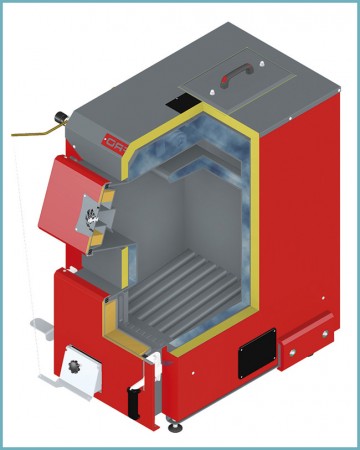

Combination of the boiler with the heating water system

A system of pipes and radiators connected to the water circuit allows you to evenly distribute heat over the entire area of \u200b\u200bthe building. The simplest type of heat exchanger can be a water tank, when a heat source is located directly below it. But such heating is ineffective, since the heating of the liquid will be carried out only from below.

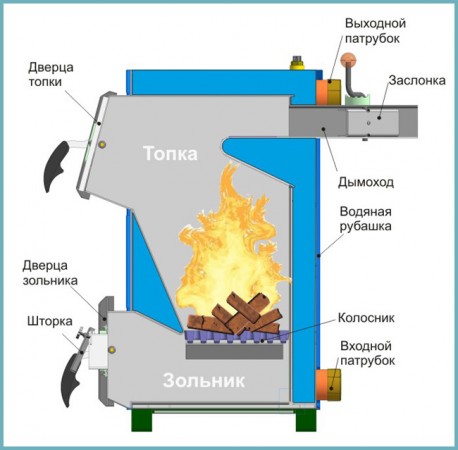

The so-called "water jacket" will be much more effective in terms of transferring thermal energy. A more complex type of water circuit is a double top and walls along the entire contour of the boiler, inside which the coolant circulates. Due to the constant circulation, the water does not stagnate, and the thickness of 3-5 cm between the walls allows the liquid to warm up as quickly as possible.

Another equally effective type of water circuit is welded from steel thick pipes, curved by waves along the walls and the top of the combustion chamber in a “coil” type. The coolant moves slowly through pipes with a diameter of 5-6 cm, providing excellent heat transfer

In addition, this type of circuit has an important advantage - improved maintainability.

Control and monitoring unit

The boilers are equipped with special systems for regulating the temperature of the water in the water circuit. The simplest system is based on the operation of a thermostat - when the required temperature is reached, the blower damper is closed and thus the air flow is reduced. As soon as the water cools down, the system will work in reverse order.

More advanced control systems work with the inclusion of the most accurate temperature sensors and forced electrified air supply. When installing forced ventilation, an upper air supply is carried out, due to which the fuel is burned almost completely. Boiler equipment of this type needs to be connected to the mains, but in the absence of electricity it is not able to work.

Equipment with a circulation pump can save the system from its complete defrosting. A boiler left unattended in the winter, having used up all the fuel, will not be able to maintain the temperature level of the water in the system for a long time, as a result of which it will freeze over time. In such a critical situation, the control system will turn on the circulation pump, which will lead to the circulation of the coolant - in mild frosts, running water will not freeze.

What should be in the composition of the water heating system

The scheme of water heating of a private house, it is also liquid, involves the use of a liquid coolant in the system, which “delivers” heat from the heating boiler to radiators or underfloor heating, constantly circulating in the system.

In other words, the coolant "runs in a circle", heating up in the boiler and giving off its heat in the heating appliances.

To ensure the operation of such a system, a lot of other equipment is used, which makes the system more flexible (differentiated heating of various zones), safe (protection against overpressure and leakage of coolant from the system), and automate the process of controlling home heating.

The block diagram of the water heating system looks like this:

Structural diagram of the water heating system

Water heating systems can be:

- with natural circulation of the coolant;

- with forced circulation of the coolant.

Systems with natural circulation of the coolant

In a system with natural circulation of the coolant, the driving force is the difference in the density of the heated and cold liquid (coolant) in the supply and return pipes, respectively.

Natural circulation system

When the coolant is heated in the boiler, its density decreases, and it is displaced up the vertical pipe, displaced by a denser cold liquid returning through the return pipe.

In this case, the coolant passes from the boiler along the vertical riser to the open-type expansion tank, spreads further along the horizontal risers along the heating radiators and returns to the boiler through the return pipe.

In such systems, important parameters are: the diameter of the pipes (especially the central supply riser), as well as their slope.

The advantage of such a system can be called its energy independence (when using a simple solid fuel boiler), and in the list of disadvantages we will name the inability to regulate the heat regimes of various rooms, increased fuel consumption, the need to use large diameter metal pipes.

Systems with forced circulation of the coolant

Such a system is also supplemented by a circulation pump, which “forcibly” creates a driving force applied to the coolant.

"Forced" heating system

The advantages of such a system include the possibility of separate and flexible (differentiated) control of the power of each radiator or underfloor heating using manual or automatic valves, which makes it possible to use energy sources more economically for the operation of the boiler. In such a system, plastic pipes can be used, which significantly reduces the cost of materials and facilitates installation work, and the plastic pipes themselves can be “hidden” in the walls.

The disadvantage of such a system is only its "energy dependence" on the presence of electricity in the house to ensure the operation of the pump. In some cases, a combined heating system is used.

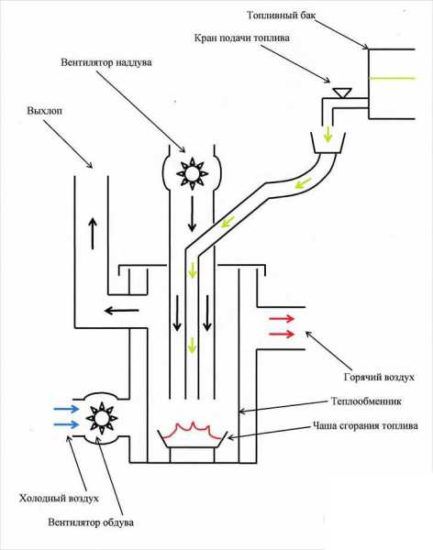

Video. How does a mining boiler work

Pavel Vorobyov editor-in-chief

Author of the publication 06/22/2018

Water heating systems were first used in the baths of ancient Rome. After several tens of centuries, these brilliant inventions have become familiar and accessible to everyone.

How are

One of these miracles of thermotechnology is a heating boiler. The principle of operation of a hot water boiler is that the coolant is heated in it to 115 degrees and transfers this heat to the heating system of the building. Water passes into a vapor state at a temperature of 100 degrees, therefore, to prevent boiling, an increased pressure is maintained in the boiler.

The higher the pressure in the unit, the better: the likelihood of near-wall boiling is reduced, which means that less scale is formed. Therefore, a pump is installed at the inlet, which pumps the cooled water inside.

There are the following modifications of water heating units:

- Gas-fuel

- Liquid fuel

- Electrical

- Solid fuel

Regardless of what fuel the system runs on, the principle of operation of the hot water boiler is the same: the fuel is burned in the furnace, and the heat is transferred through its walls to the water circulating through the heating pipes. The design is created in such a way as to ensure the most complete combustion of fuel and optimal heat transfer.

Hot water boiler burners vary depending on the type of fuel used. They can be built-in atmospheric, or replaceable supercharged. Built-in burners cause the use of only a certain type of fuel. Replaceable burners are more convenient because they allow you to switch from one type of fuel to another.

How are they used

Functionally, hot water boilers are divided into:

The purpose of single-circuit units is only heat supply. Water passes through pipes, batteries, and returns to the boiler again.

The scope of generators of this type is becoming wider.Due to the presence of not one, but several inputs and outputs of the coolant, the boiler is additionally able to ensure the operation of boilers, water heated floors, a pool heat exchanger, etc.

Double-circuit heating systems are designed not only for heating, but also for flowing hot water supply to the premises. Their design provides for the presence of built-in plate-type heat exchangers, with the help of which double-circuit boilers are able to supply the house with hot water around the clock and almost unlimitedly.

The principle of operation of models with water circuits

The process of heating water is carried out exclusively during the period of fuel combustion. The main fuel is coal or wood. At the same time, one load is enough for 3-4 hours, a longer period of fuel burning will be provided by a gas-generating (pyrolysis) solid fuel boiler.

The higher the quality of the boiler, the efficiency of heat exchange processes in the water circuit and the more accurate the control of the heat carrier temperature, the lower the cost of each kilowatt of heat produced. The special design of the water circuit allows the most efficient heating of the main heat carrier during boiler operation.

A wall in a water jacket is capable of accumulating the resulting thermal energy. Due to this, the heater quickly heats the water, and also maintains a high temperature for a long time. Boiler heating equipment with a water circuit works equally effectively both in a system with natural and forced circulation.

How to make a mining boiler with a water circuit with your own hands

In order to independently perform this unit, you need to stock up on the following materials:

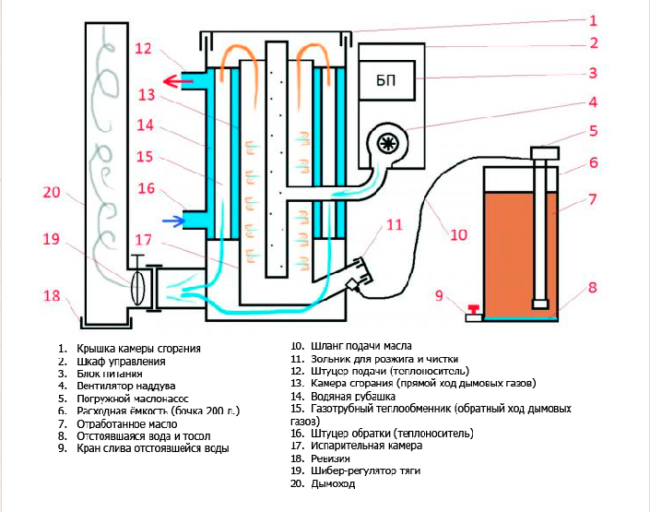

Diagram of a mining boiler with a water circuit

- sheet metal for the tank (thickness 4 mm);

- sheet metal for the cover (thickness 6 mm);

- chimney pipe;

- oil pump;

- fan;

- steel adapters;

- heat resistant sealant;

- metal corners for supports.

- grinder with a circle for cutting metal;

- pencil and construction tape measure;

- drill with a drill for metal;

- hammer and a set of keys;

- electrode welding.

To facilitate the work on the implementation of the boiler, you can take ready-made barrels for propane or oxygen.

Boiler working out scheme

The assembly diagram of the unit will look like this:

- The boiler body must be divided into 2 parts. In the upper part, you will need to mount a water jacket, and connect the lower part to heating radiators. The lower part must necessarily be separated from the upper part, to which the pressure pipe is connected.

Before performing work, it is necessary to determine the place where the boiler will be placed. It is necessary to make sure that there are no flammable things nearby and the boiler body itself does not block the movement, does not interfere with work.

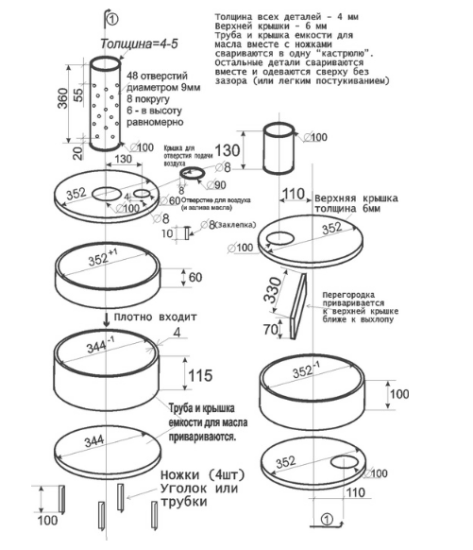

Numerical parameters of the boiler

Step 1. Preparing the base and walls

Under the mining boiler with a water circuit, it is best to make a concrete screed. It is also possible to tile the floor and the wall to which the boiler structure adjoins.

Walls must be of non-combustible material

If the walls are wooden, then an asbestos sheet must be laid between them and the unit.

Step 2. Making the main tank of the boiler (internal)

This body is a tank with a water jacket, an oxygen supply channel and a tube through which oil flows to the bowl.

At the bottom of this case, it is necessary to make a door to remove the bowl and ignite the oil.

- Draw a diagram of the boiler.

- Measure the dimensions of the tank on sheet metal and cut it out with a grinder.

- Cut out the bottom of the tank.

- We connect a sheet of metal in such a way that a pipe with a diameter of 60 cm is obtained.

- We attach the bottom.

Weld the base securely

Step 3. Making the outer casing of the pipe

- The length of the outer pipe must be 5 mm less than the height of the outer pipe.

- Using a grinder, we cut a hole in the pipe for the chimney, doors, supply pipes (at the top of the pipe) and a hole for the return of the coolant (at the bottom).

- We put the outer part of the pipe on the inner and hermetically weld the bases.

Bowl with welded bottom

Installation of a water bath

Step 4. Making an air supply channel

- Measure a pipe with a diameter of 6-8 cm on sheet metal and cut it out with a grinder. The length of the pipe exceeds the overall design by 10-15 cm.

- We measure from one end 50 cm and make a hole.

- Now we are making an oil supply channel, which will be inside the air supply pipe. To do this, we take a piece of tube 8 cm long (d = 1 cm) and weld to the other end of a tube of the same diameter, but 50 cm long at an angle of 130-150 0 .

- Carefully install the oil supply tube into the air supply pipe.

- On the side we carry out a tie-in for the compressor. We connect the fuel supply pump and the circulation pump.

- We place the bowl in the cauldron.

- We fix the door.

Step 5 Installing the chimney

After the boiler itself is securely installed on the base, we proceed to the installation of the chimney, the length of which should be 3.5-4 m.

Assembling a chimney from sandwich pipes

At the same time, try to make a vertical pipe without horizontal sections.

- We connect the outlet pipe of the boiler with the chimney pipe.

- Depending on which chimney outlet scheme: through a wall or roof, we perform markings. If we pass a pipe through the wall through the ceiling.

We carry the chimney through the wall

External fastening of the flue pipe

Chimney outlet above the roof

Step 6. Connecting the water circuit

If the boiler is to be used as a connection to radiators for heating a large room, the entire battery network must first be laid through the room.

To connect the boiler to the radiator, we use a pipe with a diameter of 43 mm.

- We take a small metal container (water tank) with thick walls, and securely fix it with bolts to the boiler. You can use welding as a fastener.

Connecting the boiler to the system

Installation options for water heating systems

If an unprepared person considers all existing installation options for water heating systems, especially with natural circulation, he can “drown” in an abundance of information.

Within the framework of this article, we will focus on the most commonly used water heating installation scheme, available for repetition by a person without experience in such work.

Today, water heating in a private house is considered the most effective, made according to a two-pipe water heating installation system, in which “hot” liquid is supplied through one (supply) pipe, and “cold” is discharged through another (return).

Two-pipe installation scheme with forced circulation

Such a scheme allows you to connect heating devices (radiators, underfloor heating circuits) in parallel with independent manual or automatic (the thermostat is “nada” here, however) regulation of the flow of fluid passing through them. In such heating systems, it is convenient to use special devices - a collector, to which all "consumers" of heat are connected.

The use of collector nodes in the heating system

For more information about installation systems for heating water systems, see the article “Heating Scheme for a Private House”

Design features

Boiler equipment of this type, in fact, is a slightly modified version of standard boilers - the water circuit is additionally included in the design.

- firebox;

- grate;

- ash chamber;

- water circuit.

If single-circuit models are intended only for space heating, then double-circuit models are used both for heating the building and for supplying it with hot water.

Fuel loading can be done manually or automatically. The second option involves the presence of a reservoir in the boiler, where fuel is poured every 3-7 days.But models are more expensive than those with manual fuel filling, and therefore less common.

In addition, only fuel that has undergone special training is suitable for supply - coal up to 2.5 cm or the so-called "eco-peas". Some models are equipped with built-in electric heaters that start up when the fuel supply is cut off - this ensures their continuous operation.

Mounting Features

To heat a dwelling of a small square, it is advisable to install it directly in the house itself. Also, the boiler room can be equipped as a separate building or inside other outbuildings.

In this case, the heating pipe is always laid underground, necessarily below the freezing level of the soil, thermal insulation is provided. In the boiler room, the air temperature should be at the level of 10 degrees; separately, you should take care of high-quality ventilation equipment.

The floor covering at the installation site must be non-combustible, level and firm. To increase the strength of the floor, the boiler is installed on a thin concrete screed. In front of the heating unit, a sheet of metal with an area of at least 1 sq. m.

During installation, you should strictly follow all the recommendations given in the operating instructions for the boiler equipment regarding the main parameters of the chimneys: section and height. The joints between the chimney and the chimney must be filled with a heat-resistant sealant or coated with a clay solution.

CLAIM

1. The water boiler contains a furnace, an ash pan framing their body in the form of a water jacket, the inner wall of which is connected to hollow water partitions forming a zigzag gas channel, each of which is connected to the water jacket of the boiler from three sides, a vacuum system in the boiler furnace, network water inlet at the bottom, hot water outlet at the top, while windows are made in the body, characterized in that the mentioned water jacket is internal, and the boiler body is equipped with an external water jacket with an outer wall in the form of a cylinder, truncated along the chord from the front side and from the inside a wall in the form of a parallelepiped, which simultaneously acts as the outer wall of the inner water jacket, metal partitions are fixed between the walls of the outer water jacket of the boiler at the same distance from the side walls of the inner water jacket, and pressure metal tubes are connected to the space of the boiler cut off by the partitions to supply hot water from the hot water pipe using a pump installed on the top cover of the boiler, the hollow water partitions are located at the same distance between themselves and the inner wall of the inner water jacket, the inner water jacket of the boiler and the hollow water partitions have the same thickness, while in the outer water jacket, the distance between the inner wall and the partition is equal to the thickness of the inner water jacket, and the distance between the upper wall of the inner water jacket and the common cover of the boiler is at least 2 times greater than it, the hollow water partitions are made with a horizontal lower wall and with the upper wall located under at an angle of at least 3° to the horizontal and have a length that is at least 3.5 times greater than the distance between the hollow water partition and the inner wall of the inner water jacket of the boiler, the vacuum system in the boiler furnace includes a thermostat connected to the air damper on the door pki, the zigzag gas channel of the boiler is connected to the chimney through a confuser, which is connected with the larger side to the back wall of the boiler, and the smaller side to the chimney, while the ties are evenly installed on the top cover of the boiler.

2.Hot water boiler according to claim 1, characterized in that the metal partitions form a slot with the bottom of the boiler at least 30 mm high on both sides of the boiler.

3. Hot water boiler according to claim 1, characterized in that the discharge metal pipes for hot water are connected in the center of the space of the outer water jacket, closed by metal sheets, cut off by a partition.

4. Hot water boiler according to claim 1, characterized in that the discharge metal pipes for supplying hot water are lowered by at least 2/3 of the height of the partition.

5. Hot water boiler according to claim 1, characterized in that the angle of narrowing of the confuser is at least 15°.

6. Hot water boiler according to claim 1, characterized in that the thermostat is connected to the air damper on the firebox door using a lever and, for example, a chain.

7. A method of manufacturing a hot water boiler, which consists in the preparation of parts, blocks and then assembling the boiler, characterized in that flat parts are prepared from steel sheets of calculated thickness for the manufacture of the entire boiler, seats and holes are cut out on the flat parts, then hollow water partitions are assembled, which are the basis for the assembly of the entire boiler, since all other parts are then attached to them and rigidly fixed gradually until the complete structure of the boiler is obtained, the connection of flat parts is performed by welding in a horizontal position.