The choice of insulation

Thanks to the emergence of new modern heaters, frame houses have gained their popularity. The core of the frame structure is an effective and safe insulation

It is very important that the thermal insulation material retains its functionality for many years. In frame construction, the choice of insulation is a responsible and serious process.

All thermal insulation materials are divided into two types - organic and synthetic (inorganic). Organic insulation has been used since ancient times. These include shavings, sawdust, peat, tyrsa, straw and other materials. The second type of insulation is polystyrene foam, polystyrene foam and mineral wool. They are more modern and optimal for warming frame houses.

Styrofoam is considered the most popular insulation for frame houses. It has a number of significant advantages: low cost, lightness, ease of use.

This material practically does not absorb moisture, and this is a very important quality of insulation.

A big disadvantage of polystyrene is its strong flammability. When foam plastic, as well as polystyrene foam, ignites, toxic combustion products are formed. Styrofoam sheets are brittle and should be checked for cracks and damage.

Mineral wool

Recently, mineral heaters have been increasingly used to insulate walls and ceilings in frame houses. Basalt wool is produced in the form of a fibrous substance in the form of dense slabs. Insulators are very popular, which consist of glass fibers, 10-15 cm long and several times thinner than a human hair. These heaters are simple and easy to install, non-flammable, resilient and elastic, perfectly retain their shape. Due to the air gaps, fiberglass isolates sound and heat well.

This material has a drawback - the content of formaldehydes harmful to health. Small fragments of fiberglass and mineral wool are harmful to human health. To reduce the possibility of a negative impact, they are produced in the form of pressed plates. After insulation, frame houses are finished from the inside with vapor barrier membranes that cut off small particles and prevent them from penetrating into the room.

In Canada, where frame construction originally appeared, instead of a vapor barrier membrane, walls, floors and ceilings are covered with thick polyethylene. The seams and joints of the sheets are glued with adhesive tape.

Wadded heaters are afraid of getting wet, in which the thermal insulation properties are significantly reduced.

With this type of insulation, serious attention should be paid to waterproofing. The service life of mineral wool is approximately 25 years

After this period has elapsed, the heater will have to be replaced.

Ecowool is the most modern material. It consists mainly of cellulose, which is treated with an antiseptic (boric acid) and a fire retardant (borax). These substances are non-volatile and non-toxic. The material resists fire well, does not rot, is an excellent insulator of sound and heat.

Ecowool is considered one of the best insulating materials. After installation, the resulting thermal insulation layer is obtained without voids, seams, voids. The insulation fills all the cavities and cracks, and the insulating layer protects well from the destructive influence of the natural environment. Installation of heat-insulating protection from ecowool requires high qualification and the use of special equipment.

Fire protection of metal structures of two different types

Structural fire protection system for steel structures ET Profile

Structural fire protection system for metal structures with different fire resistance limits.

It provides for the use of basalt fire-retardant foil material (MBOR) in combination with the fire-retardant adhesive composition "Plazas".

It is used to protect against the effects of open flame and high temperature in the event of a fire in buildings and structures of any type and purpose.

To learn more

Structural fire protection system for metal structures ET-Metal

Structural fire protection system for metal structures with different fire resistance limits.

It provides for the use of EURO-LIT basalt mineral refractory board in combination with the fire-retardant adhesive composition "Plazas".

It is used to protect against the effects of open flame and high temperature in the event of a fire in buildings and structures of any type and purpose.

To learn more

Environmental cleanliness, radiation safety

Basalt insulation Tizol, which is used as the main material for fire protection of metal structures, is made from natural, environmentally friendly raw materials - basalt.

It is absolutely safe for use in residential and industrial areas, does not contain adhesives or binders, and therefore does not emit harmful substances even under high temperatures or during prolonged use.

EFFICIENT FIRE PROTECTION

Due to the fact that basalt fiber is able to withstand temperatures up to 1000 ° C, the material made from it is able to significantly enhance the refractory properties of metal structures protected by it.

Vibration resistance, moisture resistance

Even in conditions of increased vibration, all the unique properties of Tizol basalt insulation remain unchanged. Pressure, bending and compaction of the material do not lead to a deterioration in its physical and mechanical properties, since basalt fiber is able to withstand high static and vibration loads.

Low structural load

The material used for organizing fire protection is basalt mineral wool.

In the material for fire protection of metal structures, this wool is formed in the form of a canvas or plate and has different thicknesses and densities, which makes it possible to optimally calculate the fire resistance threshold and the consumption of the required amount of material with a minimum load on the structure.

Aesthetic appearance

The surface of metal structures coated with fire-retardant material MBOR looks aesthetically pleasing and finished. In this regard, there is no need to use additional decorative means.

The surface of metal elements, covered with fire-retardant basalt slab, can be plastered or covered with various non-combustible building materials, which will give it a completely aesthetic appearance while maintaining all fire-resistant characteristics.

Frame wall insulation technology using mineral wool

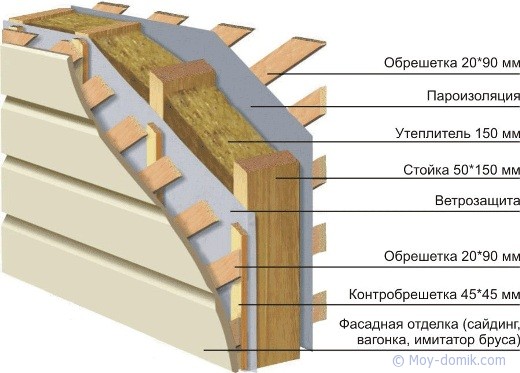

The technology for installing thermal insulation in frame housing construction is almost the same for all materials, so the procedure for insulating frame walls can be considered using mineral wool as an example.

The frame of the wall from the inside of the room is sheathed with particle boards, joining them along the beams and strapping beams. Subsequently, the walls are covered from the inside with a vapor barrier film and finished with drywall or clapboard. Outside, layers of insulation are laid. Their number depends on the region where the house is being built. To prevent cold bridges, laying should be carried out with overlapping joints of the previous layer. After installing the insulation, the last layer is covered with a windproof membrane and fixed with a stapler.

A crate is stuffed on top of it, which will hold the insulation and create a ventilation gap between the membrane and the outer skin.

After the crate, chipboards are mounted, which can later be closed, for example, with clapboard, siding or other finishing materials.

When choosing a heater for a frame house, the most important criterion is its price. But it is impossible to save on the insulation of an environmentally friendly building. The increased price of insulation will pay off many times over in the saved thermal energy. If the thickness of the mineral insulation is 200 mm, this is equal in terms of thermal conductivity to 500 mm of a wooden wall, or 1000 mm of stone. But such results can be achieved only with the correct installation of insulation, hydro and vapor barrier.

Features of frame walls

Moisture, which is formed and accumulates in the cavity of the frame, is the main scourge of the insulation. It can penetrate from the outside from rain through cracks or form as condensate. Moisture has a detrimental effect on the thermal insulation material, especially on mineral wool. Therefore, during frame construction, it is necessary to protect the insulation well, equipping high-quality waterproofing. Ground moisture should also be taken into account, which rises up from the foundation.

Over time, various gaps appear in the construction of panel houses, which lead to blowing, water leakage and violation of the vapor barrier. The easiest and cheapest way to eliminate them is to fill the gaps and seams with mounting foam or foamed polyethylene. After their application, additional protection from moisture and ultraviolet rays is required. The frozen layer of foam or polyethylene is treated with a layer of waterproofing mastic.

Proper insulation of a building made of metal structures

There is a lot of information about non-destructive insulation systems used in construction. But there are few adequate sources that describe the correct insulation of a building made of metal structures.

Therefore, we decided to pay attention to this topic and tell the reader about the properties of thermal protection, which, in terms of its technological and operational parameters, will be the most functional in the project.

Proper insulation of a building made of metal structures is distinguished by technology and methods that are habitually grouped into external and internal. First, consider the question of whether there is a difference in the use of heat-shielding technologies in various operating conditions of metal buildings and structures.

In addition, there are fewer problems with servicing them than with construction projects from the times of the USSR, built of brick or reinforced concrete panels. But it has long been known that metal has a high thermal conductivity, which is why proper insulation of a building made of metal structures is required.

Various specialists from different branches of construction, science and technology are working on the creation of thermophysical properties. Experimentally, they achieve the necessary indicators, and with the help of simple mathematical dependencies, they create the theoretical physics of the process. In practice, the correct insulation of a building made of metal structures cannot be carried out outside the factory. In the same way as it is impossible to determine the reliability characteristics of strength. Therefore, we control the heat-shielding properties of multilayer building structures and products during their production.

In order for metal structures to be used for a long time, without violating the integrity and performance characteristics, it is necessary not only to insulate them, but also to reliably protect them from moisture, while not weighing down the elements of the frame system.

In modern production, machines and equipment are used, with the appropriate software algorithm, which ensures the correct insulation of the building from metal structures. Using this equipment, the manufacturer can be sure of the quality of their products.

Metal structures are produced after the calculations. Due to the required thickness and additional thermal insulation in the enclosing building structures, construction objects have high thermal insulation performance.

In addition, the correct insulation of a building made of metal structures includes such characteristics as:

- Low thermal conductivity - the effectiveness of preventing heat loss in winter and protection from heating in summer;

Plasticity - integral insulation of the frame with materials that evenly cover the structure of any shape;

Lack of additional fasteners - adhesion - the ability to stick to various surfaces;

Impermeability to gases and liquids - protection of the coated surface from the negative effects of moisture and various gases;

Vapor permeability - the ability to pass steam from the inside;

Durability - the service life of the insulation should be equal to the life of the building;

Environmental friendliness - the inadmissibility of the release of substances harmful to health.

Proper insulation of a building made of metal structures is the result of the competent use of insulating materials, which are now in great abundance in Russia. Our company has many options for thermal insulation, but each project uses the most effective method of insulation, which allows you to create optimal additional thermal insulation of metal structures of buildings in order to ensure the energy saving conditions indicated in the urban planning complex of Russia.

You can find out about thermal insulation materials online by referring to the publications of the Encyclopedia of Construction. If you are interested in the correct insulation of a building made of metal structures, taking into account the current GOSTs and SNIPs, please contact the specialists by phone and ask your questions. We are waiting for orders!

Do-it-yourself installation of the frame of the house and the roof from a metal profile pipe

Previously, a profile pipe frame was installed only at industrial facilities - builders used a similar metal frame in the construction of a workshop, warehouse, hangar and other similar structures.

However, at the moment, after a qualitative improvement in building technologies (modernization), builders put a metal frame during the construction of such structures as:

- residential apartment building. In a similar situation, workers build 1-3-story houses;

- cottage;

- supermarket;

- a restaurant;

- car refueling;

- office, etc.

The frame can be made for both residential and non-residential buildings

Also, buildings from a metal frame are erected during repair work on various structures - the superstructure of floors, the construction of attic rooms and an outbuilding.

wall insulation

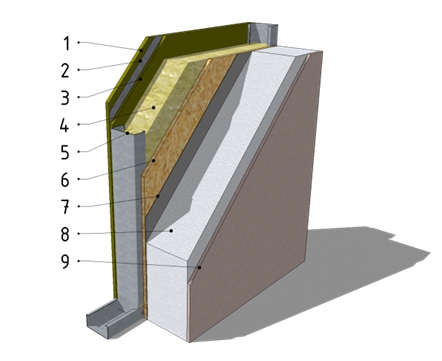

1. Polystyrene + stone wool

|

1. Gypsum board 2. Vapor barrier 3. Gypsum board 4. Thermal insulation material 5. Metal frame 6. OSB panel 12 mm 7. Glue for Styrofoam 8. Expanded polystyrene EPS 70 9. Facade decorative plaster |

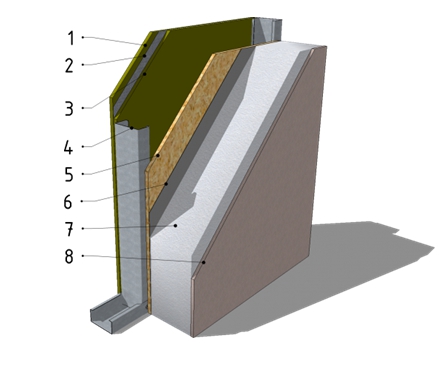

2. Polystyrene

|

1. Gypsum board 2. Vapor barrier 3. Gypsum board 4. Thermal insulation material 5. Metal frame 6. OSB panel 12 mm 7. Glue for Styrofoam 8. Expanded polystyrene EPS 70 9. Facade decorative plaster |

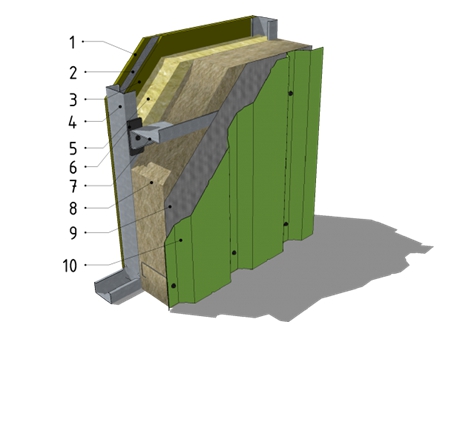

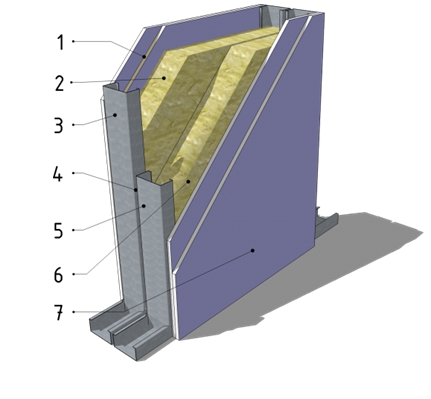

3. Stone wool + Z profile

|

1. Gypsum board 2. Vapor barrier 3. Gypsum board 4. Metal frame 5. Thermal insulation material 6. Thermal break insert 7. Galvanized Z profile 8. Thermal insulation material 9. Diffusion membrane 10. Profiled sheet |

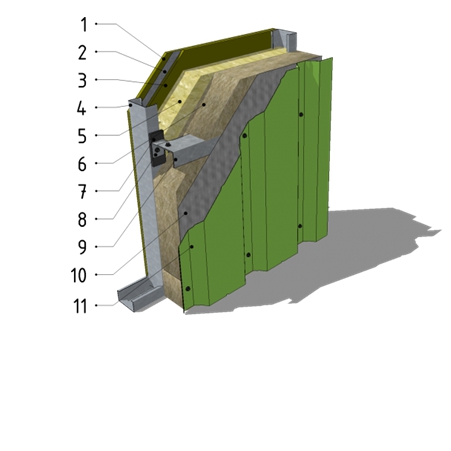

4. Stone wool + fixing bracket

|

1. Gypsum board 2. Vapor barrier 3. Gypsum board 4. Metal frame 5. Thermal insulation material 6. Thermal insulation material 7. Thermal break pad 8. Corner fixing galvanized 9. Galvanized corner 10. Diffusion membrane 11. Profiled sheet |

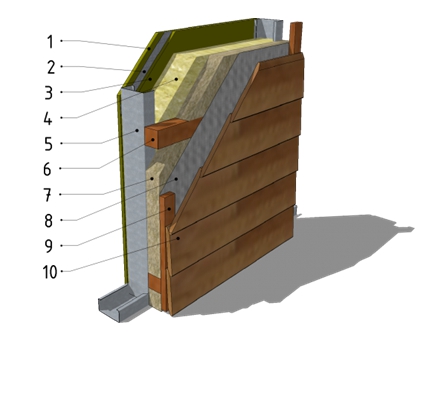

5. Stone wool + wooden blocks

|

1. Gypsum board 2. Vapor barrier 3. Gypsum board 4. Thermal insulation material 5. Metal frame 6. Wooden crate 50x50 mm 7. Thermal insulation material 8. Diffusion membrane 9. Longitudinal crate 1520x40 mm 10. Decorative facade finish |

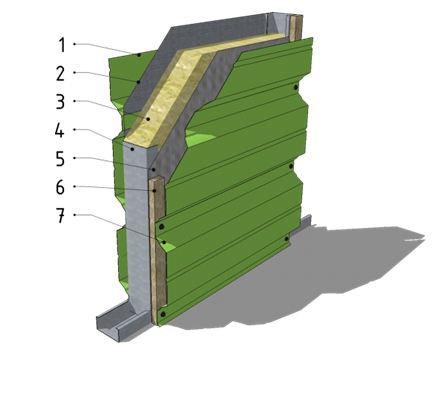

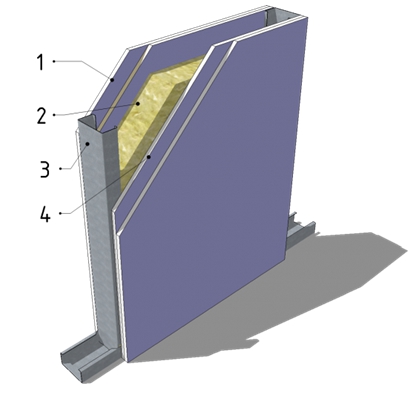

6. Stone wool

|

1. Profiled sheet 2. Vapor barrier 3. Thermal insulation material 4. Metal frame 5. Diffusion membrane 6. Gasket (strip 20 mm thick and 50 mm wide of high density insulation) 7. Profiled sheet |

7. Double frame + gas / foam concrete

|

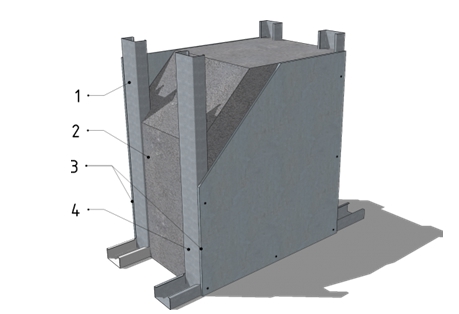

1. Metal frame 1.2mm thick 2. Gas / foam concrete 3. Fiber cement boards 4. Metal frame 0.8mm thick |

8. Sandwich panel

|

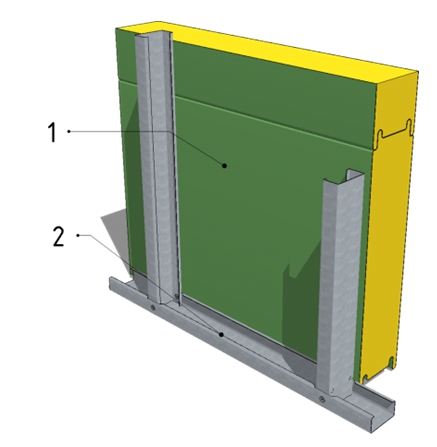

1. Sandwich panel 2. Metal frame 1.2mm |

9. Polyurethane (closed cell)

|

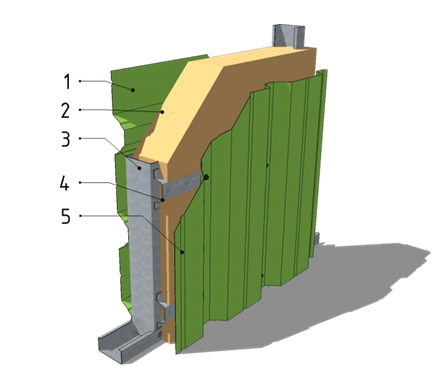

1. Profiled sheet 2. Polyurethane (closed cell) 3. Metal frame 1.2mm 4. Omega profile h=30 mm 5. Profiled sheet |

10. Polyurethane (open cell) + double frame

|

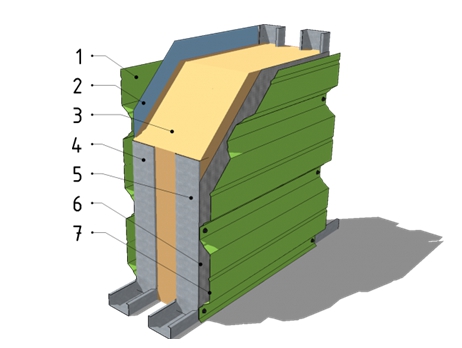

1. Profiled sheet 2. Vapor barrier 3. Polyurethane (open cells) 4. Metal frame 1.2mm 5. Metal frame 0.8mm 6. Diffusion membrane 7. Profiled sheet |

11. Inter-apartment walls

|

1. Plasterboard soundproof sheets 2 cl. 2. Soundproofing 3. Metal frame 4. Air gap 5. Metal frame 6. Soundproofing 7. Plasterboard soundproof sheets 2 cl. |

12. Interior walls

|

1. Plasterboard soundproof sheets 2 cl. 2. Soundproofing 3. Metal frame 4. Plasterboard soundproof sheets 2 cl. |

How to properly insulate a frame house. Heaters and insulation technology

Perhaps, most often, modern technology for building a frame house provides for the use of mineral wool as a heater. It does not burn, creates good sound insulation and is environmentally friendly. As for the thermal insulation characteristics, a mineral wool layer thickness of 5 cm is equivalent to brickwork 58 cm wide.

The main task when insulating with this material is to protect mineral wool from condensate and “dew point”. For these purposes, special vapor barrier and membrane films are used.

The technology of warming a frame house with basalt wool

Usually, the vertical racks of the frame are fixed in increments of 60 cm, which fully corresponds to the width of the mineral wool slab. The thickness of one plate is 5 cm, so the required number of layers is determined locally, depending on climatic conditions.

If in the south there is enough insulation thickness of 10 cm, then in the northern regions it needs twice as much. At the same time, 15 cm (3 layers) of mineral wool are fastened from the inside between wooden racks, and 5 cm (1 layer) is located outside so as to cover all the beams of the frame, thereby eliminating the possibility of the formation of "cold bridges".

As a rule, there is already a vapor barrier on the outside of the frame house, so there is no need to do it from the inside before laying the mineral wool.

It is very important to lay the material correctly

- It should be placed between the racks tightly, but at the same time not bend, but fit the entire surface.

- A vapor barrier film is necessarily mounted on top of the insulation, all joints of which are fixed with sticky reinforced construction tape (adhesive tape).

This completes the insulation of the frame house with mineral wool from the inside.

Ecowool insulation

This modern material is quite popular due to its environmental friendliness, affordable price and excellent thermal insulation qualities. The thickness of the ecowool layer of 13 cm is equivalent to the thickness of the aerated concrete wall of 60 cm.

In fact, ecowool is cellulose treated with boric acid (antiseptic) and borax (fire retardant). In total, there are three ways to insulate it: in the form of a dry backfill, spraying with water or with glue.

The first method is the most inexpensive in terms of budget (it is equally good for insulating walls, floors and roofs), and therefore the most popular.

Manual ecowool insulation technology

- The easiest way to insulate a horizontal surface in this way.First you need to prepare the material. Ecowool is sold in the form of pressed briquettes weighing 15 kg. After loosening (with an electric mixer or a baking machine), its volume triples.

- Then the ecowool is poured between the lags and evenly distributed, forming a small hill. This is done so that after laying the floorboard, it is additionally compacted.

- To insulate the walls, a vapor barrier or OSB boards (OSB oriented strand boards) are attached to vertical wooden racks, drywall (gypsum board) can be used. At the same time, there must be a gap at the top through which the material will be laid. At first, ecowool is simply poured into the resulting space, filling it and compacting quite tightly under its own weight. But at the end of the backfill, it will need to be compacted manually.

- To simplify and speed up the process of warming the walls of a frame house with ecowool, you can use a loosening and blowing installation for installing ecowool, for example, Uralekomaster-650 (UEM-650). But you have to look for a company that will lease it.

Insulation of the walls of a frame house

Modern frame houses are practical and reliable housing with an attractive appearance. For those who want to build a comfortable home at an affordable price, a frame structure building is the best solution.

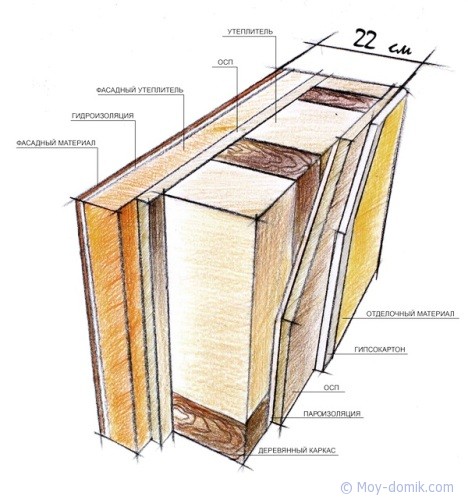

The current construction distinguishes two main ways of mounting frame houses. The first method is frame-panel, when houses, in the form of finished elements, are assembled at the factory. The second method is called frame-frame, when the preparation and assembly of all elements is carried out at the construction site. In the section, the wall of a frame house consists of many layers. Schematically, from outer to inner, they are arranged as follows:

- Facade cladding;

- The membrane is windproof;

- Frame filled with insulation;

- Vapor barrier layer;

- Internal lining.

In modern low-rise construction, two types of frames are mainly used - wooden and metal. Wood has been the traditional building material for centuries. The main advantage of wood is its availability, rather high strength, ease of processing, low thermal conductivity, low weight. The metal frame is made of thin-walled light steel structures. It is based on perforated galvanized steel profiles. Galvanization extends the service life of such structures up to 100 years.

Foam insulation

Most often, expanded polystyrene (EPS) is used for external insulation of buildings. But do not forget that the foam plastic has practically no soundproofing properties, and when burned, it emits toxic gas. In addition, he often suffers from rodent teeth.

Despite the obvious disadvantages, due to its excellent thermal insulation properties and low cost, its popularity does not decrease.

Stages of work on the insulation of frame walls with foam

Walls before insulation must be cleaned and free of irregularities. In order for the foam to form a flat surface as a result, vertical suspensions are first made in increments of 60-70 cm. Thanks to them, it will immediately become clear where you need to remove a little material, and where, on the contrary, apply more glue

It is also important to set the profile bar evenly using the level. Then glue is applied to the sheet (previously diluted according to the instructions on the package) at five points and with a strip along the entire perimeter

After that, the foam is glued to the wall and pressed tightly. Additionally, the foam is fixed with dowels or self-tapping screws with wide caps. All subsequent rows are arranged like brickwork - apart. A wall insulated in this way can be decorated with any facing material.

P.S. And for dessert, I suggest watching a video clip: Insulation of a frame house (ForumHouseTV)