We connect the relay to the water line

It is necessary to connect the pressure switch to water first of all, and to electricity second. Setting up the relay is the last, third stage.

Suppose everything turned out great and we found that piece of threaded pipe to which the pressure switch must be screwed. Do you know how to make reliable threaded connections? If yes, then good. If not, then you have to practice. Now there is a Tangit Unilok thread on sale. It's pretty cute and comfortable. It is more convenient than flax for sealing threaded water connections, but it is quite expensive. we will use it!

The procedure for connecting the pressure switch to the water line for dummies (specialists can not read)

So let's pray, let's get started. When sealing threads with flax or tangit, there are some tricks. Tangit is wound, which is obvious, on the thread, which is on the tube. We have this tube end, that is, the end face towards us. It turns out that we are looking directly at the end, on which we will wind whatever it is. We estimate approximately how much thread we will use. We take the tangita thread and start wrapping it. We start this process not from the end, but to the end, stepping back from the edge to the distance that will be inside the nut. In the above diagram, I indicated the approximate position from which you need to start with a green arrow. When winding the tangit, twist the thread clockwise (red arrow in the diagram), looking at the end of the pipe. The first loop should firmly secure the thread. so that it does not stretch and does not bloom. Then we act according to the instructions for the tangit, that is, we make sure that the thread does not lie inside the thread grooves.

You need to wind quite evenly and tightly. Do not try to wrap it so that you get a whole tumor of tangit. This is where some experience is really needed. Wrapping a little is bad. Will flow. A lot - do not screw the nut, crush the thread and again it will flow. Dont be upset! Get it - good. No - practice. Suppose wrapped. We start to wind the relay

Let's spin slowly! very slowly and carefully. First with hands, but not for long

As soon as resistance is felt, we begin to work with a wrench. The first sign that everything is fine is that the nut is not screwed too easily along the tangit. The presence of the thread should be felt, but in moderation. We carefully monitor how the relay nut is screwed on. If it is wound on a tangit, then this is just fine. Unfortunately, you may find that the tangit under the nut forms loops, bunches up and comes out of the thread. This is bad. In this case, I propose to twist a little more and, if the situation with the loops worsens, then it is better to unscrew the relay and redo the entire winding. In this case, it is better to free the thread from the old thread and make everything clean.

Suppose everything worked out, there were no loops, or there was one small one that formed when we had practically wound everything up. Then we twist the relay to the end. But not too much! We translate the spirit. There is a high probability that everything will be in order and there will be no leakage.

Overview of popular models

There are two types of pressure switches: mechanical and electronic, the latter are much more expensive and rarely used. A wide range of devices from domestic and foreign manufacturers is presented on the market, facilitating the choice of the required model.

RDM-5 Dzhileks (15 USD) is the most popular high-quality model from a domestic manufacturer.

Specifications

- range: 1.0 - 4.6 atm.;

- minimum difference: 1 atm.;

- operating current: maximum 10 A.;

- protection class: IP 44;

- factory settings: 1.4 atm. and 2.8 atm.

Genebre 3781 1/4″ ($10) is a Spanish-made budget model.

Specifications

- case material: plastic;

- pressure: top 10 atm.;

- connection: threaded 1.4 inches;

- weight: 0.4 kg.

Italtecnica PM / 5-3W (13 USD) is an inexpensive device from an Italian manufacturer with a built-in pressure gauge.

Specifications

- maximum current: 12A;

- working pressure: maximum 5 atm.;

- lower: adjustment range 1 - 2.5 atm.;

- upper: range 1.8 - 4.5 atm.

The pressure switch is the most important element in the water intake system, which provides automatic individual water supply to the house. It is located next to the accumulator, the operating mode is set by means of adjusting screws inside the housing.

When organizing autonomous water supply in a private house, pumping equipment is used to raise water. In order for the water supply to be stable, it is necessary to select it correctly, since each type has its own technical characteristics and features.

For efficient and trouble-free operation of the pump and the entire water supply system, it is necessary to purchase and install an automation kit for the pump, taking into account the characteristics of the well or well, the water level and its expected flow rate.

The vibration pump is chosen when the amount of water spent per day does not exceed 1 cubic meter. It is inexpensive, does not create problems during operation and maintenance, and its repair is simple. But if water is consumed from 1 to 4 cubic meters or water is located at a distance of 50 m, it is better to purchase a centrifugal model.

Usually the kit includes:

- operating relay, which is responsible for supplying and blocking voltage to the pump at the time of emptying or filling the system; the device can be immediately configured at the factory, and self-configuration for specific conditions is also allowed:

- a collector that supplies and distributes water to all points of consumption;

- pressure gauge for measuring pressure.

Manufacturers offer ready-made pumping stations adapted to specific requirements, but a self-assembled system will work most efficiently. The system is also equipped with a sensor that blocks its operation during dry running: it disconnects the engine from power.

The safety of the equipment operation is ensured by overload protection sensors and the integrity of the main pipeline, as well as a power regulator.

Connecting the pressure switch to the water supply system

When installing the relay in the water intake system, the following rules must be observed.

- The hydraulic accumulator for water supply systems and the connection point of the device to the water supply are located nearby - this will avoid pump switching during sudden short-term pressure surges.

- When installing, you should take into account the temperature regime - some models operate only in warm conditions.

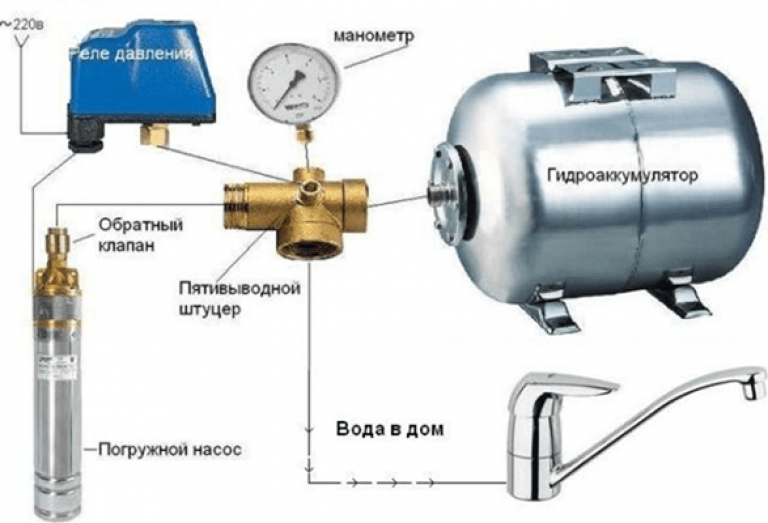

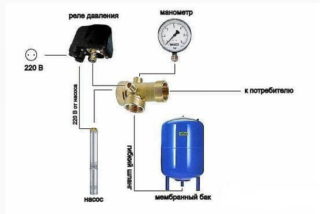

- To simplify installation in modern surface-type pumps, a fitting is installed to which a relay and pressure gauge can be directly connected.

Connecting a pressure switch to a submersible pump can be done in two ways:

- The device is connected to water pipes through a tee by means of a transition fitting.

- Before connecting the accumulator to the submersible pump, a five-outlet fitting is connected to it, the connected devices (hydroaccumulator, pressure gauge, relay) and the water main are connected at one point.

Wiring diagram

Depending on the needs of the user and his financial capabilities, you can choose one of the methods for connecting the deep pump to the electrical network.

Without automation

Without auxiliary control devices, the pump is connected using a pre-installed electrical outlet with a ground contact. The pump is also grounded. For this, the main bus of the house is used, which is connected to the existing ground loop of the building.

A three-core cable is used to supply electricity to the outlet. The power supply voltage of the submersible pump is 220V.Do not use 380 or 150 volt outlets.

Via pressure switch

To reduce the cost of a set of pressure equipment, you can apply a connection scheme for a borehole pump only with a pressure switch without a control unit. The device turns off the pump when the pressure reaches its maximum, and starts it when the indicators decrease to a minimum.

With control box

When choosing an automation model, you first need to find out which protective system has already been supplied by the manufacturer in the pump. Modern devices are already protected from overheating and idling. Sometimes the equipment is equipped with a float mechanism. Given these data, you can choose one of three options for automation - simple, with a second or third generation electric control unit.

The simplest protection is most often used for automatic water supply. The control unit here is assembled from three devices:

- Dry run blocker. It will turn off the machine, which works without water, preventing overheating. Sometimes an additional installation of a float switch is allowed. It performs the same functions, turns off pumping equipment when the water level drops, preventing it from overheating. It may seem that the devices are primitive, but they provide effective protection for the electric motor.

- Hydraulic accumulator. Without it, it will not work to provide automatic water supply. The hydraulic tank works as a water storage tank. Inside is a working mechanism - a diaphragm.

- Pressure switch complete with pressure gauge. This device allows you to configure the operation of relay contacts.

It is not difficult to equip pressure equipment with your own hands with simple automation. The principle of operation of the system is simple: when water is consumed, the pressure in the hydraulic tank decreases. When the minimum indicator is reached, the relay starts the pressure equipment, which pumps water into the storage tank. When the pressure in the hydraulic accumulator reaches its maximum, the relay device switches off the unit. In the process of water consumption, the cycle is repeated.

Adjustment of the pressure limits in the accumulator is carried out by means of a relay. In the device, using a pressure gauge, set the minimum and maximum response parameters.

In second-generation automation, the connection goes through an electrical unit with a set of sensors. They are mounted directly on the pressure equipment, as well as inside the water supply network, and allow the system to function without a hydraulic tank. The impulse from the sensors is fed to the electronic unit, which controls the system.

The operation of pressure equipment with such a scheme for connecting a submersible well pump to automation:

- The liquid accumulates only in the water supply, where one of the sensors is placed.

- When the pressure drops, the sensor sends an impulse to the control unit, which starts the pump.

- After reaching the desired pressure of the water flow in the water supply, the pump is turned off in a similar way.

To install such automation, you will need basic knowledge in electrical engineering. This and the previous protection work almost the same - according to water pressure. However, the electric unit with sensors is more expensive, which is why it is not so popular among consumers. Even when using automation, you can not use a hydraulic tank, although in case of power outages you will not be left without water with it. There is always a reserve in the drive.

Automation of the third generation is reliable, high-quality and expensive. Its installation allows you to significantly save on electricity due to the ultra-precise adjustment of the operation of the electric motor. The scheme for connecting advanced automation to a deep well pump is very complicated, so you should contact a professional to connect it. But it provides complete protection of the motor from various breakdowns, for example, overheating during dry running or burning of the windings during power surges in the network.

The unit operates from sensors without a hydraulic tank.Efficiency is achieved through fine tuning.

Is a hydraulic accumulator really necessary?

A reasonable question: is it possible to do without a hydraulic accumulator? In principle, this is possible, but with a conventional automation unit, the pump will turn on and off very often, reacting even to a slight flow of water. After all, the amount of water in the pressure pipeline is small, and the slightest flow of water will lead to a rapid drop in pressure and its same rapid increase when the pump is turned on. It is precisely because of the fact that the pump does not turn on for each of your "sneezes" that they put a hydraulic accumulator, at least a small one. Since water is an incompressible substance, air is pumped into the accumulator, which, unlike water, compresses well and acts as a kind of damper that regulates the accumulation and flow of water. If there is no or too little air in the accumulator, then there will be nothing to compress, that is, there will be no accumulation of water.

Ideally, the capacity of the accumulators should be only slightly less than the debit of your water source, and the pump, in this case, will turn on only when some fairly decent supply of water is used up, i.e. very rarely, but for a long time. But then it will be very expensive in cost.

Now pumping stations with improved automation units with built-in dry-running protection have appeared on sale, which smoothly start and stop the pump, regulate its power depending on the given pressure. It is believed that the accumulator, in principle, they do not need. But all this works well only in the absence of power surges, which our remote areas and summer cottages cannot boast of. And, unfortunately, stabilizers do not always save from this trouble. In addition, the price of such a station is very often much higher than usual, which, in my opinion, does not justify itself.

Is it possible in principle to use your pressure switch with your pump

The pressure switch is connected not only to electricity, but also to water. For water connection, a nut is used, which is rigidly attached to the relay. This means that when screwing the pressure switch to the pump, you will have to turn the switch itself. Thus, first of all, think about whether you have the ability to turn this very relay clockwise on the pump? Will it fit? Is it hitting other pipes or the pump housing itself?

We will assume that this issue has been resolved positively, because otherwise we need to look at the place and, for example, take care of some kind of extension cord or something like that.

At the pressure switch, the water inlet is not quite standard in diameter. For most household relays, this is a quarter of an inch. For professional relays, the connection diameter may be larger. This issue must be taken care of and, if necessary, buy a brass adapter for the desired diameter.

Previously, in the production of automatic pumping stations, a special and quite standard part was used, commonly called a herringbone. This is such a nice piece of brass pipe 10 or 12 centimeters long and 1 inch in diameter. The herringbone is screwed onto the pump outlet at one end and has standard “outlets” for connecting a pressure gauge, pressure switch, water storage tank and the water line itself. Now everything has become much more complicated. There are pumps where the pressure switch is screwed directly onto the pump or into very inappropriate, at first glance, places. This diversity makes my job of writing detailed instructions quite difficult.

Relay adjustment

Upon purchase, the relay is set to a specific switching mode, the standard values are 1.4 and 2.8 atm., That is, at 2.8 atm. the pump will be turned off and turned on if the pressure is less than 1.4 atm. Usually, when installing a device into the system, it is necessary to select the response threshold - for this you need to know what pressure the pump gives in the well.

If the pressure of the well pump is 2 atm, and the standard value of 2.8 atm remains in the relay, then the pump will never turn off (it physically cannot create a pressure that reaches the response threshold) and after intensive work will go to eternal rest. A less tragic situation is when the pump can deliver a pressure of 5 atm., And the relay turns it off at 2.8 atm. In this case, the system works inefficiently and it is desirable to install a device corresponding to the pressure of the borehole water pump.

For measurements when adjusting the relay, a pressure gauge is required, the work consists of the following steps.

- Water begins to be drained from the system, and the pump turn-on pressure is recorded on the pressure gauge.

- The valves are closed and the pressure gauge readings are recorded at which the pump is turned off.

- Adjust the device with a large screw, periodically turning the water on and off until the desired lower pressure value is obtained.

- Then they proceed to adjust the range that sets the upper pressure with a small screw. Water is also periodically turned on and off until the required value is obtained.

1 What does the pumping station consist of

Well pumping stations consist of the following functional elements:

In the arrangement of pumping stations with their own hands, two types of pumps are most often used for water intake - vibration pumps (such as "Kid", "Brook", and the like), or centrifugal units. It is worth choosing a vibration pump if water is taken from a shallow source - a well, or a sand well, the depth of which does not exceed 10-15 meters.

The advantages of vibration devices include minimal cost, simple repair, and sufficient productivity for undemanding domestic use.

However, if you own an artesian well that is over 30 meters deep, you will need a submersible centrifugal pump. Such units are much more expensive, but their power and service life are incomparably higher than those of the Malysh pumps.

Surface pumps are also often used, but they have a relatively low possible water intake depth (about 12-15 meters), and therefore are not suitable for use inside deep wells or wells.

Conventional pumping station with accumulator, pressure switch, pump and pressure gauge

A hydraulic accumulator for pumping stations is a container that performs the function of water accumulation. In addition to the fact that the house will always have the required amount of water, such a tank will protect the entire system from water hammer and ensure the optimal operation of the pump.

The hydraulic accumulator controls the smoothness of the change in the water supply pressure during its operation, and eliminates the need to constantly turn the pump on and off (which has an extremely positive effect on the service life of the Malysh vibration devices, since in most cases their repair is associated precisely with overheating and damage to the winding of electromagnetic coils) .

However, do not think that installing a hydraulic accumulator alone will protect the pump from overheating. This device, of course, will reduce the operating time of pumping equipment. However, submersible models, especially the Malysh pumps, can also overheat due to too little water around, since it is water that performs the main functions of cooling their engine and housing.

The pressure switch is what unites all the equipment into a common system and ensures its autonomous operation. It is impossible to assemble a pumping station for a well without this element. The relay constantly monitors the level of internal pressure that the storage tank (hydraulic accumulator) has.

If the pressure in the hydraulic tank drops below the permissible level, which indicates that the water level in it has decreased, the pressure switch connects the contacts of the submersible pump, as a result of which it turns on and starts supplying water.As soon as the accumulator is filled to the required level, the relay turns off the pump.

It is installed on the hydraulic tank, if the container was not originally equipped with it. Based on the readings of the pressure gauge, the entire system is monitored and adjusted.

A couple of tips on how to choose a pumping station: it is best to give preference to equipment from trusted manufacturers Grundfos, Pedrollo, Ergus.

Connecting a surface pump to a hydraulic accumulator

Why assemble the pumping station themselves.

First of all, it seems to me that the pumping station is worth assembling yourself if you already have some of its components, usually the most expensive ones. This is a pump and a hydraulic accumulator. Because the cost of a pump is about half the cost of a pumping station, respectively, a hydraulic accumulator is about a third. That is, it does not make sense to buy a new pumping station if your accumulator was crushed in winter or the pump burned out for some reason. You can buy both separately and just replace what you have broken, since the pump fasteners and the hydraulic accumulator mounting pad are usually standard and you can connect one to the other without much difficulty.

Another reason to assemble the pumping station on your own may be the discrepancy between your requirements and the characteristics of the equipment of the finished pumping station. For example, you need a pump with a higher head or water flow than the pumping stations offered to you, and what suits you in terms of characteristics does not suit you - in terms of cost or reliability. Either the dimensions of the pumping station are too large for the place where you are, or you are not satisfied with the capacity of the accumulator, well, etc. You just need to keep in mind that the final cost of the pumping station may well be much more than what you planned.

The third, most common option, when you are forced to assemble a distributed pumping station due to very. As a rule, in this case, a powerful submersible pump is used, and a hydraulic accumulator with an automation unit is placed somewhere at home.

Equipment selection rules

For autonomous water supply systems, you should choose a household relay

Such systems are characterized by the main parameters: the maximum pressure value is not more than 5 atmospheres, the operating pressure values usually range from 1.4 to 2.8 atm.

When setting the relay, it is important to remember that the magnitude of the difference between the limit values \u200b\u200b(settings on the springs) directly affects the volume of water that the pump will pump into the accumulator tank with such settings. A large volume contributes to the fact that the pumping unit will turn on less often, but the technical capabilities of the system should not be exceeded in this regard.

Do not save excessively by purchasing a relay of unknown origin

Such equipment will not only not be able to ensure correct operation, but with a high degree of probability will cause more damage to other equipment included in the system.

Connecting the automation of the pump and the pressure switch, together with a high-quality pressure gauge installed next to the relay, will allow you to control the parameters of the system and help detect violations at an early stage, when there are no external manifestations yet.

We have information about hydraulic accumulators here

What are the models and what is important when choosing them

We talked about how to clean the well in this material.

Setting

To set the pressure switch, it is necessary to set the working pressure in the system. To do this, after assembling the circuit, the equipment should be turned on and wait for automatic shutdown when the relay is triggered. After that, the roof is removed and the setting is performed in the following sequence:

- Loosen the nut that presses the smaller spring.

- Set the required value of the minimum pressure value (pump activation parameter). Clockwise rotation of the nut of the large spring - an increase in the set pressure value, in the opposite direction - a decrease.

- Having opened the tap, they empty the system, controlling the threshold of automatic operation by the pressure gauge. If the result is unsatisfactory, adjust the setting.

- Similarly, the pump off parameter is adjusted by turning the nut on the second (smaller) spring.

To supply water to the house from a borehole or well source, pressure equipment is needed. The most commonly used submersible models, because they are easy to operate and unpretentious. For self-assembly of a water supply system, it is necessary to have an idea about the scheme and features of connecting a submersible pump in order for it to function correctly.

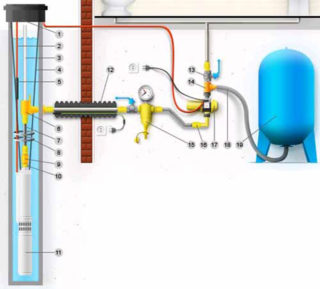

How to connect the pump to the well and water supply

Before installing a submersible pump, a thorough cleaning of the well shaft is required. For this purpose, using a temporary pump, liquid is pumped out of the column until all sand and impurities are removed. To protect the pressure device from water hammer, a non-return valve must be installed on it.

The pump is connected to the well in the following sequence:

- Install the pipeline. When connecting the pump to a rigid pipe between it and the main line that transmits water to the consumer, it is better to insert a small piece of flexible hose to dampen the vibration of the electric motor.

- A cable, an electric wire, a hose are connected to the device.

- The device is smoothly lowered into the well.

- When the pump reaches the bottom, it is raised by half a meter.

- The cable is rigidly fixed, the cable is connected to the mains, the hose is connected to the rest of the system and laid in the mounting channels.

What are the advantages of a ready-made automation module

- The finished module is fine-tuned to interact with a specific type of hydraulic equipment.

- A smooth start is guaranteed, which means that the possibility of water hammer is excluded.

- There is no need to spend time and effort on assembling the module, setting up devices and synchronizing nodes, since the manufacturer has already taken care of this.

The ready-made kit also has a minus - the consumer does not have the opportunity to select individual parameters for each element. Requirements for placement

The installation site of the module must be provided with quick and unhindered access. The most optimal location for automation is as close as possible to the source of water supply.

To achieve a uniform water pressure at different points and prevent pressure drops, the automatic module is located close to the collector assembly.

It is not worth saving on automation, since it is with its help that the required pressure in the water supply system is maintained, uninterrupted water supply is ensured, and pumping equipment will be protected from breakdowns.

And in what cases is it justified to assemble a pumping station from disparate parts that can be bought in a store.