KROKHA FURNACE, improved version N3

HOME IDEAS > FURNACE, FIREPLACE, GRILL PROJECTS

MENU

×

-

PROJECTS: FIREPLACES, STOVES, GRILLS, BBQ

-

Brick oven for a bath

-

A simple sauna stove

-

Kamenka stove with water boiler

-

Do-it-yourself barbecue in the gazebo

-

Barbecue complex for summer cottage part 1

-

Barbecue complex for summer cottage part 2

-

Barbecue complex for summer cottage part 3

-

We make a barbecue with a stove

-

How to calculate the heat loss of a room

-

How to calculate the heat output of a furnace

-

Chimney schemes

-

Mini fireplace for a country house

-

Corner fireplace "Annushka"

-

double bell oven

-

Double bell oven with oven

-

Heating and cooking oven 2.5 x 6 bricks

-

Heating and cooking oven 1020 x 770

-

Heating and cooking oven for 65 70 m2

-

Furnace with water heating boiler

-

Oven with drying chamber

-

Heating and cooking stove "Swede"

-

Oven "Swede" on 2 floors

-

Stove "Swede" with a stove bench

-

Furnace "Swede" with three firing modes

-

Stove "Swede" with a fireplace

-

Baby oven options 1 and 2

-

Baby oven option 3

-

Small-sized heating stove 2x3

-

Heating stove 1880x640 “Ya.G. Porfiriev"

-

Heating stove 51x89 cm “V. Bykov"

-

Heating stove 51 x 140 cm “B. Bykov"

-

heat capacity oven

-

Compact stove with fireplace

-

Small oven with fireplace

-

Stove with a fireplace "E. Doktorova"

-

Furnace fireplace for giving

-

Homemade long-burning stove

LIKE THE OVEN PROJECT?YOU CAN BUY ITS DRAWING IN WORD and PDF FORMAT FOR ONLY 75 RUBLES!OR ALL 35 PROJECTS OF STOVES, FIREPLACES, GRILLS AND BBQ, DRAWINGS + REGULAR LAYOUT FOR ONLY 490 RUBLES!

BUY A FULL SET - 490 RUBLES (click - buy, then place an order)

BUY THIS PROJECT FOR 75 RUBLES (click - buy, then place an order)

Do you have any questions? Ask them boldly, we will solve!

How to build yourself

Do-it-yourself baby oven is built in stages. First you need to determine the location of the furnace and proceed to the formation of the foundation. To do this, a litter is laid at the selected place; polyethylene or another oilcloth base can act as it. It is necessary to pour a centimeter layer of ordinary sand on it. Then you can start laying.

ordering

1 row.

Spread 12 pieces of brick on prepared sand, bonding is not required. The bricks are covered with a layer of mortar, immediately fix the door for blowing in asbestos.

2 row.

Laid out on top of the first layer.

3 row.

Chamotte brick is used. A grate is placed on top, it should subsequently be located above the blower.

4 row.

Laying is done with an edge, and a partition is left in the chimney. When laying the back wall, mortar is not required, the bricks should protrude slightly to the outside. You can start installing the firebox door, previously wrapped in several layers of asbestos. You need to wrap it taking into account that the door should open freely.

5 row.

This row must be laid flat along the contour of the previous one.

6 row.

Rib laying. The chimney should be wiped with a damp cloth.

7 row.

Like the 5th row, it fits flat, you need to start with a three-quarter.

8 row.

Two bricks are placed on top, with which the door closes. For this row, you will need a brick in a beveled form, it will serve as a kind of canopy.

9 row.

Must be offset to support the open state of the door. Moistened asbestos must be laid first.

10 row.

The formation of a chimney begins with it. It lines up expanding backwards. Taking into account the design of the crumb oven, it must be remembered that the installation of a brick overhead pipe is not possible due to the shifted center of gravity of the entire oven.

11 row.

We proceed to the installation of the valve, sealed with asbestos, lubricated with clay.

The next step is to remove the knockout bricks and clean the bottom of the chimney from debris.

The do-it-yourself baby oven is almost ready; it remains to whitewash. So that subsequently the oven does not turn yellow, blue and milk must be added to the mixture.

Without well-organized heating, comfortable living in a private house is out of the question. However, it often becomes necessary to arrange heating in other secondary rooms. In such situations, compact heating and cooking stoves of the "Baby" type will be an excellent solution.

Such a unit can heat a small country house, workshop and other premises up to 25-35 m2. The baby stove is built in the shortest possible time from available materials. After reviewing the further recommendations, you can lay out the furnace unit with your own hands without any problems.

Ordering the laying of the furnace

First, choose a place for the oven.

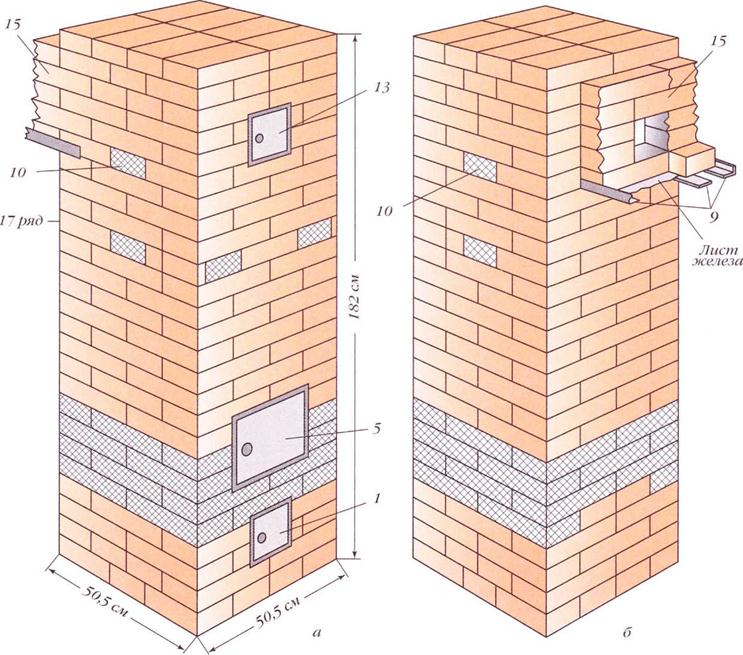

Scheme of laying the furnace - babies

A plastic film, roofing felt, hydroisol or glassine (780x530mm) is placed in the place where the furnace is supposed to be located. After the litter is laid, a layer of dry sand 1 cm thick is poured on it and leveled. On this sand without bonding, the first row is laid out, consisting of 12 bricks. The row must be leveled to ensure proper horizontality. From above it is necessary to apply a thin layer of clay mortar and put a blower door. The door should be wrapped in wet asbestos cardboard or cord. Next, the door is fixed, after which the laying of the second row begins.

Fireclay bricks are used for laying out the third row. On top of the third row, it is necessary to install a grate. It should be above the blower after the formation of the row.

To lay out the fourth row, the brick is placed on the edge, a stand for the internal partition is placed inside the chimney. The back wall of the furnace is laid without clay mortar so that the brick protrudes slightly.

Now you need to start installing the furnace door. Before installing it, it is wrapped in several turns of an asbestos cord, and it should be possible to open it both from above and from below. The door must be fixed with wire and fixed for a while with the help of two bricks (one behind, the other on it, and the door on top).

The brick of the fifth row is laid flat along the contour of the previous row.

Option for laying a baby oven

The sixth row of bricks must be laid with an edge. Then wipe the chimney with a damp cloth.

The seventh is laid flat again, starting with a three-quarter, to ensure a connection with the next row. The back part should consist of two bricks laid out edgewise.

The eighth row closes the furnace door, it is completed by two bricks laid out on top. This row is laid out with the help of beveled bricks, which should hang over the firebox. This is necessary so that the flame moves to the center of the hob burner when using the stove as a fireplace with the firebox door open.

The ninth row moves back to keep the door open. Before laying the brick, a moistened asbestos cord must be laid to ensure the tightness of the joints of the cast-iron hob and brick. The slab must not be laid directly on clay, as there is a difference in the thermal expansion coefficients of the materials in contact (clay and cast iron).

On the tenth row, a chimney is formed, it should have a gradual expansion back. Consideration should be given to the design of the furnace, which does not allow the installation of a packed brick pipe due to expansion upwards. When installing such a pipe, the center of gravity of the entire structure shifts. Therefore, an attached or packed pipe made of light iron is installed.

On the eleventh row, you need to install a valve, sealed with asbestos cord, lubricated with clay.

Scheme of laying brick rows for a baby oven

Now a chimney is placed in the quadrangle, which must be joined to a light metal pipe. When the pipe is shifted to the side, an overlap is made of 3 rows of bricks.

The knockout bricks are removed and the lower part of the chimney is cleaned from debris and moisture that have fallen in the process.

Now you can start whitewashing the oven. Milk and blue are added to the whitewash so that the stove does not turn yellow over time.

Next, a plinth is nailed to frame the bottom of the furnace and avoid sand spilling out from under the furnace.

So the little brick oven is ready. The doors are left open for a couple of weeks to dry.

Construction of a country stove made of bricks

Order drawings for masonry with explanations.

We will need a clay-sand mortar, building bricks (double silicate brick M 150 will not work, we need clay), a trowel, a bucket, a mixing trough, a plumb line, a level, an asbestos cord, fireclay bricks, doors, valves and other furnace fittings, galvanized steel wire, a hammer with a pickaxe, a grinder with a disc for concrete.

The oven will take 0.4 m², while its weight will be insignificant, so you can do without a foundation. If your floor is weak, then it is better to make a screed for masonry.

So, laying a small country stove in steps:

- On the place chosen for the stove we put roofing material or glassine 530 × 780 mm in size for waterproofing;

- Pour sand one centimeter thick on top and level it;

- According to scheme No. 1 (the figure at the beginning of the paragraph), we lay out the first row of bricks without fastening them, and level it with a level;

Lay out the first row.

- We apply a thin layer of clay mortar. We take the blower door, wrap it with a double layer of asbestos cord and fix it with twisted wire.

- We lay out the second row of bricks.

Second row with door.

We take fireclay bricks and lay out the third row. After its formation, we install a grate. We observe gaps for thermal expansion of materials up to 1 cm.

We lay out a row of fireclay bricks with a place under the grate.

- With a brick installed on the edge, we lay out the fourth row. Inside the chimney channel we make stands for the internal partition. We put the “knock-out bricks” of the back wall without clay with a slight protrusion outward.

- We install the furnace door, pre-wrapped with asbestos. We fasten it with twisted wire and temporarily fix it with two bricks: we put one on the back of the priest, the other on him and the door on top.

Installing the firebox door.

We lay out the fifth row flat along the contour of the fourth, and the sixth on the edge. We wipe the chimney walls with a wet cloth.

We fasten the door with wire.

We lay the seventh row flat from three-fours (3/4 of the whole brick is cut off with a grinder) for a bunch with the eighth row. The back wall is on edge again.

We cut the bricks with a grinder.

In the eighth row, we close the furnace door with two bricks above it. We install a beveled brick above the firebox to center the flame under the burner.

We cover the furnace door.

- We put the ninth row with an offset back (small) to maintain the door open. Before laying, we lay out a wet asbestos cord to seal the joints of the brick and the hob.

- With the tenth row, we begin the formation of a chimney, which will gradually expand back. We will make a pipe attached, so as not to shift the center of gravity of the structure, or a pipe made of light iron.

We begin the formation of the pipe.

In the eleventh row, we lay the valve, seal it with an asbestos cord coated with clay.

There will be a latch here.

Next comes a chimney in a quadruple, which is joined to a light metal pipe.

We continue the chimney to the docking point.

Now we take out the knockout bricks and clean the bottom of the chimney from debris.

We bring the chimney under the pipe.

- We close the gap between the first row of bricks and the floor of the metal L-shaped sleeve and nail the plinth.

- We whiten the oven or cover it with oven varnish, seal all joints between metal and brick. Metal parts can be painted with black refractory paint.

We whiten and decorate the oven.

We make a test furnace with paper and small branches, then we give 2 weeks to dry.

As you can see, all the manipulations are not so difficult to do on your own. Material and labor costs are relatively small, the construction does not take up much space.

At the same time, we received a heating and cooking device that will perfectly heat a small country house, give your cooking a unique taste and aroma of smoke, and create a pleasant atmosphere and comfort.

Advice! If there is an opportunity to invite a person who is more or less experienced in the furnace business, at least as a consultant, by all means use it, since it is rather difficult to build stoves according to the book, it is better to see once.

Brick stoves are considered bulky, expensive and difficult to build. However, it is easy to see with concrete examples that these opinions are somewhat exaggerated, and it is possible to build an inexpensive compact cottage stove out of bricks, and on your own.

In the presented video in this article you will find additional information on this topic.

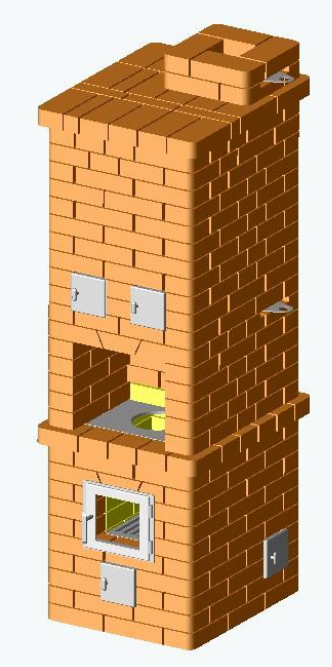

The design of the furnace Malyutka

Inside there is a cooking chamber and two compartments for drying, located one above the other. One of them, the lower one, is on the right just above the slab overlap. This chamber is closed, it is used for vertical drying of mushrooms or fruits strung with bundles. Therefore, during the construction of the Potapov heating furnace, hooks made of thick wire are inserted into the ceilings on the sides of the lower chamber, on which it is convenient to hang products for drying. Another option for decorating the drying chamber is to make shelves for baking sheets.

Inside there is a cooking chamber and two compartments for drying, located one above the other. One of them, the lower one, is on the right just above the slab overlap. This chamber is closed, it is used for vertical drying of mushrooms or fruits strung with bundles. Therefore, during the construction of the Potapov heating furnace, hooks made of thick wire are inserted into the ceilings on the sides of the lower chamber, on which it is convenient to hang products for drying. Another option for decorating the drying chamber is to make shelves for baking sheets.

The temperature in the drying chamber can be maintained at the same level for a long time. To monitor temperature fluctuations, you can place a special thermometer with heat-resistant glass on the door. The door of the drying chamber is mounted on a metal frame. If desired, the hinged door can be replaced with an L-shaped damper.

The upper drying chamber is supposed to be without a door, although a damper is installed on it if necessary. This should be thought out in advance, and put a metal plate for fastening the damper between the side bricks. It is not recommended to cover the walls of the drying chambers with plaster - it is enough to cover the seams. Potapov's stove can be made higher by laying 2 additional rows of bricks after the 18th and 19th rows.

The design of the Malyutka stove is simple enough that it can be folded independently at home. Initial building skills will be needed for this, but usually even for beginners, this small-sized stove is obtained the first time and without flaws."Baby" is adapted for any solid fuel, but if you intend to heat with coal, peat or dung, be prepared for the annual cleaning of gas ducts clogged with soot. You can heat such a stove only in winter.

Repairing the structure is quite simple, because there are no horizontal channels in it, and there is a cleaning door in the vertical channel.

Formation of heating equipment

For the construction we need:

- red oven brick (solid);

- fireclay brick (for firebox);

- clay or cement mortar M300;

- reinforcing rod;

- blower door;

- grate;

- furnace door (if you choose a glass door, then the baby can serve as a fireplace);

- cast iron hotplate;

- valve.

Of the tools you need:

- trowel (leveling the mortar, cutting seams);

- hammer and pick (for brick);

- level;

- Master OK;

- plumb line (weight with cord) for checking angles;

- a rule (a wooden ruler with a section of 1.5 x 6 cm and a length of 1-1.5 m, having parallel planes) for even masonry;

- roulette.

Foundation

It is recommended to use M300 concrete as a fill, it is strong and durable. Its curing time is about 25 days.

If the brick oven is planned to be light, without constant intensive combustion, then the first row of bricks should be laid on a layer of insulation:

- polyethylene film;

- ruberoid;

- hydroisil, glassine;

- dry sand 1 cm.

Furnace ordering

The first and second row are alignment, each row is checked by a level.

The third - a blower is laid out on the frontal part, its dimensions are two times smaller than the size of the firebox.

The fourth is the installation of a steel window in the blower, from above it is covered with a grate.

Fifth - fixing the grate, circular masonry.

The sixth - the beginning of the calculation of the firebox. The window is slightly narrowed for convenience.

The seventh is the installation of the firebox door. The firebox must hold firmly in the masonry; for this, the fasteners are wrapped with asbestos cord.

Eighth - a strip of sheet steel is installed on top of the firebox.

From the ninth to the eleventh - circular masonry.

The twelfth, thirteenth - the formation of the rear wall, it fits on the dock, and two small grooves are formed.

Fourteenth - the grooves are increased by half a brick, the rest of the space is laid out with a brick.

Fifteenth - a place for a channel, an oblong channel is left near the back and side walls. In the main masonry, a compartment is made with a supporting brick in the center (under the column).

Sixteenth - strips of steel are laid on the column, they form another channel.

Seventeenth - the channels are separated and form four channels under the walls and one in the center.

From the eighteenth to the twenty-second - the continuation of the channels.

The twenty-third and twenty-fourth - channels, except for the central one, are connected and form an L-shaped form.

Twenty-fifth - channels, except for the central one, are blocked with bricks.

From the twenty-sixth to the twenty-eighth - the size of the masonry narrows to the size of the pipe (chimney).

Twenty-ninth - installing a damper.

From the thirtieth - the formation of a chimney and its output to the street.

In the process of laying, it is necessary to make dressings for one second or one fourth of the brick. Every six rows, the masonry must be wiped with a damp cloth.And in order for the corners to be even, it is better to install plumb lines on the ceiling (temporarily on nails). Brick during laying should be installed flat and on edge for structural stability.

How to DIY

Preparatory stage of construction

At the preparation stage, you must have the following tools available:

- welding machine;

- roulette;

- bayonet shovel;

- grinder;

- waterproofing;

- scrap;

- rod;

- water and sand;

- solution.

The first thing the preparatory stage begins with is determining the location of the future fireplace

It is important to correctly position the brick stove to eliminate energy loss. The walls of the structure are not located near the outer walls of the room, but it is also not recommended to place the fireplace in the center of the room.

Not in all cases, the "baby" brick oven is built simultaneously with the building. Sometimes you have to lay the foundation on finished floors. If the house uses a "warm floor" system, you have to lift the entire screed. After the place for the furnace has been prepared, a hole is dug up to a depth of 35 cm, completely covered with waterproofing. Next, reinforcement is laid, and the solution is poured.

Step by step instructions for work

Brick is a priority material for laying furnaces. A small or large “baby” stove, although it has simple construction drawings, a detailed work order scheme will come in handy in any case. Step-by-step instruction:

- A layer of waterproofing is applied to the foundation. It is recommended to use ruberoid.

- The ordering starts from the corners, three rows each.

- The vertical and horizontal plumb lines are measured.

- The laying of the first row (solid layer) must be perfectly accurate.

- A thin layer of clay is applied to a row of bricks and three rows are instructed around the perimeter. At the same time, a door is installed. Everything is done quickly and accurately.

- A steel wire is inserted into the attachment area, the ends of which are twisted and wound in order.

- Visible defects are eliminated using a grinder.

- Grates are installed.

- The next row involves the use of fireclay refractory bricks and the installation of a firebox door wrapped in asbestos cord.

- All subsequent rows are laid flat. The ordering is completed with the expectation that there is room for a slight shift back.

- An already installed door is laid over and a stove is placed. It is recommended to buy a cast-iron version for cooking.

- The last step is to finish the outer walls of the furnace. Used most often in such cases whitewashing. Before starting work, it is recommended to protect all walls in the house from dirt, since it is problematic to remove whitewash stains.

Drawings and diagrams

There is a lot of material available on the web for study. Therefore, a detailed scheme for laying out the furnace is not a shortage, and masonry variations allow each user to choose the most suitable scheme. First you need to figure out what the main provisions are contained in the step-by-step instructions, and then make your own adjustments. The improved model is applied directly in the work. Do-it-yourself "baby" oven is not sky-high fantasies, but a completely realistic plan. Thanks to the clarity and clarity of the drawings, each summer resident can independently equip a similar design at home.

Do-it-yourself small rough masonry

Start by creating 2 starting rows. It is necessary to ensure that the rows and corners are even, the edge of each brick must coincide with the neighboring one, since the entire structure will be held on the starting masonry. Clay solution is used.

In the 3rd row, a blower door is installed and the base of the chimney is formed.

4 - is placed similarly to the third.

At 5 - they divide the chimney in the center into 2 channels and close the blower with a door.

At 6, they put a grate over the blower door.

On 7 - the base of the furnace is laid out and its door is installed.

From 8 to 9 - masonry is done, similarly to the previous one.

10 - the firebox door is closed and a window is set up from the furnace compartment inside the furnace channel.

At 11 - a cooking panel is mounted.

12 - close the hole laid on the 10th row and form the wall of the stove for cooking.

13 - similar to the last one.

14 - to create a second horizontal channel, a cleaning hatch is removed from the rear side.

15 row repeats 14.

16 layer - close the hole formed in the 14th row, in the opposite direction from the channel, which is in the 12th row, leave a branch.

17 is placed in the same way, forming an overlap for the brewer and a drying compartment.

18 row - the formation of 3 horizontal channels, from which the smoke will go into the chimney. At the end of the channel, a hatch must be provided for cleaning.

Layer 19 repeats layer 18.

20 - the final horizontal channel is led to the chimney pipe.

21 - a connection to the chimney and the construction of a structure for smoke removal are being created.

From 22 rows and above - laying the chimney.

Next comes the finishing. But you can neglect it or just paint the oven. A little refractory brick will look very aesthetically pleasing.

//www.youtube.com/watch?v=K5qgPXeDKDo

But do not rush, it is better to treat your goal longer and more carefully. Clay for the solution should not be greasy. It is better to take an average fat content, its solution will ensure the reliability of the structure for many years.

close ×

To equip a house with a high-quality heating structure, it is not necessary to have specialized skills and knowledge. A simple and affordable option for every owner is a baby oven that requires a minimum of time and investment. In the article we will consider all the stages of the construction of such a furnace with our own hands.

The brick baby stove is a compact mini-fireplace that can be placed in a small area of only 0.4 square meters. meters. It has the simplest design, in which the fuel cap replaces the whole system of heating channels standard for furnaces. She does not need an additional foundation, and the total heating area can reach up to 35 square meters. meters.

Little brick oven

A small brick oven does not need a lot of high-quality fuel. For its operation, the most common firewood, anthracite, coal or other materials are sufficient. It can easily replace a potbelly stove for giving and at the same time be many times more functional. If you add a cast-iron stove to the main structure, you get not just a heating stove, but also a cooking stove.

But the main advantage of this design can be considered a high laying speed. One day is enough for detailed projects. This time is enough to build and start heating the oven with paper and wood chips. True, it will be possible to throw logs not earlier than the masonry mortar is completely dry, otherwise there is a risk of cracks.