Some subtleties of soundproofing walls in an apartment

The most the best soundproofing of walls in apartment can be performed by your neighbors. But, we very much doubt that you will be able to agree with them on such a comprehensive reconstruction of the walls in their apartment.

Negotiations with neighbors

The second option remains - to install a sound-absorbing layer from the side of your home.

Before soundproofing a wall, it is necessary to analyze the current state of the wall, its integrity. All existing holes, cracks, gaps (especially in panel houses) must be carefully plastered.

Cracks in the walls - sound-conducting channels Socket boxes are placed on drywall and soundproofed with non-combustible material

Socket boxes are placed on drywall and soundproofed with non-combustible material

After that, having studied the "market" of soundproofing and sound-absorbing materials, you need to choose the appropriate ones for your room, taking into account the need for "protection" from various types of noise. Soundproofing materials

Since the soundproofing of the walls in the apartment involves a complex of works, their final stage (except when using solid soundproofing decorative panels) is the finishing decorative finish of the wall surface of the room.

Also, the “channels” for transmitting sounds from neighboring rooms can be water and sewer communications, pipes of the central heating system. Due to the violation of the rules for the installation of such pipes during construction, it is necessary, if possible, to soundproof them yourself, or at least eliminate the cracks around them.

Varieties of partitions in a log house

Structures that are mounted on beams and logs are divided into

frame-panel, carpentry and solid, plasterboard, glass,

designed by designer

Installation of partitions can be done independently

without the involvement of specialists, while it is important to correctly calculate the dimensions

design and reliable sound insulation. Only if all requirements are met

you can make a partition that will not only divide the room into zones, but

and will create optimal conditions

Soundproofing wooden walls will protect the house from

extra sounds and cold.

Frame-panel

Such partitions are considered one of the most

common. Their main feature is that they can be made

independently, having some understanding of carpentry and relevant

tools. A partition is made using a beam. frame

is formed in such a way that between the jumpers there is a distance of 60

centimeters. The thing is that most heaters have just such

parameters, which will greatly help with the installation.

During the installation of sound insulation, waterproofing and

mineral or basalt wool. Sometimes foam is taken as a heater.

The main requirement for installation is double waterproofing. To fibrous

the material has not been exposed to moisture vapor barrier is extremely important.

It is not difficult to make a partition with sound insulation, especially if you know what it is.

must be. If the end result should be perfectly even, then the facial

it is better to sew up the sides with plywood or drywall.

Wooden, carpentry partitions

The design of the partition inside is the same as in the frame-panel one,

except for the exterior finish. In this case, you can use

decorative panels from expensive wood species or design elements. How

as a rule, such partitions are covered with varnish solution and other materials

for an external effect.

@peregorodki

@peregorodki

The degree of sound protection of such a design is low and

it is not possible to supplement it, since in most cases they are made

under the order and exclusively as a decorative element.

Solid partitions

If it is planned to install a solid partition in the house, then

it is mainly made from the same material as the structure itself. If

the building is made of profiled timber, then the partition will be the same, but

sheathing can be installed from fiberboard panels or drywall sheets. depending

From the choice of material, the cost of construction also affects.

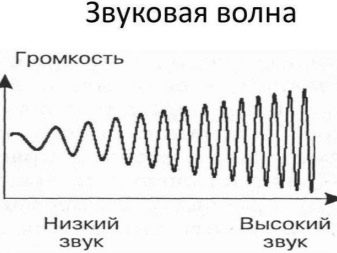

Types of noise

When soundproofing rooms, different types and sources of noise are identified. Internal discomfort does not create, external are divided into several types. An insulator is selected and work is planned taking into account the type of sound waves.

Taking into account the type of impact transfer, they are divided into shock, structural and air. The transmission of the latter goes through the air, they have no connections with the fences, a simple sound insulator will suffice. Percussion go with direct contact of surfaces with objects. Structural ones appear after the object of influence enters the overlap structure itself. The structural type is able to overcome significant distances in one building.

Frequency spectra that are taken into account for sound insulation:

- low - well audible for the elderly, bad for young children, represent the background of industrial installations, phone vibration, train horns;

- medium - audible to almost all people, this includes the hum of the TV, washing machine;

- high - clearly distinguishable by children and poorly elderly people, it can be sharpening knives, violin music, squeaking electronic devices.

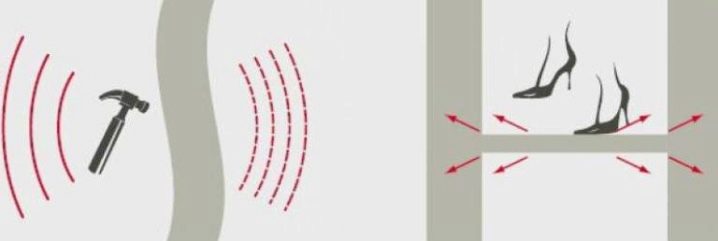

Drums

Sound loads created by solid bodies using vibration or shock actions. This includes the noise of a hammer, a perforator, as well as the loud stomp of people, the impact of falling objects, moving trains. Noise isolation from shock sounds is needed for residents of busy streets and railways.

Combined

A mixture of percussive and acoustic effects. For example, a hammer drill emits several types of noise at once: acoustic from the operation of the motor, plus private percussion as a result of the impact of nozzles on work surfaces.

materials

They muffle sounds or are used in heat and sound insulation of external walls, interior interior partitions.

Cork

The main type of sound insulation. Outside, fillers with cotton wool are installed, the lining of the inner surfaces of the walls is made using light options: they do not eat up space, they dampen noise. Suitable cork in the form of wallpaper, panels. It does not let in noise, retains heat, and is suitable for decoration.

Noise Blocks

For large rooms, vinyl film or noise blocks are used. Their thickness is not more than 3 mm, weight is about 5 kg per meter. The film has a high noise attenuation factor.

Loaded vinyl is a dense, durable membrane. The price is high. The film is not afraid of moisture, has high elasticity. Mineral dust is responsible for soundproofing.

The film is heavy and thin - this is what provides a high noise insulation coefficient.

ZIPS

The panels are glued under the wallpaper. They have the appearance of a two-layer sandwich, the composition includes panels with basalt fibers and solid sheets of gypsum fiber. The layer thickness is about 7 cm, the noise absorption index is up to 10 dB.

Substrates

Soundproof adhesives are attached to the wall, their thickness is slightly higher than the film, the price is the same as for ZIPS panels. The soundproofing effect is mediocre. Underlayment is a handy and cheap choice.

Fiberglass

Fiberglass plates - the middle part of the partition, absorbing sound vibrations, waves. They are laid in floor slabs, ceiling structures. Fiberglass has a special structure, does not crumble, in addition, a non-woven fabric is used in the manufacture of the lower layer.

Drywall

Gypsum boards delay sound, are stacked with a "sandwich" of fiberboard, chipboard, in its purest form.The number of simultaneous laying of materials determines the price of finishing and the level of sound absorption.

mineral wool

Thick fiber board absorbs noise, eats up usable area, non-combustible

When looking for an answer to the question, foam or mineral wool, the budget is taken into account. Styrofoam costs less, mineral wool better insulates heat, sounds, it is durable, environmentally friendly

Expanded polystyrene

Eco-friendly polystyrene has low thermal conductivity. The layer is smaller than that of mineral wool, resistant to moisture, not afraid of mechanical stress. The sound retention rate is 4 dB. Apply polystyrene in its pure form or combined.

Types of noise

Before planning measures for soundproofing, it is necessary to take into account the main sources of noise and the types of noise from which it is necessary to protect the interior of a wooden house. External noise can be divided into several types.

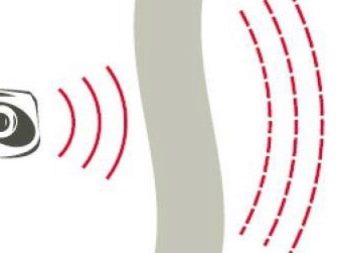

Acoustic

These are sounds that propagate through the air and are acoustic waves. The sources of such noise can be both the conversations of neighbors and the working audio equipment (players, tape recorders, amplifiers, radio tape recorders, TV), the sounds from the operation of car engines, the voices of animals.

Drums

This kind of sound is transmitted quite well and far directly by solid bodies, to which shock or vibration is applied. Such sources include, for example, perforators, hammer blows, the clatter of walking people, the sound of objects falling on the floor, the sound of a train moving along the rails.

Combined noises

This is the presence of noise, both acoustic and percussive. For example, the same perforator creates two types of noise. When the nozzle is exposed to the surface, frequent impacts are created, and from the operation of the perforator engine - acoustic noise.

Thus, when carrying out sound insulation, it is necessary to take into account which particular sources of noise are nearby, and from which type of noise it is necessary to isolate the room. In addition, the intensity of the sound (its loudness) should also be taken into account.

How to choose a material for high-quality soundproofing walls in a private house

To localize sounds in a room, it is necessary to correctly

decide on the choice of materials. First of all, it is worth considering

noise-absorbing characteristic of the insulator, which is the main

performance indicator. To protect the house from airborne sound, you need

use massive, and porous components. When the sound comes through

wooden wall, it is dispersed in a fibrous structure. Of course it's difficult

use thick insulation indoors, the best option

becomes a multilayer structure. Facing surface depending on

material reflects part of the sounds, and the rest are distributed in the porous

insulator structure.

To eliminate vibration sound, it is necessary at the stage

construction use special substrates. As a material for

substrates use porous rubber pads, but are no less effective

fibrous products are also considered. Due to the pads, vibration sounds will not be able to

reflect and annoy you, and the interior soundproofing of the walls will be done in accordance with all the rules.

Today modern

materials are presented in a huge range, which can be

use for both wooden and reinforced concrete structures. For

Fibrous materials should be used for maximum sound protection. Very

well suited for such purposes: mineral wool, felt, basalt slabs and

other porous structures.