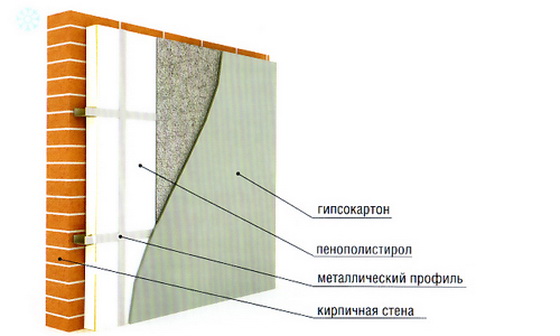

An example of using insulation inside a wall structure

The photo below shows a fragment of the implementation of thermal insulation work during the construction of non-residential premises.

After the publication of the article, during its discussion, different points of view were expressed on the use of this method of insulation. Now, after six years of using this premises, I can only confirm that in terms of "efficiency - price" I had no other alternatives. Moreover, structurally this room is almost closely adjacent to the house. It is almost impossible to make external insulation of the room along the wall adjacent to the house. If I had left one wall without any insulation, the temperature in the boiler room would have been noticeably lower. Now, depending on the frost, the temperature is stable around (10-15) degrees in the absence of heaters in the boiler room and hallways.

Since my house is wooden, I am not talking about the main method of using foam plastic as an external facade insulation. Moreover, there are many publications on this topic. I will only highlight a few of the most important points.

- Firstly, despite the higher performance of extruded polystyrene compared to foamed polystyrene (in terms of thermal insulation, mechanical properties, etc.), it is impossible to use extruded polystyrene when insulating the facade of a brick building. This is explained by the fact that it has such vapor permeability indicators that it is practically impossible to select a wall material with the appropriate vapor permeability in private construction.

- For external facade insulation of a brick structure, only foamed foam is suitable. It is recommended to use foam specifically designed for this, such as PSB-S-25F (facade). Although, as practice shows, the usual one is quite suitable. Do not use foam with a lower density (such as PSB-15).

- Another important point that really takes place in practice when insulating the facade of a house with foam plastic is the use of foam plastic in one layer, usually 50 mm thick. For most regions of the Russian Federation, from the point of view of the effectiveness of insulation, such a layer of thermal insulation is clearly not enough. In addition, when insulating with foam plastic in one layer, the number of non-closed joints during the installation of PSB sheets along the entire facade of the house will be quite large, which will further reduce the quality of thermal insulation work due to the formation of cold bridges. Those. foam must be insulated in two layers in a checkerboard pattern (with overlapping joints).

Wall preparation

Even taking into account all the ease and simplicity of this work, it has many nuances and subtleties. For example, preparing a wall. This is the initial stage of work.

Here are some tips:

If your house is brick, then its walls should be plastered.

Next, the surface dried from the putty is primed and the final alignment is carried out with putty.

And provided that at the same time as the insulation in the house is also being repaired, then the following conditions must be observed:

- Cleaning the work surface from the previous material: paint, wallpaper, cork;

- Search for defects and irregularities in the wall;

- elimination of these defects. Here putty or plaster will come to the rescue again. And large cracks can be eliminated with mounting foam;

- Leveling the restored surface;

- The resulting smooth walls should be primed again: this will ensure the reliability of the installation of the material.

- Laying waterproofing material. It will limit the access of moisture to the insulation. As a rule, polyethylene film can serve as such a waterproofing material, although the modern building materials market provides an unlimited amount of such material.

So, before starting laying, you need to make sure that the wall is dry, the heat insulator layer has no cracks or joints, the insulator has maximum moisture resistance.

Thickness and density for home insulation

First of all, expanded polystyrene is distinguished by density. Based precisely on the nuances of this property, the following grades were assigned to the foam: 15 - the most loose polystyrene, the most fragile and least thermally conductive; 25 - has sufficient density, is easy to use, and it is used for construction work and insulation of a private house with foam; 35 is a very dense foam that can be safely used in areas where some load is expected.

The density mark number is the thickness of the foam board in millimeters.

In addition to the above standards, foam sheets can have a density of 100 mm. Ten centimeters thick! This is already, almost finished, a fairly solid wall. Such foam is used to create special conditions in the structure. For example, if a full-fledged cellar cannot be dug out due to the proximity of groundwater, they build a ground storage facility for products with decent wall thickness, supplemented with foam-paste protection.

Advantages of polystyrene foam insulation

The advantage of wall insulation with polystyrene foam is that this material is inexpensive, easy to install and durable enough to use. If you do everything right, put a layer of decorative plaster on top, then such a coating will serve for a very long time, and will save more than one thousand rubles.

There is a large selection of this material, in size and density. The maximum density is 50, one such sheet 5 centimeters thick allows you to replace about 50 centimeters of concrete in terms of its thermal insulation. Therefore, when choosing the density of the material, you should take into account the climatic zone where you live.

If the expanded polystyrene is chosen too dense, then the house will not “breathe” well, which will negatively affect the microclimate. Air exchange will be difficult, and there will be a thermos effect inside, which will make the walls get wet and mold and fungus may appear.

Therefore, from the very beginning, decide what thickness of polystyrene foam will be optimal for you, so that later there will be no problems. Next, we begin the very insulation of the walls with polystyrene foam.

Facade insulation

Wall insulation is most often carried out outside the house, and there are more than enough reasons for this. Firstly, the internal usable area of housing does not suffer. Secondly, insulation is easy to carry out both at the stage of building a house and already in the process of its operation. Thirdly, even styrofoam boards perfectly smooth the surface and serve as an ideal basis for applying the finish coat.

The thickness of expanded polystyrene sheets for external insulation should be about 10 cm. If you purchased thinner sheets, they will have to be applied in several layers. Only with a thickness of 9-10 cm can you create reliable protection against cold and wind, as well as reduce the outflow of heat from the room by 50%.

How is the wall insulation with polystyrene foam outside:

First of all, you need to prepare the wall - remove or clean the old coating and level the surface. If plaster is applied to the wall, then it can be left, but if the coating is old, cracked and crumbling in places, it is necessary to get rid of it and putty all the holes. Perhaps the only significant drawback, or rather, the difficulty of working with polystyrene foam, is that it is necessary to level the walls. Sheets of material will only adhere firmly to a flat surface.

When the wall is prepared, you can start gluing the polystyrene foam boards. For fixing, use a special weather-resistant glue and “mushroom” dowels.

Before gluing the sheets to the wall, they must be scratched with something to make the surface rougher - then the glue will hold well.

To fix the first lower row of expanded polystyrene plates, a base profile should be attached, the width of which is equal to or slightly greater than the thickness of the insulation. The installation step of the profiles is 30 cm. In order for it to fit snugly against the wall, it is screwed with special washers, and the ends are joined with connecting elements with a gap of 2 mm. Corner profiles are used at the corners.

Start the installation of polystyrene foam should be from the bottom up from the corner. So the sheets will not slide down during the setting of the adhesive mixture. However, even professional builders cannot get away from small shifts. In this case, their own standards are provided - the maximum allowable shift is 10 cm.

Laying is carried out end-to-end and as tightly as possible, but in no case should glue get into the junction.

When the entire wall is pasted over with polystyrene foam, it must be closed as soon as possible so that direct sunlight does not harm the material. For this reason, it is not recommended to interrupt work at this stage.

A special adhesive mastic is applied over the plates, in which a fine facade reinforcing mesh is embedded.

Important: When choosing a mesh in a store, be sure to check with the seller if it is suitable for outdoor work.

The mesh is needed to strengthen the surface and increase rigidity before applying the plaster. If you plaster the wall directly on polystyrene foam (albeit rough), then it will not hold and eventually fall off under its own weight, maybe even together with insulation.

When the mastic dries, and the mesh will hold securely inside, the wall is covered with another layer of mastic to level the surface.

A primer is applied over the mastic so that the plaster holds as firmly as possible.

Only after that you can proceed to the finishing of the facade - covering with decorative plaster, artificial or flexible stone, siding, etc.

We recommend that you familiarize yourself with an interesting article on the related topic “Facing facades with stone”.

Thermal insulation of the house outside should be carried out in not too hot, but not rainy weather. Despite the fact that expanded polystyrene is not afraid of water, other materials can be saturated with moisture, and as a result, the quality of work will decrease significantly. The air temperature must be at least +5C. It is recommended to carry out the work promptly, but do not rush and wait for the layers of material to dry completely before applying the next ones.

The video on wall insulation with polystyrene foam shows in detail all the stages of work:

https://youtube.com/watch?v=yYClVc3ptLg

Is it possible to insulate walls with foam from the inside

Before you start to be interested in warming the house from the inside, let's remember what polystyrene is, its positive and negative sides. It is a special composition of expanded polystyrene, which is foamed in a certain way. Styrofoam for wall insulation inside has the following properties.

Perfectly insulates (keeps heat well in the house);

Does not load the foundation, because it has a low weight;

Beneficial: has an inexpensive cost;

Does not absorb moisture;

It does not penetrate mold and fungus.

When heated, it emits an unpleasant odor;

It ignites quickly because it has a low fire resistance;

Poor air passage;

Reduces living space.

From the foregoing, it can be decided that it is possible to insulate walls with foam only from the outside. But it is not so. You can insulate your room from the inside. But this can only be done in certain cases:

If the building has architectural value and the authorities put a ban on changing its facade;

There is an expansion joint between the buildings behind the wall;

If the adjacent room is unheated, in which it is not possible to conduct insulation. For example, an elevator shaft.

But it should be remembered that the insulation of walls inside the apartment can only be really effective if such a process is provided for by the construction project.

The benefits of polystyrene

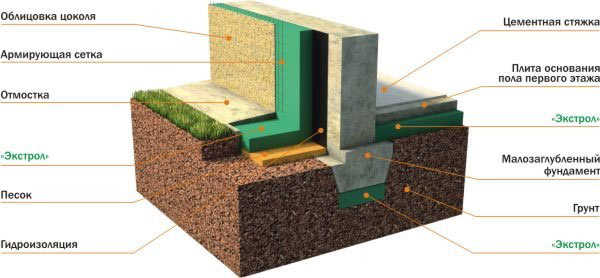

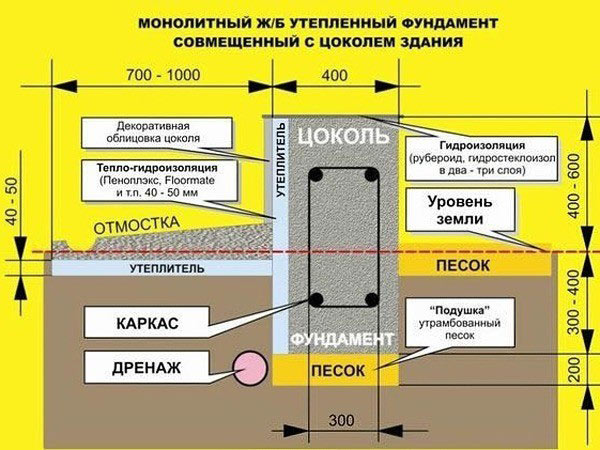

The scheme of thermal insulation of the foundation.

A building material such as polystyrene has recently become very popular for insulating apartments. Warming the house with polystyrene has become in demand due to the advantages of this building material, among the advantages it is worth highlighting the following:

- High rates of thermal insulation. The thermal conductivity of polystyrene is several times higher than that of natural materials such as wood and brick. So, for example, to insulate the facade of a house, it is necessary to use a foam sheet 12 cm thick instead of a wooden insulation 45 cm thick or brickwork 2 m 10 cm.

- Wide range of application temperatures. Polystyrene can be used at temperatures from -180°C to +80°C, which allows the material to be used in different climatic conditions.

- Ease of installation of polystyrene. polystyrene can be done independently without the involvement of professional specialists. During installation, there is no need to use expensive equipment or materials.

- Such a system of insulation is distinguished by its efficiency and reliability. The instructions for using polystyrene say that this material is resistant to wear, during operation it does not lose its size, shape and properties. According to manufacturers and experts in this matter, which is confirmed by practical research, the thermal insulation created by polystyrene can be effectively used for 30 years.

- The ignition temperature of polystyrene is much higher than that of other building materials. If this material is treated with flame retardants, then the material does not lend itself to combustion at all.

- Resistance to moisture absorption. Polystyrene is considered a unique building material, because it does not dissolve, does not absorb moisture and does not deform. There is one small nuance: a special coating must be applied to the surface of the insulation, which will significantly reduce the rate of moisture penetration inside.

- High level of noise absorption. Polystyrene is a porous material, which is why it perfectly traps air and does not let extraneous sounds into an insulated room. The thicker the plate, the higher the sound insulation performance.

- Environmental friendliness. Polystyrene is completely safe for humans and nature. It is non-toxic and does not emit toxic substances into the atmosphere.

- Profitability. The initial price of a polystyrene board is much lower than other thermal insulation materials. Material costs in the process of insulation are low, which significantly reduces the total cost of construction work.

Following all the above tips, you can quickly and easily insulate your house with polystyrene with your own hands. When insulating a house with this building material, you can not only keep warm, but also protect the room from fungus and protect it from noise.

Warming inside

Before proceeding with the insulation of the walls of a private house with foam inside, you need to pay close attention to some details:

- the presence of gaps between the door (window) openings and the wall. If there are any, they must be urgently eliminated;

- tightness of windows;

- the quality of the heating system (if the batteries are old, they will have to be changed or sections added).

The preparation of the walls in the case of insulating the house from the inside with foam plastic is identical to the preparatory work outside: we level the walls, remove the old putty and paint, remove all the nails and screws, wash the wall surface.

The list of tools and materials is similar:

- Styrofoam;

- antifungal putty;

- glue or cement-based adhesive;

- "umbrellas";

- mesh and tape;

- roller;

- spatulas;

- drill.

The surface to be insulated must be dry, even and clean - a universal requirement for such types of work.

Installation of foam inside is usually started from the lower far corner. Holes are made in the slab and an "umbrella" is driven in. "Umbrellas" in one sheet of foam should be placed on average 5-6, and the cap of each should fit snugly against the surface of the foam (do not stick out and do not "sink").

Judging by the experience of most of the owners who carried out the insulation of a private house with polystyrene foam, it is most inconvenient to mount the last element of the insulation in a row - it must be adjusted in size.

When the insulation is applied, the seams and hats of the "umbrellas" are masked. Regarding the seams: if they are narrow, then they are simply blown out with foam, and the wider gaps are laid with foam scraps.

IMPORTANT! To insulate the walls from the inside, it is better to use thin sheets of foam - 20-25 mm. Thus, you will not “steal” the place .. A reinforced tape is applied to the finished wall and attached with an adhesive, then a mesh

There is one feature in fixing the grid on the wall: it is embedded in glue, and after drying it is treated with sandpaper

A reinforced tape is applied to the finished wall and attached with an adhesive, then a mesh. There is one feature in fixing the grid on the wall: it is embedded in glue, and after drying it is treated with sandpaper.

The final stage is decoration.

brick house

In this case, the insulation is fixed with adhesive mixtures. They are preferable because of their ability to "cling" even to a not very prepared surface. Although here it is necessary to take into account the element of economy: if the brick mill is leveled and prepared, then the consumption of the mixture, respectively, will be less.

Warming a private house with polystyrene foam is the most common way among the owners of brick housing.

frame house

When insulating a frame house with polystyrene foam, the insulation is laid between the skin, having previously protected it from moisture.

You can use sheets with a density of 50 to 150 mm - they will provide a high energy-saving effect.

wooden house

Thermal insulation is produced inside the house, it also plays the role of sound insulation. The walls are sheathed with slabs 4-5 cm thick, leaving a kind of air “cushion” between them and the wall, which will protect the material from moisture.

Inside timber houses foam sheets can be sheathed with drywall.

Hydraulic accumulators for water supply

How to choose what to pay attention to, types .. And this article talks about autonomous gasification of a private house

And this article talks about autonomous gasification of a private house.

Modern insulation with polystyrene

If it is necessary to insulate the whole house or a separate room with polystyrene, you should first purchase the necessary building materials

The first step is to pay attention to the thickness of the polystyrene sheet that you want to purchase. If your house is built of white, silicate bricks using reinforced concrete block, then you need to choose a five-centimeter polystyrene sheet

Scheme of insulation of the foundation with foam.

If there is a foam block pillow in the house, then the thickness of the polystyrene sheet may not exceed 2 cm. In addition to the sheet of building material, you need to buy a special glue for gluing polystyrene sheets to the surface. To do this, you can use a special adhesive VSH 39 and plaster on the surface of the wall brand VSH 40.

Table of comparative characteristics of thermal insulation materials.

A complete list of the necessary materials and tools for creating thermal insulation is as follows:

- polystyrene plates, the dimensions of which in each case are selected the same;

- special glue (for example, VSH 39);

- parachutes at the rate of 3.5 for each sheet of material;

- dry putty mixture (for example, VSH 40);

- special mesh with a section of 5X5 and with a density of 145 g per m;

- notched trowel;

- straight spatula with a length of at least 30 cm;

- punch drill.

Particular attention should be paid to the surface of the walls on which polystyrene sheets will be glued. If the wall is created using silicate brick, that is, it is smooth, then you can use a special primer that will significantly improve the adhesive ability of the material

Wall preparation and framing

Before starting work, it is necessary to prepare the surface of a brick (or other) wall. It is necessary to remove the old paint, peeling plaster, clean it from oil stains or other contaminants. Then the quality of the surface should be assessed and, if necessary, a leveling layer of plaster should be applied. After it has cured, you can proceed with the installation of the crate.

The location of the lathing bars is perpendicular to the future sheathing strips - for vertically located wall panels (for example), the lathing is placed horizontally and vice versa. The step of the bars corresponds to the size of the insulation boards in order to avoid unproductive material losses.

The thickness of the bars should correspond to the thickness of the PPS or be slightly larger. It is recommended to cover the bars with an antiseptic to protect against mold or fungus.

Installing a wooden crate