Why does this effect occur?

Where does it come from and who is to blame? Well, the most common cause is an error in the design of the chimney. Further, no less popular “culprits” are debris in the chimney, strong air currents in the pipe, and even a certain influence of atmospheric phenomena.

Reason #1 - Chimney Design

First of all, the design of the chimney itself matters - at too high a draft is always strong, and at a low one it is often insufficient. The optimal length is just over 5 meters, then problems with traction rarely occur and certainly not due to the height of the pipe.

Also, the cross-sectional area of the chimney must correspond to the furnace - with too small cross-sectional dimensions and at the same time with a powerful furnace, a large volume of combustion products simply cannot leave normally, sufficient traction is not created. As well as a disproportionately large chimney, it will lead to the fact that all the heat, as people like to say, "will fly out into the chimney." And in no case should pipes of different diameters be installed at the chimney in different areas - there will be soot and problems with traction.

The uneven surface of the pipe also serves as a serious obstacle to the movement of smoke - any deposits reduce the diameter of the pipe, and it is more and more difficult to melt the furnace every time. Tilt angles with turns of the chimney also create their own difficulties - if soot constantly accumulates in the corners, it will also interfere with normal draft. To prevent this from happening, when designing, adhere to standard norms - 45 ° bend, 90 ° turn.

The very shape of the smoke hole is also important: round is the most favorable for good traction, but with square and rectangular, problems often arise. So, in these corners, there is an additional twist at the corners, which slightly interferes with the overall flow and reduces thrust in total.

By the way, the most common problem of poor draft is in metal chimneys. Their trouble is that they quickly heat up, but also quickly cool down, and cold air always sinks down. Good old brick chimneys are more reliable in this regard.

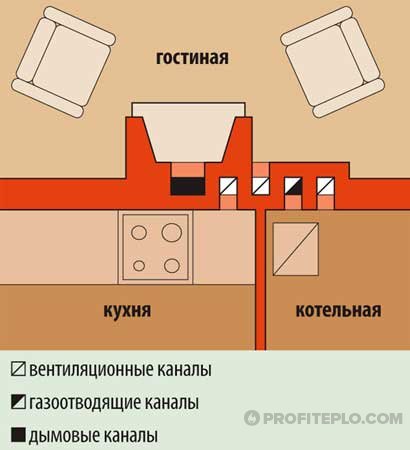

Reason # 2 - violation of ventilation

Also, the lack of ventilation in the room where the stove is heated can lead to such a misfortune. Check for drafts - are they too strong? Such whirlwinds right in the room can "confuse" the direction of the smoke, no matter how strange it may sound. By the way, intense air currents in the baths often arise because of the stairs to the second floor. Keep an eye on this, and never open the windows on the landing if it is much higher than the level of the firebox.

Also pay attention to ventilation if you have a geyser in the boiler room. It will still draw air from the combustion room, over time a serious lack of oxygen will form and a critical air rarefaction will occur.

From time to time, a stream of air will rush through the chimney, the column will go out, and the room will smoke. Do you have such a situation? Are there still deaf-tight plastic windows? Urgently deal with the issue of ventilation.

Eliminate causes of reverse thrust

Poor chimney draft requires immediate elimination of this problem, which is why many people often resort to using a special regulator. With it, it is easy to control the flow level, as well as create it if necessary. The automatic chimney draft regulator is produced in several variations. It can be a chimney stabilizer or a ventilation stabilizer.

Of course, the device for the chimney is aimed at regulating air flows. At the same time, it is characterized by increased economy, which cannot but rejoice.In addition, savings are also achieved by controlling fuel consumption. Such a device guarantees the accurate functioning of the chimney, and therefore the appearance of combustion products in the room will be impossible.

The ventilation stabilizer provides the room and the stove with the necessary air exchange. The stabilizer is produced in the form of an aerodynamic design, and it has two types of installation - at home or on the street as a stand-alone device. Thanks to the use of this device in the room, the appearance of any odors or unpleasant blowing will be excluded.

Also, this device helps to reduce the development of mold and other harmful fungi. It is extremely convenient to use in combination with a chimney stabilizer. In addition to these devices, checking the draft in the chimney will identify the reasons for its absence, after the elimination of which, the pipe's performance will again be at its best.

How to increase traction in an already mounted channel

The above calculations make it possible to build a chimney with optimal parameters to obtain a normal level of natural draft. But what if there is a reverse thrust? Is it possible to increase the indicator and how to increase traction on your own? There are several ways:

- cleaning the chimney. When soot and other types of deposits settle, the working diameter of the pipe is significantly reduced, which leads to a decrease in traction. You can clean up:

Using a chimney brush

special means such as log "Chimney sweep";

Special soot cleaner

When using special products, it is necessary to strictly follow the instructions provided on the product packaging or a special insert.

folk remedies. For example, peel from raw potatoes, aspen firewood, and so on;

- elimination of design flaws made during the construction of the pipe (elimination of cracks, lengthening or shortening, elimination of excessive bends, insulation, and so on);

- installation of additional equipment.

As additional equipment to enhance traction, you can use:

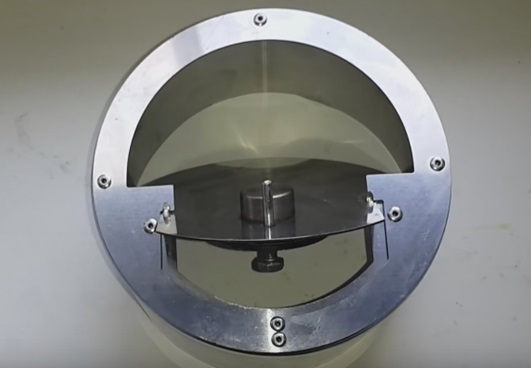

regulator. The device is installed on the pipe and by opening / closing the damper allows you to adjust the traction force in the heating system;

Traction control device

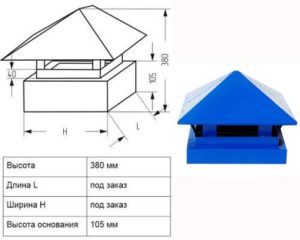

deflector-amplifier. The increase in thrust occurs due to the redirection of air flows formed due to an increase in the diameter of the device;

Device for redirecting air flows

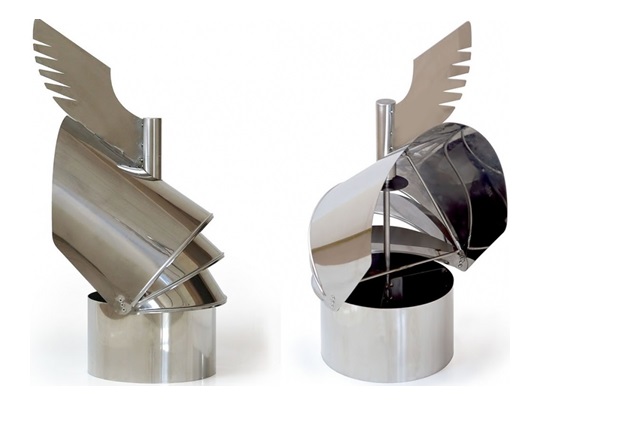

vane. The draft stabilizer, as well as the deflector, is installed at the end of the chimney and serves to enhance draft due to the streamlining of air flows. In addition, the weather vane helps to stabilize the level of traction during strong gusts of wind;

Traction stabilizer

rotary turbine. When exposed to wind, the device begins to rotate, creating a low pressure area around itself, contributing to an increase in thrust.

wind traction booster

Unlike other devices, a rotary turbine performs its functions only in the presence of wind. In addition, the device does not protect the chimney from clogging with leaves, small birds and other pollutants.

All additional devices require periodic maintenance: cleaning in the warm season and cleaning from ice in winter. If you do not clean it in a timely manner, then the performance of the device will be minimized and the desired effect will not be achieved.

Useful information about chimney draft

All residents of country or private city houses are familiar with the concept of chimney draft. Do they know the meaning of this term?

If we move a little away from dry scientific terminology, then draft can be defined as a natural phenomenon in which air moves from one area to another, namely, from an air zone with high pressure to a zone with low pressure.All this happens with the help of a ventilation device - a special channel in the chimney.

Using this process of aerodynamics, mankind began to use fireplaces, stoves, boilers, heating their homes with the help of various types of fuel - coal, firewood, peat, etc.

Furanflex produces material for the restoration of chimneys of stoves and fireplaces. The material can be used to repair chimneys of any type and complexity of execution. Fast installation and quality installation. Warranty from 10 to 30 years.

With good draft, the stove quickly flares up and the room is filled with pleasant warmth.

From a properly designed and built chimney and, accordingly, from good draft depends:

- the quality of space heating;

- reduction of fuel costs;

- safety of being in buildings with their own heating.

House moments

A number of factors indoors can significantly affect the presence / absence of traction and its strength:

- The material from which the building is built.

- Average room temperature.

- The maximum amount of air space in the dwelling.

- The number of people permanently inside the dwelling.

- The presence of internal sources that additionally consume oxygen (heaters, heaters, stoves, etc.).

- The regularity of fresh air intake (ventilation, ventilation).

External factors

There are other factors that determine the draft of the chimney, and they are located outside the heated room. We are talking about the temperature of the external environment, atmospheric pressure, humidity, wind direction. Such a phenomenon as temperature changes during the day can also affect traction - due to the movement of cold and warm layers of air.

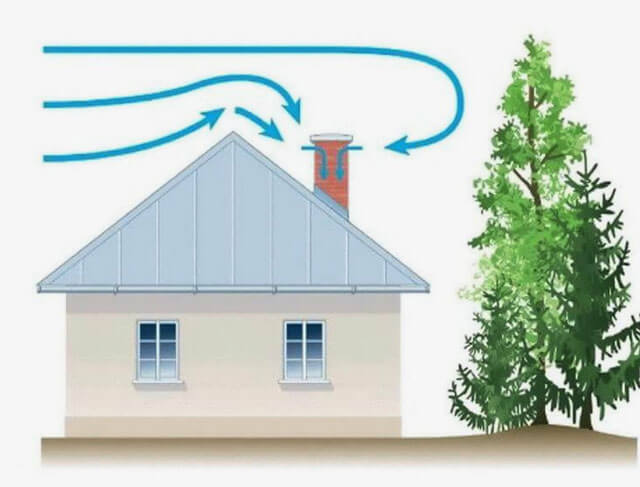

Difficulties with traction appear for various reasons, some can simply be overlooked. For example, problems with air escaping through a chimney can occur if the chimney is located well below the ridge of a building or tall nearby trees.

Features of the design of the chimney

The draft may be different depending on the design characteristics of the chimney:

- height;

- the presence of insulation;

- tightness;

- location (internal/external);

- length;

- presence / absence of irregularities or roughness, etc.

It is necessary and possible to control the traction in the room using the "levers" of the first and third factors (intra-house and design). Natural changes, of course, do not depend on man.

Keeping the draft in the chimney under control is a prerequisite for safe and comfortable living in your own premises. If the draft is very weak, then it is almost impossible to light the stove and heat the home.

With reverse thrust, the gases resulting from combustion are “thrown” into the living space, and not into the air through the pipe. This is very dangerous for human health and life!

It is impossible not to notice such atypical smoke behavior

With a very strong draft, all the heat is rapidly drawn out through the chimney channels without having time to warm the heated room to the desired temperature.

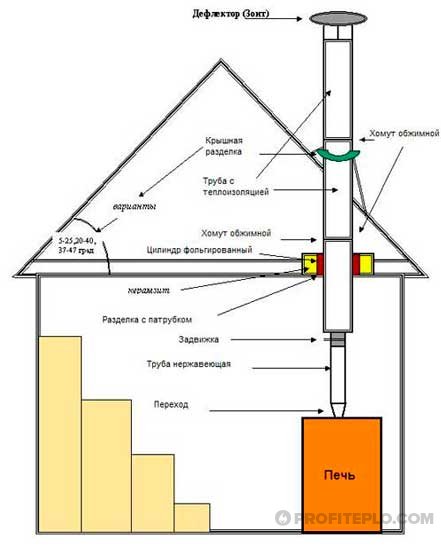

Chimney design

When using various heating devices - a geyser, water heaters or fireplaces - chimney systems are installed. The heater and the chimney are a single structure, during installation of which special rules and regulations are observed to ensure uninterrupted and safe operation of the system; it must meet the following requirements:

- withstand exposure to high temperatures;

- be resistant to moisture arising from the condensation process;

- do not collapse under the influence of aggressive chemicals;

- have the necessary traction for safe operation.

The cross section of the pipe, the height of the structure, the material of manufacture depend on the type of heater. In addition to the main parts of the structure, special devices are installed to enhance the draft in the duct: dampers, deflectors, stabilizers, etc.

Why does backlash occur?

Weak thrust can become the basis for the formation of reverse thrust. How can you recognize that traction is not all right?

This is “said” by moments that can be ascertained with the naked eye: a lot of smoke in the stove, soot on the door, incoming movement of smoke inside the house. In other words, smoke, cinder from combustible fuel does not go into the chimney through the chimney, but tends to get into the living room with the door open and through the cracks.

Causes of reverse thrust:

- Design flaws in the chimney. Low pipe - increased risk of reverse thrust. The higher the pipe, the better the process of extracting exhaust gases and smoke. The optimum height of the pipe is about five meters.

- Correspondence of the pipe diameter with the parameters of the furnace device. For a powerful furnace, a chimney with a pipe of a rather large cross section is required. But the measure is very important here, because using a pipe that is too wide will make the combustion process unprofitable (all the warm air will literally fly into the pipe). It is unacceptable to use several pipes with different sections in the chimney!

- Use of non-smooth pipes. Irregularities, chips, roughness, etc. - an obstacle to good traction. Over time, the chimney opening may narrow due to soot deposits and other combustion elements and impede the process of kindling the stove, its normal functioning.

- Violation / lack of ventilation. Drafts, open windows in rooms above the firebox do not help the process of fuel combustion, but distort it, making it useless and unsafe.

Chimney channels made of metal are in many ways inferior to brick pipes. Rapid heating and the same rapid cooling do not benefit the heating system in general and the chimney in particular.

Brick pipes are much more efficient in terms of smoke extraction.

Reverse thrust can also appear for objective reasons that do not depend on a person. Strong gusts of wind, rainy, overcast weather with high humidity are unfavorable moments in terms of traction problems.

There is such a term as temporary reverse thrust. What's this? In this case, it is worth talking about violations of traction temporary, for several days. After a certain period, traction returns to normal.

Temporary back draft can occur due to a cold room that has not been heated for a long time. Very cold air accumulated in the chimney pipe prevents the fuel from burning quickly. Therefore, smoke can be “pushed out” from the chimney into a dwelling, bathhouse or other room with a stove or fireplace.

It is very easy to eliminate cold air in the chimney - heat the pipes by burning ordinary newspapers, wallpaper, paper in the oven. The main thing is that these materials are well dried.

If problems with traction can be fixed constantly or with a certain frequency, then measures must be taken to eliminate bad traction.

Thrust calculation

So, the draft calculation is the calculation of the section of the chimney for a gas boiler, fireplace, stove or other heating equipment. How to calculate the cross section? To do this, you need to define:

- the volume of gas that will pass through the chimney in 1 hour;

- cross-sectional area of the chimney;

- section diameter.

Gas Volume Calculation

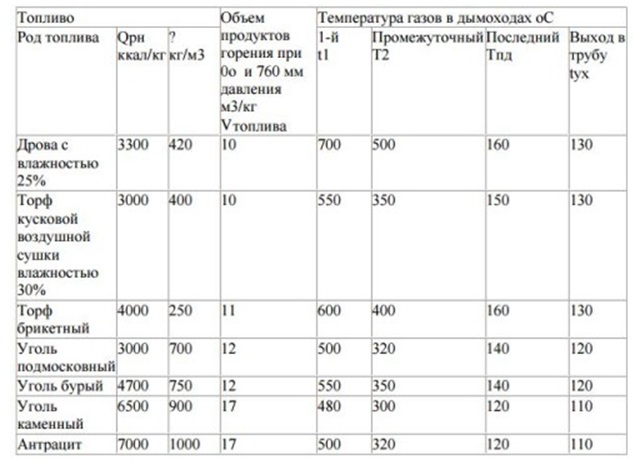

To calculate the volume of gas passing through the flue channel, the following formula is used:

V = B x V1 x (1 + T/273) /3600 where

B is the mass of fuel burned in 1 hour of heating equipment operation;

V1 - correction factor, which depends on the type of fuel used for heating;

T is the gas temperature determined at the outlet of the chimney.

Indicators V1 and T can be obtained from the table available in GOST 2127 - 47.

Table from GOST to determine the calculation parameters

Section area calculation

After determining the volume of gases passing through the flue channel, you can calculate the size of the pipe section:

S = V/W, where

V is the volume calculated earlier;

W is the speed of gases passing through the smoke channel (this value is constant and equal to 2 m/s).

Diameter determination

The next step is to directly determine the diameter of the chimney. For this, the following formula is used:

D = √4 * S/ π, where

S is the cross-sectional area of the smoke channel;

π is a constant equal to 3.14.

Example

For example, we will calculate according to the indicated formulas with the following parameters:

- in the stove installed in the bath, 10 kg of firewood is burned every hour;

- the temperature of the gases at the outlet of the pipe is 130ºС.

Calculate the volume of gases:

V \u003d 10x10x (1 + 130/273) / 3600 \u003d 0.041 (m³ / h)

Determine the cross section of the chimney pipe:

S = 0.041/02 = 0.0205 (m²)

We find the most suitable pipe diameter for the given parameters:

D \u003d √ 4 * 0.0205 / 3.14 \u003d 0.162 (m)

This means that for the stove used in the example, it is enough to install a chimney with a diameter of 165 - 170 mm.

How to make calculations and install a chimney on your own, look at the video.

Strength test

Before you throw your energy into fighting bad traction, make sure that the traction really leaves much to be desired.

You can check the traction with the help of special devices or on your own. Simple ways to fix traction:

- Light a paper sheet, let it burn a little. Bringing it to the stove or fireplace, extinguish the paper and observe the direction of the smoke. If it goes to the pipe - good traction, deviates in the opposite direction - reverse thrust, if it maintains "straightness" - there is no thrust. Similar manipulations can be done with thin cigarette or toilet paper without setting fire to it.

- If there are smokers in the house, then follow the direction from the smoke of cigarettes or from the flame of a match, lighter near a fireplace or stove. Draw conclusions in the same way as the first paragraph.

- The flame of an ordinary candle can also help in determining the draft in a home.

- A pocket mirror brought to the firebox and covered with condensate may indicate problems with removing smoke from the stove.

- The presence of too much draft, which takes away useful heat from the room, is indicated by an audible hum in the furnace - a loud hum.

- The color of the fire in the furnace can be an indicator of different traction. Golden hue - good traction, white flames - excessive traction, red color and black smoke - poor traction, high probability of reverse thrust.

A regular lighter can help check the draft.

Anemometer is a device familiar to many people of the Soviet period. With this device, it was possible to measure the draft of the chimney. Readings within 10–20 Pa were considered normal. The disadvantages of the device are its low accuracy when the wind strength is less than one meter per second.

Such a simple device will help secure your life in a house with stove heating.

Modern industry offers a sufficient number of devices for measuring draft, there are devices that fix draft at the inlet and outlet of the chimney.

Causes of poor traction

First you need to figure out why there is poor draft in the furnace. Problems can arise both from the very beginning and during operation. Below are the most common causes:

- Clogging of the channel (soot on the walls or all sorts of debris that has fallen from the street).

- Errors at the construction stage (a large number of bends and horizontal sections entail an increase in pressure losses along the length of the channel; in addition, the pipe must be of the same diameter along the entire length for uniform speed, which determines the formation of soot stagnation).

- Leakage of pipeline joints (it can occur both at the construction stage and over time, so it is necessary to periodically check the quality of the channel).

- Wind support (it is often because of the wind that a temporary overturning of the draft occurs, so it is advisable to carefully choose the installation location of the chimney pipe).

- Incorrectly selected channel diameter relative to the power of the stove.

- Lack of supply air.

To control the cleanliness of the smoke channel, on the vertical part of the pipe from below, you can mount a piece of pipe with a plug, removing which periodically, you can get rid of most of the accumulated debris.

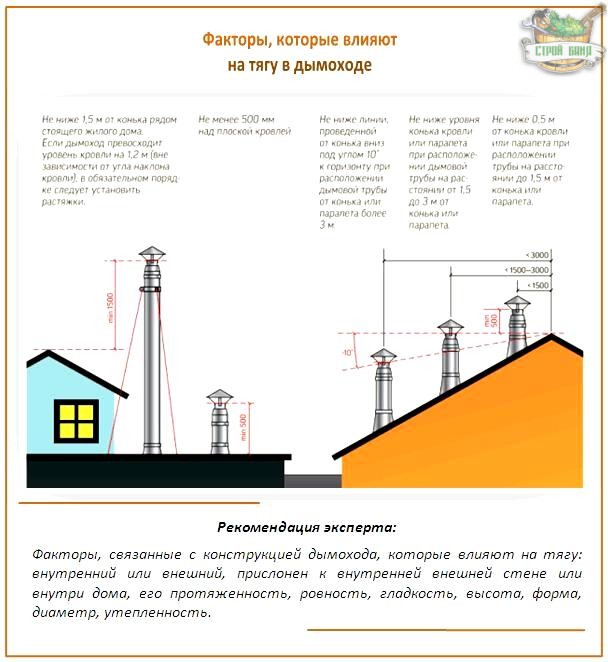

Chimney design

The location of the chimney on the roof of the building is very important for the correct operation of the furnace. Earlier in the article it was already mentioned that the height of the chimney should be at least 500 mm

But these are only general indications regarding a flat roof, in fact, the height of the chimney depends on the distance to the ridge and tall nearby buildings. Below are a few general rules for chimney height:

- If the distance to the ridge of the building is less than 1.5 meters, the height of the chimney must also be at least 0.5 meters.

- If the chimney is located at a distance of 1.5 to 3 meters from the ridge, it is made no lower than the ridge, regardless of height.

- If the chimney is located more than three meters from the ridge, then it should not be lower than the line drawn from the ridge at an angle of 10 degrees to the horizon.

- If higher buildings are attached, the pipe must be taken out above them.

- If exhaust ducts are located near the chimneys, the height of the hood should be taken at least as high as these pipes.

Violation of ventilation

On ventilation it is worth dwelling in more detail. If most people know or guess about other problems, then ventilation is usually forgotten. Often problems arise due to the second floor in the bath, for example, when the emission of combustion products is located too close to the windows of the second floor. Encountered air flows create excess pressure, which interferes with normal traction.

Often forget about ventilation in the boiler room itself. Now everywhere there are plastic windows, which are very tight and do not let in outside air at all. If they are closed and there are no supply openings, then when the stove burns, after a certain period of time, a critical vacuum will occur in the room, and small air flows will periodically burst through the pipe. This phenomenon is extremely unpleasant and you should take care of sufficient ventilation in advance. In some cases, natural ventilation is not enough and it is required to install a fan, because with a mechanical impulse, air exchange is more active and there will be no lack of oxygen.

External factors

If you do not use the stove for a long time (for example, in summer), birds can build nests in the pipe or build a hornet hive

This phenomenon is very common, so it is important to check the chimney every time before the start of the heating season. When visually inspecting the inside of the chimney, one can also detect a large amount of adhering soot, which creates additional resistance.

Unfortunately, chimney channels are not eternal, and over time they can collapse, which also needs to be monitored periodically.

Often the reason for the deterioration of traction is changing weather conditions, such as fog, rain or sudden gusts of wind. The swirl of air currents near the outlet of the chimney creates additional resistance. Such phenomena not only worsen traction, but can also cause it to tip over.

External factors

Why is there bad draft in the stove, if it is arranged correctly, and the chimneys have been recently cleaned? In addition to these reasons, stove draft depends on external environmental factors and weather.

The most common of them:

- improperly arranged ventilation in the house,

- fluctuations in temperature and humidity outside,

- wind and other climatic factors.

Let's take a closer look at what we have to do in these cases.

Violation of ventilation

The influx of fresh air helps to establish the desired pressure drop in the furnace and chimney. If the house is cold and the stove has not been heated for a long time, this difference is minimal.And the lack of air in the combustion room can create a temporary vacuum in the room and provoke back draft. On the other hand, excessive drafts are also unfavorable, since vortex air flows can disrupt the air flow into the furnace, knocking down the correct draft.

This is often observed in the summer, and also if the windows are above the level of the firebox, in this case it will be easier for hot air to change direction towards the hood through the window. You need to be especially careful with gas stoves, there is a danger not only of changing the direction of the draft, but also of extinguishing the burner and filling the room with gas.

Before the first attempts to kindle the stove, it is necessary to check not only the draft in the furnace, but also the air movement in the room, and when using the stove, constantly monitor ventilation. This is also necessary to prevent carbon monoxide poisoning.

Strong wind

Strong wind gusts can temporarily obstruct the exit of smoke from the chimney. With such a churning of the hot gas flow, the thrust can work in the opposite direction. This happens more often with chimneys connected directly to the firebox without passing heating wells.

The situation with wind worsens the horizontal location of the pipe outlet, which is often used in the utility rooms of the lower floors of the house (exit through the wall).

Protection from the winds prevailing in the area is arranged with the help of pipe caps, "chimneys" or "flue vanes". They also prevent getting wet in rain and snow. The humidity of the outside air is another obstacle to good traction.

Installing a chimney will solve the problem

High humidity

This factor is indirect, but no less unpleasant. High humidity of the external air can be formed due to low atmospheric pressure, which already reduces traction. The increased density of the humid surrounding atmosphere reduces the rarefaction and impairs smoke movement.

It is easy to see that in the rain and snow, the smoke reluctantly leaves the chimney, spreads along the roof, and with every gust of wind escapes through the stove door into the room. And vice versa, in clear dry weather, the draft is excellent and the smoke is worth pillars in the sky. Finally, at high humidity in winter, a dense coating of frost forms in the pipe, which sharply reduces the cross section and prevents the normal release of gases.

In this situation, you will often have to clean the chimney.

Solving the problem with reverse thrust

Now you need to check the traction. You can use a special device that measures the speed of air flow - an anemometer. Often there is no such device, then you can use folk methods, for example, bring a burning match or a sheet of paper and see the direction of air movement. Moreover, draft quality can be determined by the color of the flame in the furnace:

- white or very light color - a sign of insufficient traction;

- if the flame is of an even golden color, the draft is normal;

- dark shades of orange color - insufficient.

If the stove is inside the house, the draft will be better than if it is located at the outer wall.

Basic ways to solve problems with traction:

-

Improving the quality of the chimney.

First of all, to improve the draft of the chimney. To do this, it is necessary to check the entire channel for soot sticking and leaks in the joints. Everything needs to be cleaned and fixed. If this does not help, move on to the next method.

-

Installing a deflector at the end of the pipe.

The method is good when the air currents around the pipe are constant and strong. The deflector perfectly increases traction, however, without wind, the deflector is useless. In some cases, it can even reduce thrust due to the creation of additional resistance to the movement of air from the channel.

-

Chimney extension.

Simple and fast solution.The main thing is the correct calculation of the location of the channel relative to the ridge of the building, as well as an analysis of the likelihood of air flows at the installation site. After all, even a chimney 10 meters long, installed in the wrong place, will not solve the problem.

-

Installing the draft regulator.

The device compensates for the lack or excess of internal pressure in the channel relative to the external one. The regulator allows you to maintain the optimum temperature in the furnace by controlling the air supply to the furnace. With it, the air flow rate is constant, which means that the thrust is stable and does not depend on external factors (wind, pressure changes, etc.).

Another important concept is reciprocity. It occurs when the resistance in the chimneys is too high (due to the proximity of the ridge of the building, standing next to tall buildings, etc.)

In this case, the air from the fire goes along the path of least resistance, that is, into the room, that is, the thrust we need disappears altogether. There is also the term “thrust overturning” - moving air changes its direction only for a certain time. The first signs of a possibly imminent draft tipping are the formation of a large amount of smoke during combustion, which, when the stove is opened, bursts into the room. This means that the thrust has worsened, which means that it can completely become reversed.

The methods for eliminating reverse thrust are the same as for improving thrust. In fact, reverse draft is the extreme and most unpleasant degree of poor draft, the smoke in the room is unpleasant and even dangerous. Therefore, in a critical case, it makes sense to turn to specialists. They will quickly analyze all the factors and fix the problem.

The safety and efficiency of stove heating depends on sufficient draft in the chimney. When the first even minor problems are detected, it is necessary to conduct a full check of the system to identify the causes of problems and find ways to increase traction. Most of the repair and restoration work can be done with your own hands, but if there is no self-confidence, you need to invite a specialist.

Related video:

How to check

The presence of a problem with a chimney requires a solution at the first sign. For those who do not know how to check the draft in the chimney, you can offer several ways:

- Take a sheet of thin paper, which easily reacts to the movement of air, and light it by bringing it to the heater. If paper, flames or smoke oscillate in the direction of the room, then this is a sign of a problem with the chimney.

- The smoke from a cigarette is a particularly sensitive way to determine the direction of air movement, even with a weak reverse draft.

- You need to watch the fire in the furnace. If the flame has a white tint and a rumble is heard in the chimney, then the draft is excessive, and when the fire has a golden hue, then the combustion conditions of the fuel are normal.

There are modern electronic devices for measuring chimney parameters, which are called anemometers and are available to any user.

Return draft in the chimney

Watch this video on YouTube

The reason for the extinction of the boiler in windy weather

In city apartments, boilers equipped with a coaxial duct are installed. Thanks to this, even a strong wind does not get inside and does not cause the burner to blow out. However, in a private house, a situation often arises when a gas boiler blows out with a strong gust of wind. Why does a gas boiler blow out in the wind? This is due to an incorrect ventilation device and a mismatch in the technological parameters of the chimney. Such malfunctions should only be repaired by heating specialists.

In addition, the extinction of the burner flame occurs due to the design features of the entire heating system or as a result of external factors.

In most cases, the cause of the flame extinction of the burner is the following: the air mass entering from the outside exerts excessive pressure, as a result of which the check valve operates and becomes in the closed position. The automatic system of the boiler reacts to this position of the valve and the gas supply to the furnace is stopped. The frequent repetition of such a situation is the result of an incorrect design of the chimney. So what to do if the boiler blows through the chimney.

Particular attention should be paid to the height of this element: the normal functioning of ventilation is ensured if the upper part of the chimney is located half a meter above the extreme point of the roof of the house. To determine the diameter of the duct, special calculations should be applied, taking into account the parameters of the boiler equipment.

Choice of devices for regulation

Consider some of the characteristic features and methods of using devices for controlling and adjusting thrust.

Deflectors

Such structures are installed on the chimney (in its very upper part) to create obstacles to air flows. The intensity of the wind force drops noticeably when it encounters such devices placed on a pipe. The smoke comes out through the channel "to the will" due to the ingress of weak air currents into the pipe. These flows "hook" the exhaust gases and "push" them out.

Deflectors eliminate the possibility of clogging the pipe, and also tastefully made, significantly improve the appearance of the entire building.

There are several types of deflectors:

- TsAGI;

- round Volpert;

- Grigorovich;

- in the form of a plate;

- in the form of the letter H;

- rotating;

- vane.

Almost all of these devices are made of stainless steel, in rare situations - of copper. Using brackets, clamps, bolts, sealing tape, the deflector is attached to the chimney pipe. Some devices are also equipped with additional functions: to extinguish sparks (to eliminate a possible roof fire), to control the temperature of the outgoing air (in this case, the sensor is triggered if hot air does not come out and there is a possibility of reverse draft).

The disadvantages of using deflectors are their minimal efficiency in calm weather.

Photo gallery: types of deflectors

The most common device for improving traction

Such a device can be purchased in specialized stores.

The choice of device depends on the design features of the pipes and your preferences.

Rotary devices

Turbines installed at the top of the chimney use the energy potential of the wind. Air currents set in motion a rotary nozzle (it always moves in the same direction), and thus the air is rarefied near the chimney. The ingress of any foreign objects and precipitation into the chimney with a rotary pipe is completely excluded.

Rotary pipes have a big disadvantage, similar to the operation of the deflector. Their use on a calm day is ineffective.

If you do not have great abilities, buying such devices is not a problem.

Draft regulators

Such devices are a real find for residents of country houses, lovers of baths and fireplace gatherings. These devices are attached to the chimney of the boiler. They are equipped with a metal plate with a load that balances it on one side. When the draft is good, the metal plate does not prevent the free access of air to the chimney. With weak or reverse thrust, the metal plate serves as a kind of stupor.

The range limits for thrust are set by the consumer himself, the usual parameters are 10–35 Pa.

The device works completely autonomously, it does not require the supply of electric current.