Draft floors from DSP on logs device technology

Leveling the subfloor for a decorative finish can occur in more than one way. Cement screed for this case is the most time-consuming and time-consuming process. Often, sheets of chipboard are simply laid on the base. This material shows its weaknesses both in the process of working with it and in subsequent operation. Chipboard has a fair amount of fragility, the ability to break at the ends and corners of sheets when sawing and fastening. Floors with such a base do not tolerate excessive moisture, therefore they are not suitable for bathrooms and kitchens.

Due to its strength, density, environmental friendliness, resistance to moisture, fire, decay, chemicals, DSP is considered one of the best sheet building materials and is an excellent basis for a subfloor.

For those who are already familiar with a relatively new building product - DSP, the question of choosing a material for a rough base disappears by itself.

Preparing for floor tiling

To lay the material on a wooden floor, you will need a draft floor (old wooden), insulation, vapor barrier material, DSP sheets. Before laying the DSP, the base is equipped, the logs are laid, and to perform the work, it is required to prepare a tool:

- hacksaw;

- kapron fishing line;

- pencil, felt-tip pen, ruler;

- nails, dowels, screws;

- drill;

- cipher machine.

You will need the following materials: timber, antiseptic, putty.

The basis for the lag

The base (soil, reinforced concrete) for laying the floor must be solid. In a private house on open ground, the surface is initially leveled, a sand and gravel cushion is laid with a layer of 20 cm, which is well compacted.

Supports for logs are laid out on the ground in the form of brick columns, inside of which cement mortar is poured. The distance between the supports (0.5-1 m) depends on the beam used for the log. To improve hydro and thermal insulation, a waterproofing material is laid, for example, a thick plastic film. It is laid with an overlap on the walls.

Concrete flooring is checked by the level horizontally. The floor is considered suitable if the deviation is no more than 3 cm, and the differences are eliminated by laying gaskets.

If there are serious irregularities, then a screed is made, otherwise the subfloor will be unstable and lead to deformations and damage to the decorative coating. Small cracks, pits puttied, sealed with cement mortar.

Installation of a log under the plates

- The beam is installed horizontally at opposite walls, leveled. The rest of the logs are stuffed along them in increments of 50 cm - this is an acceptable distance for mounting chip materials.

- The same step is used for fastening the ribs of the transverse crate. Fix materials with self-tapping screws, dowel-nails. Pieces of plywood are placed between the concrete and the lag, which gives strength.

- Insulation material is laid using a suitable material: polystyrene foam, mineral wool.

Cement chip sheets are laid on the installed logs.

Installing the DSP on the floor

Due to its excellent thermal insulation and water resistance qualities, DSP has established itself as an excellent material for rough floor construction in almost any room: on verandas, in the bathroom and in the bathroom.

Scheme of floors with DSP

Scheme of floors with DSP

The use of DSP floor slabs is strongly recommended in the construction of frame houses using Canadian technology. Since the plate (26-40 mm) is able to withstand a sufficiently large load, it is allowed to make floor logs not 40 cm, but 50-60 cm (under the width of the insulation).

Preparation for DSP before installation is not required (only sawing to the required dimensions), the plate can be laid on logs 50-80 mm wide, leaving a deformation gap of 2 mm (between the sheets).

Before attaching the DSP to the subfloor, you need to see if the sheet will cover the pipe hole. If the plate still covers the pipe, it is necessary to make markings 1 cm larger than the pipe diameter and cut the opening with a jigsaw (if the diameter is large), having previously drilled a hole with a 6-8 mm drill or made a cut with a hacksaw for metal, and then knock it out with a hammer (if the hole is edge).

Based on the characteristics of the rough floor, it is possible to “put” the DSP on the floor using an adhesive solution, additionally fixing the fastening with self-tapping screws.

Before installation, the adhesive is diluted in a certain proportion with water and mixed with a mixer to the desired consistency, after which it is evenly laid out on the floor surface (not less than the size of the sheet), only then the sheet is laid down. A gap must be observed between the sheets (as with mounting on logs). When the flooring is laid, all gaps are filled with glue. For details of wall and floor finishing, see this video:

Cement particle board, despite its heavy weight, has won a large army of "fan builders" who will never refuse to use this product due to the huge list of its positive advantages.

>

Characteristics of cement particle boards

DSP has a multilayer structure, as it is made by pressing from small chips, wood fibers, cement, and plasticizers. This is a universal material that is used for various construction, repair work in any climate for any finish. It does not have complete perfection, but it has a lot of advantages:

- High resistance to mechanical influences. Its mechanical strength is 3 times higher than the strength of chipboard.

- Immunity to the appearance of mold, fungi due to the alkaline environment.

- Ability to withstand humidity, critical temperatures.

- Fire safety due to the presence of additives in the composition that reduce the risk of fire.

- Long service life.

- Convenient installation, ease of drilling, fastening, cutting.

- There is no need for additional leveling - the surface is flat, smooth.

- Environmental friendliness - in the composition of natural wood and cement.

- Good noise isolation (up to 30dB).

- Low cost due to simple manufacturing technology, the formation of voids and internal defects is excluded during production.

Of the shortcomings, only two are distinguished: when cutting the material, cement dust is released, and during installation, the large weight of the plate causes inconvenience.

Given the characteristics of the material, the method of manufacture, it becomes clear why the chipboard laid on a wooden floor is popular.

Benefits of using cement particle board for flooring

This material is becoming more and more in demand, due to its excellent parameters.

The main advantages of the products include:

- Strength. This quality ensures the stability of products even to serious mechanical stress. Point loads do not weaken the part structure.

- Environmental friendliness. The base, consisting of cement and a wood component, to which special modifiers are mixed, does not pose a threat to human health.

- Fire safety. The resulting coatings are highly fire resistant. Exposure to severe temperatures does not lead to deformation or the release of harmful substances.

- Resistant to mold and mildew. The presence of alkali in the composition excludes the development of microorganisms on the surface.

You can lay the parts with your own hands without the involvement of specialists, but the work has certain nuances.

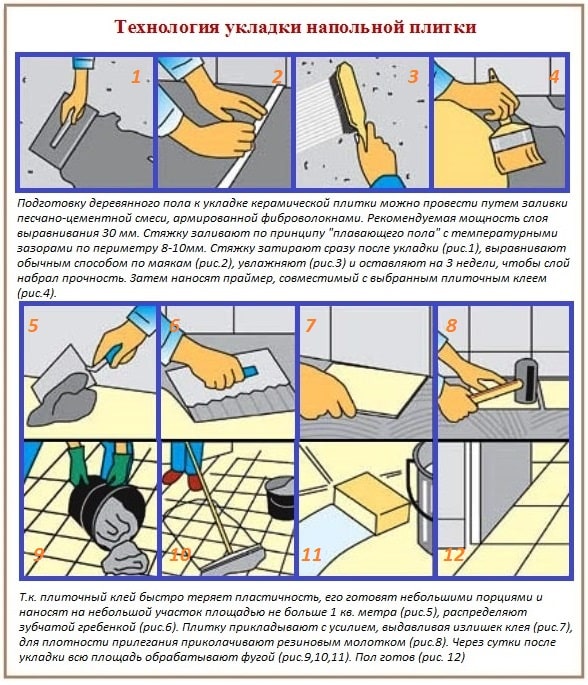

Laying tiles on a wooden surface

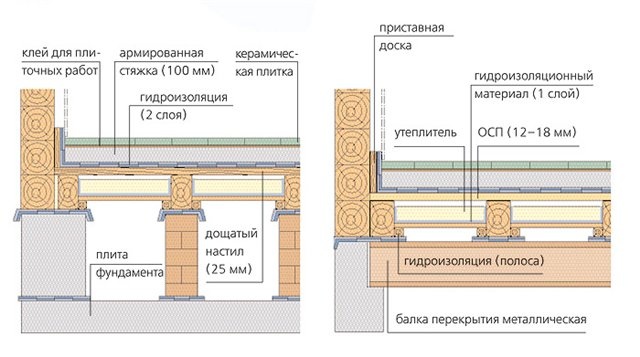

The scheme of installation of tiles on wooden floors.

Installation of a tiled coating on a wooden base is possible only if it maintains integrity and does not rot. The weight of ceramic tiles, further increased by the adhesive, can lead to deformation of the wooden floor, its cracking and destruction. Plank floors, which, when examined, look unsuitable to withstand a large load, are best dismantled. It is more expedient to get rid of the rotten subfloor, which will no longer be helped by any surface preparation. If the wooden boards have a reliable fortress, it is enough to make sure that they are well attached to the logs and that there are no too wide gaps between them.

Loose floorboards are fixed with self-tapping screws or dowel-nails, and the gaps between the boards are puttied, previously reinforced with thin wood chips. The preparation of the floor from chipboard or plywood is carried out in the same way. The use of a waterproofing underlay when laying tiles on a wooden surface is mandatory. Wood has the ability to absorb moisture well and change size with temperature changes, and the insulation of the subfloor will protect the tiled floor from instability.

https://kuhnyamoya.ru/youtu.be/ukXcbORkvWA

What is the best way to apply

Between the tree and the monolith, it is necessary to lay a moisture-proof layer

For greater reliability, the method of "incoherent" screed for a wooden floor is used. At the same time, its isolation from the floor covering and walls is observed.

The floor is leveled first. A moisture-proof barrier is created between the moving part of the floor and the monolith.

For this it is used:

- thick polyethylene film;

- material in the form of a damper tape, which is fixed at the bottom of the wall and floor;

- expanded polystyrene;

- ruberoid;

- material impregnated with bitumen.

Wood must be treated with an antiseptic and a layer of waterproofing, preferably from bituminous mastic, should be applied. Then you can lay the film, leaving a ledge of 20 cm on the walls and be sure to make overlaps. They are glued with adhesive tape, they achieve a complete absence of joints, holes and wrinkles. How to make a screed on a wooden base, see this video:

Helpful Hints

To achieve the best result, you can use some recommendations:

- Installation of DSP on the floor is most relevant when laying tiles: in this case, the highest quality adhesion is achieved.

- Before use, it is better to keep the material indoors for a day. This will eliminate possible errors.

- If work is carried out on a “wet” screed, then you should wait for it to dry completely.

- Procedures are best done with an assistant, especially when using thick plates.

Provided that all work is carried out correctly, the surface will be distinguished by increased reliability.

Such innovations include DSP floor slabs, which are excellently used instead of cement-sand mortar screed as a rough floor covering, especially in wooden and frame houses.

Styling features

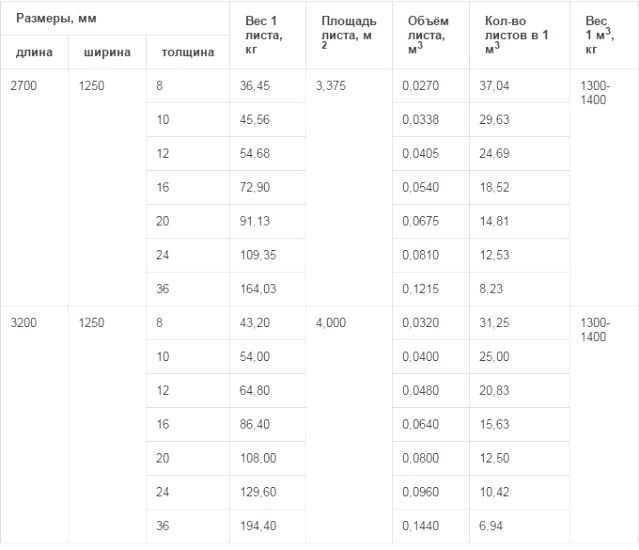

To properly lay the products, you need to accurately select the thickness of the cement-bonded particle boards:

- The optimal value when working with a concrete or plank base is 10–16 mm.

- If the installation is carried out on logs with a step of 50–60 cm, then elements with a thickness of 20 to 26 mm are selected. On the first floor, it is recommended to lay products with a thickness of 10–14 mm in two layers.

- Prefabricated floors in domestic and technical premises can be made with sheets with a thickness of 24 to 36 mm.

Preparatory work

So that the installation of floors from DSP does not take much time, you need to carry out all the preparatory procedures in advance.

markup

The area of the room is measured and a detailed diagram is drawn up with the data obtained.

It is very important to pay attention to difficult areas. If there are tapering parts or niches in the room, it is necessary to break such places into several sections in order to get the right result.

Temperature gaps are left from the walls, which level out deformations during shrinkage of the building.

According to the plan, taking into account the selected size of the plates, it is determined how the sheets will be attached

The technology of laying on logs involves laying parts across.

Cement-bonded particle boards are being prepared

To do this, the dimensions are transferred to the details according to the location on the floor covering.

Sawing

Further work may cause some difficulties: it is necessary to choose how to cut the DSP.

To cut the slab, the following tools are used:

- Bulgarian. This is the most efficient option if panels over 12-14mm thick are used. To work, you will need special diamond blades that provide a quick and reliable cut.

- Electric jigsaw. The use of such a tool is limited: only thin parts can be cut with it. Thicker elements will require a set of good files, which are selected by experience, and a lot more time and effort.

- Construction knife. It is possible to cut thin plates with this device as follows: with a blade resting on the edge of the ruler or rail, a recess is formed along the line, after which the product is shifted beyond the border of the table and breaks off.

Mounting plates

To lay the parts on a horizontal base in a private house or apartment, you can use different methods, which depend on the type of surface.

Mounting with glue or screws

The fixation method is selected based on the specific situation:

- Screws provide reliable fastening to wooden bases.

- When using self-tapping screws, it is recommended to pre-drill the holes with a high-speed tool. They should be slightly larger to prevent shrinkage cracking.

- It is necessary to glue the parts with a special composition after preliminary priming of the surface of the plates and the floor.

In some situations, methods can be combined.

Laying on logs

For the process, a wooden beam with a cross section of 5 * 8 cm is selected, which will provide the best reliability and rigidity. Parts must be dried and treated with protective compounds.

- Lags are mounted. All elements are aligned with each other and fixed. It is recommended to place insulation under them, cut into strips, which will avoid the appearance of cold bridges. If required, jumpers are arranged.

- The empty space is filled with heat-insulating material. A dry screed is created in a similar way.

- DSP boards are laid according to the drawn up scheme with a gap from the walls. If the house was built recently, it is advisable to leave a small distance between all the details, sealing it with putty or sealant.

- It is necessary to fasten the panels to self-tapping screws in increments of 20 to 35 cm. The hat must be immersed flush.

Mounting on a concrete screed

You can lay the plates on such a base as follows:

- The surface is cleaned of everything superfluous, dirt and debris are removed. Work is carried out only at low humidity of the coating.

- Priming is carried out with a deep penetration composition, the floor is dried.

- The mixture is being prepared. For laying, you will need a notched trowel, which will ensure an even application without the formation of voids.

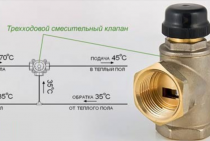

This method is great for a warm water floor, but all the gaps between the tubes are pre-sealed with a bulk mixture.

Laying tiles on CSP boards

The process of laying tiles on the surface of a DSP slab is not difficult, it is very similar to laying on a regular drywall or other even prepared surface. After the primer layer is completely dry, it is necessary to start preparing the adhesive composition, which must be done in small portions. One such portion should be enough for about 1 m² of surface. When choosing an adhesive, it is necessary to take a special elastic solution, which is designed to work with cement-bonded particle boards, and liquid nails are also suitable.

Scheme of laying floor tiles.

When laying tiles on the DSP, it is best to take an elastic adhesive. It provides excellent adhesion of the coating to the surface of the base base. You can start laying from the corner or from the center of the first row - it all depends on the features of the chosen scheme and whether cutting of the tiles is necessary. After laying the first row, it is required to check its horizontal and vertical position with a building level. After 2-3 rows, it is recommended to stop work for about an hour. This is required not so much for rest, but for the DSP plate to normally take all the loads. If you do not take such a break, then after laying during operation, deformation of the surface may occur, the tile may crack. To ensure the evenness of the masonry and tile joints, it is necessary to use special plastic cross-separators. They are placed in this way: one in the corners between individual tile plates and two on each side.

When the laying of the tiles is completed, it is necessary to leave the surface of the cladding for 24 hours. This is quite enough for the adhesive solution to set. After a day, you can proceed to the next stage of facing, which consists in the fact that the seams must be filled with grout. All plastic separators are removed, start grouting. As such work is done, it is necessary to carefully remove all the glue from the surface of the tile, otherwise it will harden and it will be problematic to remove it. To increase the moisture resistance of the coating, it is recommended to use a special sealant, it is applied with a thin, soft brush.

Tiled flooring is one of the most popular today for bathrooms, toilets, corridors, kitchens. Some types of tiles can be used for flooring in bedrooms, living rooms, offices. To lay a tile, you need a perfectly even base, which is best to use DSP boards with the required properties. The installation of the coating itself is quite simple, it is no different from the lining of drywall or a concrete base.

Preparing a linoleum floor for tiling

Before deciding on the suitability of linoleum as a base for laying tiles, you need to examine its reverse side, lifting the edges. If this material was poorly glued, mold and fungus could appear on the back surface. Small formations can be cleaned and treated with oil paint or primed. In case of a large accumulation of dirt and microorganisms, it is recommended to remove the old linoleum and lay the tiles on a concrete base.

https://kuhnyamoya.ru/youtu.be/WeVlg1fqn-g

The coating suitable for further work is treated with a sharp object, applying cross-shaped notches for better adhesion of the slippery surface to the tile. Processing with coarse sandpaper will enhance the effect, giving the material the desired roughness.

Characteristics of the DSP, its advantages and disadvantages

Cement particle board (CSP) is a durable building floor material that has excellent thermal insulation and water repellency.

The DSP floor is characterized as a fast-installing structure, which has varieties in thickness, directly dependent on the patency in the room.This type of subfloor has its own characteristics in installation and structure, as well as certain distinctive characteristics.

Characteristics of the DSP

One of the most important indicators that characterize the DSP board for the floor is the density. For a standard cement particle board, its value reaches 1300 kg per m 2.

Plate density is high

Plate density is high

Also, the most important property of the material can be considered humidity, which is always in the range of 6-10% (the product passes factory tests). If the particle board has been in contact with water for a long time, its swelling percentage should not exceed 2%. Only if this requirement is met can the material be placed on the market. This property is one of the main advantages of DSP.

Answering the question: “What is a DSP?”, we can say that this is a multi-component product. Indeed, this type of slab contains 65% cement, 25% wood shavings of various species, 8% water or other moisturizing liquid and 2% liquid glass or its equivalent.

The content of a large amount of cement in the product allows it to be used for a long period without losing its properties and the integrity of the sheet (without delaminations, like chipboard).

DSP for the floor has a standard size of 3200x1250, but this does not mean that the product cannot be of other sizes (on order, a cement-bonded particle board of any parameters can be made at the factory).

This type of product has differences in the thickness of the building material, which is 10, 20, 25, 30 and 40 mm, which adds versatility to the product and makes it possible to use it in a fairly wide area for both indoor and outdoor use.

Some plate parameters are given in the table.

Advantages and disadvantages of DSP

Cement particle board is definitely a high quality sheet material that is widely used in indoor and outdoor applications. DSP is very often used when organizing floor coverings and making facade cladding.

Like any other material, it has its positive and negative properties. The clear advantages of CSP include:

- good water repellency;

- ease of installation;

- relatively low cost of the material;

- good sound insulation performance (indicators reach 30dB);

- resistance to sudden changes in temperature;

- the product is not subject to rotting and fungal infections;

- high degree of fire resistance (due to special additives in the DSP);

- long service life;

- environmentally friendly material (no harmful resins);

- perfectly flat surface of the product (ready for installation of tiles or stone).

The disadvantages of a product made of cement-bonded material include, first of all, harmful installation (sawing DSP) and the weight of the slab. For more information about the types of plates and the features of their application, see this video:

Since the dust emitted during sawing of the material has harmful elements and can easily clog the respiratory tract. In addition, due to dust, the visibility of the work being done is deteriorating, so you should be extremely careful and careful to avoid injury.

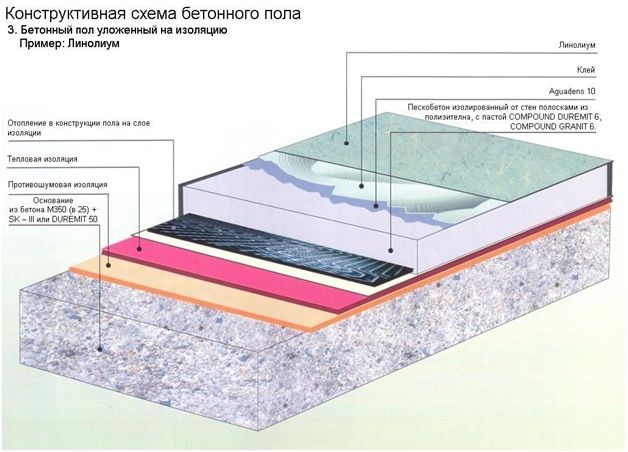

What are the screeds

Screed is the top layer on a wooden or concrete floor, which is then finished with a floor covering.

There are the following types:

- Dry.

- Cement.

In the first case, when using this type of screed, the surface becomes resistant to various loads and becomes high-strength.

It is made of drywall, moisture-resistant plywood or PVC sheets by laying on expanded clay or quartz sand. This type of flooring is the most suitable for a wooden floor.

A cement or concrete screed on a wooden floor is used as a base for a polymer coating or ceramic tiles.