Swedish wood window insulation technology

Step 1. We carry out an audit of the condition of the wood

It is important that the sashes, if they are old, are strong enough not to crumble into dust. We carefully examine the lower part of the sash - it is there that the wood most often rots under the influence of moisture.

Checking the condition of window fittings. We tighten the screws, if necessary. If there are small gaps on the windows, we close them with wood putty. If necessary, remove the old paint and sand the wood with sandpaper. All actions of this step should be aimed at identifying and eliminating minor frame defects.

Preparing windows for insulation using Swedish technology

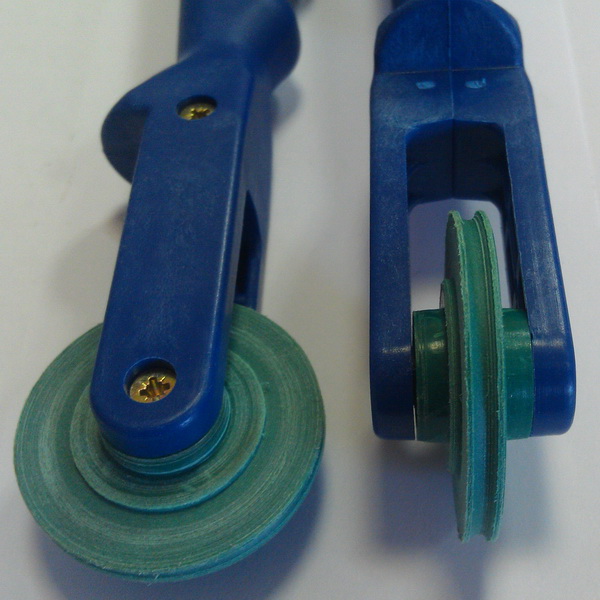

Step 2. Prepare the tools. You will need a sealant directly, a sharp clerical knife, a roller for installing the sealant and a milling cutter for cutting a groove on the frame.

Video clip

Step 3. Remove the frames. With the help of the level we make markup. It is necessary to draw perfectly straight lines so that the seal does not deform.

With a milling cutter along the perimeter of the sash, we select a groove of 3x7 or 3x5 mm. We select the groove at an angle of 45 degrees. In places where hinges are attached to the frame, we do not cut the groove. We clean the dust from the grooves with a vacuum cleaner.

Work with a cutter

Step 4. We begin to insert the herringbone seal into the groove, rolling it with a roller. We move the roller in the “back” direction (towards the already inserted edge) so as not to stretch the seal.

Seal installation diagram

Rolling on the compactor

Step 5. We increase the effect of warming. We remove the glazing beads, take out the glass, apply a layer of silicone sealant to the seat. We install the glass in place and fix it with glazing beads.

If a little silicone has leaked out and hit the glass, do not smear it, but wait until it dries, and then clean it off with the edge of a clerical knife.

Insulation scheme for a double-leaf window using Swedish technology

As a result of window insulation using Swedish technology, draft protection is provided, the room becomes warm and dry. A high-quality sealant will last more than one year and retain an aesthetic appearance.

An example of well-insulated windows

10 way Insulation of the entire perimeter of the window frame

The whole process of warming a wooden window consists in the choice of material for the implementation of the work and the method of its installation, taking into account the characteristics of the wooden window. We insulate mainly the gap, which is located at the junction of the frame and sashes.

If you are guided by Swedish technology, then you need to make a groove inside the perimeter of the window with a special tool - a cutter and fill it with a tubular silicone sealant that will cover all the smallest cracks and defects. The process is complicated, if the window is old, then it may not withstand removal and hanging, it is not cheap, it requires the work to be done by professionals.

An easier way is to place and glue the seal around the perimeter onto the transom of the window. When we close the frame, it will bend the seal, and not slide on it, it will fit tightly, closing all the cracks. Such insulation can be laid in rows in several layers. Its use must be combined with the installation of glass on a layer of sealant. The sealant laid in this way will serve for many years and it will not be necessary to remove it in the spring and mount it in the fall.

From the different options for window insulation, you can choose any that is most suitable for your house or apartment. Window insulation will give a positive result. You will raise the temperature of the indoor air and save money.

Reasons for replacing seals

The tightness of a plastic window depends on many things: from the quality of the frame itself to the tightness of the double-glazed window. But every factor is important, including the degree of pressing the sash, which is ensured by the presence of sealing rubber bands.If they are worn out, then such negative phenomena may appear:

The appearance of condensation on the double-glazed windows.

When closing, the sash has a backlash and is covered loosely.

There is a draft near the openings.

Of course, it may be that the whole reason lies in the system settings, and a simple adjustment of the plastic windows will correct the whole situation. But, if all the options have been tried, but there is no result, then the seal will definitely need to be replaced.

Method 1 Insulation of wooden windows with paper and fabric strips

The simplest, rather primitive, but very economical way is to insulate wooden windows with paper and paper or fabric strips. Completing of the work:

- we tear paper, newspapers, wallpaper into pieces, twist it into strips;

- soak in water and fill the gaps between the window frame and sashes with a knife or ruler;

- carefully glue strips of paper or fabric of small width (4-5 cm) at the joints, coat them with a solution of laundry soap or make a special glue (paste) from flour or starch.

Paste recipes:

- Flour paste: take flour and water in equal proportions (1: 1), mix well until the lumps disappear and bring to a boil, stirring constantly.

- Starch-based paste: 2 tbsp. dissolve the starch in water and combine it with a glass of boiling water in a thin stream, keep it on fire for a short time.

It is not easy to clean the window from this insulation, sometimes paint is removed along with the paper, and its pieces and prints of printing ink remain on the surface of the window frame.

Simple and forgotten heaters also include window putty, and even children's plasticine.

Which sealant is better

Seals are an important component of a window. After all, it depends on them how tightly the sash will fit to the profile, and, accordingly, whether it will be warm in your house. There are many different types of seals. We will look at the most common ones.

Types of seals:

TPE (abbreviation for English Thermoplaste Elastic - elastic thermoplastic) - this type of sealant is mainly used in the automatic assembly of plastic windows. It is very convenient for automatic profile assembly. It has a very small corner radius and is welded at the corners of the profile. Its cross section can be given an arbitrarily complex shape. It can be painted in all colors of the rainbow. Finally, it is fireproof and relatively cheap.

But this type of seal has a number of big disadvantages:

-Poorly tolerates temperature changes, it becomes brittle in the cold, and too soft in the heat (problems can occur starting at temperatures of -20 and below or + 35-40 degrees and above)

-Low UV resistance

- Poor elasticity (poorly returns to its original shape after mechanical impact)

EPDM is ethylene propylene rubber. (Eng. EPDM: Ethylene Propylene Diene Monomer).

The most popular type of sealant for plastic windows. It does not change its properties at temperatures from -60 to +120 degrees, it is resistant to mechanical stress cycles, it is not afraid of either ultraviolet radiation or precipitation.

This seal is characterized by high resistance to temperature extremes and moisture. Practically does not undergo aging processes under the influence of ultraviolet radiation and aggressive substances.

However, the cost of this type of seal is quite high. That is why it is rarely used in glazing. In addition, it has low resistance to mechanical stress, in which the silicone seal loses EPDM

And finally, we must not forget about the most ordinary rubber. That is - about vulcanized rubber. It has all the advantages and disadvantages of natural material. Provides good sealing, but can "succumb" to atmospheric and climatic factors.For example, crack at sharp and frequent temperature fluctuations.

Seal form

More seals can be divided by shape. They are solid and petal. Both types are used for glazing houses. However, solid seals do not tolerate temperature changes, so it is recommended to use flap seals.

When choosing a flap seal, it is important to pay attention to the number of seal loops. Seals can be both single-circuit and double-circuit. We recommend choosing a double-circuit seal, as it is more airtight than a single-circuit seal by an average of 26%

We recommend choosing a double-circuit seal, as it is more airtight than a single-circuit seal by an average of 26%

As a result, we choose the EPDM dual-circuit seal, as it showed the best results.

But, the quality of an EPDM seal depends on the brand of the seal, or rather on who made it.

The best seals come from Germany, so it is better to choose them. Then ask to see the following seal certificates: Certificate of conformity to GOST and ISO 9001:2008.

You can check the quality of the seal yourself.

Ask for a piece of sealant, stretch it hard and see if it regains its original length. If not, then the quality of the seal is not the best. It is also worth smelling it - it should not exude sharp or unpleasant odors, except for a slight smell of rubber.

Window Empire recommends a double-circuit EPDM seal of the German brand Semperit!

7 way Insulation of wooden windows with heat-saving film

An innovation in glass insulation is a special film that allows daylight to enter the room, but does not emit infrared radiation. Such a film has two sides, which must be taken into account when sticking to glass. We glue the side with a metallic sheen to the glass, and the transparent side inside the room. When performing work, hands should be clean, and it is better to use cotton gloves so that there are no greasy spots on the surface of the film.

We cut out the sheet with a margin and overlap it so that it can be easily fixed on the window frame with double-sided tape. Such a film, if well glued, does not violate the design of the window, and it looks aesthetically pleasing and neat. In order for it to lie evenly and without wrinkles on the glass surface, we will thermally shrink with a jet of hot air using a hair dryer.

Which plastic window seal is better

Some of the citizens come to the hardware store as if to play checkers. The main question: “Do you have a white or black window seal?” - everything else is of little interest to them

Although if the sealant turns out to be of crappy quality, then it doesn’t matter what color it is - you are tormented in the winter cold. And in the spring you will already be asking about other characteristics of window seals - heat resistance, wear resistance, etc.

We will try to talk about these characteristics in our note (the reader can learn some information about window seals from the article “Types of window fittings - an overview” previously published on our website).

Seals for window glass in section

Further, we will only talk about seals for factory-made plastic windows - we will leave the story of various kinds of rag and foam pads for the Samodelkin.ru website.

Myth #1: Seals come in black and white.

In fact, they are all black. Or an unimaginable mud color. They are made gray by special additives in the plastic mass from which they are made.

Sometimes they are made "gray" so much that they are perceived as white to the eye. These are the seals that are considered the most fashionable, bringing excitement to managers and sellers of hardware stores.

Myth #2: White seals turn gray over time. Including because of the dust that eats into their porous structure.

By no means! Modern science and technology have reached such heights that allow you to keep a stable color of rubber or polymer. And you need to wipe the sealant of the most delicate white color no more often than other parts of your plastic window.

Myth No. 3: Additives that brighten the sealant material make it more brittle and sensitive to temperature changes.

Not at all! All the same science has long ago invented dyes that in no way affect the properties of the material to which they are added.

Myth 4: you need to buy a heater with a maximum service life.

Pretend seal in the window profile

It must be said that advertising brochures usually indicate the service life of the seal in 30-40 years. In fact, this is the time during which irreversible chemical changes will occur in the structure of the sealant. So to speak, its natural aging will take place.

In reality, this parameter matters only for those insulating gaskets that are mounted between the glass and the profile. For the most critical gasket - between the sash and the frame - the "lifetime" is usually calculated as 5-7 years, and even then at best.

If the householder forgot to switch the window from winter to summer, then the feigned (from the word "pretend" and not "pretend") insulation can wear out in one season. And it will have to be changed.

Therefore, it is necessary to look not at the color of the seal and not at the advertising service life, but, first of all, what material the seal is made of and what are the properties of this material.

What is a sealant for wooden windows

This material allows you to ensure a snug fit to each other elements of the window or door. It is made from silicone, rubber, PVC, and other elastic raw materials. The use of seals in wooden windows significantly increases the thermal and sound insulation of the building.

As a rule, a sealant is a rubber strip of various shapes, which can be on a pliers basis or without it. At present, the following types of seals are present on the building materials market.

Self-adhesive. Rubber tape made in the form of the Latin letters D, C, E, V on one side of which an adhesive is applied. For installation, it is enough to remove the sewn-in tape from it and stick it in the place necessary for sealing. The disadvantage of this type is the poor quality of the adhesive base, which after some time loses its properties.

Without adhesive backing. It is also a rubber tape of the same shapes as self-adhesive, but without an adhesive backing. Fasteners of such a seal are made using frost-resistant and moisture-resistant glue.

When choosing an adhesive, it is important to purchase a certified and branded product. Otherwise, the seal will peel off.

Groove seal

It is made of rubber in the form of a tape and also has various shapes. A distinctive feature is the fastener, which is inserted into a pre-prepared groove along with the seal. The advantage of this type is that no adhesive bases are required, but at the same time, grooves must be sawn for installation.

Silicone. Refers to liquid seals, preferably used on windows that will not open during the sealing period. This type has high tightness and thermal insulation. Also, on this liquid base, glass can be installed in wooden frames for better sealing.

Each type has its advantages and disadvantages depending on the design of the window and how it is operated.

This is interesting: Sewer well for a private house

How to replace the seal

The sealant is used to ensure the tightness of the window. One of the important elements for caring for it is a lubricant for the seal, which, unfortunately, not everyone uses. It is necessary to apply such a lubricant twice a year - before and after winter.If you do not follow this instruction, then after some time the rubber seal begins to dry, wear out and lose its tight properties, and after that the lubricant will no longer give any result. In this case, the solution is simple - buy a new one from the manufacturer of your windows and replace it. The installation procedure is simple - you need to get the double-glazed window from the sash, and then remove the glazing bead

Important: the glazing bead is a fragile part, and if it is broken, the double-glazed window can no longer be put back, so be careful. After these manipulations, you need to remove the old seal from the groove and insert a new one.

After that, everything is going back.

Material selection

One of the main issues when insulating plastic windows at home is the right choice of insulation.

As a heater can be used:

- Mounting foam

- "Warm" mixes (heat-insulating masonry mixes)

- Mineral wool (glass wool, basalt fiber)

- Styrofoam

The choice of material depends on the characteristics of the insulation. So, the most common and convenient way is polyurethane foam, but it quickly collapses under the influence of air and temperature changes. Therefore, it is better to insulate windows from the inside with foam, and use “warm” mixtures from the outside. The greatest difficulty is that in order to choose the type of thermal insulation material and its quantity, it is necessary to dismantle the window sill, as well as slopes and ebbs.

Insulating plastic windows with your own hands is not an easy task, but with due care it does not require any special skills. Despite this, dismantling work should be entrusted to specialists. If dismantling is not required to eliminate the cracks, then the old foam is carefully removed, and the cracks are filled with a new one, after which they are covered with plaster or putty. Small gaps are eliminated with sealants. Before using them, you must first clean and degrease the surface.

The hinges on the frame have a bolt that is adjusted with a hex wrench. For greater tightness and, accordingly, thermal insulation, it is necessary to turn this bolt so that when the window is closed, it is as close as possible to the seal. A risk is applied to this bolt, and if it is directed towards the seal, the sash is pressed as tightly as possible to the frame, and if it is outside, the clamp is as loose as possible.

Why insulate plastic windows

Today, many residents of the country have changed old wooden windows for energy-saving metal-plastic structures. Beautiful and reliable plastic windows retain heat well, which is why they are so in demand. But not everyone thinks about how they will behave in the future. Expectations of impeccable warmth are not always justified.

Even the highest quality and most expensive plastic windows can let in cold air from the street. The main nodes from which it can blow are as follows:

- double-glazed window holders;

- sealant;

- hinges and handle.

Cold can penetrate along the perimeter of the frame, including the window sill and the junction of the slopes. You can determine the leak tactilely or with a lighter, the light of which will tell you where there is a draft.

Why does the cold still penetrate the house? The reasons for heat loss can be different. Often a draft from the window appears due to the mistake of the installers. Even small non-compliance with technology and ignorance of GOST standards can eventually manifest itself in the form of unwanted penetration of cold air into the room.

Photo: subscribe.ru

The gaps are formed due to the subsidence of the new building, which occurs with new buildings for the first two years.

Another reason for drafts is savings in window installation. This is affected by the lack of foam, low-quality insulation and the use of cheap components when assembling the structure. It blows from the window and due to the physical wear and tear of individual parts.

Do not forget that heat loss also occurs due to improper operation.Therefore, do not forget to treat the seals with glycerin and clean them regularly with a damp cloth to avoid loss of elasticity.

In any case, the source of the draft must be removed. If the plastic window was installed recently or the draft appeared due to a factory defect, call the master of the company where the construction was purchased. The services of a professional will be required if the plastic windows are located at a high altitude or if the fittings need to be replaced.

But given that the cost of the work of the masters will be equal to the installation of a new design, then you can try to insulate the windows yourself.

How to insulate plastic windows with your own hands

Photo: bigl.ua

How to insulate windows cheaply and effectively? Despite the apparent complexity of the activities, it is quite possible to do the following on your own:

- carry out internal insulation of the window opening;

- insulate the window sill and frame along the contour;

- replace seals.

Insulate plastic structures before the onset of frost, as some materials, including sealants, are used only in a certain temperature range.

Photo: 3brothers.ru

The type of insulation depends on the place of blowing:

- polyurethane foam is used to fill voids around the perimeter. It is an ideal sealant, as it consists practically of air;

- mineral wool is a heat-insulating material suitable for warming window sills and slopes;

- expanded polystyrene is used as a slope insulation.

Please note that rigid insulation is used only when the joint width does not exceed 3 mm. In other cases, give preference to mineral wool

Do not use duct tape for insulation - it is very difficult to wash off the surface.

For self-insulation, follow this algorithm:

Carry out internal insulation

Pay attention to internal slopes. Don't forget that they must be aesthetically pleasing.

To do this, process them, remove the remnants of the old foam and apply a primer. Seal the gaps with mounting foam, then use foam or cotton wool. Install drywall or paint the surface. Insulate the window sill by sealing the cracks.

Insulate slopes and ebbs from the outside

This is necessary to shift the dew point and prevent mold growth. First, clean the slopes of dirt, and then use a high-quality hard insulation. It is also important to seal all cracks with glue and finish plaster. When insulating ebbs, it is enough to blow out the cracks with foam.

Adjust window mechanisms

To reduce heat loss, it is important to adjust the fittings. Change the seal if necessary. Please note that black material is much more elastic. But light gray is more attractive, but its tightness is lower.

Photo: yandex.kz

In addition to the main methods of insulation, additional ones will help. Regular window cleaning will help reduce heat loss. This is due to the fact that sunlight passes through dirty glass worse. Thick long curtains will also help, which help to retain heat indoors.

After completing all the work, do not forget to regularly ventilate the room or install forced ventilation, which will prevent mold on the walls.

Do-it-yourself gum installation

Replacing the self-adhesive sealant on wooden windows occurs according to the following scheme:

- thorough cleaning of the window surface from contamination;

- its degreasing and drying;

- determination of the installation location (sash or frame);

- actually fixing the material.

In this case, you need to take into account some nuances:

- the tape is cut into strips of the required size (you can first divide it in half);

- the protective layer should be removed carefully so as not to stretch the seal itself;

- during fixing, the tourniquet must be pressed, but not very strongly;

- the window will be ready for use after 2 hours.

To fix the conventional sealing gum on the frame, rubber glue or sealant is used. Except for this moment, the replacement is carried out according to the above technology. It happens that consumers use a stapler to install such a heater. But this method eventually leads to a deterioration in the appearance of the sash, so it is undesirable to use it.

The groove seal for the porch of wooden windows is fixed using Swedish technology. The sashes are removed from the frame, and a groove is made along the contour with a cutter (angle - 45 ° relative to the flashing). The groove is cleared of chips. A tubular seal made of silicone or TPE is laid in the resulting recess. A gap is left for loops with a small gap (up to 15 mm from each edge). The sealant is installed with a seam into the channel and pressed in with a roller specially designed for this operation. To avoid stretching the product, you need to move the tool "back and forth". After the installation is completed, the sashes are returned to their place, the ease of opening and closing the window is checked.

This is interesting: How to make glass frosted: we cover it in general terms

Blows from the gap between the window and the window sill

If your case does not apply to the above, and it really blows out of the window, there are two reasons for this development of events: the window was initially installed incorrectly, or the sealant that was used to install it sank and lost its properties.

In the first case, you need to contact the company that installed the windows and demand that they solve this problem. But if the warranty period has already expired, you can act on your own.

Unfortunately, the only way you can completely fix this problem is to completely reinstall windows. All other means will not be able to completely solve the problem, and sooner or later you will need a full repair.

The gap that has formed between the window sill and the window must be closed with a sealant. However, it does not apply to thermal insulation materials, so the room may be a little cool even after repair.

If the gap is very large, it will be possible to close it completely only with special foam. This should be done by a specialist.

In any case, when you have just installed plastic windows, you need to immediately check the work of the installers. Works of this magnitude should be carried out only by those firms whose reputation you trust.

Method 5 Insulation of wooden windows with mounting foam

Modern insulation that hermetically closes all cracks, cracks, both on the outside and on the inside of the window - polyurethane foam.

Removes gaps and crevices:

between the frame and the slope (pay special attention from the outside);

under the windowsill - the place where the warm air leaks the most;

between the window and the beam located above it;

between the slope and the window sill.

Insert the end of the tube into the crack and start blowing foam by pressing on the cap. After filling all the cracks, wait until it hardens, and remove the excess with a knife. Outside the window, the foam must be plastered or painted, since polyurethane foam (the composition of the mounting foam) is exposed to the damaging effects of ultraviolet rays.

It is necessary to remember:

- it is possible to work with polyurethane foam if the air temperature is not lower than +5° - (+30°);

- the foam is able to expand, so the frame must be secured with struts, otherwise skew is possible;

- we fill the gaps with mounting foam 1/3 of the width, because it, having increased in volume, will take the necessary space;

- filling goes from bottom to top along the seam so that there is no loss of sealant.

A cheaper, but troublesome way of warming is a putty of gypsum and chalk (2: 1) with the addition of water. With this mixture, we easily close the cracks, and the surface has a nice appearance.By the way, there was a time when gypsum bandages were used to insulate windows, which were used in medicine to fix bones in case of fractures. They were moistened with water and applied to the joints and along cracks and crevices.

Installing a rubber seal on a wooden window

For example, consider the option of mounting a self-adhesive rubber seal for windows and doors. Brown profile, 6 meters per pack. Suitable for gaps 2-5 mm.

Seal packing

Self-adhesive seal

Step 1. Preparation for work must be thorough - the sealant will not stick to a dirty and damp surface!

Wash the sash or frame with soapy water, wipe dry. If the window is painted and the paint peels off, we clean it with a spatula, after which we sand the surface, remove dust and wash the surface with a rag.

Step 2 We unfold the package. Remove the protective film from the seal.

Removing the protective film

We apply the seal to the frame or sash without pulling. We press by hand so that the bonding is better.

Bonding the seal

Step 3We close the sash and make sure that it no longer blows from the cracks.

The flap closes tightly

We glue the sealant without a self-adhesive layer on a sealant or glue. We apply the adhesive composition on a clean and dry surface with a thin layer, after which we press the profile strip. If excess glue comes out, wipe it off. We are waiting for drying and close the doors.

Wooden windows and seals for them

Old wooden windows were made without seals as such, and they didn’t come up with anything so that it wouldn’t blow out of the sashes in winter. And they plugged the joints with cotton wool, cloth, and put a pile of soft rollers on the windowsill ...

An outdated way of warming

Today on sale for both old and modern wooden windows there are modern sealing profiles that differ in the method of installation:

- on glue;

- with self-adhesive base;

- grooved.

Self-adhesive seals

Groove seals

In addition, seals vary in rigidity and size. The most rigid seals are chosen in cases where the gap is large and a tight fit of the sash is required. Soft seals are suitable for windows where the gap is uneven along the perimeter of the junction of the sash.

Thickness of seals from 1 mm to 12 mm. Product labeling is as follows:

- the thinnest (up to 1 mm) - C and I;

- no more than three millimeters - V and E;

- seals of medium thickness (about 5-7 mm) - P;

- all products thicker than 7 mm - D.

Sealing tape options

How to determine the size of the gap? You will need a small ball of plasticine, which must be wrapped in a film. We put the ball between the frame and the sash. The comb, which is “pinched” by the sash, will clearly show the size of the “problem”.

We have listed the main materials from which seals are made, but there are several more options for wooden windows.

-

Foam seal. Relevant, perhaps, only if finances are very limited, or quality does not play any role. Foam rubber - the material is soft, easily absorbs water, quickly dries out, deforms. And it won't last more than one year.

Foam seal

-

Polyethylene self-adhesive seals. A good option, quite durable, aesthetic, does not deform.

Self-adhesive sealant based on polyethylene foam

-

PVC and PU foam seals with an adhesive layer can become too soft in the hot season and freeze in the cold.

The self-expanding sealant is a self-adhesive polyurethane foam impregnated with a special mixture of modified acrylic

-

Rubber seals can be not only grooved, but also attached to glue or sealant, which should be included. Perhaps the best option for wooden windows.

Universal brown EPDM rubber seal

Universal acrylic seal