Tactile tiles are the main means for the implementation of floor markings for people with poor and absent vision. It is its use that is specified in the Code of Rules and GOSTs on the Accessible Environment.

However, tile for the disabled has a number of disadvantages that make it far from the best option for tactile markings.

In particular, there are often difficulties with installation, cleaning and maintenance in a "working" state.

The main disadvantages of tactile tiles:

- The minimum size of 30 cm makes it impossible to create tactile zones of a strictly specified width.

- You have to make them smaller, or saw the tiles.

- Dirt accumulates between the reefs, making cleaning more difficult and more frequent.

- Installation of tiles made of concrete and ceramics involves the creation of pits of the same depth, which is quite difficult.

- Due to the large area, the glued tiles often begin to move away at the edges.

- High total cost of tactile markings.

- Fragility (the maximum service life does not exceed 10 years, and the average barely reaches 4-5 years).

- Not always tiles of the desired material are available with the required pattern.

- But is there a viable alternative?

- Unfortunately, there is no replacement for tactile tiles that do not have significant drawbacks.

However, there are products that are better than tiles for one reason or another. And they should be used if these criteria are important for the conditions in a particular room or on the street.

Tactile indicators cone and bar

Two types of tactile indicators "cone" and "strip" allow you to simulate any tile layout, including straight ahead, decision zone, obstacle, turns and service area.

Moreover, the markup can be laid to any required width, simply by adding or removing one row of indicators. This is incredibly convenient and adds aesthetics to the tactile markup.

Indicators also win in terms of service life. It is on average 1.5-2 times higher than that of tactile tiles made of the same material.

Well, installation with special stencils is an order of magnitude easier. It is possible to make markings that are ideal in geometry even in the absence of building skills, and it will all be the same height.

The better indicators:

- Longer service life by 1.5-2 times.

- It's easier to do even markings.

- No pits needed.

- Easy to adapt to the width of surmountable obstacles (stairs, doors) and service areas.

- You can perform any markup with just two indicators, which are always available.

What problems remain:

- Rapid soiling and difficult to clean.

- High price.

The worse indicators:

- As a rule, the markup price is higher than that of a tile.

- The complexity of installation is less, but the laying takes several times more time.

Guide tactile tape

The guide tactile tape can replace the 3-reef tactile tiles. In particular, it can be used to implement two types of markup "Movement straight ahead" and "Zone for receiving services."

Use is allowed only indoors. Moreover, with low permeability, since PVC or polyurethane used to make the tape is afraid of ultraviolet radiation, temperature changes and quickly wears out.

The better tactile tiles:

- Quick and easy installation.

- Cheapness.

What problems remain:

- Complicated cleaning.

In what the tape loses:

- For low traffic areas only.

- Short service life (about 2-3 years).

In rooms where the flow of visitors is extremely small, but adaptation for the visually impaired is still needed, the tape is ideal.

You can markup literally in a day with minimal investment and forget about it for several years.

It is better to combine tactile tape with tiles and indicators, which are also made of PVC and polyurethane. Similar softness and height make it easier and safer for disabled people to use the markings.

Anti-dirt coating

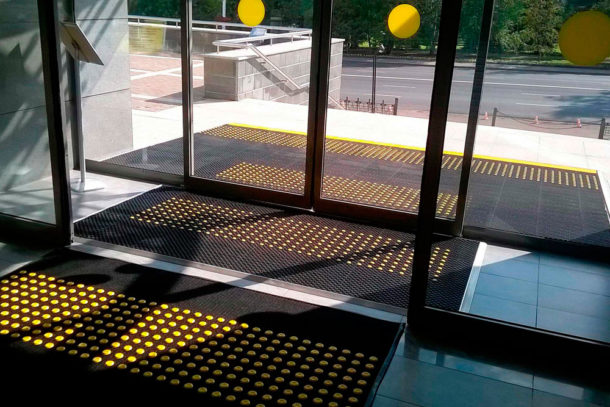

Relatively new type of tactile markings. It is an anti-mud mat with tactile indicators attached on top.

The main area of application is the input groups. The block collects most of the dirt from the shoes of incoming people, preventing it from spreading around the room.

What solves the main problem of tactile tiles - rapid pollution at the entrance to the building.

Cleaning of the tactile coating is carried out similarly to the usual anti-mud mats. You can take it off and shake it out or wash it.

The better tactile tiles:

- Containment of the spread of dirt throughout the room.

- The best option for entrance groups.

- Removable block for the possibility of shaking and washing with a stream of water.

- There is practically no dirt left on the reefs, which makes marking more efficient.

You can use a tactile anti-dirt coating not only at the entrance groups, but also in any other areas.

The range of available blocks allows you to perform almost any markup.

Are there any disadvantages:

- Reduced service life.

- This is explained by the lack of rigid fasteners for the indicators, which is why they fall off over time.

- Plus, the coating itself becomes unusable faster than the tile.

Solution schemes

Successful schemes for replacing tactile tiles with other floor markings are different in each of the premises.

However, there are several universal solutions that fit most objects of a particular class.

1. Reducing the amount of dirt in the room.

At the entrance door on both sides there are blocks of anti-dirt coating with markings "decision-making field".

The blocks do not get dirty as quickly as tiles or indicators, and reduce the level of dirt brought into the room by 3-4 times. This is especially true for high traffic areas.

2. Marking for low-visited premises.

In organizations whose offices, due to the specifics of work, are visited by a maximum of 20-50 people per day (in addition to employees), it makes sense to use soft tactile tiles and tactile tape for marking. With such a low load, polymer products will last for a long time. At the same time, they will cost very cheaply, and installation can be done even on your own, since there is nothing complicated in gluing.

3. For large public spaces.

In rooms with an impressive number of objects that require marking (doors, stairs, elevators, cash desks, reception windows, etc.), it is advisable to use tactile indicators. They will allow you to make markings in accordance with GOST (according to the width of obstacles and waiting areas).

What is especially important if the organization monitors its reputation and cannot afford a "curve" adaptation.

With low traffic, rubber indicators (PVC, polyurethane) can be used. With medium and high traffic of people, it is better to give preference to solid materials (aluminum, stainless steel, brass).

And it is optimal to use combined indicators made of steel, but with a recessed contrasting insert made of some kind of polymer.

The advantage is that such a marking is clearly visible, unlike a simple metal, but at the same time it has high wear resistance, since there is no mechanical effect on the polymer inserts.