Types of anaerobic sealants

Polymer sealants of the new generation differ in the degree of strength: low, medium and high

Of no small importance is the degree of viscosity, on which such characteristics of the adhesive as fluidity and penetrating power depend.

Anaerobic sealants have a wide range of applications and in the line of each manufacturer there are compositions for working not only with threaded, but also with spigot, pipe connections, fittings and flanges. To facilitate the task of selection allows color marking, the decoding of which is given in the technical table on the package

Therefore, when choosing a thread sealant, you need to pay attention to the color of the marking.

Strength

Low strength anaerobic sealants are designed for fixing joints that are not subjected to increased loads and require frequent dismantling. A joint sealed with such a composition can be disassembled with a conventional tool. The moment of failure of sealed joints is from 3 to 10 Nm.

Compositions of medium strength are used when carrying out service and repair work, sealing joints subject to increased vibration loads. This type of glue is considered to be universal, since the moment of disconnection varies between 15-25 Nm.

Anaerobic adhesive of strong strength is used to fix threaded connections that do not require frequent dismantling or do not require re-disassembly at all. This type of sealant is resistant to extremely high shock and vibration loads, increased pressure, and has a high breaking torque from 16 to 50 Nm.

Viscosity and color

With a decrease in the gap between the fixed elements, the penetrating power should increase. Therefore, the viscosity index should be lower.

To create a reliable seal for a gap of 0.07 mm, it is necessary to use a sealant whose viscosity does not exceed 20 MPa. Otherwise, the adhesive will not be able to penetrate into the space between the threads.

For joints with large threaded sections, sealants with a higher viscosity are required. If the gaps are up to 0.5 mm, then the viscosity of the fixative used should be maximum.

Color marking serves only to indicate the scope and characteristics of the retainer. It differs for different manufacturers. The palette can be white, green, yellow, red, blue, orange.

Sealant for carving connections. General information

Specifications

Laying pipes near expensive household appliances will entail additional costs if, when water leaks, it fails. Old-fashioned ways to solve the problem of leakage include thread, tow, plasticine, but in the era of high technology, to put it mildly, it is strange to use such inefficient materials. Sealant for threaded connections does an excellent job with such tasks.

fum tape

With fum tape, everything is clear from the name. It is sold in coils in the form of a thin tape, which is tightly wound around pipe threads. Teflon thread is used for tight connection of pipes made of various materials for ventilation, heat exchange, drainage, refrigeration systems, etc. Often used in medical institutions, the food industry, etc., where there are high requirements for sanitary standards.

Anaerobic Thread Sealant

It has gained particular popularity in recent times, and all thanks to the best level of pipe fastening to each other, completely sealing the thread. When properly applied, this material can withstand pressures of about fifty atmospheres, as well as decent vibration loads. Anaerobic sealant is rightly considered a good solution for domestic use, as well as for professional use.

This is interesting: Rusean M300

Using Anaerobic Thread Sealant in Plumbing

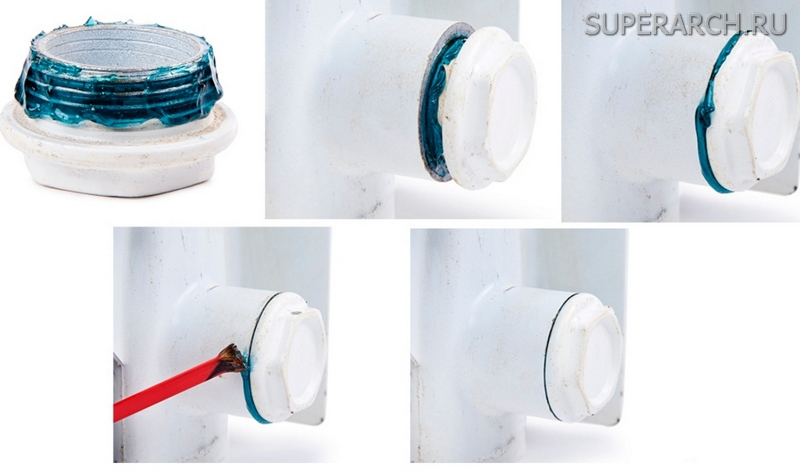

Sell anaerobic glue in packages with a flat neck. Some manufacturers attach a special brush to the sealant. If it is not, this tool is purchased separately. You will also need a cleaner to work. No wrenches and other tools that are used when working with other types of sealants are required.

When sealing is carried out on a new connection, the surface is degreased. New parts are lightly sprayed with cleaner. Carrying out similar work with old threads requires pre-treatment with a brush. Otherwise, the quality of fixation will be significantly lower.

How to use

There is no need to add anything to the sealant. The product is completely ready for use. If it is necessary to connect a plastic product, its surface is pre-treated with an activator. Regardless of this, the order of work remains the same:

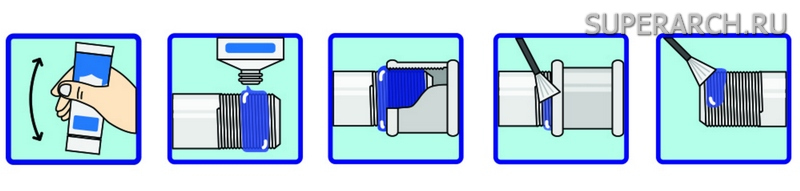

- the sealant packaging is shaken;

- open the cap and apply glue with a tight locking ring over the entire surface of the thread;

- parts are interconnected and wrapped;

- excess protruding glue is removed with a rag or transferred to an adjacent area with a brush.

To achieve the highest quality seal, it is better to apply the sealant to both the external and internal threads, you need to monitor the uniform distribution of the composition over the entire surface.

Anaerobic fixative setting time

The polymerization of the composition occurs at a temperature of +15 degrees Celsius. There is no need to create any special conditions for the hardening of the sealant. If work is carried out at a lower temperature, additional heating may be necessary. This is necessary when it is necessary to speed up the setting time of the adhesive.

After a quarter of an hour, it hardens. The connection is checked for leaks under pressure of about 10-15 atmospheres. A second check is carried out after a day. The working pressure of the supplied liquid should be up to 40 atmospheres.

Advantages

The main advantages of anaerobic glue include:

- wide operating temperature range;

- resistance to mechanical stress;

- economy of consumption;

- immunity to vibration and aggressive environments;

- when cured, it does not dissolve in water;

- the possibility of connecting metals that are dissimilar in structure and composition;

- resistance to pressure over 50 atmospheres;

- ease of use and high practicality;

- the best value for money.

- The temperature at which you can work with the sealant depends on the type of adhesive. Some are suitable for use in temperatures from -196 to +150, others - from -60 to +300 degrees Celsius.

Flaws

The latest generation polymer thread adhesive also has disadvantages. They are not as essential as those of mechanical sealants, but they need to be known:

- not recommended for use with pipes larger than M80;

- low temperatures significantly increase the polymerization time of the solution;

- can only be used on dry surfaces.

For many buyers, the downside is the cost. It is higher than for other types of seals. However, given the economical consumption, high quality and reliability of the joints formed, the reliability of sealing, the price of aerobic adhesive is fully justified.