How to fix a leak and how to fix it

How to fix a leak in a heating pipe depends on where it was formed: at the junction of sections, at the connection of the radiator with the pipe, on the pipe itself. Repair is carried out in different ways, consider the main methods.

The heating pipe is leaking at the junction Important! If it drips from a pipeline that supplies hot water for heating, and this area is under pressure, then the fistula can be eliminated for a very short time. In this case, you will have to call the emergency service and do a thorough repair.

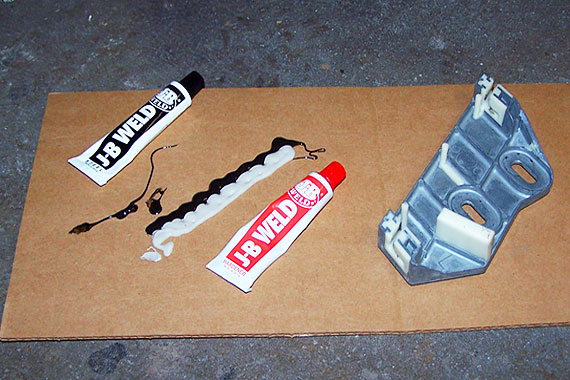

Cold welding

As a rule, it is used at the junction of two sections of the battery, it helps to temporarily close the damaged area. Produced using adhesive sealant, which can be bought at a hardware store. It has a special composition that crystallizes when dried and fills the hole.

- thoroughly clean the damaged area of paint and rust using a brush with metal bristles or sandpaper;

- degrease, alcohol, solvent, acetone are suitable for this;

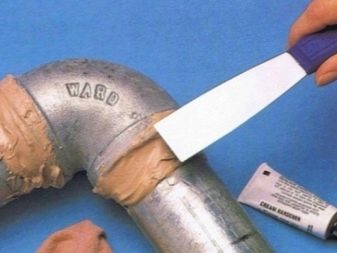

- cut off a piece of sealant, knead with wet hands until smooth;

- press well into the damaged area on the radiator and smooth;

- until the composition has completely hardened, it must be pressed tightly to the surface;

- curing time approximately 20-25 minutes, full polymerization - after 3 hours.

Advice! Be sure to wear protective gloves as the sealant is reactive and corrosive to skin.

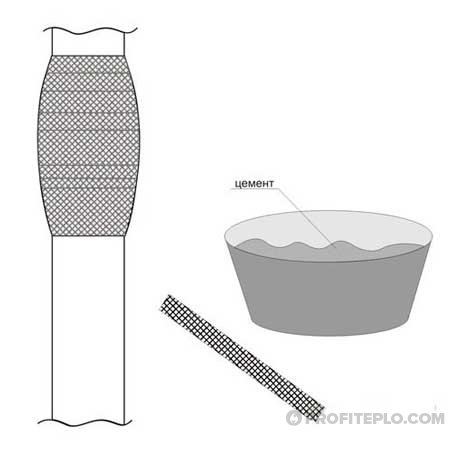

Cement plaster bandage

If a hole is found on the heating pipe or the junction of battery sections, you can make a cement-gypsum bandage, for this, prepare the following consumables:

- medical bandage, piece of gauze or thin cotton fabric;

- alabaster (gypsum);

- cement;

- bucket or bowl of water.

- dilute cement in water by mixing it with gypsum, the consistency should be like that of fatty sour cream;

- take strips of fabric or bandage 25-30 cm long, soak with the resulting composition;

- wrap the damaged section of the pipe with a cloth;

- overlays are made until the bandage is strong and dense.

Use of clamp and rubber

If you notice a heating pipe leak, as a temporary measure, you can apply a purchased or home-made clamp, as well as a rubber lining. If a factory clamp of a suitable diameter is available, it must be applied to the leak and tightly secured with a bolt. If there is none on the farm, you will have to make a rubber pad yourself.

Advice! A bicycle tire, a thick household glove, a ball, a rubber boot can serve as consumables.

- cut a rectangle from a piece of rubber that will be 2-3 centimeters wider than the hole, the length should be the same as the diameter of the pipe;

- tightly wrap the overlay around the pipe, and fasten the edges with wire or metal clips, you can make a winding of wire along the entire length of the bandage.

Application of welding

If a heating battery (not metal-plastic, but cast-iron) flows in a house or apartment, welding will help eliminate the defect. It can be used anywhere on the radiator. Therefore, after you have made minor repairs yourself or cut off the water supply to the battery, call the emergency service or a private company that provides hot welding services.

How to use cold welding correctly

First of all, decide on the choice of the glue itself. Universal or specialized, for a specific material. If you purchase it after an accident, take a narrow-profile one. And as a home "first aid kit" you should have universal glue.

And finally, advice on how to remove cold welding. There are only two ways: soak with a solvent (if the material allows) or remove it mechanically (file, chisel).

How to use cold welding for metal - video.

Subtleties of use and method of mixing components.

Another example of how to glue linoleum with cold welding is a video.

Cold welding for metal is a frequent guest of repair kits that many motorists carry with them. Indeed, it is difficult to imagine a long road without this repair material, because any trouble can lie in wait for the driver, for example, a broken gas tank, a radiator, and similar situations.

Cold welding can be an indispensable assistant in many cases, so we strongly recommend that you not only keep it at home at all times, but also take it with you on a long journey.

A video instruction on the use of cold welding for metal can be viewed at the end of the article.

In this material, we will talk about what cold welding is for metal, give instructions for its use, and describe the features of repairing a muffler, radiator, body and gas tank using cold welding.

Cold welding for metal is a special composite polymer that has high adhesion to various materials (in this case, to metals). In simple terms, cold welding is a glue that hardens quickly and does not react with motor oil, gasoline, diesel fuel and similar petroleum products.

Such products are divided into 2 types: liquid and plastic formulations.

- Liquid formulations are usually based on epoxy resin, which gradually hardens after entering into a chemical reaction with a hardener. A distinctive feature of the resin is the possibility of its combination with various substrates and reinforcing elements (fiberglass, metal mesh), as well as the absence of emissions in the form of moisture, harmful substances or a strong odor.

- As for plastic compositions, these are special putties. They look like two-layer or two single-layer bars. Outwardly, they are easy to confuse with simple children's plasticine.

After we figured out what cold welding is for metal, we can move on to the next item in our educational program.

Peculiarities

Cold welding glue is a substance that can help connect two metal parts without the participation of a thermal reaction. The composition can be deformed so that it is possible to reliably cover the parts by gluing them. Most often used in the process of repairing plumbing equipment and shows excellent results in working with machines. The big advantage of this glue is the ability to glue elements that were not prepared in advance for this procedure, which speeds up the process and makes it more convenient.

"Cold welding" is the mixing of substances with polymers and obtaining the final result. The strength characteristics of the substance will depend on how high-quality the ingredients are in the composition, as well as on the correctness of its manufacture. If conditions close to ideal are created during the repair process, then the glue can become stronger than the metal itself, but in reality this can almost never be done, because the use of glue can be useful for temporary needs and a short-term way out of a problem situation.

It is especially convenient to use this composition where elevated temperatures cannot be used, and the parts must be securely soldered.The convenience lies in the fact that in the process of soldering it is not necessary to work with homogeneous metals, several options can be connected that will be well attached to each other with glue.

If we talk about a number of advantages, then they should include:

- no deformation of the metal surface due to the absence of temperature effects;

- the seam is neat and quite strong;

- for a number of metals, only the use of "cold welding" is possible, these include aluminum and copper, which are not connected through other options;

- after work there is no metal waste;

- no need to use electricity;

- environmental friendliness of the procedure;

- you do not need to have training for the procedure;

- no specialized equipment is required.

Leak on the radiator

Such troubles usually happen with two types of heaters: steel and cast iron. If the hole is small, you need to clean everything around, close the hole with a wooden cork. Top coat with sealant, "cold welding". The solution is unaesthetic, but you can hardly imagine a better one here. You can try to close the leak in the battery only with the help of "cold welding".

You can fix a small leak, sometimes you can’t help me.

There is one more tip - to wrap a self-tapping screw in the hole. Find a suitable diameter, lubricate with sealant or sealing paste. Unusual decision. May work if the hole is small.

But all these are only temporary options. Such a radiator (if it is a panel one) or a leaking section needs to be changed.

Quick repair of a heating battery by cold welding

This express method will restore the battery seal to 100%. Why is it not worth solving the problem with a jar or a basin under a dripping radiator or pipe? The consequences can be very sad - a rupture of the radiator, a fountain of hot water, expensive repairs from the neighbors below at the expense of the hero of the occasion. Not worth the risk! It is urgent to fix the leak, and in the summer it is better to change the battery. In a private house, it is advisable to regularly carry out preventive maintenance of an autonomous water heating system in order to avoid such troubles in winter.

1. A small fistula can be quickly covered with cold welding on your own. And you can easily find cold welding in a plumbing store, in an auto shop, in any construction shop. Before buying, do not forget to look at the date of manufacture on the back of the liner, since the shelf life of such a miracle glue is limited, and if you use an expired putty, you will be very disappointed - this glue tends to dry out even in the package.

2. Where to start? First, you should find the exact location of the leak and determine the size of the fistula, perhaps there is more than one. The fistula may be hiding under swollen paint on an aluminum heating radiator. If the fistula has formed in such a place that it is difficult to get close to it, then you may have to remove the modern heating radiator from the fixtures and drain the water from it.

Most often, the radiator does not need to be removed - a fistula in a place accessible for repair. And yet, before covering up the fistula, many plumbers advise turning off the water supply taps on it and opening the Mayevsky tap to drain the water from the battery by substituting a bucket under the stream of water. Other experts say that this is not necessary, cold welding will do its job so well - it is not afraid of moisture.

3.But the swollen paint will have to be scraped off. This can be done with a knife, a metal spatula, or a flathead screwdriver. Under the paint, you will probably see a small hole, or even two, maybe three.

4. Before you start gluing, it is desirable to sand and degrease the surface around the fistula. To do this, you can use sandpaper and alcohol or acetone.

5. Cut off a piece of cold welding necessary for repair.Thoroughly mix all its components together with wet hands (work with gloves) until a homogeneous mass is obtained. The glue should warm up in your hands and become elastic and sticky.

6. Quickly apply putty to problem areas, and then once again firmly press the weld with something hard, such as a knife or screwdriver, to the surface of the radiator or pipe. If the surface is wet, it is necessary to press and smooth the adhesive until a feeling of adhesion to the surface appears and the flow stops. You can hold the composition with a tourniquet for 15-20 minutes until completely hardened.

7. Now it remains to wait until the glue hardens. If the connection is heated, for example with a hairdryer, this will increase the strength of the connection. The firm hardening time must be indicated on the packaging. Cold welding "Diamond press glue" hardens within 1 hour. Fully hardens after 24 hours. And the leak is gone!

Watch a video on how to fix a heating radiator leak / Cold welding

Application area

The use of "cold welding" becomes possible for products made of aluminum, cast iron, copper and other options. It is actively used in the process of eliminating the problems of plumbing equipment and heating pipes. For batteries, it is not always convenient to use the hot welding option, and the right glue, applied in the right way, can completely replace it. In addition, the composition successfully copes with the repair of metal containers and radiators for cars, therefore, in this case, its application is especially welcome.

For polypropylene and plastic pipes, this glue is considered the best helper, because the option using a welding machine will not be possible. In addition, building supplies, garden tools, stainless steel products, all this has the ability to correct or correct it with the help of the desired composition. Equally important is the use of glue to work with copper wires, which are not easy to weld aluminum lugs, but with the presence of a welding compound, the process is easy.

A special type of welding adhesive makes it possible to glue parts made of rubber, ceramics, wood and more, for which you need an appropriate adhesive that can hold parts of the products. Having decided on the material and its application, you need to choose the right glue.

If work is done with automotive parts: radiator, gas tank, muffler, then a metal-filled composition is used.

For those options when operation is carried out under the influence of temperatures, and these are some parts, as well as machine components, it is important to choose a heat-resistant variety. When choosing the right variety, it should be understood that the use of “cold welding” for those parts that are operated under pressure is impossible, this composition will not withstand and will burst

The exception is heat-resistant varieties, which are several times stronger, which means they sit more firmly in place.

Ways to use

To repair pipes, you need to prepare everything you need - the welding agent itself, acetone or alcohol, sandpaper, rags and clamps. The method of sealing radiators varies somewhat depending on the type of welding - liquid or plastic

It is important to choose a suitable product that is suitable for pipes under pressure (metal or polypropylene). Next, you need to prepare, mix the material, and you should work faster with liquid products

Ways to use welding:

- simple sealing of the defect with a piece of mass, flattened and kneaded with fingers;

- the use of special fiberglass fabrics, threads for wetting with epoxy, followed by wrapping with rubber, wire or without it;

- gluing on a large defect coated with a metal patch.

If the leak is strong, you can make the composition even more durable with your own hands.You need to take any aluminum or bronze part, grind it a little over the paper, getting a metal powder. It must be added to the epoxy mass, which is then impregnated with turns of threads or fabric.

What is technology

Cold welding is an adhesive composition specially made for joining metal elements. Glue in composition is one-, two-component:

- epoxy resins serve as the base, which perform the tasks of plasticity, homogeneity of the mixture;

- additional fillers - sulfur, metal elements.

By consistency - a polymer mixture with adhesive properties in the process of slight heating, deformation.

The strength characteristics of the connection will depend on the quality of the selected adhesive, the correctness of its application, and the preliminary preparation of the pipeline.

If you strictly follow the cold welding technique, ideally, the welded area, for example, a riser, will be much stronger than the base metal of the product, but the seam is inferior in reliability to the connection made using electric arc welding. Therefore, it is recommended that this method of joining metals be used only when performing minor repairs, for example, if a leak is detected in a pipe, a crack can be welded.

General recommendations

- remove old patches;

- clean the leaks with a metal brush;

- treat cracks and holes with a grinder with a cleaning wheel;

- eliminate the defect by soldering or welding.

Next, paint the battery (you can read about paint for radiators here) and install it in place

At the same time, it is important to follow the installation rules - use tow, FUM tape, high-quality shut-off valves and pay special attention to the joints

After installing the battery in the circuit, it is worth filling the system with water and checking the tightness of the heater

It is important to carry out this step with the boiler running, as the circulation of the pressurized coolant can reveal leaks and weak points in the connections. If no leak is detected during the intensive use of the heating system during the day, then the problem can be considered solved.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

How to correctly drain the water from the heating battery? Effective flushing of the heating system: methods and recommendations Pressurization of the heating system with air according to the norms of SNiP What is it - pressure testing of the heating system and when is it needed?

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement entails legal liability. Contacts

Flaws

- Welding for batteries is designed only for low loads, so it is not suitable for serious repairs and other methods must be used;

- The reliability of the seam largely depends on the technology of the process, since if all the rules have not been followed, the composition may not be taken properly;

- When applying welding, it is necessary to adapt to the specified temperature conditions;

- The resulting seams cannot be attributed to very durable.

Varieties

Cold welding for steel heating pipes is a popular tool that is manufactured by several companies. There are both domestic and foreign manufacturers on the market, differing both in price and quality. The recognized leaders in this area are HI-Gear and Abro. Among domestic manufacturers, there are also several specialized brands that are marked "for pipes". Among manufacturers, Polymet and Almaz are popular.

Cold welding HI-Gear and Abro

Compound

The composition of the material includes the following elements:

- Epoxy resin - the basis for glue, which gives the whole substance uniformity and plasticity;

- Additional components - to improve the bonding property, such as sulfur and so on;

- The metal component is responsible for strengthening the strength of the material in the solidified state and a longer service life.

Specifications

The characteristics of the material used are one of the main factors to pay attention to. This variety has the following features:

|

Characteristic |

Meaning |

| Minimum use temperature, degrees Celsius |

-60 |

| Maximum use temperature, degrees Celsius |

-150 |

| Plasticity retention time, min | |

| After how much time can be subjected to load, hours | |

| Packing weight, g |

Choice

Cold welding for plastic and metal pipes can make a big difference. The difference lies in the strengthening element included in the composition. For metal products, it is desirable to select those options that match the filler material with the pipe metal. Accordingly, for plastic heating pipes, you do not need to choose too hard brands. In any case, liquid grades are not suitable for the pipe surface.

Cold welding of heating pipes under pressure will be the strongest. For it, the most resistant materials are used, which have high tensile strength.

Instructions for cold welding of heating pipes

The first step is to prepare the surface on which the composition will be applied. It should be cleaned of dirt and dust particles so that it is as clean as possible. Then it needs to be dried. A dirty and wet surface sticks together several tens of times worse. After that, you can cut off a part of the rod from the glue, the size you need, and knead for 5 minutes until it becomes as elastic and soft as possible.

A sticky homogeneous mass must be applied to the site of a crack, leak or other problem with which you are dealing. The surface must be completely covered with the composition. To smooth the glue, you need to use a spatula, or other similar object.

Security measures

Cold welding for PVC and other materials is generally not safe in contact with skin and mucous membranes. Do not allow direct contact. Work must be done with protective gloves. The cutting knife should then not be used for food. In case of accidental contact with the mass, wash hands or eyes in running cold water. If complications arise, it is best to consult a doctor.

Features of the use of cold welding

The main feature is the great attention to the preparatory stage. From the thoroughness of its implementation depends on how well everything will turn out.

Even the service life of cold welding for heating pipes depends on how well the material sets.

Installation of the heating circuit by cold welding

Cold welding is the connection of two or more elements without heating them. The connection is formed due to chemical reactions occurring in the adhesive.Ductility, high adhesion and fast hardening into a monolithic mass are the distinguishing features of the components used for cold welding.

The adhesive composition may include various elements to improve the mechanical characteristics of the adhesive joints. As a rule, the compositions are based on epoxy resin, and the filler is a hardener. The packaging indicates whether it is possible to weld heating pipes with cold welding, or is it a composition for repairing plastic pipes of the cold water supply circuit.

Cold welding is a plastic mass that provides a hermetic connection of pipes

There are two types of components for cold welding:

- Plastic two-component substance, which immediately before use must be thoroughly kneaded to mix the components. The advantage of cold welding of this type: the composition is quickly prepared, stored for a long time, requires minimal preparation before use. Disadvantage: hardens quickly, must be applied very carefully, it is recommended to use as soon as possible after preparation.

- liquid components. Before starting the application, it is required to combine the substances in the proper proportion, and the adhesive is ready for use. The advantages of a liquid composition for cold welding: the adhesive easily penetrates deep into the joint, forming a durable layer that is resistant to mechanical stress when solidified. Disadvantage: requires special conditions for long-term storage. Different materials - plastic, metal - require different chemical components.

The main advantage that distinguishes cold welding of any kind is the ability to quickly repair a section of the plumbing, heating or sewer system without turning off the water supply. Welding, or in this case, bonding of components, can be carried out in conditions of increased fire hazard.

As a repair compound for cast iron radiators, the surface should be carefully prepared for cold welding. Despite the strength of the joint, the repaired area may not withstand the maximum pressure test.

For plastic plumbing systems, the cold welding method is recognized as one of the best solutions for local repairs when it is impossible to replace the damaged element. Also, cold welding is successfully used to restore the tightness of butt welds on plastic water pipe fittings.

Cold welding is an effective method for urgent repair of any pipe

Waiting time for the finished composition of cold welding: from 2 to 20 minutes, depending on the intended purpose. Temperature range - from 0 to 1300 degrees.

It is enough to read the instructions for use in detail, and the installation of the system will be successfully carried out. For work you will need:

- container for the preparation of the composition;

- gloves to avoid skin contact. It is recommended to moisten them with water;

- thin spatula, for applying a viscous composition to the area of \u200b\u200buse;

- compliance with safety rules when working with chemical components.

If the composition gets on the skin or in the eye area, it is recommended to rinse the affected area of the skin and, if a burning sensation occurs, consult a doctor, having a package of “cold welding” components with you.