Basic rules for laying vapor barrier film

After finding out which side to the room or insulation you need to lay the vapor barrier material, you can proceed directly to its installation. In this case, the following rules must be observed:

- The first is the installation of heat-insulating, sound-proofing material, then a vapor barrier film.

- Secondly, the film should be well stretched, there should be no sagging areas.

- Third - the fastening of the vapor barrier material is carried out using ordinary adhesive tape (adhesive tape). You can also use nails with a wide hat (step - 30 cm) or a furniture stapler as fasteners, which will greatly facilitate the work and reduce the time it takes to complete. The film can be fastened with wooden slats, which are screwed with screws in 30 cm increments.

- Fourth, individual sheets of vapor barrier film are overlapped up to 15 cm. At the same time, it is necessary to make ventilation gaps up to 5 cm wide. These are general rules for the use of vapor barrier material, but when laying it on different bases, the roof has its own characteristics.

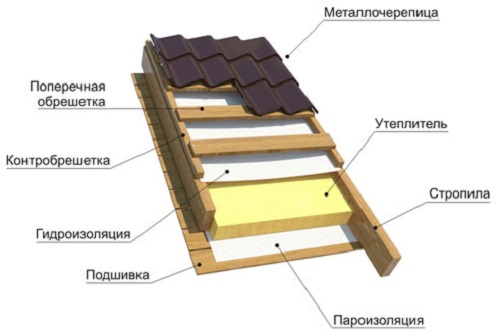

What is a roofing pie

In the process of studying the question of how to properly lay a profiled sheet, you will need to understand the nuances of arranging the roof structure. At the beginning of construction work on the construction of the roof, a truss system is mounted. This procedure must be performed in compliance with all technical standards, since significant static and dynamic loads are placed on the rafters during operation. It is better if this work is performed by specialists who have the appropriate skills in the design and installation of the structure.

Before laying corrugated board on top of the finished truss system, you need to decide on the lining material. This is directly affected by the type of roof structure and the characteristics of the material itself. For example, if the role of waterproofing is performed by a volumetric vapor-permeable diffuse membrane, there is no need to install a vapor barrier. Separate heaters endure exposure to moisture and are able to pass steam. Roofs are warm or cold - this is affected by the purpose of the room.

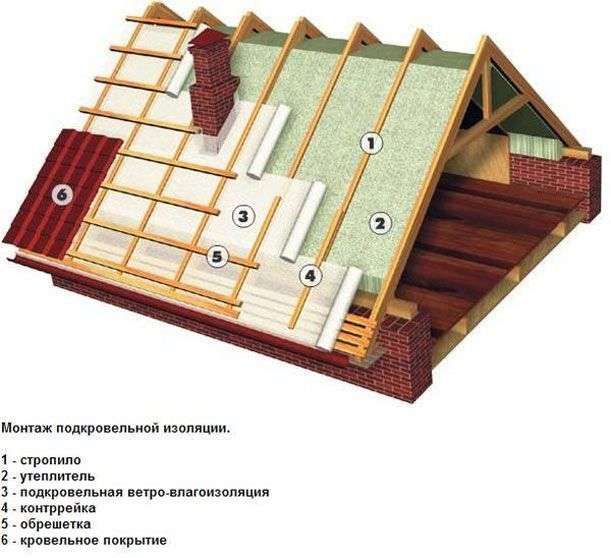

If we are talking about an attic room, then the roofing pie will include the following elements:

- Vapor barrier.

- Internal crate.

- Insulation.

- Waterproofing.

- Control grate.

- crate.

- profiled sheet.

A cold roof provides for the presence of only a waterproofing layer, which must necessarily have vapor-permeable characteristics. This will allow excess moisture in the room to leave it unhindered: in this way, the attic will be saved from the accumulation of dampness.

It takes much less time, effort and money to equip a cold roof than to build an insulated structure. After arranging the roofing cake, you can lay the roof with corrugated board.

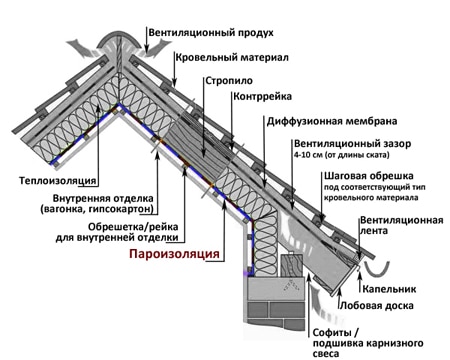

Vapor barrier installation

It does not matter whether you are making a vapor barrier for a flat roof or working with a gable roof - the film or membrane should be installed only after the insulation has been laid. Features of installation of vapor barrier:

Features of installation of vapor barrier:

- Cloths can be installed both vertically and horizontally.

- If you prefer horizontal installation, start installation from above.

- Lay the pieces of cloth with an overlap of at least 10 cm. Be sure to glue the seams with single-sided or double-sided adhesive tape.

- Choose a wide ribbon of at least 10 cm.

- Double-sided tape is glued inside the overlap - first stick it on the bottom layer, then remove the protective coating and fix the top one with an overlap.

- If you are laying a vapor barrier along the rafters without a rough filing of insulation, overlap and fix the sheets directly on the rafters.

- The vapor barrier is attached to a wooden crate or rafters with a construction stapler or galvanized nails (they do not rust).

- It is recommended to strengthen the places where the sheets are glued with clamping strips. This advice is especially relevant for roofs with a slope of up to 30 degrees and with loose thermal insulation.

- At the junction points to the aisles, hatches or dormer windows, a so-called dormer apron should be organized through the roof, which is usually included in their package. If it is not available, glue 2-sided butyl tape around the perimeter of the window frame or opening.

- In places where water pipes pass through the roof, wrap the vapor barrier material down, wrap it around the pipe and seal it tightly with electrical tape.

When the vapor barrier is laid, attach antiseptic-treated bars on top of it at a distance of 50 cm from each other. Thus, you will create an air corridor where condensate will quickly evaporate, and the film will not touch the ceiling sheathing. If you are using a vapor barrier membrane, the bars are optional. But they will come in handy to occupy this space with various communications. If you are planning to finish the interior of the house with drywall, use a galvanized metal profile instead of wooden bars.

Errors when installing vapor barrier

Very often, when arranging a roofing pie, builders make mistakes that lead to fatal consequences. If you confuse the location of the insulating layers, the roof may become unusable after a year of operation.

We have prepared a list of the most common mistakes when installing a vapor barrier:

- The joints of the film are not hermetically sealed, as a result of which the effectiveness of the vapor barrier is reduced to a minimum, the insulation becomes damp, and the truss structures begin to rot.

- Using a narrow adhesive tape to seal the seams - during operation, adhesive tape 5 cm wide or less will simply peel off. The recommended tape width is 10 cm or more.

- There is no deformation margin when working with window openings - any house shrinks, so it is required to leave a margin in the form of a fold of 20-30 mm.

- The film around the roof windows is not protected by the interior decoration - if this is not done, after a few months of operation, the vapor barrier will completely become unusable and collapse under the influence of sunlight.

- The film wraps around the rafters - if the vapor barrier material goes around the rafter legs, moisture will penetrate to the wooden elements, as a result of which they will begin to rot.

- Where the vapor barrier is adjacent to the internal walls of the house, shafts or chimney, it is necessary to take into account the specifics of the irregularities to which the material will be attached in order to ensure the tightness of the fixation.

- If you are attaching the film to a rough brick wall or rough wood surface, you can only do this with polyurethane, acrylic adhesive or synthetic rubber.

- Do not use polyurethane adhesive tapes and butyl rubber tapes, as they do not adhere well and may soon peel off the surface.

The penetrating power of water vapor is extremely high, so you should approach the vapor barrier device very responsibly. In addition to the popular Izospan, TechnoNIKOL roof vapor barrier is widely used today. The most important thing is to correctly select the materials and install them in the right sequence, then the roofing pie will last for decades without repair.

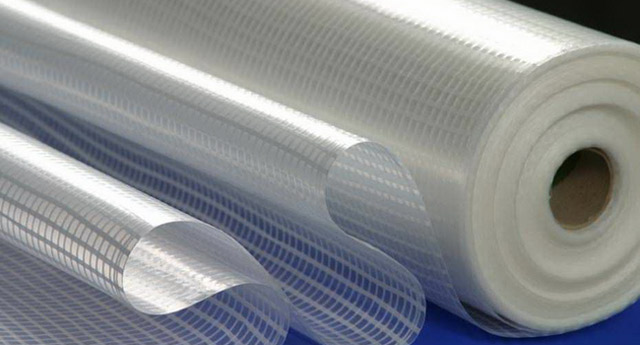

Vapor barrier materials

Today in the construction market you can find a lot of roofing materials. Most of these are films based on polyethylene. They are waterproofing, vapor barrier and antioxidant.The latter are special in that they are covered on the inside with an absorbent fleecy fabric layer that actively collects condensate, preventing it from getting onto the next layer of the roofing pie.

Previously, parchment was the main material for roof vapor barrier. Today, only overly economical builders use it, but if you look at the performance characteristics of glassine and compare them with the qualities of modern materials, then the benefits of the latter will be obvious.

Depending on the physical and technical parameters, three types of vapor barrier films can be distinguished:

- Polyethylene - used not only for steam, but also for waterproofing. Distinguish between perforated and non-perforated film. In any case, during installation, it is recommended to reinforce it with a light mesh or fabric. Perforated films are mainly used to provide waterproofing, non-perforated - vapor barrier. It would seem strange, because the “leaky” surface allows water to pass through, but the holes in the film are so small that water simply does not have time to seep through them. They serve for better ventilation of the roofing cake. There are also foil polyethylene films, one side of which is able to reflect the heat coming from below (from the house). Therefore, such material should be laid with the mirror side down.

The polyethylene vapor barrier is supplied in rolls. In the process of installation, the cuts of the material are glued together with special seals and adhesive tapes. Thus, a dense monolithic layer is obtained. - Polypropylene - have a higher strength compared to polyethylene films. They are mainly used for laying a waterproofing layer, but can also serve as a vapor barrier. On the one hand, they have an antioxidant coating of viscose-cellulose fabric.

-

Diffuse - a material that appeared only a few years ago. It is a well-ventilated membrane that has increased vapor permeability, but does not allow moisture to pass through. The main advantage of such a "breathing" vapor barrier is that it does not need to equip a ventilation gap in the under-roof space. Thus, you save space and time.

The diffuse vapor barrier film works very simply - when steam passes through it, it settles on a rough layer, is absorbed into it and dries evenly, leaving the insulation dry and unharmed. There are single and double sided films. One-sided can only be laid in a certain way on the insulation, two-sided - as you like.

All film materials used for vapor barrier must have good elasticity, be tear resistant and be as comfortable to use as possible.

It is extremely important that the vapor barrier film does not tear during fixing, but wraps around the fastener. Even in case of accidental mechanical damage to the roof, for example, due to a tree branch that fell during a hurricane, the vapor barrier must maintain integrity, minimizing losses.

Ideally, the thickness of the roof vapor barrier should be such that the material can withstand the load of thermal and waterproofing if the battens and rafters fail.

Vapor barrier isospan

One of the most popular materials in the domestic market is isospan roof vapor barrier. It is relatively inexpensive, has excellent performance, durability and ease of installation. Izospan can be used for waterproofing and as a vapor barrier at the same time.

The manufacturer offers several different modifications of Izospan, each of which is designed for a specific purpose, but there are also universal films.

Therefore, it is very important to clarify the characteristics of the selected material before purchasing, so as not to accidentally buy the wrong variation of Izospan

Izospan V is widely used among professional builders and self-taught owners. It can be combined with any type of roofing. In addition to protecting the insulation from moisture, it does not allow the microfibers from the cake to crumble inside the room, as is often the case with other materials.

Materials used and their installation

To resolve the issue of which vapor barrier to choose for the roof, the following materials are produced by the industry:

- Vapor barrier films. Are used for all types of roofs and roofing coverings. They are laid directly on the insulation with an overlap of 10 cm, for sealing the seams are sealed with adhesive tape. Sheathing is arranged while maintaining a ventilation gap of about 5 cm. It is recommended to fasten to the rafters with thin slats. Popular: Russian "Izospan", German "Delta" and "Tyvek" (manufacturer Luxembourg). The latter is the most expensive, but better quality and durable.

- Films from antioxidant materials. The inner side, facing inside the attic, consists of fleecy fabrics on which condensation collects and then evaporates without penetrating into the insulation. Laying is similar to vapor-tight. The most commonly used film is SVITAPFOL AC.

- diffuse membranes. Available in single and double sided. The former conduct pairs in only one direction, therefore they are stacked on a certain side. According to the number of layers, single and multilayer are distinguished. In multilayer, condensate accumulates with its gradual return. The membranes are thin, strong and durable, but expensive. They are laid close to heat insulators and do not require a gap device.

Installation of roof vapor barrier with membranes is an effective modern method.

The seams are sealed with hot air. On flat roofs with a concrete base, bituminous membranes welded onto concrete are good. The entire surface is completely covered with bitumen, creating a completely impervious coating, including fasteners. Vapor barrier materials from TechnoNIKOL, Bikroelast, Linocrom are of high quality. The only disadvantage of bituminous materials is their significant weight.

Laminated membranes consisting of reinforced films laminated on both sides and a foil screen (food aluminum) are fixed directly to the thermal insulators from the side of the premises with a mandatory ventilation gap.

The characteristics of vapor barrier and roofing materials must match in quality and durability, because the need to replace the vapor barrier layer will lead to a rework of the entire roofing pie.

The vapor barrier of the roof is extremely important for the durability of the entire building and the conditions for comfortable living in it. Incorrectly executed vapor barrier or its absence leads to moistening of the elements of the truss system with the appearance of fungus and mold, loss of thermal properties by the heat insulator (with an increase in the humidity of the insulation by 5%, its characteristics deteriorate by 2 times)

The role and functions of the roof

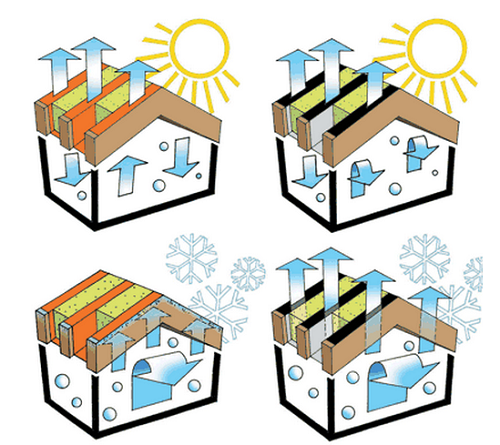

In order for the house to be warm, dry and easy to breathe, a competent combination of different design solutions is needed.

When choosing the design and shape of the roof, it is necessary to take into account not only its functional, but also decorative and artistic qualities.

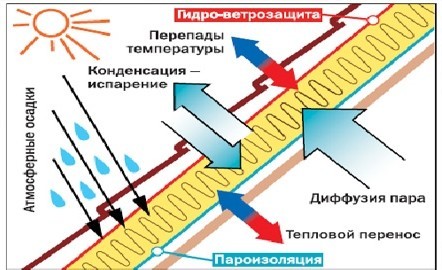

The roof experiences the greatest temperature, atmospheric, mechanical loads from the outside, as well as exposure to air and moisture from the inside of the room, so the technology of its construction with its own hands does not tolerate negligence.

Factors affecting the environment on the roof structure.

Roof features:

- Be warm (thermal insulation).

- Be waterproof (waterproofing).

- Be resistant to mechanical stress.

The first and third functions are achieved with your own hands by simply using durable roofing (tiles, metal, slate ...) and reliable heat-insulating (damask, mineral wool, expanded clay ...) materials, but to achieve 100% impermeability, a rather complex prefabricated filling is needed.

In this case, it is necessary to provide both waterproofing of the roof from the outside and internal vapor barrier.

Choosing the right roofing material

The modern construction industry offers a large selection of special films for arranging vapor barriers.They perform the same function, but have different physical properties and quality indicators. There are three types of materials:

- waterproofing films. Used to prevent steam from entering the heat-insulating layer. They have a special microperforation of the internal structure, due to which water vapor can pass through the coating into the outer space. They must be mounted in such a way that the film lags behind the roofing by the amount of the crate. Such a ventilation gap allows air to circulate between the outer and under-roof space, improving the vapor barrier. Thus, the material, which has one-sided permeability to water vapor, keeps the insulation and structures dry.

- Anti-condensation films. They have a special absorbent layer of fleecy fabric applied to their inner surface. It retains moisture, preventing it from flowing onto the insulation. Due to the air circulation in the ventilation gaps, it subsequently quickly erodes. The material allows you to provide reliable vapor barrier and improves the thermal insulation properties of the insulation. The anti-condensation film must be laid with an adsorption layer towards the inside of the room. At the same time, the pitch of the rafters cannot exceed 1.2 m. It is attached using a counter-lattice with a small ventilation gap.

- Vapor barrier films. They form a protective barrier on the inside of the thermal insulation layer of the roof. They can be equipped with a special reflex aluminum foil that is layered on the material. The foil is located in such a way as to reflect part of the radiant energy into the room, which creates a kind of thermos effect. The film is mounted close to the insulation with a mandatory ventilation gap, which prevents the formation of condensate on the inside of the material. Perfectly protects the structure from the formation of moisture and heat loss.

When choosing a material, experts recommend paying special attention to:

- Vapor permeability. The value characterizes the rate at which the vapor pressure equalizes between media separated by a vapor barrier film. The indicator depends on the structure and thickness of the material. The thicker the film, the lower the vapor permeability.

- Strength. The greater the margin of intrinsic strength of the material, the more reliable the finished coating will be. In addition, in the case when the heat-insulating layer loses its original elasticity and sags, a dense film will not allow the insulation to collapse under the influence of gravity.

- Fire resistance. A necessary condition for ensuring fire safety.

- Environmental friendliness. The material must be made from safe raw materials using "clean" technologies.

- Durability. The higher the service life, the less often it will be necessary to repair and redo the roofing cake.

Installing a vapor barrier

The difference in the partial pressure of water vapor in the cold season between the interior of the room and the street leads to an increase in the amount of moisture that tends to penetrate through the roofing cake to the outside. To stop this process, a high-quality vapor barrier layer is needed. To create it, dense high-molecular materials are used, characterized by low vapor permeability, and sealed fasteners.

For high-quality fixation of the vapor barrier, it is necessary:

- mount sheets or webs of material overlapping. The overlap of adjacent fragments must be at least 10 cm;

- use for fastening coatings special nails or self-tapping screws with a rubberized cap, which provide tight contact when twisting or driving.It is possible to use a construction stapler, the staples of which minimally deform the material and seal the place of penetration;

- when installing combined materials (polymer with reflective aluminum foil or non-woven geotextile), the smooth side of the polymer layer should be turned to the insulation;

- between the vapor barrier and the heat-insulating coating, it is necessary to leave a gap that provides ventilation and prevents the accumulation of moisture.

Video: Condensation on the roof + incorrect vapor barrier. Roof repair from Krovmontazh

Choosing a vapor barrier

Vapor barrier, namely a vapor barrier film, is an important component of the “roofing pie”

The vapor barrier film is attached directly to the rafter using a construction stapler.

It allows the accumulated condensate to escape and protects the thermal insulation materials so that they do not get wet.

The vapor barrier film is attached directly to the rafters, using a construction stapler, with an overlap of at least 10 cm, a roofing sheathing is laid on it and only then roofing material (slate, corrugated board, metal tiles, etc.). It is desirable to glue the joints of the film with construction tape (tape).

In addition, vapor barrier is also made from the inside of the room. In this case, the film is laid on the inside of the insulation, the counter rails are stuffed and sheathed with finishing material (GVL, siding, OSB, etc.).

It is necessary to do vapor barrier, since vapors, due to the temperature difference in the street and in a heated room, can settle on the insulation, as a result, the heat-insulating material becomes damp and will last much less. And thanks to the highly permeable vapor barrier, this condensate is released through the ventilation gaps.

Scope of application

Vapor barrier is usually applied:

- for the roof;

- for the ceiling;

- for the walls of a wooden house and not only;

- for the floor.

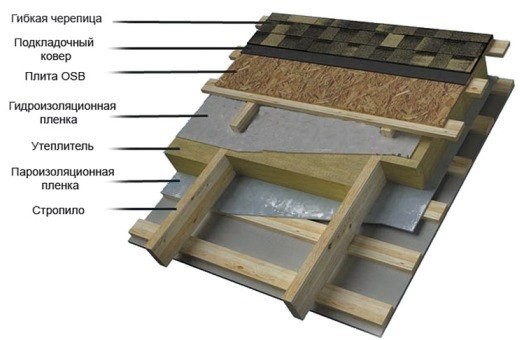

Roof vapor barrier

Vapor barrier of the roof is required in order to protect the insulation material from rising vapors. The absence of a barrier is the presence of moisture in the heat-insulating raw material, which is fraught not only with its destruction and loss of heat-insulating properties, but also with the formation of mold and fungus on the building structure. And getting them, as you know, oh, how difficult.

- internal lining;

- vapor barrier;

- rafter system;

- thermal insulation;

- wind and hydroprotective membrane;

- roofing.

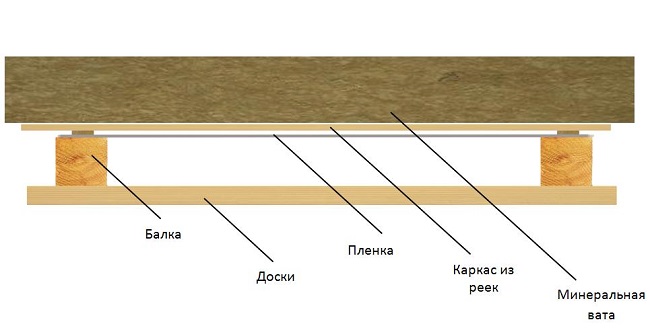

Vapor barrier of interfloor ceilings (ceiling)

Ceiling vapor barrier is necessary to prevent the penetration of moisture, which is born as a result of the passionate love of steam to travel up into the insulation. If the barrier is neglected, the thermal insulation will collapse and lose all its properties, and mold will “decorate” the ceiling.

- ceiling cladding;

- slats;

- vapor barrier material;

- rough flooring;

- beams;

- heat-insulating raw materials;

- vapor barrier material;

- slats;

- flooring.

Wall vapor barrier

The vapor barrier of the walls is carried out using a barrier known for first-class characteristics, since it has not one, but two tasks: the first is to keep steam away from the heat-insulating material and to the cannon shot, and the second is to show a direct path to moisture, which nevertheless managed to get into insulation. How does she get there? And it's easy. So, for example, through the formed cracks, cracks, gaps and joints.

- clean lining;

- rail;

- vapor barrier materials;

- frame;

- thermal insulation material;

- moisture-proof raw materials;

- rail;

- clean finish.

Floor vapor barrier

Floor vapor barrier is needed if:

- high humidity prevails in the building;

- the floor is insulated with mineral wool;

- concrete floor slabs are located above the ground.

- flooring;

- vapor barrier materials;

- thermal insulation material;

- logs (beams);

- waterproofing materials.

You can, of course, do without vapor barrier, but it is unlikely that living in a house will differ in the desired comfort and plush cosiness.

Does every construction project require a vapor barrier? Well, look, protection is required:

- in a building whose walls are insulated with mineral wool;

- in a frame house;

- in a structure whose facades are ventilated;

- in an object with a pitched or flat roof, insulated with fibrous or bulk materials;

- in a room in which there is no permanent heating system (for example, vapor barrier is needed for a bathhouse, for a country house, for a garage, etc.);

- in a building with high humidity.

If you have a design with the above features, do not spare money, buy a vapor barrier material so that in six months or a year you do not gallop around Europe in search of a new insulation and antifungal agents.

Do-it-yourself principles for proper roofing

Of course, there are professional builders who have worked out their own optimal one for any type of premises, but often, for various reasons, both construction and repair work have to be done by hand

And here it is important to know the basic principles, including modern, competent roofing.

Not so long ago, almost all buildings had so-called cold attics, when a well-ventilated non-residential space is located between the roofing and the living space. In this case, the ceiling of the last floor is insulated, and the vapor barrier is laid directly on the floor under the insulation.

Roofing cake.

Recently, warm attics or attics have become widespread, when residential areas are brought directly under the roofs. In this situation, the roof itself is insulated. The design of such a roof is a kind of building cake, in which the extreme layers are the outer and inner coatings, in the middle there is a powerful layer of thermal insulation, it is separated from the outer coating by a waterproofing layer - a hydrobarrier, and from the inner one - a vapor barrier or vapor barrier.

The scheme of a modern multilayer is as follows:

- inner lining;

- vapor barrier;

- thermal insulation;

- wind and moisture protection (waterproofing);

- crate;

- counter-lattice (creates a ventilation gap);

- roofing.

Thus, vapor barrier is the most important element of the roofing device.

Purpose and location of the vapor barrier

It is known that the roofing cake consists of several layers (that's why it is called so). It may include a different number of layers, but hydro, heat and vapor barriers remain unchanged. And if the waterproofing is designed to prevent moisture from penetrating inside the house from above, then the vapor barrier does not allow evaporation from the inside to enter the roofing pie.

It is extremely important to place the vapor barrier below the thermal insulation material, otherwise it will absorb steam coming from below, swell and become damp. However, we all know that there are non-insulated roofs, can they really be made without vapor barrier? Unfortunately, no - the vapor barrier not only preserves the insulation, but also maintains a comfortable microclimate indoors

If it is not there, the house will be very stuffy and humid, and cozy housing will turn into an ordinary greenhouse.

In order to fully appreciate and understand the roof vapor barrier device, you should study the structure of the roofing pie:

- Roof covering can be continuous or consist of segments (tile, slate). It is laid on a wooden crate or a monolithic base.

- Waterproofing layer - protects subsequent layers from the penetration of moisture from the outside. It is a waterproof non-woven material that is attached to the crate, leaving a small gap between the next layer.

- Insulation - roofing heat-insulating materials are plates with minimal thermal conductivity.They can be made from pressed mineral or rock wool, styrofoam or polyurethane foam. Depending on the material, water absorption is also different, which also affects the choice of vapor barrier. Polyurethane foam and polystyrene are practically not afraid of moisture, but mineral and stone wool require the installation of high-quality vapor barrier.

- Vapor barrier layer - films or membranes are installed on the crate immediately after the insulation and leave a gap between the sheathing ceiling material to ensure natural ventilation. When water vapor coming from below hits the membrane, condensate will form, which will flow down and dry out due to the ventilation of the under-roof part.

Even the highest quality and most modern vapor barrier will not “work” if you do not take care of roof ventilation. Ventilation is important at any time of the year - in winter it will help to keep warm and prevent ice on the roof, and in summer it will give more coolness.

If the roof of the house is missing or incorrectly installed vapor barrier, this will inevitably lead to the formation of non-weathered condensate, dampness, mold and fungi. Eventually the wood structures and roof elements will rot and collapse.

Varieties

The owners of companies specializing in the production of vapor barriers, unlike the owners of certain structures, understand that their product plays an extremely important role in the construction industry. In view of what they produce a material that differs in composition, price, properties and purpose. As they say, we are happy to try, which is quite good, because there are plenty to choose from.

So, the following types of protective material proudly flaunt on the market:

Ordinary polyethylene

Polyethylene film is the simplest material for vapor barrier. To date, perforated and non-perforated films are on sale. For vapor barrier, as a rule, non-perforated films are used. The advantage of the product is its low price. Disadvantages - short service life.

Reinforced polyethylene

Polyethylene reinforced with a twisted polymer thread is usually used for vapor barrier or ceiling, or walls, or floors. Why? Because it does not allow moisture or air to pass through - and this is a plus. However, if you decorate the whole room with them, you get the effect of a thermos - and this is a minus. In addition, the raw material has an advantage - a pleasant price and a disadvantage - a minimum service life.

Membrane insulation

Membranes are an innovative material designed to reliably protect heat-insulating raw materials from steam. Single and double sided products available

The first conducts steam in one direction, which is why it is important not to confuse which side to lay the vapor barrier material to the insulation. This is stated in the instructions for each material.

The second acts in two directions, therefore it is attached to the thermal insulation on either side. Single and multilayer membranes are also available. By the way, the second option can collect moisture, and then, when required, give it away. Advantages - durability, wear resistance, environmental friendliness and functionality. The disadvantage is the high price.

foil insulation

Foil vapor barrier is a versatile raw material that plays a role and vapor barrier. and hydro. and sound. and thermal insulation. And it is also an impeccable material for protecting the insulation, where would you think? That's right, in a bath or sauna, because it is not afraid of high temperatures and humidity.

It is attached with a furniture stapler. and the joints are glued with metallized adhesive tape for vapor barrier. A typical example is foam. Advantages - long service life, versatility, wear resistance. And the disadvantage is the high price.

Burlap is a raw material designed to protect heat-insulating material. Its basis is polypropylene film-type threads. They are laminated with low pressure polyethylene.The layer thickness reaches 20 microns. Advantage - low price. The disadvantage is the formation of microcracks.

There are other types of material, but they are either "children" or "parents" of the above raw materials. In view of what I see no reason to talk about them. I will say one thing: today the best barrier is a membrane. It's expensive, but totally worth it.