of a diesel boiler, so that in the future there will be no problems with operation.

As soon as the unit is turned on, the pump also starts. In the nozzles of the unit, the pressure necessary for operation immediately arises. It is due to him that the liquid (diesel oil) is distributed throughout the installation as needed. At the same time, a mini-transformer supplies voltage to the electrodes, due to which the fuel ignites.

Further, the unit operates in autonomous mode. The operation of this type of heating system is regulated by special sensors. It is they who will regulate further fuel consumption and maintain the heating temperature at a certain level.

Single-circuit diesel heating boilers can only warm up the room. But double-circuit units can also heat water, so many homeowners stop at them. If large volumes of hot water are needed, then it makes sense to purchase a device with a built-in boiler designed for a certain number of liters.

It is important to know the advantages and disadvantages of such installations, what fuel consumption will be during operation. All this will help you make the right choice and not regret buying in the future.

Servicing the heating device

It is necessary to service the diesel fuel boiler regularly and this can be done at home with your own hands. Basically it consists in cleaning the burner. The burner component is a fuel filter, it must be cleaned as it becomes dirty. It depends on the quality of the fuel. Sometimes this should be done once a week.

Cleaning the chimney is also very important for the normal operation of the heating boiler. It can be carried out less frequently than cleaning the burner, approximately 2 times per season. Chimney cleaning can be done by hand.

Ignition electrodes, which may be supplied with the burner, must also be cleaned 2 times a season. This should be done with a swab soaked in solvent. The nozzle that makes up the burner cannot be cleaned. If it gets dirty, you need to change it (this can be done at home with your own hands, since this is not a difficult process). If the replacement is not done on time, then the burner does not function well. And as a result, low efficiency and poor operating parameters of the unit for heating. In some heating models, you need to change the nozzle in the burner once a season. In order not to adjust the burner again, you need to install the same nozzle as before.

Sometimes, after cleaning the filters and replacing the nozzle, the burner does not start the first time. This happens because the lines are not filled with fuel. It is necessary to turn the burner on and off several times, and it will start. But still, if the fire does not light up, you need to make sure that the fuel is of high quality without impurities, water.

There are several reasons why the burner does not work:

- Fuel is not supplied to the heating boiler;

- Air does not enter. If, when the heating boiler is turned on, there is no noise from the operation of the air pump, this means that it does not work;

- No spark. This problem can occur if the ignition electrodes are too clogged or the distance between them is incorrect;

- Too much oxygen enters the system. The instructions for using the burner indicate which parameters to change in order to restore normal air supply. This can be done by hand. But this will only help if all the components are in order.

The solar heating boiler is made of steel or cast iron. Models made of cast iron are considered to be of better quality heating installations.Since the operation of the cast-iron unit (in particular the burner) is much longer, and it is not afraid of corrosion that occurs from the appearance of condensate.

A steel heating boiler, of course, is cheaper and lighter, but it also breaks down faster. At the same time, corrosion processes shorten the service life.

Alternative heating of the house with diesel fuel

What could I do to make solar heating at home a little less expensive, and could use a diesel boiler as the main source of heat for the house?

The first thing I think about is using a waste oil burner. I put such a burner for testing and collect virtually free fuel, where I can - at service stations, at express oil change kiosks, and so on.

What are the disadvantages of this option? The first and most basic is the price of the burner. The cost of the burner for testing is 60,000 rubles. Which is comparable to the purchase of almost 2 tons of diesel fuel.

A mining burner might have solved the issue of heating the house with a diesel boiler, but it is not cheap.

Secondly, working off also needs to be collected, spending gasoline and time, transporting it in cans to the house, defending it somewhere and storing it at this time.

And, thirdly, I'm not the only one so smart. More than once I have already watched comrades who collect mining at the service station and take it out for their own needs. This is exactly the same topic as with our own production of pellets. Looks like it's free. But in fact, it turns out that it is easier to heat with briquettes than to make pellets yourself from “free” sawdust.

There is, of course, also solar oil and light oil. But it also has its pitfalls. Starting from the fact that a standard burner will not be guaranteed to work on these types of fuel, and ending with the complete impossibility of obtaining this fuel in some regions.

Here the analogy with the coal-fired boiler Carborobot suggests itself. The boiler is good, no doubt. But in our region there is no fuel for it, there is no coal of the required fraction, there are no good suppliers. And to carry from somewhere - it turns out to be unrealistically expensive.

Share with friends:

Konstantin | 3.06.2016 10:57

I have a house of 120 square meters, at first I fell for advertising and hung infrared heaters throughout the house, 8 pcs for the whole house, all in accordance with those. regulations for them. When the temperature drops to -5, it becomes cold, there is no other heating. At the same time, they also click and dry the air, it is not possible to sleep. I changed it under warranty due to clicks - the result is 0. I installed a Kiturami boiler of 30 kilowatts, a barrel of 220 liters and I’m happy, the consumption is 1500 liters per year, I live all year round, two small children, the boiler gives hot water, I collect three tons of pool in the summer, so as not to wait when it warms up from the sun, the neighbor does not even eat a ton. the house is 60 meters, in practice we have almost doubled the savings with electricity. Leningrad region. Do not believe provocateurs))) Everyone is warm.

Oleg | 06/22/2016 12:03

Konstantin, why did you take Kuturami for 30 kW? There are also models for 19 kW and 24.4. How many hours a day does the boiler work in severe frosts?

Tatyana | 28.10.2016 07:06

Konstantin, hello! I also choose a boiler. I would like to know more. Is it possible somehow in a personal? Also Peter, the conditions are similar. We lived for 6 years on a pellet house. Got fuel problems...

Our authors are practitioners

Vladimir Zastrelchenko. Zelenograd, author of articles on home insulation and site planning.

Vladimir Tolbukhin. writes about stoves, boilers and autonomous heating of a private house.

Artem Stebanov. Chelyabinsk, preparing materials for planning and estimates.

Xenia Sinitsyna. Moscow, Guild of Designers, publishes materials on home improvement.

Rinat Nigmatullin. Naberezhnye Chelny, author of articles on the insulation of houses and outbuildings.

Marat Borchan. Tomsk, heat engineer, author of articles on thermal resistance of enclosing structures.

Sergey Pozdnyak. Perm, author of articles about country life and farming.

Features of liquid fuel equipment

Boilers that consume diesel fuel, diesel fuel or kerosene can be used, as already noted, for domestic and industrial buildings. Fuel must be stored in a special container - it can be located anywhere, as long as it is convenient:

And this is one of the main advantages of the described equipment.

Note! It is most advisable to use these boilers in non-gasified settlements, because the fuel consumption in this case is quite low. As for the principle of operation, it is not much different from devices that consume other types of fuel.

The device includes a combustion chamber where the burner is located; with the help of the latter, fuel is burned. During operation, the coolant warms up, after which it is fed into the heating system. A traditional chimney is used to remove combustion products. What is characteristic, when moving, they are passed through the heat exchanger, sharing with it part of the thermal energy. This allows a significant increase in efficiency.

Devices operating on diesel fuel, in most cases, have a body made of steel - it is known to be practically immune to rust. Under the body there are automation units (they control the functioning of the boiler) and control of the device. In the manufacture of heat exchangers, either cast iron or steel is used; thanks to this, the units are able to withstand exposure to critical temperatures for a long time.

In order to reduce heat loss during operation, as well as in order to reduce the amount of diesel fuel consumed by the boiler, a heat-insulating gasket is installed under its outer body, which in parallel prevents accidental burns when touching the surface.

The process of operation of the heating boiler

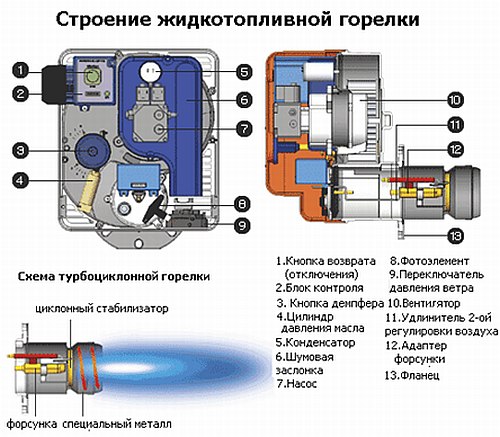

Many people make a diesel fuel boiler with their own hands, since its design is quite simple. The burner built into the housing is equipped with a turbine (fan) that mixes liquid fuel with oxygen. It does this by spraying the fuel. It is because of this system of the structure of the burner that the unit makes noise. This principle of operation significantly increases the efficiency of fuel combustion, and hence the heating power increases.

When the fuel is burned, the necessary thermal energy is released, which heats the heat exchanger. And as a result, the coolant that fills the heating system of the house.

A pump is also required in the design. It pumps fuel fluid from the fuel tank into the combustion chamber. It is installed on the highway. Such equipment must be grounded, as it is connected to electricity and, moreover, diesel fuel is a flammable substance. So grounding is necessary to ensure the safety of the house. Especially if the heating boiler is made by hand. To do this, you need to ground the fuel tank to the ground.

Such a heating boiler can also operate on fuel oil, but it is necessary to regularly change the filters, which become clogged much faster than when heating with diesel fuel.

To ensure that thermal energy is not wasted, the device must be equipped with radiators and thermostats. That is, automation that will regulate the burning of the flame and its intensity in the burner.

The efficiency of such heating devices is quite large, only for gas boilers it is greater, but only by a few units.

Is a solar boiler profitable for a home

The benefits of heating a house with diesel become obvious if we consider the main advantages:

- No need for permits - the boiler room is installed in any technical room of the house. The installation itself costs the price of the strapping. For example, connecting a gas boiler must comply with strict standards.For obtaining permits and preparing project documentation, you will need to spend from 60,000 to 120,000 rubles. Additional costs will be required for the equipment of the boiler room, the connection of the gas pipeline to the house, etc. The real cost of heating is made up of not only operating costs, but also connection costs.

- Costs directly for the heating itself - the calculation of fuel consumption is carried out according to the formula, 10 kW = 1 kg of diesel fuel / hour. Accordingly, to heat a residential building of 100 m2, you will need 1 kg of diesel fuel per hour or 24 kg during the day. In a month, it will be necessary to spend already 720 kg. During the heating season, 4320-4500 kg or 5200 liters of diesel fuel will be spent.

- Additional maintenance - the principle of operation of domestic heating boilers on a solarium is associated with the use of a special burner and fuel pump. During operation, it is necessary to change the fine filter, nozzles. All this increases the cost of heating.

- Additional costs - diesel fuel is supplied to the boiler by a fuel pump, and air is forcibly supplied to the combustion chamber - all this requires connection to the mains.

A diesel boiler, in its efficiency, is inferior to a classic heat generator running on natural gas. But, given the high cost of obtaining permits and approvals, a diesel-fuel heating device is quite capable of competing with gas-fired boilers.

How to save on fuel Criteria for choosing heating equipment

Units consuming liquid fuel are calculated for both one and two circuits. And it is quite obvious that in the second case, the fuel consumption will be large, because of which the costs will only increase. For this reason, the best option for dual-circuit appliances may only be to reduce the consumption of hot water consumed, which will help save on fuel.

Experts advise one more thing. According to them, it is possible to reduce fuel consumption by setting the lowest temperature for the heat carrier. And the final point - it is advisable to install a thermostat in the warmest room. If you follow all these recommendations, you will be able to reduce the fuel consumption required for the operation of the boiler, and save a certain amount of money.

On many thematic forms, users are interested in: which units are more economical - diesel or electric? And what kind of fuel consumption does a diesel heating boiler have? It is quite difficult to answer this question unambiguously, since it depends on a number of points, including:

- the quality of the thermal insulation of the building;

- the cost of the fuel used;

- the area of the heated room;

- features of a particular climatic zone;

- number of people in the house.

And if you know about all these factors, then you can roughly calculate the consumption of both fuels by comparing costs. And now - a few more practical tips regarding the choice of a heating unit.

- Heating equipment that consumes diesel fuel, in the presence of a combustion chamber made of steel, will be immune to temperature changes. However, steel undergoes a rusting process, so it does not last as long as, for example, cast iron.

- The higher the cost of a heating boiler, the higher the risk that its maintenance will cost you a lot (compared to models that have a lower cost).

- Devices that are equipped with a cast iron furnace chamber can last up to twenty years, but temperature changes affect them, moreover, very significantly. In this kind of heating systems, it is necessary to install valves that will mix the heated liquid into the "return" pipeline. All this is required so that the combustion chamber simply does not crack.

Video - Diesel heating boiler - fuel consumption

Why diesel fuel?

When choosing a heating boiler, each user is guided by specific individual requirements. And if, for example, you live in a locality where there is no centralized gas supply or there are often drops in the supply of electricity, then diesel fuel boilers, the consumption of which, as we have already found out, are insignificant, will be the best option.

Moreover, such devices have one more advantage, which we did not talk about - the fuel tank can be installed in any place convenient for you. And this has become a decisive factor for the fact that the popularity of diesel equipment has only increased in recent years.

Factors affecting the fuel consumption of diesel boilers

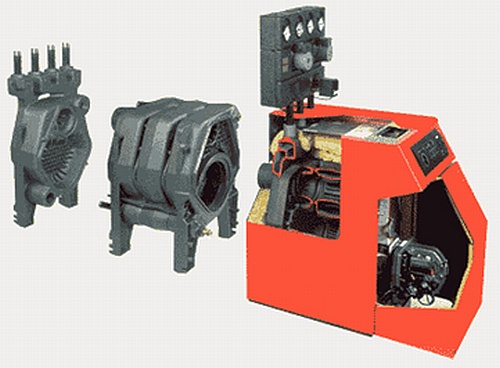

When choosing heating equipment, it should be remembered that in terms of which a diesel boiler is characterized, fuel consumption is, although important, but not a determining characteristic of the efficiency of a home heating system. Liquid fuel boilers consist of the following main units:

- boiler bodies with a steel or cast iron heat exchanger;

- burners with fuel supply pump;

- autonomous heating systems;

- solar storage containers.

Boilers with cast iron heat exchangers have a capacity of 16 to 1000 kW, so if it is not enough to heat a large cottage, you will have to choose steel heat exchanger, allowing to reach a power of 30,000 kW, however, during its operation it is necessary to maintain a constant temperature of the coolant not lower than + 60ºС, otherwise the intense corrosion process will quickly disable the steel walls of the heat exchanger. This feature leads to increased diesel boiler fuel consumption, as well as constantly high room temperatures. Cast iron heat exchangers, unlike steel ones, last up to 50 years, however, only under the condition of normal operation: without sudden temperature changes and when using a high-quality coolant.

Economic efficiency autonomous heating systems largely depends on the characteristics of the burner, whose tasks include the preparation of the air-fuel mixture and its combustion. One of the main indicators of the burner, affecting the efficiency of the entire heating system as a whole, is way to regulate its power. Now the trading network offers:

- inexpensive single stage burners operating only in the maximum mode - 100% (temperature control is carried out by turning off the burner);

- two-stage - can work in two power modes - 40% and 100%;

- smoothly two-stage - with smooth power control ranging from 40% to 100%;

- modulated - capable of smoothly changing power in the range from 10% to 100%, which makes it possible to adjust the temperature regime of the heating system depending on weather conditions (in addition, burners of this type can significantly reduce diesel boiler fuel consumption, and also due to the absence of sudden temperature changes to extend the service life of thermal equipment).

Automatic control of the heat supply system although it requires tangible costs, it makes it possible to safely operate diesel heating boiler in offline mode, allows you to adjust its operation depending on the temperature in the room and the weather outside. All this leads to savings of up to 15% of liquid fuel, which ultimately pays for the costs of acquiring automation.

Fuel storage tank should be chosen based on the optimal mode of its refueling - 2 times a year, subject to continuous operation of the heating system during this period at full capacity. There are tanks on sale from various materials with a capacity of 500 to 2000 liters, so choosing the right one will not be difficult.

Manufacturers overview

Ferroli devices made in Italy are an example of reliable, economical and safe equipment.

It is also important that the products that are supplied to the Russian market are designed taking into account the climatic features of the territory of our country.

The diesel boiler for heating the Ferroli building can be called suitable for heating systems of residential buildings and cottages.

Heating appliances running on diesel fuel do not depend on the ability to connect to communications.

In addition to all this, it is necessary to say about one more advantage of these boilers, namely the possibility of replacing it with a liquid fuel gas burner. What makes this model of diesel boilers universal. Thus, it will be possible to switch the heating system to gas in the future.

Disadvantages of Ferroli devices, including:

- the need to store large volumes of fuel, which specialized tanks can handle;

- you need to constantly check the fuel level so that the system does not stop working.

If we consider all products by functionality, then we can see that the devices from the GN1 series provide the opportunity to heat rooms and heat water for domestic needs. The power of such equipment is 91 kW. But the GN2 line can only heat the air.

The efficiency is quite high, which allows you to spend fuel with greater efficiency. In addition to all this, Turbo boilers are equipped with special sensors that ensure safe operation.

The heating boiler of the Turbo model, running on diesel, has a turbocyclone burner, and is carried out with greater efficiency. Apparatuses of the KSO series, if necessary, can be converted to work on other fuels.

In all units for heating systems, manufacturers from Korea are equipped with special sensors, which ensures safe operation and automatic control of the system.

Another Korean company, Navien, produces equipment suitable for heating a country house. The salient features of this equipment are:

- low level of generated noise;

- modern automatic control system;

- convenient set.

If we talk about diesel-powered boilers manufactured by Russian companies, then it is worth saying that in most cases these are specialized models. Such equipment is characterized by low efficiency, not exceeding 70%.

Russian-made diesel boilers are assembled on the basis of designs developed back in Soviet times, namely:

- AOZhV

- Flame

- KChM

All these systems are outdated and do not meet modern requirements.

As is clear from the above information, a diesel boiler is quite economical. With its installation and subsequent operation, you can significantly save money on the purchase of fuel.

However, it should be said that a diesel boiler with its high efficiency and low fuel consumption is suitable for large houses and detached buildings. The fact is that such equipment requires the presence of a boiler room and a fuel storage room, as well as the organization of communication between them. All this will pay for itself only if you need to heat large areas.

Some technical specifications

It is not so difficult to guess that the cost of equipment increases with the improvement of operational and technical characteristics.

In particular, power must be taken into account.Usually 1 kW is enough to heat a room of 10 square meters

Therefore, if you have a house of 100 square meters, then you need to buy a 10 kW boiler, such equipment will consume about 1 kilogram of diesel per hour.

As for weight, this parameter in most cases is not so important. Almost all models are placed on the floor. True, it is worth looking at the dimensions, since sometimes there is no place to install a wide or, conversely, a high boiler. If we talk about the ratio of power / weight, then it is difficult to find any regularity. Much depends on the manufacturer and the materials used during assembly. So, boilers for 10-20 kW weigh about 100-160 kg, 25-30 kW - 170-200 kg and so on.

Features of using a diesel boiler

The main guarantee of the correct stable and efficient operation of a liquid fuel boiler is the proper quality of the fuel. However, when confronted with reality, it comes to the understanding that high-quality fuel is either very expensive or difficult to obtain. Therefore, you have to use what is available, and many owners of diesel boilers even use fuel, to put it mildly, not of the highest quality. This is where a series of problems associated with this begins, the most important of which is clogging of the fuel filter. Cleaning it will not be difficult, but in this case you will have to do it regularly.

Another problem, more significant, is the clogging of the burner nozzles. If this happens, then you will leave more than one kilometer of nerves when heating the house in such conditions. To begin with, clogged nozzles threaten not only a significant decrease in the efficiency of home heating, but also increased fuel consumption. Simply put, you will be cold, but you will spend a crazy amount of diesel fuel to maintain such a cold in the house. Plus, with high speed, the boiler heat exchanger will begin to be covered with soot from the inside. And he, in turn, will further reduce the efficiency of the boiler.

How to clean the nozzles and restore the original power of the boiler? On your own, you are unlikely to be able to do this, since the process is very complex and requires skills. Therefore, to carry out this procedure, you will need to call the service personnel.

It’s also impossible to clean off soot just like that - for this you will have to disassemble almost the entire boiler.

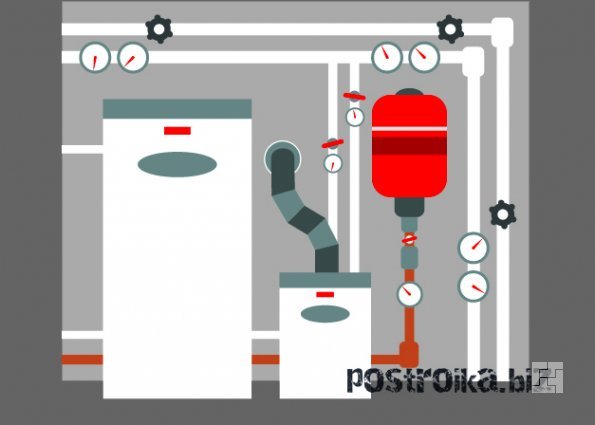

Requirements for a diesel boiler house in the house

Installing a diesel boiler in a house is a complex technical process that requires qualified assistance. When connecting, take into account the current regulatory requirements and fire safety regulations. Adjustment and maintenance are carried out using special computer software.

The organization of heating in a private house with a diesel boiler is carried out subject to the following conditions:

- The room for the boiler is chosen from technical rooms with sufficient area, lighting, ventilation.

- The placement of diesel boilers in residential country houses is carried out on a non-combustible base. Wall and floor decoration is carried out using non-combustible building materials: ceramic tiles, plaster.

- Automation - maintaining the temperature in the house is carried out automatically. Human participation in the operation of the heat generator is reduced to a minimum. Be sure to install safety automatics that turn off the operation of the boiler in the event of an emergency.

- Ventilation in the boiler room is provided through channels with natural and forced supply and air exhaust. The cross section of the ventilation duct is calculated based on triple air exchange for an hour.

- Diesel fuel storage is installed in a separate building. In the boiler room, it is allowed to store a reserve tank, with a maximum capacity of not more than 3-5 m³.

The correct installation of a diesel boiler in a residential private house is based on an understanding of work processes.The burner device creates strong noise interference, therefore, soundproof measures are carried out in the boiler room.

Additionally, a UPS and a stabilizer are installed to ensure the system's performance, even during power surges or power outages.

Advantages and disadvantages of domestic diesel fuel boilers

Reviews of diesel heating boilers for private houses and cottages indicate the same problem. A domestic consumer, if he reads the instruction manual, adjusts the operation of the boiler to his needs, violating the manufacturer's recommendations, which is the main cause of malfunctions.

The performance of boiler equipment depends on proper operation, from precisely set settings to the need for regular maintenance. If you properly heat the house with a diesel boiler, there are high rates of efficiency and heat transfer. Any violations lead to excessive fuel consumption.

The disadvantages of heaters are:

- Noisiness of boilers - as a rule, noise is not heard if the passage to the boiler room is closed by a door. It is not recommended to install a diesel boiler in the kitchen or any room adjacent to living rooms.

- Maintenance cost - you will need to regularly clean the heat exchanger and chimney from accumulated soot. When switching to another type of liquid fuel, as well as before the start of the heating season, it is necessary to adjust the burner. The best solution that allows you to save money is the conclusion of a contract for ongoing maintenance.

The advantages of boilers are considered to be low installation costs, quick commissioning, no need for permits and approvals.

The most economical boiler is one that is installed and operated in accordance with the manufacturer's recommendations. After installation and connection, a representative of the company will instruct on the use of the heat generator.

Operating experience shows that following the recommendations is the best way to extend the life of the boiler, ensure maximum heat transfer and comfortable heating of residential premises.

Calculation of power and temperature of a warm water floor

note

Installing a diesel boiler in a house is a rather important issue, so it should be taken more than seriously, because comfortable living in a country house during the cold season directly depends on it.

For heating with diesel fuel, it is first recommended to determine the type of power that will be required to fully heat the whole house. To do this, it is necessary to carry out a special calculation, which will fully take into account the total living area of the entire room, as well as the heat-insulating properties of the materials of your suburban building, the height of the ceilings and the presence of windows. In addition to these data, it is necessary to estimate the maximum sub-zero temperature in the region of your residence.

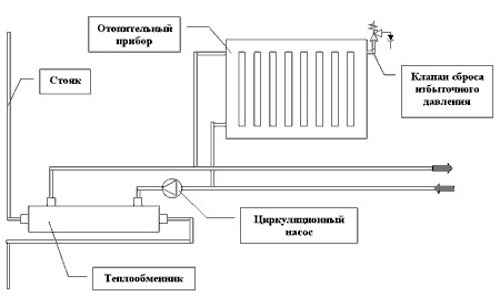

The principle of heating a house with diesel fuel.

Let's look at what important characteristics diesel fuel has in terms of heating the premises of a country house. First of all, it is worth noting autonomy, which means independence from central systems. Diesel heating installed in the house does not require additional permits for the installation and further operation of the boiler, which will entail a significant reduction in costs for the entire heating process. It should be noted right away that at the very beginning this is not a very impressive amount, but if you calculate the annual percentage of savings, you get a lot. Thanks to the high level of automation of the entire system, you can not only comfortably control the entire system, but also significantly save diesel fuel consumption.

We will not hide the fact that in order to install a boiler for heating with diesel fuel in a house, a number of mandatory conditions will need to be observed.The main condition can be considered the acquisition and installation of a special container in which the supply of all fuel will be stored. The room in which the boiler will operate must be equipped with exhaust ventilation according to safety rules.

Scheme of a liquid fuel boiler.

In order for the boiler for diesel fuel to last longer, you need to use only high-quality fuel. This fact will force you to purchase combustion products from trusted suppliers who have proven themselves. If you fulfill this condition, then the heating system will not have to be constantly repaired.

Recently, liquid fuel boilers, which are equipped with special replaceable burners, have become very popular. The basis of such technological equipment is the possibility of replacing the burner. If everything is done efficiently and professionally, then such equipment can be easily converted to gas heating. This question is relevant in the sense that your country house will soon be connected to the gas main.