Causes of leaks in the heating system

When solving the problem of how to find a leak in the heating system, it is useful to know the causes of its occurrence - this will help to quickly and effectively eliminate the malfunction. There are quite a few reasons for depressurization of the heating main, the main ones are:

Violation of tightness of connections. This is the main cause of leaks to which all pipelines of traditional water heating are subject. They arise as a result of corrosion when using metal pipes, aging of sealing gaskets, spontaneous unscrewing of threaded connections.

One of the common causes of leaks at the joints is the thermal expansion of metals, while during the operation of the heating system in a high-temperature operating mode, water does not leak, and after the coolant cools down, the metal of the fittings at the joints narrows and a leak may occur.

Rice. 2 Connection scheme for heating boilers, radiators and underfloor heating

How to detect a water leak in the heating system

Any heating main in a private house is equipped with a pressure test device - a pressure gauge, which is used for adjustment and control. Its readings correspond to the pressure in the system and must be stable - any downward deviation indicates depressurization and possible leakage of the coolant.

Usually, heating consists of several circuits (heating radiators, underfloor heating), and installing a pressure gauge in each of them allows you to determine the depressurized area.

If a leak occurs in an open pipeline located in a house, it can be detected by wet marks on the floor or walls, when using antifreeze, the spots will have the appropriate color.

How to find a leak underground or in a screed

As mentioned above, the pressure gauge allows you to detect a leaking circuit, finding a leak under a layer of earth or a screed without special instruments is a rather difficult task. Since most problems occur at pipe joints, you should first open the screed or dig the ground in these places. The second option is to use special devices (for this you can hire specialists or rent equipment), to detect breakthroughs, they use:

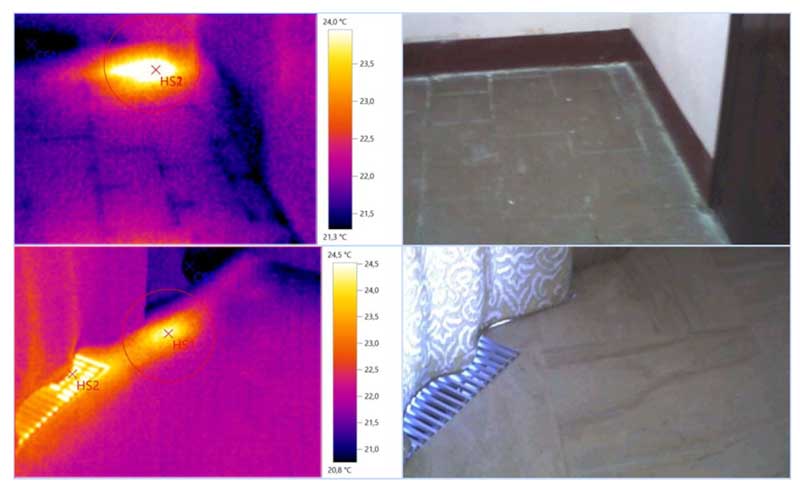

- Thermal imagers. With the help of compact devices, you can immediately find a water leak in a house or underground with a shallow pipeline. The depressurized area will look like a thermal blurred spot with an elevated temperature at the place where the coolant flows out.

- Moisture meters. High humidity signals that a leak has occurred in this area. The method is used only indoors, its efficiency is low - it can only detect a room with high humidity, and not a specific area.

- Phonendoscope. Acoustic devices that pick up sounds are more suitable for identifying noise sources from the outside, with their help it is very difficult to find a leaky area in walls or screed.

Rice. 4 Leak detection with thermal cameras

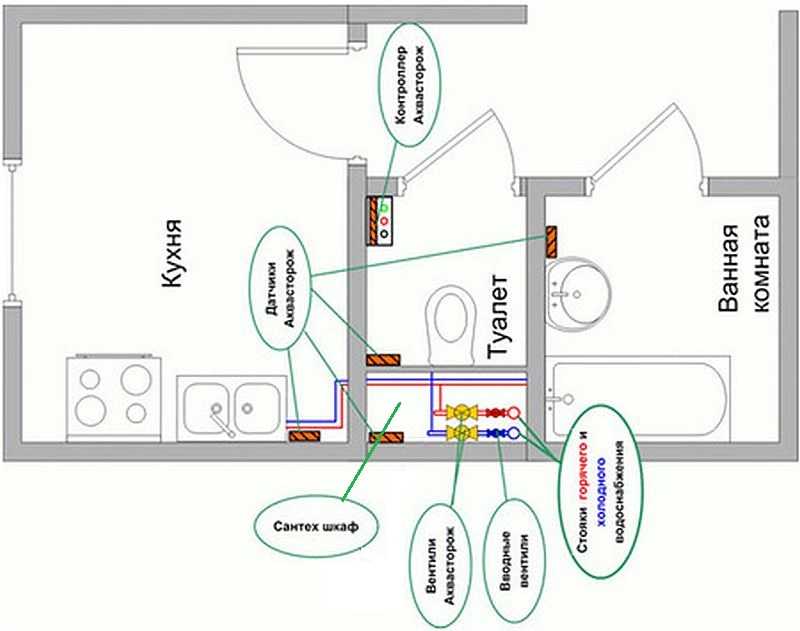

Where to install electric valve taps

With the installation of cranes is not easy. Specific installation locations vary by system design. If this is a small apartment with one or two risers - cold and hot water - everything is simple. We cover the outlets and everything. In more complex systems, it is necessary to think over the installation location of electric cranes.

The location of the shut-off valves depends on the design of the system

In apartments

If the water supply is centralized, the taps of the system against leaks are placed at the entrance to the apartment / house. It is much better if the taps are up to the counter and filter. But with such an arrangement, operational services may not agree. They usually require an electric faucet after the meter. In this case, in the event of a leak, the junction of the meter and filter always remains under pressure.It will be impossible to eliminate the leakage at these points. You can stand your ground, but you have to prove your point of view.

In some layouts, the apartment may have four risers - two cold and two warm water. In this case, there are two solutions - more correct and more economical. That's right - put two modules, each of which will serve its own zone. This is more convenient, since an accident will happen only on one of the risers / devices and it is unreasonable to turn off the opposite part. But two modules are double costs. To save money, you can put one control unit that will shut off the taps for 4 risers. But in this case, do not forget that you will have to pull the wires through the entire apartment.

You need to think about where to install the elements of the system

In the case of heating, too, not everything is simple. In most of the high-rise buildings, vertical wiring is made. This is when a riser passes in every (or almost every) room and one or two radiators are fed from it. It turns out that at least one tap must be installed for each outlet - for supply. But then the water that is contained in the radiator and pipes will flow out. This, of course, is not so much, but sometimes a couple of liters is enough for the neighbors below to have a stain on the ceiling. On the other hand, putting two taps on each radiator is too expensive.

In a private house

In order to prevent the pump from pumping water in case of an accident, it is necessary to use a water leakage protection controller with a power relay. If power is supplied to the pump through the contacts of this relay, simultaneously with the signal to close the ball valves or valves, the power to the pump will be turned off. Why not just turn off the power to the pump? Because in this case, all the water that is in the system can pour out into the resulting gap. And that's usually a lot.

To understand in which places of the water supply system of a private house it is necessary to install taps to prevent water leaks, you need to study the diagram. Most often, stopcocks with electric drives are installed after the pumping station and on the boiler.

Water leakage protection can be included, or you can assemble your own configuration from components

Heating is a little more difficult. Do not block the movement of the coolant if it is impossible to immediately extinguish the boiler. That is, in systems with solid fuel boilers, it is possible to set water leakage control only if it does not block the circulation of the coolant. If there is a small circulation circuit, it is possible to set the taps so that this small circuit is working and the rest of the system is turned off. If a heat accumulator is installed in the system, it is necessary to install taps so that water does not spill out of it. These are large volume containers - at least 500 liters, and usually many times more. If all the liquid pours out, it will not seem enough.

In heating systems with automated boilers, taps can block circulation. If the water leakage protection works and cuts off the circulation, the boiler will stop due to overheating. It's not exactly normal, but it's not an emergency either.

Causes of a toilet leak at the junction with the sewer

There are only a few reasons why a leak may form at the points of connection to the sewer:

- A skewed or damaged gasket is the most common cause of a leaking toilet joint. If it is new, and the joint is leaking, most likely you have assembled it incorrectly or there is a gasket defect.

- The corrugation of the toilet can often leak. This trouble is easily eliminated on its own. The reason for this is a dry seal. Over time, the rubber from which it is made ceases to be elastic and cracks. The result is gaps that open access to water.

- Loose drain tank mounting bolts. They are usually made of metal or plastic. Metal rusts over time, and plastic can burst.

- Another reason for a leak is a drain pipe.

Where can leaks occur?

Pipes, plumbing fittings and appliances (boilers, radiators, expansion tanks) leak as a result of their corrosion, aging of gaskets or mechanical damage.

When using steel heating pipes, depressurized joints lead to leaks in couplings, downpipes (battery connection areas), outlets, connection points for shut-off valves, heating and measuring devices, pumping and water heating equipment. Similar problems arise when using a metal-plastic pipeline, in addition to the above, water can flow out after some time through the threaded connections of the compression couplings as a result of their self-unscrewing.

Rice. 3 Detectors for detecting leaks in hidden pipelines

Some technical points

Wired sensors are usually supplied with 2 meter cables. Electric ball valves are sold with the same cable length. This is not always enough. You can increase the length using the cable recommended by the manufacturer. Brands are usually indicated in the instruction manual. Only when buying, check the cross section of the wires. Unfortunately, very often the actual diameter is much smaller than the declared one.

Generally speaking, we can recommend the following extension cables:

- for wired sensors, a shielded twisted pair cable with a core cross section of at least 0.35 mm² is suitable;

- for cranes - a power cable in two-layer insulation with a core cross section of at least 0.75 mm².

Not always the correct arrangement of elements is obvious

It is desirable to make the connection serviceable. That is, if you are laying wires in a wall or floor, the connection must be made in a junction box. Connection method - any, reliable (soldering, contactors of any type, since the equipment is low-current). It is better to lay wires in walls or in the floor in cable channels or pipes. In this case, it will be possible to replace the damaged cable without opening the strobe.

First steps to take

As soon as you notice that the washing machine is leaking, you need to immediately take measures to protect yourself and the apartment from unpleasant consequences. To get started, follow these steps:

- Unplug the machine from the mains, in no case stepping on a puddle to avoid electric shock. If you can’t reach the outlet from a dry area, turn off the electricity in the entire apartment (house).

- Shut off the water supply to the household appliance by closing the tap or completely turning off the water supply in the apartment.

- Drain the water from the washing machine tank using the emergency hose or drain filter (they are located below the loading door).

- Remove the laundry from the drum and proceed to inspect the equipment.

Most manufacturers of washing machines (LG, Beko, Samsung, Bosch, etc.) equip their equipment with a leak protection system. What does it mean? If any of the components leak, the Aquastop function blocks the further supply of water and its distribution to vital parts of the machine, such as the control panel. This prevents flooding of the apartment and the troubles associated with it.

What is an anti-flood and how does water leakage protection work?

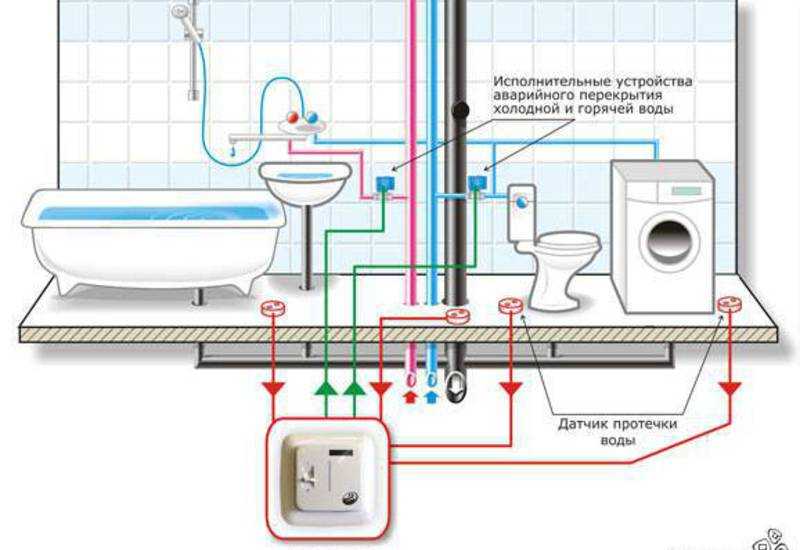

The anti-flood system consists of several elements: sensors for the presence of water, electrically controlled taps or valves, and a control unit. Sensors for monitoring the presence of water are placed in places of the most likely leaks. Electric taps are placed on risers with water, in key places of the water supply and heating system - in order to minimize the amount of spilled water in the event of an accident. Crane drives and sensors are connected to the control and management unit (controller). It processes the signals from the sensors and, in the event of an emergency signal, supplies power to the cranes. Those work by blocking the flow of water / coolant.Here, in a nutshell, is how water leakage protection works.

Protection against water leakage consists of three components: sensors for the presence of water, taps with electric drives and a controller that controls it all

These systems are installed both for water supply - hot and cold, and for heating. After all, an accident in the heating system is probably even worse than on the water supply - hotter water causes more damage, and can also cause serious burns. In general, in order for flood protection to be effective, it is necessary to think carefully about the installation locations of sensors and taps.

Where to place sensors

Since water protection is designed to protect against a flood, it is necessary to place sensors in all places where water is most likely to appear. It often happens that the system worked with a delay precisely because of the wrong location of the sensors. By the time the water reached the sensor, it poured out a lot. Based on the experience of the owners, we can recommend the following places for installing water leakage sensors:

Under each flexible hose. This is where emergencies most often occur.

Under household appliances that use water during operation: dishwasher, washing machine

Please note: you need to slip the sensor under the device. Those

install not next to it, but under it.

Catchment points are the lowest points where water will flow first.

Under the boiler, heating boiler, next to the pumping station, in the pit where the pump is installed.

Under the radiator, heated towel rail.

Near (under) with a bath, shower, sink, toilet.

When installing water leakage sensors, try to position them so that water hits them first. For example, to control a faucet in the kitchen, you need to put the sensor not under the cabinet, but in the cabinet - under the siphon or somewhere in the area. If something happens to the faucet, the water will first be in the closet and only then will flow under it.

If you need to control leaks in household appliances - a washing machine, a dishwasher - put sensors under the appliances. Not next to, but directly next to the connection point of the drain hose.

Repair of plastic and polypropylene pipes

Most modern sewerage, water supply and heating systems are made of PVC pipes. Water leaks occur in them less often and, as a rule, due to mechanical damage or due to improper installation.

In the event of a leak in the fitting connection, it is enough to tighten it - this is easy to do even without shutting off the supply. If the reason is a burst pipe, then almost any of the above methods is suitable for do-it-yourself repairs.

Taking into account the characteristics of the material, a slight leakage of water in PVC pipelines can be eliminated by soldering. To do this, carefully heat the burst area to a soft state, and also bring a small piece of pipe made of the same material to the melting point. Immediately after this, you need to apply molten plastic to the breakthrough site. Make sure that the pipe section does not deform from heating.

In case of severe damage, the pipeline can be cut at the leak and both ends can be covered with polyurethane, epoxy or hot melt adhesive. Then both pipes should be combined, after putting a cut plastic bottle on them. Next, a hair dryer is taken and the repaired area is heated until the home-made “sleeve”, shrinking and welding to the water supply, forms a tight connection.

Before repairing polypropylene pipes with your own hands using improvised means, consider whether it makes sense to expose your home to the risk of flooding, or is it still better to immediately replace the damaged area. If you have a welding machine and experience with it, this process will take no more time.

Recently, special nozzles for this kind of equipment have appeared on sale, allowing you to reliably seal through holes in polypropylene pipes. You can see how this is done in the video below.

Remember: almost all of the above methods for eliminating water leaks are only a temporary measure. Depending on the condition, it is necessary to replace all pipes or only the damaged section with a new one as soon as possible. In the absence of the appropriate skills and tools, you can always turn to professionals for help.

A flood in an apartment is always easier to prevent than to eliminate its consequences. By installing the Neptune automatic leak protection system, you will be reliably protected from unforeseen costs for the restoration of your apartment, as well as for compensation for damage to affected neighbors from below,

( 1 rating, average 5 out of 5 )

Leak Repair Materials

The heat carrier of the heating line of private houses is under pressure of 1.5 - 2 atmospheres, its maximum temperature rarely exceeds 80º C. The materials used to fix the leak must withstand these physical and thermal loads. To eliminate leaks, use:

- Clamps. The most common effective way to repair any pipes, metal brackets withstand pressure in the system up to 70 atmospheres with a coolant with a temperature of 100º C or more (depending on the material of the gaskets). They consist of two parts or one horseshoe-shaped plate, tightened with bolts, designed for standard pipe diameters (you can always find the right size on sale), they are used only on straight sections of the pipeline.

- Elastic bandages. Rubber elastic bandages are used to seal curved areas or fittings where they are leaking. The bandage does not withstand the supply of coolant under high pressure, so after winding it will have to be reinforced with wire or a steel clamp.

Rice. 5 Materials for fixing leaks in the heating system

- Repair tapes. On the construction market, you can buy a wide range of special tapes for pipe repair (Siloplast). Before repair, the tape is filled with water and then wound around the damaged section of the pipeline. After polarization, the coating withstands pressure up to 40 atmospheres, temperature range from -70 to +370 C., its service life is 50 years.

- Two-component formulations. Repairing leaks with special compounds, the most popular of which are epoxy and cold welding, is an effective method of dealing with leaks in curved areas or in hard-to-reach places. For better adhesion, the sealing site must be dry, free of dirt, paint and grease, epoxy resin is best used in combination with strapping materials - fabric, bandage, nylon tights, fiberglass.

Rice. 6 Installation of repair clamps in the heating system - examples

Light-curing plastic B. The kit includes liquid plastic and an ultraviolet lamp, under the radiation of which the material poured into the fistula polymerizes, the operating temperature range of Bondic is from -40º to +150º C.

The listed methods of eliminating leaks are the main ones; for short-term sealing of the fistula, chopiks (wooden wedges), bolts, cement coatings, various adhesives, individually and in combination with soda, are used. These options are ineffective even for a short time and cannot be the main methods for eliminating leaks in the heating main with high temperature and pressure up to 2 atmospheres.

What to do if the toilet is leaking at the junction with the sewer

The procedure depends on the area and the cause of the leak.

The junction of the bowl and tank is leaking

If the plumbing parting has worked for you for some time, then most likely the leak was formed due to the fact that the gasket cracked or the drain tank was warped.What to do if water oozes due to the fact that the gasket has served its purpose is clear without much explanation. It needs to be replaced. We do everything according to the instructions:

- turn off the water and empty the drain tank;

- wipe the inside of the tank dry so that not a drop of moisture remains there;

- disconnect the supply hose;

- unscrew the fixing screws holding the tank, and remove it;

- remove the locknut on the drain;

- remove the old gasket and replace it with a new one - it is better to immediately put the gasket on the sealant, it should not differ in shape and size from the old one;

- we assemble in the reverse order.

We supply water to the tank and admire the result of the work.

The corrugation is leaking

To fix the problem, ideally it is better to remove the toilet in order to have more room to work, but you can do without it. What is needed is to remove the corrugation, which has worked out its own, and clean up the landing sites.

The surface of the corrugations and seats must be treated with silicone sealant. The fit must be tight. After two hours, when the sealant seizes, you can check for leaks.

In cases where dismantling the toilet is impossible or there are difficulties, and the corrugation is not removed, there is one trick:

- the toilet must not be used for at least a day;

- climbing under the device, use a stick made of wood or plastic;

- at the place where the corrugation connects to the toilet, pry it off;

- after squeezing the corrugation, apply silicone sealant inside;

- gradually walking around the entire perimeter, treat with sealant.

Loose bolts

Loose bolts should simply be replaced with new ones. Everything is done very simply:

The water is shut off, the drain tank is drained.

The supply hose is unscrewed.

The bolts are dismantled - you need to act with extreme caution, since from time to time they have rusted and it is difficult to move them.

New bolts are installed, the main thing is not to forget about the gaskets - the bolts need to be tightened tightly, but not particularly zealous.

pipe leak

Very often, pipe leaks occur where the toilet is on cement mortar. Such installation was very often used, and it is used in old houses, where there has not been a major overhaul for a long time. The technique is simple and reliable, but over time the pipes leak. The fact is that gradually the coating crumbles and falls off. This leads to leaks. The remaining solution enters the sewer, and the leak expands more and more.

What is the right thing to do in such cases? You need to act as follows:

- arm yourself with a chisel with a narrow sting or a flat screwdriver and a hammer;

- beat off all the old plaster - you don’t need to hit it too hard, otherwise you will beat off the release of the toilet bowl;

- clean everything from dirt and debris;

- fill in the remaining gaps.

To seal, you can also use cement mortar. Simply dilute one part sand and one part cement with water. But this is the past century. Silicone sealant is much more convenient and effective. Yes, and it is in all hardware stores.

Before buying, consult with the seller which sealant is more suitable. Sanitary sealants are usually used, as they have better adhesion to the sanitary ware, from which the toilet is made.

If everything is done accurately, but the leak has not been eliminated, the best option would be to invite specialists. They will be able to quickly and efficiently eliminate all malfunctions. If the pipes in your house, like plumbing, have long outlived their usefulness, then it would be wiser to update them.