What criteria to evaluate when choosing a drainage pump

When choosing a drainage pump, its purpose and other features are taken into account:

- working conditions;

- possible immersion depth and generated pressure;

- constructive performance.

The capabilities of the equipment are laid down in the technical specifications and are limited by water pollution. If the particles present in the liquid are larger than the grid of the working chamber allows, the equipment will not cope with the task in full.

Each unit has its own purpose: to pump clean water with small fractions of foreign impurities or dirty water with solid particles. Application features are embedded in the design. To dry a flooded room, you will need pumping equipment with a built-in float. At a construction site, fecal waste is suitable for sewage grinder pumps.

The main parameter of any pumping equipment is the pressure generated at the outlet and performance. The pressure developed by the impeller must not only lift the liquid, but also overcome the hydraulic resistance in the pipelines. Water should reach the place where it merges further by gravity. If the pump is used to irrigate the site, an excess pressure of at least 0.5 atm is required for the irrigation devices to work.

Take into account the diameter of pipelines

If it is greater than 25 mm, the internal resistance is not taken into account. Reducing the section of the hose leads to an increase in resistance

For example, 4 m of a horizontal pipe with a diameter of 16 mm reduce the pressure as 1 m of a vertical hose - by 0.1 atm.

Design features include voltage and motor power. Household appliances are designed to be powered by 220 V, three-phase 380 V are rare. The minimum power is 350 watts. It is not worth striving to choose the most powerful equipment - it has a high cost, high weight, dimensions, it heats up rather. Power is not of decisive importance - it is important to calculate the power line, protective automation.

Pay attention to the material of the case, the features of the working unit, the presence of a float switch. An important point is the temperature of the liquid

Household appliances are designed for a maximum of 40°C.

Labeling rules

When designating a model of pumping equipment, which today is produced by many domestic and foreign companies, manufacturers do not adhere to uniform rules and regulatory requirements, but a certain pattern in this matter can be traced. So, in the marking of many models of such equipment there are both alphabetic and numeric characters. The letter part of the mud pump marking usually contains the following information about the equipment:

- pump type;

- speed factor.

The digital part of the marking indicates the diameter of the inlet pipe in mm.

The labeling of faecal mud pumps contains the following information:

- SM - waste-mass type device;

- XX is the diameter of the suction pipe;

- XX is the diameter of the discharge pipe.

An example of deciphering the marking of a drainage pump

On many models of high-pressure drainage pumps, you can find this type of marking - XXX / X FN, which is deciphered as follows:

- XXX - the volume of supply in liters, which the pump is able to provide per unit of time (min);

- X is the pressure of the liquid, measured in meters;

- Ф - type of pump (fecal);

- H - body material (stainless steel).

The marking of pumping equipment may also contain other information (in particular, the presence of automation).

Characteristics

Depending on how the drainage pump is located in relation to the water it pumps, it can be:

- surface pump for dirty water;

- submersible pump for dirty water.

Drainage electric pumps of the first type, installed on the surface of the earth, are used to pump out water in which there are insoluble inclusions with a particle size of not more than ten millimeters. Before starting, the surface drainage pump is installed on a flat surface, and water is taken from the basement, pool, reservoir and any other place using a special hose connected to the equipment inlet.

Cantilever type surface drainage pump is used for pumping large volumes of water

A surface pump for pumping heavily polluted water is, as a rule, a low-power device that is not designed for very intensive use, but is more suitable for occasional work. So, using a surface self-priming pump, you can pump out water from the basement or cellar several times a season, free the pool from water, organize watering of the garden and vegetable garden.

Submersible drainage pumps, which are located in the thickness of the pumped water, have a higher power. They are capable of lifting liquid from greater depths than surface-type devices. Moreover, submersible drainage pumps can be successfully used for pumping dirty water with insoluble inclusions, the particle size of which reaches fifty millimeters.

The drainage pump is indispensable in case of various emergency leaks resulting from breakdowns of household appliances or plumbing fixtures.

It should be borne in mind that for pumping sewage containing a large number of various inclusions, typical drainage pumps for dirty water are not entirely suitable. For this, fecal pumps are used, the main difference of which from drainage devices is that their design has a special device that grinds large inclusions in the pumped liquid.

If we talk about the areas of application of various types of drainage equipment, then submersible pumps for dirty water are purchased in cases where it is necessary to pump out liquid from a great depth, and also when such a liquid is characterized by a high degree of pollution. If you have to pump out not very dirty water from basements and other shallow places, then a surface pump is quite suitable for such purposes.

Drainage pump suitable for pumping water from a drain well

The versatility of domestic drainage pumps

Sewer pumping devices are universal equipment. The main purpose is to pump dirty water, but if necessary, they are used to lift clean water from wells, wells, and tanks. The maximum size of inclusions in liquids depends on the equipment model. For household appliances, this is no more than 10 mm, professional units cope with solid particles with a diameter of 140-300 mm.

For its intended purpose, drainage pumps are used in such cases:

- pump out sewage and liquefied sludge from septic tanks;

- drain the soil flooded by spring floods;

- organize watering of the garden plot;

- pump out liquid from pools, fountains, other artificial reservoirs and fill them;

- arrange an open or closed drainage system;

- drain flooded cellars, cellars, construction pits;

- clean wells from accumulated dirt, deepen.

Drainage pumps are used wherever it is necessary to pump out dirty or clean water, fill the tank with it.

Calculator of the required capacity of the drainage pump used for watering the garden

Not every pump creates a pressure greater than 1.0-1.5 atm. The pressure is often not enough for irrigation, so the liquid intake points are brought as close to the site as possible. This is possible if you arrange several containers in which the water settles and then is taken.Under such conditions, the productivity of drainage equipment is sufficient for irrigation.

Each plant needs its own amount of water per 1 m². Knowing the norm, they calculate how much liquid will be needed for irrigation. The calculator takes into account all the conditions in order to calculate what pump performance is needed and pump the right amount of water in a limited time.

Pump for watering the garden with a float.

Advantages and disadvantages

The mud pump, the design of which is specially designed for pumping liquid media containing a significant amount of insoluble impurities, has a whole list of advantages:

- high mobility (this makes it easy to carry and use the drainage pump in those places where it is needed at the moment);

- high power, allowing the use of a mud pump for pumping liquid media from great depths;

- anti-corrosion properties of the body;

- a special design, which is designed in such a way that even in the cold season, the parts that make up the submersible pump do not freeze;

- low noise during operation.

Household-level pumps used to clean wells are available in sealed plastic (mostly) cases

Of course, like any technical device, a high-pressure mud pump has its drawbacks.

- The body of such a device is non-separable, so it is almost impossible to repair a submersible pump if it is out of order, it can only be replaced with a new one.

- Since the submersible pump is constantly in a liquid medium during operation, quite serious requirements are imposed on its electrical safety.

In addition to submersible mud pumps, modern manufacturers offer models of surface-type pumping equipment that are installed on the surface of the earth, and only a hose or pipe connected to the suction pipe of the device is immersed in the pumped liquid medium. If we talk about the advantages that distinguish a self-priming mud pump of a surface type, then they should include:

- a fairly low cost when comparing such a pump with submersible models;

- ease of installation and maintenance;

- high electrical safety.

Surface Type Drainage Pump

Meanwhile, surface-type mud pumping devices can be used only in cases where water containing dirt and other insoluble inclusions in its composition needs to be pumped out from a shallow depth - no more than 8-10 meters. Another significant disadvantage of high-pressure surface mud pumps is that such devices emit quite a lot of noise during their operation.

When choosing a pump for cleaning a well or for solving any other problems associated with pumping contaminated liquid media, one should take into account not only the depth of the source from which such a medium will be pumped out, but also the distance over which it will be transported in a horizontal direction, as well as the degree of its pollution and the size of the inclusions contained in its composition.

Design features and principle of operation

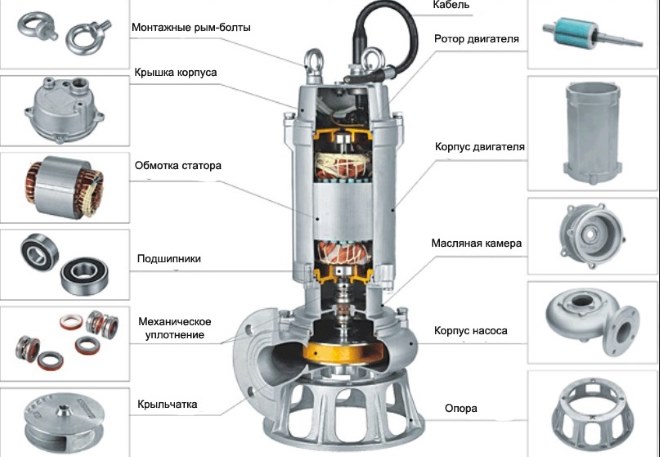

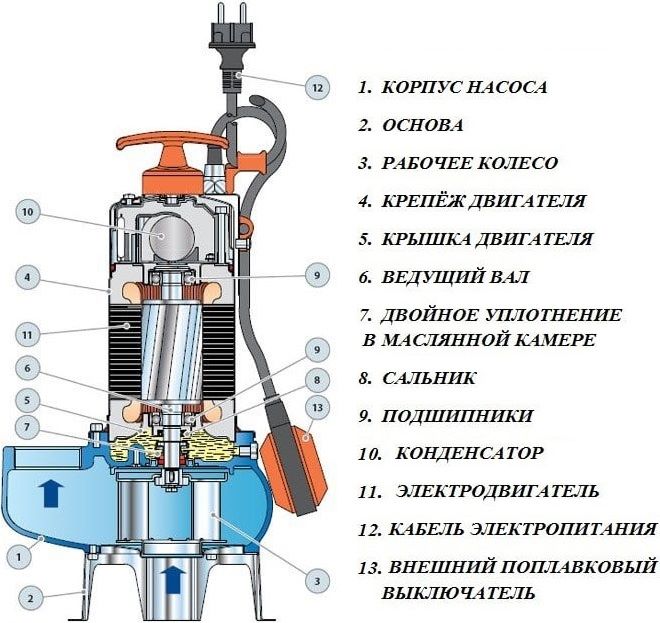

The drainage type centrifugal pump is a compact device, the main structural elements of which are:

- housing made of durable and wear-resistant materials - cast iron, stainless and ordinary steel, plastic (the choice of material depends on the purpose and technical characteristics of the device);

- an electric motor that drives the working shaft;

- an impeller, on the outer surface of which curved blades are fixed (the rotation of the impeller is provided by a drive shaft, on which such a wheel is fixed).

Drain pump device

A submersible drainage pump, which is in operation in the thickness of the liquid medium it pumps, is additionally equipped with a strainer that protects such a pump from solid particles that exceed the allowable size from entering its internal chamber.

The dimensions of the internal chamber of drainage pumps used for pumping groundwater from basements and cellars, as well as pumping dirty water from wells or ground tanks, are calculated in such a way that solid inclusions contained in the pumped liquid can freely pass through it.

The bottom of the drain pump should be easy to remove to clean the impeller

As elements of additional equipment that protect drainage pumps from the consequences of emergency situations, as well as allowing them to organize their operation in automatic mode, the following can be used:

- temperature switches that automatically turn off pumping equipment in case of overheating;

- sensors that protect the electric pump from idle operation.

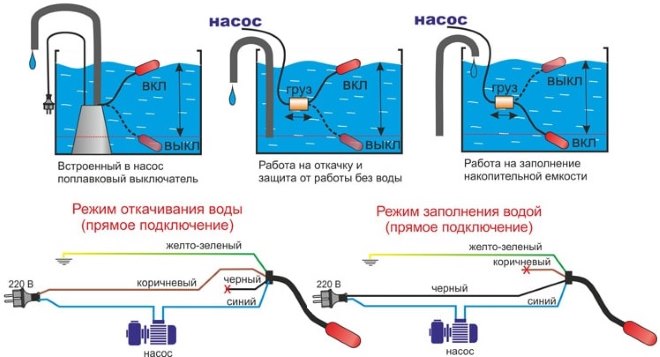

Idling sensors are float switches that automatically stop the operation of the equipment if the level of pumped water falls below a critical level. A floatless pump not equipped with such sensors requires constant attention from users to monitor its operating conditions.

When installing such sensors, it is important to correctly determine the depth of their immersion. This is necessary so that the pump turns off and on exactly at those moments when it is required.

How float switches work

Centrifugal equipment is mainly used as a submersible pump for dirty water. The main element of its design is an impeller with blades, which, moving the pumped dirty water through the inner chamber, creates a centrifugal force that increases the pressure of the liquid medium, due to which the latter is pushed out through the pressure pipe. At the same time, an air rarefaction is created in the middle part of the working chamber of the centrifugal electric pump, which ensures that a new portion of the pumped out dirty water is sucked into such a chamber.

Centrifugal pumps are considered the best in terms of working with polluted waters for a number of reasons.

Due to its high reliability, this pump does not require frequent maintenance.

Electric pumps of this type have high performance and the ability to form a liquid medium flow with good pressure, which is especially important for devices through which muddy and dirty water is pumped.

On the market you can find many different models, which allows you to optimally select a centrifugal pump, based on the nature of the tasks for which it is purchased.

The versatility of such pumping equipment allows it to be used not only for drainage, but also as a pump for pumping water from a well or well, as well as for its further transportation through a pipeline system to water intake points.

Cast Iron Centrifugal Drainage Pump

Principle of operation and scope

By its design, the mud pump is a single unit consisting of an engine and a working mechanism placed in a common housing. An oil chamber and a block of sealing elements are located between the engine and the working mechanism of the high-pressure mud pump. A conventional submersible pump has a multi-channel design, while mud pumps have only one channel through which the contaminated liquid medium is pumped.

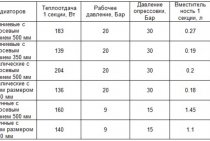

Household models of submersible mud pumps, as a rule, have a power of 1.5–1.75 kW; they can be used to pump contaminated liquid from wells up to 60 meters deep.The density of the liquid pumped by such high-pressure pumps should be 1.1–1.2 kgf/cm3, and the amount of impurities in it should reach 10%. The size of insoluble inclusions contained in the liquid pumped by domestic models of high-pressure mud pumps can reach up to 5-10 mm, and imported - up to 50 mm. During operation, the mud pump must be cooled, which is ensured by the liquid surrounding it. A special filter is installed on the suction pipe of the high-pressure mud pump, which limits the particle size of insoluble impurities contained in the pumped liquid.

Submersible mud pump device

Depending on the design, submersible mud pumps can be rotary or vibratory. The main working element of rotary pumps is an impeller with blades rotating on the rotor shaft inside the device housing. In vibration pumps, the role of such an element is performed by a steel membrane, which vibrates under the influence of alternating current and thereby creates a rarefaction of air in the working chamber. Vibration pumps, although they are characterized by lower power when compared with rotary devices, are characterized by higher reliability and a longer service life, since there are no rubbing parts in their design.

Among the high-pressure mud pumps, semi-submersible devices should be distinguished, designed to pump a medium with a density of 1.3–1.5 kgf/cm3. Such mud pumps, the working part of which can be made of corundum steel, ebonite or rubber, can operate at a temperature not exceeding 60 °.

For pumping media with a higher density, as well as media containing inclusions with a fibrous structure (fabrics, algae, etc.), mud pumping devices of a different type, fecal ones, are specially designed. In the design of such pumps, the inlet and outlet pipes of which are distinguished by expanded diameters, there is a special impeller that cuts fibrous inclusions into smaller fractions.

The fecal pump grinder is usually made of stainless steel

The most common applications for high pressure mud pumps are:

- pumping out used dirty water during construction work and maintenance of production processes (pumping out sludge water, etc.);

- a decrease in the level of groundwater after heavy rainfall, floods or flood situations;

- pumping out water and silt from basements, cellars, sewers and pools;

- cleaning of wells, replacement of polluted water in artificial reservoirs;

- organization of watering of green spaces growing on personal plots.

Calculator for calculating the required pressure for a drainage pump

Automatic calculation of pump head.

Any pump has limitations on the depth from which it can pump fluid. Another important metric is productivity. It shows the volume of liquid that the unit is able to pump. The weakest devices have a capacity not exceeding 100 l / min. The choice for this parameter depends on the conditions in which the equipment is to operate.

If large volumes are pumped, the performance is chosen as large as possible. Inefficient equipment is enough to pump out the water that comes in little by little. The main thing is that less liquid is collected in the storage tank than the pump can pump out.

When calculating the required pressure, take into account:

- the difference in height between the water intake level and the highest point of the main;

- horizontal distance from the bottom of the intake hose to the end of the pipeline;

- diameter of pipes, hoses.

In the proposed calculator, you must specify all the parameters and get the result.

Using a drain pump to clean a well

Cleaning the well with a drainage pump is a fairly common procedure, the regular implementation of which allows you to always get well water that is not contaminated with sand, silt and other foreign matter. Some owners of dachas and country houses, in whose household territories there is a source, acting in the old fashioned way, clean it manually, using a brush and a bucket on a rope for this purpose. Meanwhile, without using a cleaning pump in combination with this method, it will be quite difficult to solve the problem. In practice, in order to effectively purify well water, they try to apply both methods: first, using mechanical means, they clean the walls of the shaft, and then, using a high-pressure mud pump, they clean the water-bearing lens.

Manual cleaning of the well from large solid contaminants

To understand why well cleaning requires such a comprehensive approach, it is necessary to understand what can cause water pollution in a natural water supply. So, the most common factors affecting the pollution of well water are:

- the quality of the soil in which the source is equipped;

- operating conditions of a hydraulic structure, the reliability of protecting its water layer from sunlight, which is the cause of the development of flora (blue-green algae) and fauna (bacteria and microorganisms);

- the quality of the arrangement of the clay castle and its tightness;

- reliability of protection of the water layer from sewage and untreated water from nearby reservoirs.

If the well is not periodically cleaned, someday unusable water will come out of it

The following signs indicate that the well urgently needs high-quality cleaning:

- the water becomes cloudy and acquires a greenish tint;

- the thickness of the water layer decreases, which occurs due to the rise of the bottom;

- the water source stops functioning altogether.

To put in order the walls of the well located above the water level in it, a drainage pump is not required. It is enough to clean the green walls and seal the mechanical damage that has formed on them. To clean the walls under the water layer, as well as the bottom of the hydraulic structure, it will be necessary to solve several problems at once:

- continuously pump out water from the well;

- pump out the bottom liquid, which, in addition to water, contains silt, gravel, sand and other foreign inclusions;

- purify the pumped water using a filter unit and dump it back into the source;

- create a pressure jet, with the help of which the walls of the well are cleaned and silt deposits are stirred up at its bottom.

In order to increase the efficiency of cleaning the well, two pumps can be used to perform this procedure simultaneously. One of them is needed in order to pump out the bottom layer of liquid and feed it to a filtering unit, which can be an ordinary barrel with two valves filled with gravel. With the help of the second pump, already filtered water from the storage tank is supplied under high pressure to the lower part of the source, where it knocks the silt layer off the walls of the hydraulic structure and crushes it in the bottom part.

Overview of popular models of drainage pumps with a float switch

Grundfos products from Denmark are designed to handle clean or slightly contaminated liquids. Drainage pumps of various prices are produced, the cheapest - from 9 thousand rubles.

A high-end drainage pump from this manufacturer is Grundfos Unilift AP 12.40.06.A1. The unit is compact and lightweight, it can work for a long time not completely immersed in liquid. The design provides a water jacket for cooling the electric motor.The main working position is vertical, the drainage level is 10 cm. It can be installed on its side, while at the bottom there is more liquid that has not been pumped out.

All main components, including the impeller, are made of stainless steel. Motor power 0.9 kW, which provides a capacity of 20 m³ / h when lifting to a height of 2 m. The limit level is 12 m, the performance is reduced to 2.5 m³ / h. The maximum immersion depth is 7 m, but the developers give another 3 m of margin, which does not always guarantee pumping.

Spanish products Drainex 200 for pumping liquids with large particles have similar characteristics. Prices from 26 thousand rubles. For 18 thousand rubles. you can buy Drainex 100, which pumps water with inclusions up to 34 mm.

Pumping equipment of the CS-750S series drain small flooded rooms, empty pools, settling tanks, wells if there are particles up to 5 mm in size in the water. Pumps are used to supply liquid to fountains, irrigation. The pump has a built-in cooling jacket. Housing and impeller material – stainless steel. Pumps water from a depth of 7 m. Equipped with a universal fitting for connecting hoses with a diameter of 25 and 32 mm.

The VMtec Integra 440 pump, which is manufactured in Germany, has the ability to dry the floor from water. The content of solid particles up to 5 mm is allowed. Electric motor with a power of 440 W, a head of 7 m is created, equipment productivity is 140 l / min. Pump with integrated float switch. The case is made of plastic, the cost is 8 thousand rubles.

Belamos drainage pumps are manufactured in Russia and sold for 5.5 thousand rubles. Designed for pumping water with particles up to 16 mm. The device from a depth of 7 m creates a pressure of 7 m, has a capacity of 167 l / min. The pump with an internal float can take water from wells with a diameter of only 40 cm. The technical characteristics allow the equipment to be used for watering plots.

Drainage pump Karcher 12000 Level sensor for domestic use.

The perfect household model of the drainage pump Karcher 12000 Level sensor is made in Germany, sold for 10.8 thousand rubles. Pumps clean water with suspended particles with a diameter of not more than 5 mm. It plunges to 8 m, the pressure created is 7 m of water column. It pumps dry, the minimum distance to the surface is 1 mm. Quickly switches from pumping to floor drying. Electronic level sensor. The device self-adapts to changing working conditions.

Submersible pump VM-1500F is designed for sewer system. Pumps out water with the content of firm inclusions in the size of 10 mm. Their number can be up to 10% of the total. The design is designed to work in harsh conditions, does not require maintenance. The main components are made of cast iron and stainless steel. Immerse to the greatest depth of 5 m, it is possible to connect a hose with a cross section of 52 mm.