Arrangement of the attic

The roof of the finished attic looks like a puff pastry. The outer covering is a roofing material designed to protect the house from rain. From the point of view of thermal insulation, it does not give any effect. The upper waterproofing barrier is a roofing material or a special film that is capable of retaining water, but vapor permeable. It is laid in such a way that water flows through it to the outside. Next comes a layer of insulation, which forms a heat-insulating barrier.

The vapor barrier is designed to completely protect the installed insulation layer from moisture and steam. This polyethylene film is truly completely vapor and waterproof. Everything ends with a decorative coating to give aesthetic appeal and protection against mechanical damage.

The greatest difficulty in insulating the attic is the installation of a waterproofing layer on a heater of complex shape. The difficulty lies in bypassing all the load-bearing elements of the roof and organizing its exit under the roof for water discharge.

It is very important to maintain the integrity of the layer here. Joints and attachment points must be glued with adhesive tape, and fixed between the rafters on brackets or on vertically nailed rails

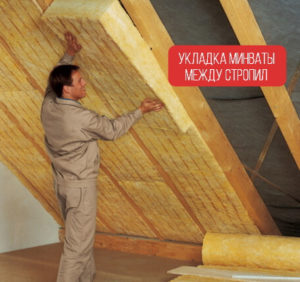

The insulation fits tightly between the rafters and, together with the hydrobarrier, is fixed with slats, which will later be a support for the finishing. It is recommended to insulate with mineral wool formed into sheets or slabs, as it is more resistant to caking and shedding during operation compared to rolled wool.

Attic wall insulation technology

Depending on the material of the walls, different ways of carrying out thermal insulation measures with your own hands are possible. The most common ones are listed below:

- construction of multilayer brick walls;

- wet facade technology;

- ventilated facades.

All these options involve external insulation. If necessary, the material can also be fixed from the inside, but this is less efficient and can lead to high costs.

Layered walls

With this method of erection, a layer of insulation is laid between the outer and inner mile, due to which the walls of the entire building are thermally insulated, including the attic (attic)

It is important to prevent the risk of subsidence of the material, otherwise a “bare” area will appear in the attic.

Wet facade technology

In this case, the insulation is attached to the wall with your own hands and covered with plaster on top. For durable materials, the layer of plaster can be 20 mm. If it is necessary to prevent damage to the heat insulator, a 40 mm plaster layer is applied along the reinforcing mesh. This option of insulation is quite simple, but does not provide reliable protection of the heat-insulating layer.

Ventilated facades

In this case, the heat insulator is attached to the wall, and the facade decoration is hung on top. An air-ventilated layer is arranged between the insulation layer and the decorative layer to remove condensate. Mineral wool materials are used for this type of construction; for expanded polystyrene and foam, the technology can be the same, but they do not require a layer of air. Do-it-yourself decoration can be done with siding, hinged panels, porcelain stoneware, wood.

Mineral wool attic insulation

This modern and popular insulation is produced in rolls or mats. Mineral wool does not burn, does not rot, various microorganisms and rodents are not dangerous to it.

Insulation of the attic floor with mineral wool is carried out in stages:

- First lay the lining material on the floor. In the case of an economy option, inexpensive glassine is laid on the floor.A more expensive and high-quality device will be a flooring device made of a vapor barrier film, which is mounted with an overlap.

- At the same time, the joints of the segments are glued with adhesive tape or fastened with wooden slats, fixing them with a stapler.

- The width of the thermal insulation material is selected taking into account the technical standards for a particular region. The mineral wool between the lags is laid out tightly, leaving no gaps. Tape is used to seal the joints.

- After the installation of the insulation is completed, even boards are placed on the logs and this is how the floor in the attic is formed.

The above solution on how to insulate the attic of a private house with mineral wool gives the material the ability to "breathe" and ventilate when moisture gets on it. To prevent the penetration of moist air into the insulation, waterproofing is mounted under the roof.

Attic insulation: mandatory preparatory measures

The order of arrangement of the heat-insulating layer depends on the selected material. However, in any case, before insulating the attic, a number of mandatory measures should be performed:

- Check the condition of the old thermal insulation (if any). Moldy or rotten insulation must be disposed of. Disinfect the attic with an antifungal compound.

- Inspect rafters, ceiling and gable for cracks. Identified damage (cracks, chips) to putty. If the defects are significant, then some structural elements are recommended to be completely replaced.

- The gaps between the floors can be sealed with sealant, mounting foam or tow soaked in lime mortar.

- Treat wooden elements with a fire retardant.

- Check the condition of the ventilation system. If the ventilation of the under-roof space is not enough and condensation accumulates on the ceiling, then the construction of additional ventilation ducts will be required.

Attic insulation in a private house: step by step instructions

To insulate the attic with mineral wool, the following materials and tools should be prepared:

- mineral wool;

- mounting stapler and staples;

- mounting foam;

- construction knife and tape;

- waterproofing film;

- personal protective equipment for hands and eyes;

- glue for mineral wool.

Preliminary activities:

- measure the insulated area - multiply the surface width by the length;

- determine the number of layers of mineral wool - for the middle zone of the Russian Federation, the insulation layer in the attic should be at least 20 cm;

- free the attic from unnecessary items, remove debris and cobwebs;

- provide good lighting and raise the necessary tools / materials to the attic;

- lay the floor logs with plywood sheets - for the convenience of performing work.

The procedure for warming with mineral wool:

- Installation of ventilation ducts is carried out in a cold attic. Under the roof, special ventilation troughs are fixed with brackets. If the attic space will be equipped as a living room, then it is not necessary to install such gutters.

- Arrangement of waterproofing, which will protect the mineral wool from moisture. Stretch the film on the truss structure, leaving small overlaps. Fix the film waterproofing with a mounting stapler.

- Placement of mineral wool. Laying is carried out in the direction from the bottom up:

- apply glue on the mineral wool slab on one side;

- press the canvas between the rafters;

- fix the insulation with screws or nails;

- according to the described technology, place the second layer in a checkerboard pattern relative to the first - this will reduce heat loss;

- insulate ventilation shafts and communications in the attic.

- Installation of vapor barrier. Using a stapler, fix the film on the mineral wool slabs. Glue the joints with adhesive tape, ensuring complete tightness.

- Arrangement of crates for finishing. A frame is mounted flush with the rafter system. Subsequently, drywall sheets or OSB boards will be attached to the crate.

- Insulation of the attic floor is carried out by analogy with the described technology for insulating roof slopes. Logs are preliminarily installed on the floor, holding the entire heat-insulating structure.

Types and characteristics

The material is obtained from molten blast-furnace slag, stone (rocks) or glass. By structure, these fibers are thin, randomly arranged villi, from 2 to 60 mm long. This insulation is produced in the form of mats or plates. In order for the fibers to be better linked to each other, the plates are additionally impregnated with special oil (to repel moisture) and phenol alcohol.

Depending on the origin, they differ:

- Glass wool. It is made from a molten mixture of broken glass, sand, limestone, soda. The fibers are 15-50 mm long, and their thickness is 5-15 microns. The material is chemically resistant, difficult to ignite (withstands up to +500 ° C). But how the Chinese metal door is insulated with such material is indicated here.

Stone wool. For its manufacture, gabbro-basalt rocks are melted. The thickness of the fibers is 4-12 microns, and they are up to 16 mm long. It heats up, without igniting, up to 300 ° C. It will also be useful to learn about how the house is insulated and sheathed with siding.

Slag. Produced from blast-furnace slag by melting it. The dimensions of the fibers are the same as those of the stone counterpart, but it withstands heating much higher - up to +600 ° C. It can also be used to insulate plastic windows for the winter.

The fiber structure of mineral wool is corrugated, horizontally layered and vertically layered. Its density also varies, in construction it is most often used from 30 kg / m 3 to 175 kg / m 3.

For different purposes, insulation of different densities is suitable. The denser the material, the more expensive it costs. Sometimes it seems that it is better to choose a material that is denser, but this is not economically feasible. It is more correct to proceed from climatic conditions and the type of object that needs to be insulated. To insulate the cold attic of a residential building, you should choose mineral wool with a density of 150 kg / m 3 to 175 kg / m 3.

But how the wooden floor is insulated in a private house, and what you should pay attention to, is set out here. Material advantages:

Material advantages:

- vapor permeability. Provides excellent breathability. Condensation does not form. And this contributes to a favorable climate in rooms insulated with mineral wool;

- by origin - it is a mineral crumb, so the insulation will not catch fire. Fire-resistant material, which means wooden buildings insulated with it, receive additional protection against fires;

- to work with it, you do not need to have special skills;

- excellent thermal insulation properties;

- affordable price;

- excellent soundproof qualities;

- repels moisture, poorly absorbs water. Prevents penetration of moisture;

- environmental friendliness;

- non-toxicity;

- resistant to deformation. Does not wrinkle, practically does not cake, does not change size and shape;

- strong and durable. The term of use is up to 50 years;

But how the floor is insulated in a wooden house from below with penofol, and what you should pay attention to is indicated here. From -30 to +30, the properties of mineral wool do not change, it does not freeze in cold weather and does not emit anything harmful in the heat

Even after repeated frosts and from intense heat, the material does not lose its properties, its structure does not change

From -30 to +30, the properties of mineral wool do not change, it does not freeze in cold weather and does not emit anything harmful in the heat. Even after repeated frosts and from intense heat, the material does not lose its properties, its structure does not change.

To all the pluses, you can add that rodents do not start in it. Since mineral wool is a product of inorganic origin.

It is also good that it does not burn, because the stone and sand from which it is made do not burn.Therefore, such a fire-resistant material is safer if there is electrical wiring in the attic. But here is how the timber house is insulated from the outside with mineral wool, indicated here.

On the video, the insulation of the cold attic ceiling with mineral wool:

Flaws:

- There is a possibility of release of phenol, a substance harmful to health. Although experts say that this is possible only at high temperatures.

- It is necessary to work with mineral wool using personal protective equipment: special thick clothing, thick rubber gloves, goggles, a respirator, closed shoes.

It will also be useful to learn about how the ceiling of a private house is insulated with sawdust.

We insulate the wooden floor

The question is often asked: “How to properly insulate an attic with a wooden base?” Many private households have just such a cold attic.

The procedure for insulating the attic floor is as follows:

- Carrying out the processing of load-bearing structures with special compounds to prevent decay, pest damage, and increase fire resistance;

- Installation of a vapor barrier film from the side of the premises, followed by installation of the crate;

- Laying insulation of the required thickness;

- The device of the subfloor from the side of the attic.

For a ceiling with wooden floors, it is extremely important to get protection from pests, fire and moisture before the start of insulation work, since in the future it will be impossible to do this without dismantling the insulation. Work on the insulation of the ceiling from the attic should begin with the isolation of the insulation from the steam coming from the heated premises

Vapor barrier of the attic floor is made with reinforced films made of polypropylene and polyethylene. These films have a multilayer structure, which allows them not to let steam from the side of the heated room into the insulation layer. One of the layers is reinforcing, which allows it to carry loads on holding heat-insulating boards. The vapor barrier must be continuous and tight. For proper laying of the strips, an overlap of at least 10 cm is made with the overlay secured with double-sided construction tape

Arrangement of floor beams and lathing is carried out taking into account the expected load. Thus, when insulating the attic floor of a cold attic using bulk materials, it is necessary to provide for a reinforced base. The weight of this layer will exert an increased load on the floor beams and the crate.

Mineral wool and basalt heaters, or loose and foamed materials are used as a heat-insulating layer. The most popular attic insulation is mineral wool because of the ease of installation.

Loose insulation must be leveled and filled with all the voids. Cold attic floor insulation completed.

The floor of the attic can be arranged in the form of:

- lathing or subfloor from edged (unedged) boards;

- finishing floor made of plywood and other wood sheet materials;

- leveling screed (installation of waterproofing on top of the insulation layer is required).

Insulation of a heated attic with mineral wool

If the attic is heated and it belongs to the living area, then this is already an attic. Naturally, she also needs warming. In this case, the thermal insulation does not fit between the floor beams, but between the roof rafters. At the same time, there are two methods for insulating the attic with mineral wool.

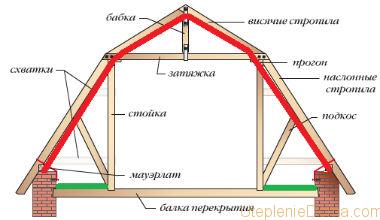

Consider the first option - laying thermal insulation between the rafters from the roof ridge to the floor of the first floor. On fig. 1 marked in red is the area of application of insulation. Remember that you need to insulate not only the attic, but also a small section of the floor of the first floor, which is marked in green. As you can see, this option solves both problems at once. Installation method (layers from the inside):

- vapor barrier - fastened with a stapler to the rafters. Fitted with overlap and stretch. Joints are sealed;

- mineral wool - placed by surprise. You can use glass wool of any configuration (mats, slabs, rolls) or basalt wool in slabs with a soft end;

- waterproofing - a three-layer polypropylene diffusion membrane. Tapes are laid horizontally and overlapped, starting from the edge of the roof;

- counter-lattice - the section of the bars depends on the length of the roof slopes;

- finish coating.

In terms of functionality, vertical tubular heating radiators are no different from horizontal ones.

In this article you will find information about plate heating radiators: characteristics, types, installation methods, operation and maintenance.

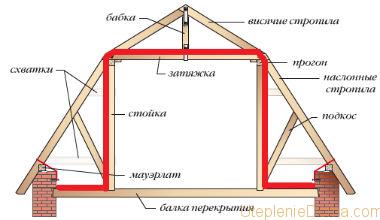

The second method of how to insulate an attic in a private house with mineral wool is somewhat different (see Fig. 2). The insulation is placed on the attic floor. Next, the wall is insulated according to the principle of thermal insulation of a frame house. Also, the insulation is laid on the floor of the first floor from the attic wall to the end of the building

It is important that the insulation lays down without breaks, that is, it must pass from one surface to another and preferably without joints. If there is a junction, then the thermal insulation must be pressed tightly against each other

With such an installation, no doubt, more material will go, but in the future there is a benefit. You do not have to heat the square meters that are not used for housing, so the cost of heating the house will be somewhat lower.

Today we figured out how to properly insulate the attic with mineral wool and came to the following conclusions. If the attic is unheated (cold), then the insulation is placed between the floor beams. If the attic is heated, then thermal insulation is placed between the roof rafters. There is a method of laying thermal insulation on the attic floor, then the wall itself is insulated and then a segment of the first floor floor from the wall to the edge of the building. This approach will slightly reduce heating costs, since there is no need to heat extra square meters.

For work, it is better to use glass wool, as it does not break and, after compression, restores its previous shape. It is lightweight and does not overload the load-bearing floor beams and truss system. If you use stone wool, then you need to take plates with a soft end so that they can be inserted between the guides by surprise. A vapor barrier is laid between the heated room and the insulation. When laying thermal insulation on the roof, waterproofing is also needed, which is placed on the outside. There must be a ventilated gap between the waterproofing and the finish.

Interesting on the topic:

- Thermal insulation of a flat roof - the choice of material.

- Choosing the best roof insulation

- How to properly insulate an attic in a wooden house.

- Roof insulation technology

The most effective expanded clay technique

Above were considered budget options that can be recommended only for residents of warm regions. In order to reliably protect the attic of a house in areas with a harsh Russian climate, it is necessary to use better and more effective methods. Among backfill materials, expanded clay is the best. This is a porous material that is obtained by firing clay (or its shale). It is lightweight and has an oval shape. Regarding the form of release, fractions are distinguished: 5-10 sand, 10-20 crushed stone, 20-40 gravel.

Expanded clay is laid as follows:

Align the rough base (if necessary). Height differences of more than 1 cm are not allowed.

We lay the film, of any thickness, the main thing is that there are no holes.

Pour a pillow (no more than 10 mm) of gravel.

We scatter expanded clay over the entire area and level it

It is very important to achieve uniformity. For convenience, you can use a laser level.

To avoid shifts of expanded clay to the side when pouring the mixture, first pour the liquid solution.

If you are going to use the attic as a full-fledged living space in the house, it is necessary to provide additional strength to the screed using a reinforcing mesh

We lay it on a liquid solution.

We install beacons to determine the evenness of the future coverage.

Pour a thick solution and level it with a rule. Our coating will be ready for full operation in 7-10 days. Until this time, it is undesirable to bring any heavy objects into the room.

The described technique is the most effective in its class. However, it is characterized by impressive spending. In addition, a serious load is created on the floors (wooden houses may not withstand it). Therefore, it should be used only if the attic is planned to be used as a living space.

Insulation with sprayed polyurethane foam

Today, it has become possible to perform thermal insulation using the PPU spraying method using special kits - disposable 2-component installations for insulation and sealing of various structures. And although this material is not cheap, it fully justifies itself.

Polyurethane foam is applied directly to the ceiling by spraying from above - either between the logs of a wooden attic floor, or on a concrete slab or screed, if it is capital

It is important to spray PPU continuously to get a uniform seamless layer of the required thickness without cold bridges.

The foam easily penetrates even into inaccessible cracks and recesses, quickly hardens and forms an even water, vapor and heat impermeable layer.

The treated PPU floor surface does not require additional flooring and can be walked on without fear of damaging or violating the integrity of the structure. However, if the attic or attic is planned to be used as a living space, it will be necessary to cover the floor with wood boards, boards, linoleum, etc.

The thickness of the sprayed PPU layer is determined based on specific conditions (heat loss at home) and the requirements of SNiP. On average, to achieve effective thermal insulation of the attic floor and attic, a layer of polyurethane foam with a thickness of 7-9 cm is required.

If access to the attic floor is limited, spraying can be applied from below to the ceiling inside the living space.

The method of insulation of the attic floor by the method of spraying with polyurethane foam is very effective, therefore, it has recently become more and more popular. Such insulation is durable, resistant to chemicals, microorganisms and temperature changes, inedible for rodents.

The weight of the insulation is small, so the supporting structures are not overloaded and even acquire additional adhesion rigidity.Due to the fact that the insulation layer is very thin, neither the total area nor the volume of the attic or attic is reduced.

One of the few disadvantages of this type of thermal insulation is its cost, but in any case, it is better to do the job well once than to return to this problem again and again. It should also be recalled that this material, suitable for arranging a cold attic, does not “breathe” and therefore is not very suitable for residential premises.

Video: Insulation of a non-residential attic of a private house

The choice of insulation

For thermal protection measures, it is better to use modern efficient materials. They will provide good insulation with a minimum layer thickness.

When insulating the floor and roof of the attic in the house, they use:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam;

- polyurethane foam.

Details about attic insulation with polyurethane foam are described in the article "Foam for floor insulation". It deals not only with floor structures, but also with walls and roofing.

Mineral wool has earned popularity due to its high degree of thermal protection and good fire resistance. It is produced in two types: rigid plates and rolls. For roof insulation, the first option is more often used, and both are suitable for walls. Read more about attic floor insulation with mineral wool.

Styrofoam is popular due to its fairly low price, but at the same time, thermal conductivity indicators are close to mineral wool. Its use in floor construction is complicated by low strength, but it suits very well for walls.

If you have enough money, it is better to give preference to the closest relative of the foam - extruded polystyrene foam. This material is devoid of the main disadvantages of the previous one, and has the following positive characteristics:

- high strength;

- low water absorption;

- incombustibility;

- excellent thermal insulation properties;

- resistance to low temperatures.

For wall insulation, it is preferable to use polystyrene foam or extruded polystyrene foam, but mineral wool is more often used for laying between rafters.

Types of lofts

When carrying out work, it all depends on the method of using the under-roof space. There are three of them:

- Cold attic. Such an attic is not heated, and air from the premises does not enter it. In this case, the temperature in the room is taken according to the norms of +5 degrees Celsius.

- Warm loft. The presence of a warm attic is typical for multi-apartment residential buildings. All ventilation ducts with heated air open in the attic space, increasing the temperature in the room.

- Attic. The under-roof space becomes a full-fledged living space and is heated, like all rooms in the house. In this case, we recommend that you read the article on attic insulation.

In a wooden or any other private house, it is correct to use the first or third option.

This is how you can transform the attic, turning it into a residential attic: