How to bring a pipe through the roof

To organize a hermetic junction of the roof to the chimney, an internal apron is created at this point. To create it, use the lower junction bars. The strips are applied to the walls of the chimney, where its upper part is marked. On this line, a grinder makes a strobe. Then dust is carefully removed from the formed border. This is done so that small particles of sand and cement do not get on the surface of the waterproofing or roofing. In some cases, fine grains of sand will turn into an abrasive over time, which can seriously damage the roofing material.

The lower apron begins to be installed from the bottom wall, while only one part of the apron is inserted into the strobe. Similarly, this element is attached around the entire perimeter of the chimney. Separate elements must be overlapped with an overlap of 15 cm. The joints are sealed.

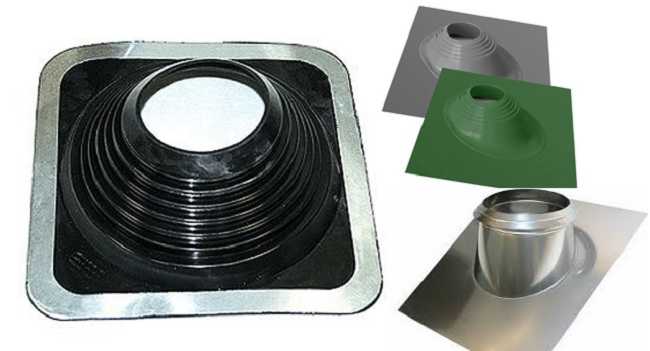

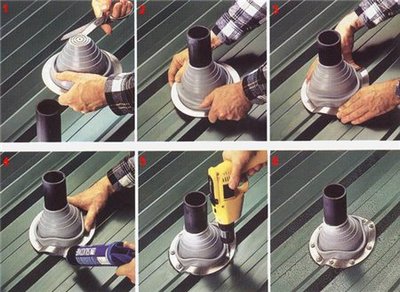

For chimneys with a circular cross section, you can purchase special passage elements in hardware stores, consisting of a steel sheet and an apron cap. Their use allows you to significantly speed up the work on the equipment for the passage of the chimney pipe through the roof. A purchased or manufactured apron should be securely fixed to the roof. At the same time, it is not rigidly fixed with the chimney, since the expansion of the material or the shrinkage of the truss system can cause damage to the chimney with an apron (be sure to read: “ Roof penetration - device“).

The passage of the chimney pipe through the roof, detailed video instruction:

At the junction of the pipe and the apron, a skirt is installed - a steel clamp, which is fixed using a heat-resistant gasket. This approach allows you to significantly improve the waterproofing of the roof in this place. Upon completion of the installation of the apron, it is necessary to apply sealant to all junctions of the element and the chimney. This contributes to obtaining a reliable connection that does not leak.

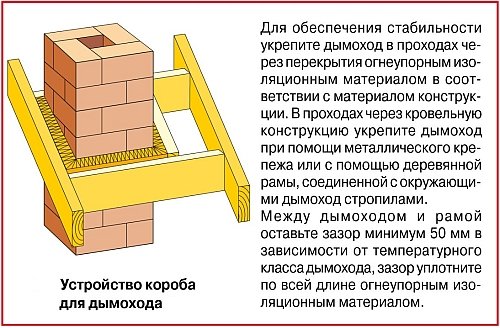

Chimney box

To properly bring the chimney through the roofing pie, you should equip your own truss system around the pipe. It must be separated from the chimney at a distance specified in SNiP. The design consists of lateral rafter legs and horizontal transverse beams from below and above, which are made of a bar of the same section as the rafters.

To insulate the structure, it is necessary to use non-combustible heat-insulating materials, such as glass wool or stone wool - it is stuffed between the pipe and the wooden structural elements.

When passing the chimney through the roofing pie of the operated roof, the vapor and waterproofing is cut crosswise, like an envelope, the edges should be tucked up and attached with nails or brackets to the rafter system.

Waterproofing the chimney on the roof requires special attention. When installing a duct for a pitched roof chimney, the vapor barrier and waterproofing membrane are fastened as follows: the edges of the films are folded over and tightly fixed with staples to the duct, in addition, the attachment points should be additionally sealed with a sealing tape or some other adhesive material. From the outside, protective elements are mounted on top of the roofing that do not allow moisture to pass into the joints of the box with the roofing pie.

It is important to consider that the installation of the box can adversely affect the air exchange in the under-roof space. To avoid deterioration of moisture removal, you can install additional ventilation systems, for example, ventilation tiles, roof aeration grilles, etc.

Razuklonka is a small private roof that drains water and snow from the pipe. Its installation is quite complicated, since all layers of insulation are part of the ramp, in addition, it should be qualitatively combined with the main roof using curly elements. To avoid mounting a slope, it is worth making a smaller pipe.

Using ready-made kits

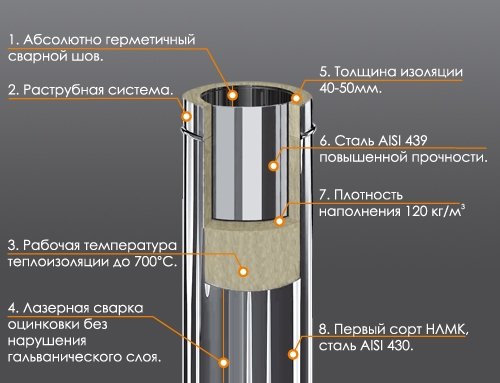

Standard modular chimneys ("sandwich") can greatly simplify the process of passing the pipe through the roof. A wide range of materials are used for the manufacture of structures, including :

The choice of a modular chimney depends on the fuel used, as they differ significantly in their technical characteristics. The advantage of such systems is the ability to install the pipe at a non-right angle. This is especially true when installing a chimney in an existing building and allows you to choose almost any place for installing a fireplace, stove or automatic boiler.

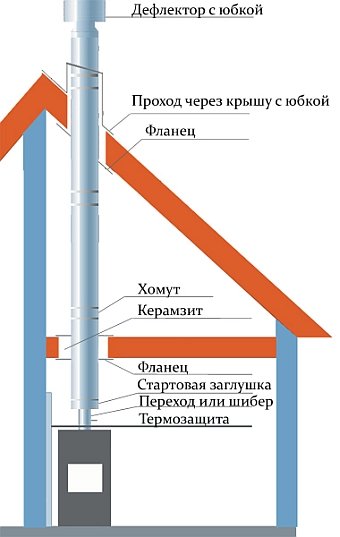

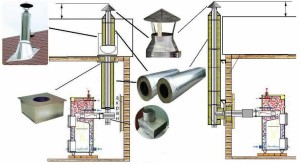

A modular chimney passes directly through the roof, consisting of such parts as :

- deflector (a device that enhances draft in the chimney by using a stream of hot air);

- clamp for stretch marks (allows you to additionally fix a high pipe on the roof);

- skirt (an element that protects the exit point of the pipe through the roof);

- roof passage (element with a fixed apron, which is directly mounted in the roofing pie).

Modular chimneys have an attractive appearance.

Steel chimneys can be installed if the temperature of the exhaust gases is not more than 500 °C. Prohibited for installation on coal-fired stoves. For asbestos-cement pipes, this parameter is 300 degrees; for coal-fired ovens, such chimneys are also unsuitable.

If the chimney is made of concrete or brick, or a prefabricated passage is installed, the structure should not be rigidly attached to the roof system. Under the influence of external factors, the roof may be deformed, and these forces will be transferred to the chimney, which may lead to its destruction. When is the exit chimney through the roof, all connections of the chimney to the roof are made using flexible elements.

Passage through the roof of a round pipe

The node of the passage through the roof of round pipes can be either metal or soft - made of rubber or silicone. Metal penetrations of the roof are made of galvanized iron, sometimes a protective coating is applied to them, similar in color and composition to the metal tile coating.

Often, metal tile manufacturers offer special penetrations: this is the same sheet of roofing material to which an elastic rubber cap is attached, which serves as an excellent insulator.

For other roofing materials, flexible penetrations can be used as a roof penetration. There are many of them on the market today. Different colors, compositions, at different angles of the roof, straight penetrations, with different types of fastening (for self-tapping screws, with adhesive, etc.).

Of all flexible penetrations Master Flash (Master Flash) has the best recommendations. It is quite easy to distinguish it: in addition to the applied company name, there are additional corrugated grooves on the back of the roof penetration, which increase the degree of adhesion to any roofing material. From the outside, the base along the edge has a metallized coating, with which it is easy to achieve any desired relief.

Roof penetrations for round pipes

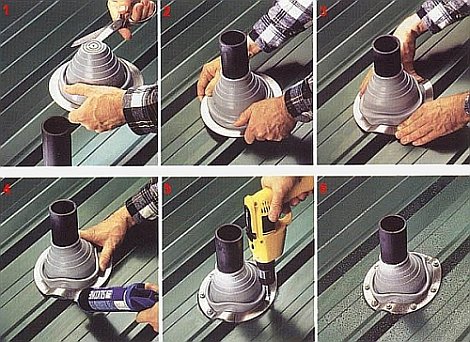

To install a flexible penetration, cut off part of the outer cap - the diameter of the resulting hole must be less than the diameter of the pipe. The penetration is pulled onto the pipe with force. To reduce the resistance, you can smear the surface of the pipe with soapy water. After the penetration is tensioned, the lower flange is given the desired configuration.On the back side, it is smeared with sealant, then pressed against the roof and fixed with self-tapping screws. This method of sealing a round pipe is not very laborious, but reliable enough.

Silicone and rubber penetrations are used at pipe temperatures up to 100 ° C. If the temperature of the chimney is higher, you will either have to make an additional layer of insulation between the penetration and the pipe, or, more likely, use a metal skirt and a glass. How they look and how to fix them is shown in the following video. Everything is done there not quite correctly, then the principle of installation is clear.

What tasks does roofing solve?

To determine the purpose of such additions to the roofing cake, it is worth referring to the function of the roof itself. It should protect the house from precipitation and other external influences, while maintaining optimal performance of heat, noise and waterproofing. The presence of holes and slots in the roof is not allowed, therefore, communications passing through the roof must be carefully sealed at the points of contact with the finishing material and the load-bearing structure. In turn, roofing penetration initially creates a minimum of free space that is not used for engineering purposes. At the same time, it contributes to the effective removal of smoke and air, protecting the roof materials from thermal effects. Ventilation systems, by the way, often lead to the formation of condensate in places where air flows are removed. Special nodes for such channels prevent the processes of drip formation, removing moisture to the outside.

Composition of roof penetrations

Roof penetration consists of two parts. They, in turn, consist of an inner and outer contour. Each of them has a special layer of insulation from the inside, the material for which is a basalt sheet. It has high resistance to temperature changes and ignition.

The material for the nodes of the passage through the roof is most often black steel with a thickness of 1 to 3 mm. It is covered on top with black heat-resistant enamel, which makes it possible for penetration to be resistant to temperatures up to 600 degrees.

Certain operating conditions, technical capabilities and wishes of the developer or architect may affect the fact that penetrations will be made of stainless steel, with a metal thickness of 1 to 2 mm.

Features of the installation of the chimney passage assembly

Distinctive design features of the chimney passage assembly are determined by fire safety rules. Since a sufficiently high temperature of the formed furnace gases is transferred during operation to the elements of the chimney, the possibility of a roof fire is not ruled out.

This applies to a greater extent to roofs with a supporting structure made of wood. Therefore, the following requirements are imposed on the installation of the pass-through node in this case:

- the presence of a gap regulated by building rules between the chimney pipe and flammable roof elements;

- in this area, the chimney should be treated with some material that reduces the fire hazard, for example, asbestos;

- at the place of passage through the roofing pie, the assembly should be mounted using a box made of galvanized metal, in which the free space (between the walls of the box and the chimney pipe) is filled with glass wool or other fire-resistant materials.

The chimney passage assembly through the roof can be installed on the roof slope or on the ridge. When mounting it on a ridge, it may be necessary to change the truss system, and when installing a passage on a slope, an unnecessary pocket for snow may form. To avoid possible leaks, an additional element is inserted under the ridge bar.

In addition to various modifications of roof penetrations, on sale today you can find similar products of a new generation - a universal sealant for roof penetrations. This element differs in that it can be used on communications of any diameter. With the help of modern models, it is possible to seal the outlets within the range of 3 - 600 mm. They are suitable for both network and television cables, as well as for air ducts and chimneys of a sufficiently large diameter. In addition, due to the conical design of these products with an angle of inclination of 20 degrees, they can be installed on pitched roofs with any slope.

A significant advantage of universal penetrations is the ability to use on various roofings: they work equally effectively on a metal profile and on slate. The elasticity of penetration makes it possible to repeat the shape of any wave. High-quality silicone, from which universal seals are made, is able to operate in the temperature range from minus 74 to plus 260 degrees. In addition, silicone retains its properties even under very aggressive conditions. Compared to conventional rubber materials, silicone products last much longer.

Installation of universal penetration is carried out in the following order:

- in order for the connection to be tight, the diameter of the ring of the selected seal must be 20% less than the diameter of the pipe. The excess part is cut off;

- so that the seal is easily mounted, the pipe must be treated with a solution, for example, laundry soap;

- the usual compression of the flange will ensure a good fit to the roof along the entire profile. For a better fit of the flange, you can use special tools;

- after sealing the joint with a special compound, the penetration is fastened to the roof surface using self-tapping screws (installation step - no more than 35 mm).

The universal roof penetration seal is in high demand due to its ease of installation, wide range of applications and high sealing performance.

Proper selection and installation of roof penetrations will ensure the tightness of the roofing pie, and this, as you know, is one of the main conditions for the strength and reliability of the roof, its long-term operation. Perhaps the information presented above will help someone independently carry out a chimney or ventilation pipe on the roof. But only professionals who have been doing roofing work for many years know all the intricacies of installing penetrations (and there are not so few of them), so it is better to entrust them with this work.

Roof penetration

As already mentioned, the roofing must be airtight over the entire surface of the roof. If this condition is not met, the temperature difference that occurs during the day contributes to the formation of condensate, some of which will be brought out, and some will settle on the waterproofing layer. In cold weather, the moisture remaining inside forms frost, which has a devastating effect on the roofing.

Ventilation will help to avoid this, creating additional air circulation in the under-roof space. All existing outlets of pipes, chimneys, antennas, ventilation are carefully sealed, using a sealant for roof passages of various configurations. Its design completely eliminates the penetration of moisture into the under-roof space.

So, roof penetration is a special passage unit, which is used for the installation of pipes for various purposes, antennas, ventilation shafts in places of passage through the roof. The modern market offers a variety of variations of such nodes, which allows you to make tight connections on roofs of any type, with different coatings.

Their design looks, in general terms, like a hole in the ceiling, into which a metal pipe is inserted and installed on reinforced concrete cups or directly on the roof. The thickness of the metal from which the penetration is made must be at least 1 mm. On roofs with a metal frame, standard roof penetrations are mounted using a metal cup. When installing a penetration on a reinforced concrete floor, it would be nice to use slabs with ready-made openings for it. That is why it is advisable to determine the location of penetrations even when designing a building.

Roof penetrations are of several types, depending on what is displayed on the roof:

- Pipes, antennas, flagpoles.

- Sewer ventilation, which is installed to prevent the appearance of unpleasant odors in the house.

- Roof hatches, which provide access to the roof for maintenance and repair of chimneys, various communications.

- Ventilation of interior spaces.

- Ventilation of the under-roof space, with the help of which excess moisture is removed from the attic and roof space.

The shape of the roof penetration unit depends on the structural solution of the roof, the types of ventilation ducts used. Sections of penetrations are:

- square;

- round;

- rectangular;

- oval.

According to the method of air flow control, ventilation roof penetrations are available in several versions:

- A valveless device in which ventilation is constantly in operation.

- Manual mechanism. With a simple valve, the amount of air passed through is regulated, and if necessary, ventilation through this channel can be completely turned off.

- A device that makes it possible to remotely control the valve using automated systems.

Choose a roof penetration, taking into account the following roof parameters:

- the size of the roofing;

- the distance between the roof ridge and the installation site of the penetration;

- slope angle;

- dimensions of the attic space, if any;

- What materials is the roof made of?

- dimensions of connected communications.

None of the listed criteria can be ignored, otherwise problems may arise either at the installation stage or during operation.

The passage of a round pipe through a metal tile

If the roof passage assembly must be made of a circular cross section, then a roof penetration is used, which provides the necessary tightness at the junction of the chimney with the roof. Roof penetrations are used for arranging the passage of antennas, masts, ventilation, chimneys and electrical outlets and are applicable to many types of roofing materials. The base of the roof penetration is made of steel sheet, with which the cap is hermetically connected. Through the hole in the cap, the sandwich pipe passes through the metal tile.

Penetrations are made of silicone or EPDM rubber. These materials have a wide operating temperature range from -74 to +260 degrees.

To install the pipe through the roof penetration, a hole is made in it 20% smaller than the diameter of the pipe. Pull the penetration onto the pipe using, for example, a solution of laundry soap. The sealant is pressed against the roofing material, and it takes the required shape of the roof surface. A sealant is applied under the flange and fixed with roofing screws with an approximate pitch of 35 mm.

In many cases, a sandwich chimney is a good alternative to a brick chimney.It consists of two pipes of different diameters, between which there is a heat-insulating material made of basalt wool. Installation, performance and service life make the use of a sandwich pipe for the waste of combustible substances a profitable business today. The pipe is protected from severe overheating of the outer wall and accumulation of condensate.

It must be borne in mind that when arranging the chimney, the roof cutting made by oneself must be done in accordance with all building codes and regulations. If you are not confident in your abilities or you do not have enough skills and experience in this type of work, entrust the work to professionals.

Penetration control methods

All penetrations provide the possibility of removing air through the roof. Thus, a channel is formed, which can also contribute to the passage of cold air into the attic. In the simplest models, this nuance is not taken into account in any way, and the nodes constantly provide uncontrolled passage of air. A more advanced roof penetration also provides for the possibility of controlling the flow with a valve. Inexpensive entry-level systems provide for manual control of gate valves, but you can also find many automated models that can be controlled from a distance. Moreover, devices with intelligent control systems that control valves based on current weather conditions are becoming increasingly popular.

Installing a sandwich chimney

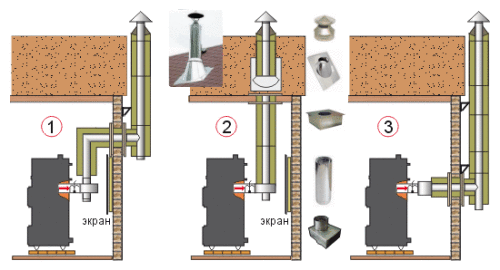

The chimney can be connected both directly to the stove and to the heat exchanger (tank) through which the chimney passes.

The first thing to do is to install a single-wall stainless steel pipe of the desired length. Installing a single-walled pipe will help dissipate a large amount of heat at the first stage.

When installing an insulated version of the chimney (sandwich), a large degree of heating will contribute to overheating of the outer contour of the chimney.

Scheme of the passage of a sandwich pipe through the roof.

With the first option with a single-walled pipe, you will significantly reduce the heat load on the chimney and at the same time ensure that the steam room heats up quickly. At the next stage, the insert-valve (gate) is installed in the absence of it in the bath oven. With a low bath ceiling, the gate is fixed directly to the stove (tank, heat exchanger), single-walled pipes are not used.

Now you need to complete the device of the lower nozzle. It will carry out the transition between two types of pipes - single-walled and insulated (sandwich). The time has come to install the insulated bath pipe. It should be the length you need and be placed up to the highest point of the chimney. It would be inappropriate to install a single-walled pipe in the upper part of the chimney after the sandwich. With this option, the flue gases will cool quickly enough, which contributes to the deterioration of traction and the formation of condensate.

To carry out the passage through the ceilings of the bath (combustible), you can use the so-called telescope. This design provides for adjustment to the desired thickness of the existing floor.

The installation technology is as follows:

- A hole 15 cm larger than the diameter (outer) of the sandwich pipe is cut out in the wooden ceiling. This hole will accommodate the telescopic sleeve.

- The space between the ceiling of the bath (house) and the installed sleeve is filled with heat-resistant insulation, as an option, expanded clay can be used.

- Sheets of square shape, fixed at the bottom and top, will mask the gap (where the passage through the roof) and help maintain an attractive appearance.

Another nuance: in order to qualitatively carry out a sealed passage through the roof of the bath, it is necessary to use a special silicone penetration made on an aluminum basis, which easily takes the form of a roof.

In the upper part of the chimney there is an insulated nozzle that covers the insulation material from the sandwich. So, protection from moisture and destruction is provided to you. An umbrella is installed in this nozzle, designed to protect the chimney from various types of precipitation. All joints of elements and thermal insulation (nozzles, pipes, and so on) are reinforced with clamping clamps that prevent separation.

Types of location of sandwich chimneys.

Chimney through the wall

- Outline exactly where the chimney will pass, this place will have to be dismantled, do everything carefully and slowly so that the wall does not collapse. If the building is old and literally falling apart before our eyes, cracks crawl along it, the structure must first be strengthened, otherwise it will not withstand the load of the chimney.

- If the wall is solid and strong, the area near the transition still needs to be reinforced so that nothing crumbles around the edges. Negligent attitude to this stage of installation in the future will lead to the gradual destruction of the wall. Most often, at the stage of strengthening, bars or special components are used, which are sold in stores that sell building materials.

- Next, fix the bracket to the hole, on which the skids are fixed, allowing the parts to easily pass through the wall.

- The wall near the chimney passage area should be lined with plywood. An asbestos sheet is laid on top, it remains to lay one more layer - galvanized metal, on this the wall treatment can be considered completed.

- You can protect the fastening components from corrosive processes with a lacquer; its label should indicate that the lacquer is designed to work with metal.

How to assemble a chimney from sandwich pipes

The narrowed part is brought to another pipe, the connection is secured by a clamp. Masters advise treating the seam area with a sealant that copes well with temperature loads.

Removing the pipe through the roof

When equipping the passage of a pipe through the roof, care must be taken to ensure that two conditions are met:

- passages through the roofing pie must be fireproof;

- the under-roof space should be protected from moisture penetration as much as possible.

The conclusion of the chimney through the ridge allows you to carry out all the work quite simply. Due to the fact that the formation of snow pockets is impossible on the ridge, it is possible to achieve better protection against leaks. But at the same time, this method of installing the passage through the roof implies that the ridge beam will not have load-bearing functions in the construction of the rafter system. And this requires additional strengthening of the rafters themselves. In the presence of an attic, the installation of additional truss supports may be undesirable or simply impossible.

That is why developers prefer to install a chimney passage on a slope, directly at the ridge. In this place, a snow pocket also does not form, and besides, the truss system does not need additional reinforcement. But besides this, the location of the heating equipment also affects the choice of the place for the passage of the roof chimney. It should be remembered that the horizontal sections of the chimney should not have a length of more than 1 meter.In some cases, it is the location of the boiler that becomes the reason for choosing the method of passing the chimney through the ridge.

Professionals recommend avoiding the installation of a passage element in the valley (the place where two slopes converge with an internal angle), since it is especially difficult to install a roof passage at this point. As a result of rains and snowfalls, the junction may not be able to cope with moisture and as a result, the roof will leak.

It is important to keep the distance between the rafters and the roof in the range of 25-30 cm. If the roof is made of combustible materials (various types of roofing material, soft roof), then a gap of 13-25 cm must be observed between the material and the chimney wall

If the material is resistant to high temperatures, then this gap can be left minimal, and the pipe on the roof of the house is removed only from the crate.

If the roof is a “pie” consisting of hydro, steam and thermal insulation, then during the installation of the passage element, some difficulties may arise associated with a violation of the integrity of this layer. As a result of an error, the protective properties of the roof can be significantly reduced. In this case, the chimney can be installed in a separate box, which will isolate the roofing materials from the hot walls. The distance between the inner wall of the box and the chimney should be about 15 cm, while the free space is filled with non-combustible heat-insulating material. It is recommended to use mineral or basalt wool, as it is resistant to moisture.

Hydro and vapor barrier is brought to the box according to the standard method: the “pie” is cut in the shape of an envelope. The sheet of films is brought to the rafters and cross beams, where they are fixed with nails or staples. Then the waterproofing layer is pressed on top with bars, and the vapor barrier is pressed with a base frame for finishing materials of the attic or attic. After that, the joints of the films and the box are treated with a sealant and glued with a special tape.

Conclusion

Consideration of the issues of additional equipment of the roof should be approached at the design stage of the roof. In the design itself, it is possible to provide technical conditions for passing the communication channel and for installing the node. For example, a wide roof penetration for ventilation may require additional fastening in the rafter area. But this possibility is not always allowed in finished structures. Also, you should not save and refuse modern offers from manufacturers of penetrations. The same automated models will save you from a lot of trouble during the operation of the installation. For example, the latest versions of such nodes allow you to programmatically configure the valve control - so that it will automatically select operating modes depending on the season and temperature amplitudes. However, simple installations without valves should not be excluded if operation is planned in a warm region.

15 Symptoms of Cancer Women Most Often Ignore Many of the signs of cancer are similar to those of other diseases or conditions, so they are often ignored.

Pay attention to your body. If you notice

10 Adorable Celebrity Kids Who Look Very Different Today Time flies and one day little celebrities become unrecognizable adults Pretty boys and girls turn into s.

Why do you need a tiny pocket on jeans? Everyone knows that there is a tiny pocket on jeans, but few have thought about why it might be needed. Interestingly, it was originally a place for Mt.

What does the shape of your nose say about your personality? Many experts believe that by looking at the nose, you can tell a lot about a person's personality.

Therefore, at the first meeting, pay attention to the nose of an unfamiliar

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair.It seems that youth was created for experiments on appearance and bold curls. However, already

11 Weird Signs That You're Good in Bed Do you also want to believe that you're giving your romantic partner pleasure in bed? At least you don't want to blush and apologize.