Design and installation of a heating system for a warehouse and workshop

The task of any warehouse is to provide manufactured and other products with all the conditions that are so necessary to maintain the qualities specified in their manufacture. In this case, the general nuances of the microclimate of warehouses, set by the degree of heating, the level of ventilation and humidity, are important. The role of heating is presented as an effective maintenance of the correct temperature in warehouses during the cold season, since it is during this period that low-temperature effects lead to freezing of liquids, fragile products, and damage to goods in the warehouse of biological materials.

Heating options

The criteria for choosing a heating system for warehouses and workshops are presented in technological standards and requirements specified by the sanitary and hygienic and fire fighting division. There are the following types:

The criteria for choosing a heating system for warehouses and workshops are presented in technological standards and requirements specified by the sanitary and hygienic and fire fighting division. There are the following types:

- Centralized, assuming the location of the sources of the system outside the premises. They can be presented with air, steam, water or combined type of heat carriers.

- The forced scheme of heating of warehouses, for distribution of heat contains systems of pumps and fans in the complete set.

- Natural heating involves the circulation of heat flow in natural ways. Natural heating of a warehouse or similar premises is carried out according to the principle of heat exchange between air or water coolants.

The criteria for appointments and the established degree of safety may imply a different heating option for each room.

Rules for choosing heating systems

You can get good heating by choosing the right type of heating. It takes into account each parameter of the building, which include:

- the area of the heated workshop and similar premises;

- the number of heated objects: rooms, workplaces (if there are requirements for such a system within the workshop);

— level of external heat exchange and heat consumption;

— compatibility with ventilation power;

- availability of free space for the installation of everything you need.

The selection and planning of the location of heating lines on the territory of a warehouse or workshop is carried out by strictly specialized companies that have all the necessary equipment, experience and access to these events. These parameters become the main ones in the choice of organizations designing space heating lines.

Criteria for companies performing heating installation in workshops and warehouses

Well-organized companies always have a large list of services and perform them professionally. The development of projects, planning the implementation of heating lines, installation of equipment with its commissioning should take into account standards and norms, as well as take into account the wishes of customers.

These are the goals pursued by the Moscow company Bien Group, which occupies a leading position among competitors. Certified masters with a large list of practical skills in the field of heating installation for warehouses, as well as the overall responsibility of the company, allowed Bien Group to offer a number of advantages:

— high quality of installation works;

– work only with the best materials;

- providing a guarantee for the operation of systems in your requirements.

Also, Bien Group can order work in buildings that involve the introduction of electrical, exhaust systems, water supply and drainage lines, which will not only perform their functions qualitatively, but also increase economic performance.

Advantages and disadvantages

The air heating method has undeniable advantages:

- The efficiency reaches 93%.When organizing heating, the installation of intermediate heating devices is not required.

- Heating systems of this type can be fully integrated with ventilation systems. This allows you to constantly maintain an optimal microclimate inside the production complexes.

- Very low level of inertia. Immediately after the activation of the equipment in the room, the air temperature begins to rise.

- High efficiency has a positive effect on the economic performance of production and lower production costs.

Along with this, air heating has obvious disadvantages:

- Constant technical maintenance of the active elements of the system is required. It is quite difficult to modernize existing installations.

- In order to avoid interruptions in heat supply, a backup power supply is needed.

Air heating based on local fan heaters

Heating of almost any retail, warehouse or sports facility can be successfully implemented on the basis of local installations (fan heaters and air heaters). This method of implementing heating is especially relevant for small objects and objects where there is no need for a significant influx of outdoor air.

The use of local air heaters is a universal, fast and economical solution for heating a mono-volume room.

Local air heaters have a different design and can be operated from any available energy source:

- Water fan heaters - work with a liquid heat carrier (water). The use of such equipment is justified when it is possible to heat the coolant at the facility and supply it to the room;

- Gas fan heaters - can be installed outside or inside the heated room. Local gas air heaters have a sealed combustion circuit and a system of forced removal of combustion products. Can be used to create separate heated zones without heating the entire room;

- Electric fan heaters are distinguished by their convenience and ease of installation, since there is no need to supply additional communications (gas pipeline, pipeline). Their use is fully justified if the only source of energy at the facility is electricity.

Heating of the football arena with GREEERS fan heaters

Local air heaters can be equipped with mixing chambers for partial air intake from the street for ventilation.

Fan heater "GREEERS" with a mixing chamber

The cost of a heating system for a warehouse, store or sports facility, as a rule, consists of several components: the cost of preparing the facility for heating (construction of a boiler house, pipelines, etc.) and the cost of purchasing heating equipment and installation.

The use of air heating systems will allow you to save a lot of money.

Savings in construction - no investment in the preparation and construction of the boiler room, since our equipment can be placed simply on the street. For outdoor placement, only a small area is enough. The normal operation of gas heat generators implies an ambient temperature of up to minus 30 degrees Celsius. There is also special equipment for the regions of the Far North, which can be operated at temperatures up to minus 45 degrees.

Saving money during the operation of the heating system - is achieved due to higher efficiency, there is no need to spend energy on heating the intermediate heat carrier - water, no leaks and the risk of defrosting the heating system, saving energy due to the "standby mode" function, i.e. maintaining a minimum positive temperature in the room without the risk of defrosting and very fast heating of the room if necessary.

Thus, if you want to rationally use funds during construction, as well as significantly save them during the operation of the heating and ventilation system, we suggest that you consider the possibility of using modern technologies and equipment from leading Russian and foreign manufacturers, as well as take advantage of the experience of our engineers and specialists in its design and installation of air heating systems.

The company "Northern Solutions" will perform for you the whole range of works on the design, selection, supply of equipment and installation of air heating, ventilation and air conditioning systems at the design or construction stage of your industrial, warehouse, sports, retail, administrative facility with high quality and on time.

Air heating on air heaters

Air heating devices are also called water fan heaters, heating volcanoes (from the name of the manufacturer Volcano), as well as water heaters with fans.

The principle of operation is extremely simple: a fan pumps air through a water heat exchanger-radiator. Through the same heat exchanger flows hot coolant from the water heating system. They are usually hung on the wall at a height of 4-6 m from the floor. The airflow at the outlet is warmed up and has sufficient speed not to go up to the ceiling, but to go down into the comfort zone. Thus, the air gives off most of the heat not to the ceiling, but to the lower part of the room.

| Advantages | Flaws |

|---|---|

| The system is very efficient due to the fact that the warmest air is always at the bottom in the comfort zone | There is a need for a boiler room or heating systems |

| Low power consumption. | Electrodependence, but it is common to all systems |

| Relatively low equipment cost | Import systems are expensive due to the exchange rate |

| Low operating costs due to the ability to use relatively cheap natural gas in the boiler room | When operating a boiler house on liquid (diesel) fuel, the cost of operation increases |

| Robust construction | Russian analogues are unreliable |

| Simple and quick installation, the ability to assemble an air heating system with your own hands | The risk of incompetent assembly is high, large volume of pipelines |

| Low inertia of the system, which allows very accurate dosing of heat without overheating the room | There is a risk of not warming up the room if the equipment is not properly arranged |

| The location of the devices at the top, i.e. outside the working area of the floor increases the usable area of the room and reduces the risk of damage to the device during economic activities | A large number of pipelines, additional coordination of sections on IP |

| The system is very simple and not expensive to automate, so that the set air temperature is maintained in the room | Increased noise from fan heaters |

| Ease of calculation of the industrial heating system and its design | More equipment and heating networks require additional maintenance |

| Small dimensions and weight of the equipment | |

| The modern and at the same time not flashy design of the units allows them to be used in trading floors and other crowded places. | |

| Does not burn oxygen in the room | |

| There are no harmful and toxic emissions in the room |

Radiant heating economical systems for large industrial buildings

To heat industrial premises, "light" and "dark" infrared heaters are installed. Natural or liquefied gas is used as a heat source. In buildings where for some reason it is impossible to install gas equipment, suspended radiant panels are mounted.

Features of the operation of different types of infrared heaters

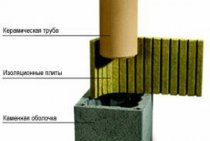

In "light" heaters, gas is burned using a special burner, the surface temperature of which can reach 900 degrees.A red-hot burner provides the necessary radiation. "Dark" heaters (they are also called "pipe" by the type of design) are emitters with reflectors that are designed to direct radiant energy to the desired areas of the premises. Tubular infrared devices heat up less (up to 500 degrees) and are characterized by less hard radiation, which greatly expands their scope.

Suspended radiant panels are universal, they are widely used in categorical, industrial and warehouse premises of all types. The systems operate with the help of an intermediate heat carrier "steam/water". Water in the appliances is heated to 60-120 degrees, and steam - up to 100-200. Today it is the most convenient and economical way of heating industrial premises and enterprises.

Pros and cons of radiant heating

Infrared heaters have the following indisputable advantages:

- quick heating of the premises (15-20 minutes);

- the possibility of creating warm zones in unheated rooms;

- no energy loss for heating the “extra” area”;

- minimum heat losses in systems operating without heat carrier;

- savings on maintenance, since there is no need to change filters, check, repair pumps, etc.;

- comfortable microclimate: the air does not dry out, the floor heats up and serves as a secondary source of heat.

Do not install infrared heaters:

- if the ceiling height is below 4 m;

- in industries where radiation affects product quality or technological processes;

- in the premises of fire categories A, B.

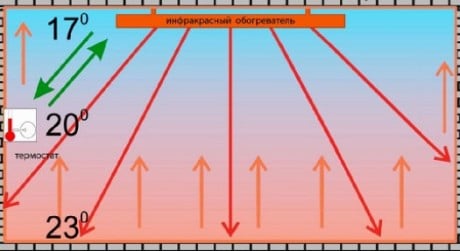

How does an infrared heater work?

Infrared heating systems for industrial premises are more economical and easy to use than air ones. Radiant heaters do not contribute to the spread of dust, create thermal zones at the height of human growth, and do not dry the air. Radiation heats the floor, making people in the rooms feel more comfortable. At the same time, there are buildings where radiant heating is not applicable, and air heating will be optimal for them.

Heating with mobile fan heaters or heat guns

The principle of operation of heat guns is simple: the air from the room is blown by a fan onto the heating element and already warm enters the room. As a heating element, either an electric heating element, or a diesel burner, or a burner for liquefied or natural gas is used. Sometimes direct heating guns are used, while together with the heated air, fuel combustion products enter the room.

Advantages: mobility - the guns are relatively easy to move and do not require installation; relatively low price of equipment; high heating efficiency.

Disadvantages: the most expensive types of energy carriers are used: electricity, diesel fuel, liquefied gas; the presence of toxic products of combustion in the air of the premises can lead to poisoning of personnel; outgoing air flow heated to excessively high temperatures can lead to a fire; the location of the air heaters at the bottom can lead to their accidental damage in the course of economic activity; occupy a significant part of the usable area of the premises; system management is difficult to automate, which requires constant monitoring by staff.

Thus, the use of mobile air heaters is justified only in cases where non-permanent or temporary heating is required. The use of guns for permanent heating leads to excessive fuel costs and a decrease in fire safety of premises.

Steam heating of industrial buildings

Heating of the industrial premises with the help of steam allows maintaining a high temperature of the environment (up to 100 degrees). When organizing the heating process, it is not necessary to take into account the number of floors.You can bring the temperature to the required value in a short time. This applies to both heating and cooling. All equipment, including communications, does not take up much space.

The steam heating method is optimal if the production room needs to be heated or lowered periodically. The method is more efficient than the water method.

There are the following shortcomings:

- there is a lot of noise during operation;

- it is difficult to regulate the flow of steam;

- the steam method is not recommended for use in rooms with aerosols, combustible gases, strong dust.

Types of warehouse heating systems

Let's take a closer look at the main design features and principles of operation of each of the warehouse central heating systems in order to identify their positive characteristics.

Central heating systems of warehouses are divided according to the type of coolant used in them: steam, air, water. There are also combined types of systems - water-air, steam-water, steam-air and others. Now about each of the systems in more detail.

The heat carrier in steam systems for heating warehouses is dry saturated steam. The advantages of the system under consideration include the absence of heat loss in heat exchangers, low inertia and rapid heating of heating devices during start-up, as well as low hydrostatic pressure created in the warehouse heating system. However, this system also has its drawbacks, for example, increased heat losses of steam pipelines, which does not have the best effect on efficiency, and intense corrosion of pipelines, which reduces their service life.

Warehouse steam heating systems are divided according to the method of condensate return (open or closed) and pressure (vacuum-steam systems in which the pressure is less than 0.1 MPa), high pressure (up to 0.27 MPa) and low pressure (up to 0. 17 MPa). In open-loop steam systems for heating warehouses, the condensate formed in heating devices is supplied to the heat source by a pump, and in closed systems it returns by gravity. The maximum steam temperature must not exceed 130°C.

An undoubted advantage of warehouse air heating systems over analogues is the ability to fine-tune and automate the air heating process, due to which exactly as much heat is generated as needed. Warehouse air heating systems are installed both with and without air ducts. A notable feature of these systems is the ability to evenly heat the air even in buildings with high ceilings, however, in this case, air jets (which can be covering and non-covering) should be correctly adjusted.

Warehouse water heating systems are characterized by a liquid heat carrier, which can be water or water-based antifreeze. The warehouse heating systems under consideration are divided into natural and mechanical (according to the method of inducing water movement), single-pipe and two-pipe (according to the connection scheme of thermal devices with heating pipes), warehouse heating water systems with upper and lower wiring (according to the location of the mains) and others.

The natural system of water heating of warehouses is mainly used in facilities with a small area, because in large warehouses of low efficiency such a system will not be enough. Often you can find combined water heating systems for warehouses, such a solution is justified: mechanical heating has a high efficiency index, and natural heating practically does not require electricity costs.

Choosing a system for heating industrial premises

Heating of industrial premises is carried out using different types of systems, each of which requires detailed consideration. The most popular are centralized liquid or air systems, but local heaters can often be found.

The following parameters influence the choice of the type of heating system:

- dimensions of the heated room;

- the amount of thermal energy required to comply with the temperature regime;

- ease of maintenance and availability of repair.

Each system has its pros and cons, and the choice will primarily depend on the compliance of the functionality of the selected system with the requirements that apply to it. When choosing the type of system, it is necessary to calculate the heating system of an industrial building in order to have a clear understanding of how much heat the building needs.

Infrared Ceiling Water Panels

One of the most popular methods of local heating and cooling in the premises of large and medium-sized enterprises are infrared ceiling water panels. The method of obtaining infrared radiation in them is clear from the name: a liquid circulates through pipes enclosed in an aluminum shell (reflector), heated or cooled to a temperature that provides a sufficient level of radiation. Moreover, different types of liquids with corresponding physical characteristics can be used for heating and cooling.

Advantages: high productivity, as well as safety for human life and the environment; water is heated centrally, while the heat is distributed due to the active circulation of a special fluid through the pipes; the heat flow can be regulated, the heaters operate silently, the energy consumption is minimal; safe for health and environmentally friendly, easy to assemble and dismantle; have a direct and remote control system that turns off the heating when a violation of the cyclic movement of the liquid or other malfunction occurs in the system.

Disadvantages: in the case of using main natural gas, heating will require a complex and extensive gas supply system, which is extremely expensive both in installation and in design.

A feature of any infrared heating and, in particular, infrared ceiling water panels is that only a certain area in the room is heated, to which the radiation is directed. In the rest of the space, the temperature can even be below zero. Thus, infrared ceiling water panels are successfully used not only in industrial plants and warehouses, but also for heating open verandas in winter ski resorts, ice palaces and other places where it is necessary to provide appropriate conditions for comfortable work of people.

Choosing a warehouse heating system

In the modern world, the construction of warehouses is not complete without such special works as the installation of a ventilation system, installation of a heating system, and electrical wiring. One of the main types of work is the design and installation of a heating system. The heating system itself is a set of technical elements designed to receive, transfer and transfer to all heated rooms the amount of heat necessary to maintain the temperature at a given level.The need to address this issue lies in the desire to maintain the quality of products. When designing a warehouse heating project, it should be remembered that all appliances must be available for repair and maintenance.