Design features

Ball valves are the most widely used today. At the same time, we note that the coupling method of connection is the most common, but the connection can also be carried out by welding. Similar models have the following structure:

- The faucet body acts as the main element. The fact that the connection is carried out using welding technology determines the use of special steel, which can withstand high temperatures. The body is characterized by the absence of various protrusions, which eliminates the possibility of dirt accumulation.

- The ball is used as the main locking element. In its manufacture, stainless steel is used, in the central part there is a hole with different patency.

- Management is carried out by the handle. It has a shape that makes it easy to manage the device.

- The spindle is used to directly connect the handle with the ball. The shape of such an element is quite complex, which allows the installation of several sealing wheels. It should be borne in mind that the spindle is installed from the inside, which ensures a high degree of reliability when operating the device under pressure.

- Inside the valve there is a ball seat, which is made of Teflon. Such material is characterized by high resistance to mechanical stress.

- The locking pin limits the rotation of the handle.

We will pay special attention to the fact that the inlet and outlet pipes are represented by tubes made of metal, which lends itself well to welding. There are no threads or other elements on the surface, due to which the welding process is complicated

Ball valve installation

In this article I will tell you how to properly install a ball valve on plumbing and heating pipes, but first I will tell you a little about the pros and cons of ball valves. At the moment, such valves are the most common, popular, and very practical and convenient, their undoubted advantage over old-style faucets is that there is no need to change gaskets, since they have a different device and principle of operation. There is a ball inside the tap, in one position it is open, and when it is turned 90 degrees, the water shuts off, but ball valves have big disadvantages: In case of bad water, the ball can become slagged, and if it is not turned for a year, especially in hot water, then close it becomes very difficult, and sometimes impossible, so you need to turn it at least once every 2 months to bring down salt deposits.

If rusty water comes out of the faucet, then when opening and closing, scale or sand can damage the surface of the ball, and then the faucet will pickle in the closed position. On ball valves of medium quality, with frequent opening and closing (most often found in hot water and heating), it starts to flow from under the stuffing box, of course it can be tightened, but in many cases the nut tightening the stuffing box spins with the lever, and continues to drip, and in some taps there is no gland at all and in the event of a leak it can only be thrown away and a new one installed. And one more minus, you can not install a ball valve in a room where the temperature can be less than 0 degrees in winter, when the water freezes, it breaks.

How to install a ball valve on a pipe

When installing a ball valve on a pipe, you must:

1. If you are replacing a faucet, then you need to remove the old one, clean the threads from flax, and try screwing on the faucet. More than once I met with the fact that when removing the old valve, 2-3 turns rot, in which case it is necessary to cut the thread. The valve on the pipe must be wound at least 4 turns!

2.If, when dismantling the old faucet, the thread remains in a normal state, but during installation, the faucet is screwed on less than 4 turns, be sure to drive the thread with a die!

3. Check that without flax, the crane is wound 4-5 turns, wind the flax. and twist 4-5 turns.

4. If you are installing a plumbing or heating system, then first measure exactly where the ball valve will be installed, cut it off in the right place, cut the thread on the pipe, and screw it on 4-5 turns.

And as usual, a few tips, if you have a centralized heating supply, and there is high pressure in the system, use Bugatti ball valves, they have proven themselves very well, do not install valves on which there is no stuffing box, if it starts to flow, then you will not be able to eliminate it before replacing the faucet.

Ball valves come with internal threads on both sides, internal - external, external - external, and internal on one side, and on the other an American, so calculate and buy those that are needed for further plumbing or heating connections.

Watch the video, installation, installation of a ball valve, and how to thread a pipe.

Features of the resulting compound

Despite the fairly widespread coupling and flange connection methods, some ball valves are connected by welding. A similar connection method can be described as follows:

- It is possible to connect a ball valve even to a pipe on which there is no thread or a flange cannot be attached.

- The resulting seam is characterized by high reliability. If the welding technology is observed, the connection will be able to withstand a high load.

- After installation work, it will not be possible to dismantle for maintenance or replacement of the locking element. An exception can be called the case when metal is cut.

- If the welding technology is violated, the resulting seam turns out to be of poor quality; during prolonged operation, a leak may appear.

- Welds are characterized by relatively low resistance to hydraulic shock.

As practice shows, a welded joint can withstand a sufficiently high load and last for a long period. That is why today you can often find a situation in industry when a ball valve is connected precisely when using this technology.

Gas valve installation

Preparatory stage

To change the gas valve in the kitchen yourself, you need to prepare:

- new faucet;

- two gas keys. One wrench is required to unscrew the threads, and the second to hold the down tube stationary. Otherwise, you can damage the pipeline leading directly to the gas stove;

- means for sealing threaded connections. FUM tape, Tangit Unilok thread or regular linen thread will do. When using linen thread, additional processing of the sealing material with paint is necessary;

Special thread for sealing threaded connections

graphite grease designed for gas valves;

Special composition for gas appliances

pipe cap. If you replace the valve with two people, then you can do without the use of a plug.

Replacement process

The replacement of the gas valve is carried out according to the following scheme:

- the gas supply to the dwelling is shut off. To do this, the handle of the gas valve is rotated to a position perpendicular to the pipe;

Gas valve in closed position

- the valve is unscrewed from the pipe. If the thread cannot be unscrewed, then it is recommended to treat the threaded connection with WD-40, which will ensure smooth running. If a welded valve is installed in the apartment, then it is cut off with a grinder, and threads are cut on the pipes;

- a temporary plug is installed in place of the valve.If the work of replacing the gas valve is done by two people, then instead of a plug, you can use a partner's finger. This procedure will facilitate the process of installing a new crane;

- a sealing thread is wound onto the thread;

Winding linen thread to make a threaded connection tight

- a layer of graphite lubricant is applied over the thread;

Final thread preparation for valve installation

- a new faucet is installed.

When carrying out work, it is recommended to open the windows in the room and turn off all electrical appliances. These actions will lead to maximum security.

The process of self-replacing the gas valve is presented in the video.

Leak test

After installing the gas valve, it is recommended to check the tightness of the device and the resulting connections. For this:

- open the tap and start the gas supply to the stove;

- prepare a saturated soapy solution, which is applied to the faucet and joints.

Finding gas leaks with soapy water

If the device and thread pass gas, then small soap bubbles will form at the pass point. If a leak is found, the problem must be corrected quickly.

It is risky to carry out the work of replacing the gas valve on your own

Any careless action or violation of safety rules can lead to an explosion. Therefore, it is recommended that the replacement be carried out by qualified personnel.

Opening and closing valves

It is possible to determine whether the valve is open or closed by several signs, depending on the type of device installed.

Determining the position of the ball valve

To determine the status of a ball valve, you can use:

- control knob;

- notch located on the stem.

The ball valve can be equipped with two types of handles:

- a handle, which is an elongated element attached to the body of the device;

- a butterfly handle consisting of two similar parts arranged symmetrically with respect to the attachment point.

The valve closes if the handle is turned perpendicular to the device and the direction of the pipeline, and opens if the handle is turned in the direction of the axis of the device and, accordingly, the pipeline.

Determining the state of the valve by the handle installed on the device

The following video will help determine the state of the valve by the handle.

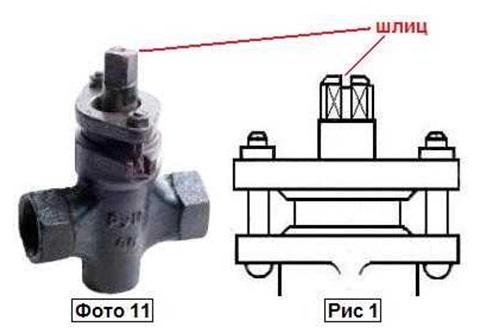

If the handles are broken or completely missing for some reason, is it possible to find out the position of the valve? To determine the condition of the device under the circumstances under consideration, you can use the groove located on the stem.

Element by which the position of the valve can be determined

If the groove is parallel to the pipeline, then the valve is open and passes liquid (gas). If the recess is located perpendicular to the direction of the pipes, then the valve is closed and the movement of fluid through the system is impossible.

Determining the position of the valve by recess

For ease of use of the ball valve, special protrusions are located on the body of the device, which are designed to limit the rotation of the handle and, as a result, extend the period of use of the device.

Determining the position of a plug valve

In which direction should the plug valve be unscrewed if there is no handle on the device, and how to find out the position of the valve in this case?

To determine the position of a valve that does not have a handle, you must:

- find a slot on the top of the stem (risk);

- visually check the status of the device.

Determination of the state of the plug valve in the absence of a handle

To close a valve of any type, it is necessary to turn the control handle or the mounting stem in a clockwise direction. To open the valve, the handle rotates in the opposite direction, that is, counterclockwise.

Welding instructions

The installation of ball valves in the production line must be carried out exclusively taking into account the requirements of the project, as well as common standards. The main recommendations are listed below:

At the time of work, it is strictly forbidden to fix the device by the handle or other technological elements. This is due to the fact that the load exerted can lead to very serious consequences. Even a slight deformation of the stem causes a decrease in the tightness of the entire device.

Welding work can only be carried out in the open position of the device. At the same time, you need to make sure that there will be no various contaminants inside that can get inside during transportation.

At the time of welding, it is recommended to remove the handle. Often, in its manufacture, a material is used that can suffer from falling drops of hot material.

When mounting in a vertical position, welding of the top seam is carried out in a fully open position. The bottom seam is obtained in a fully closed position, which eliminates the possibility of the effect of reverse draft of warm air.

With a diameter in the range from 10 to 125 millimeters, it is recommended to use electric welding, with a larger indicator this condition is mandatory.

The bevel of the pipe must ideally fit the locking element

That is why, in the case of poor surface quality, the end is cut off and carefully prepared.

When welding directly, care must be taken to ensure that the valve body does not heat up. This is due to the fact that too high a temperature can lead to very disastrous consequences.

It is considered overheating to heat the body to a temperature of 100 degrees Celsius in the seat area. It should be borne in mind that in most cases a special coolant and a moistened cloth are used. Welding can be carried out in several stages to reduce the likelihood of surface overheating. An increase in plasticity causes deformation of the surface and loss of tightness of the entire structure.

After receiving the seam for a long period, it is forbidden to open and close the reinforcement. This can only be done after the surface has completely cooled down. Otherwise, the internal elements may be damaged.

The construction length of the nozzles must not be shortened. This is due to the fact that it is selected taking into account the probability of heating the main structure.

After completion of the work, the quality of the seam is checked in accordance with the established requirements. To protect the surface, a paint coating is applied. The final stage is the flushing of the crane to remove debris that could get inside the structure at the time of welding.

Selection of gas valves

If a malfunction is detected in the operation of the gas valve, it is recommended to replace the device as soon as possible. First of all, you need to choose a new valve. When choosing, experts recommend considering:

- valve type;

- basic device settings.

Kinds

The gas pipe valve can be:

cork. A conical element driven by a flywheel is placed in the cork faucet body. In the conical element (plug) there is a hole, which, when aligned with the hole in the pipe, passes gas to the equipment. The stuffing box acts as a sealing material sealing the connection of the faucet with pipes;

Cross sectional valve

ball. The device of a ball-type gas valve differs from a cork one in that the locking mechanism is based on a ball made of durable metal. The ball has a hole, which, when the flywheel is turned, is located along the gas pipeline and in this way passes gas to the consumer.

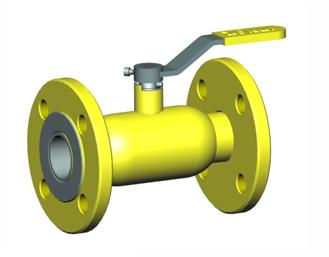

Valve for gas pipeline with ball locking mechanism

Experts recommend using ball valves for a domestic gas pipeline, as they are more reliable.

According to the method of connection with pipes, a household ball valve can be:

threaded. The valve is connected to the gas pipeline pipes with a threaded connection;

Threaded valve

flanged. Connection with pipes is carried out using flanges, which in turn are fixed with bolts;

Gas valve fixed with flanges

welded, that is, installed using a welding machine.

Welded gas cock

Threaded and flanged valves are reusable, that is, if necessary, you can remove the device from the gas pipe, check its performance, carry out repairs and install it in its original place. The weld valve can only be installed once.

Basic selection parameters

To select a shut-off valve for gas, it is recommended to pay attention to the following factors:

- pipeline diameter. The shut-off element of the valve must completely cover the pipe in the apartment. If the valve is larger or smaller, then the tightness of the tap will not be complete;

- pitch and diameter of the thread on the pipeline. To quickly replace the device, a complete match of the specified parameters is necessary. Otherwise, you will need to purchase and install additional adapters;

- the material from which the gas pipeline valve is made. It is more expedient to purchase brass taps, as they have a longer service life. On sale you can also find silumin, zinc and plastic taps. It is possible to distinguish the material used for the manufacture of the valve by weight. Brass faucets are heavier than faucets made from other materials. In addition, you can inspect the place where the thread is cut. Brass has a yellow tint, and all other materials (except plastic) are gray;

Gas valve made of nickel-plated brass

- The valve body must be free of chips, bulges, cracks and other defects. The presence of these factors indicates non-compliance with the rules for manufacturing the product, which will lead to a reduction in service life;

- it is more expedient to purchase valves from well-known manufacturers. For example, you can choose cranes manufactured by Bugatti (Italy), Dungs (Germany), Broen Ballomax (Poland).

Compliance with simple rules when choosing a gas valve will allow you to choose a reliable device with a long service life.