Leakage in the system

Logically, if the station does not turn off, it means that there is not enough water in the tank. There are two options: the pump does not have the ability to pump water, or the water leaves the system. In the second case, you need to check all pipes and taps, as well as the drain tank. If the pipes are metal, leakage may occur if the metal is rusted or corroded. Here you need to replace the segment that has become unusable. If it flows at the place of twisting of parts, it is necessary to use winding. Well, with a leaking tap, every man can deal with it.

Plumbing scheme for the house. During installation, it should be taken into account that there is free access to all elements

It has become fashionable to hide pipes in the walls. But even plastic pipes can leak on twists. Detecting a water leak behind a wall is very difficult. In addition, in private homes it often happens that pipes are damaged by freezing, which can also cause leakage. To avoid this, insulate pipes that are on the street.

Hydraulic accumulator malfunctions for water supply systems DIY repair and adjustment methods

An important aspect that ensures the comfort and coziness of suburban households is the stable and uninterrupted functioning of an autonomous water supply system.

Therefore, many owners of houses and cottages, first of all, pay special attention to the correct installation of the water supply system and all its structural elements, since the supply of water from a well or well directly depends on their work. As a rule, an autonomous water supply system consists of the following components:

As a rule, an autonomous water supply system consists of the following components:

- water pump,

- hydraulic accumulator or hydraulic tank,

- main pipeline.

Undoubtedly, for the normal functioning of water supply, the failure-free operation of all the above structural elements is important.

But today we want to focus your attention on the hydraulic tank, which plays a key role in an autonomous water supply system, and also on the uninterrupted functioning of which, it largely depends on whether you will have water in the tap or not.

Therefore, in this article we will talk about what a hydraulic accumulator is, what tasks it performs, and also give recommendations on how to eliminate various kinds of malfunctions and breakdowns of this important element of an autonomous water supply system.

Therefore, in this article we will talk about what a hydraulic accumulator is, what tasks it performs, and also give recommendations on how to eliminate various kinds of malfunctions and breakdowns of this important element of an autonomous water supply system.

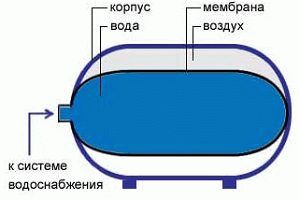

What does it consist of

- device platform,

- metal case, which can be made of both high-strength steel and stainless steel,

- accumulator membrane or pear-shaped rubber reservoir,

- flange with valve for water supply,

- nipple designed to pump air into the device.

Why do you need

For greater awareness, it is worth noting the fact that the accumulator is designed to perform a number of the following tasks:

- accumulates a reserve supply of water in case of emergencies in the water supply,

- stabilizes excess pressure that appears in the water supply,

- protects the pipeline from water hammer that occurs when the water intake pump is turned on,

- maintains a stable water pressure in the pipes when the pump is off,

- contributes to long-term operation of the pump, since the pump unit is turned on much less frequently,

- contributes to a uniform supply of water at the moments of maximum consumption.

You may be interested in an article about repairing pumping stations for your home with your own hands.

Read an article on how to make a hydraulic accumulator yourself here.

How to repair

Therefore, an important fact is that in the event of various kinds of malfunctions and failures, they will urgently need to be corrected.

Among the possible malfunctions of the accumulator, a number of the following points can be distinguished:

Weak pump power

Someone will say that there can be no problem with insufficient power, because before buying a station, the required power is calculated, depending on the depth of the well, the amount of water consumed and the design features of the pipeline. However, power problems arise when:

- wear parts of the pump;

- changes are made to the pipeline system;

- the water level in the well drops.

Wear of parts occurs more often in centrifugal pumps. If the water is not of high quality, and there are sand impurities or small specks in it, they fall between the pump shaft and cause parts to loosen. So the unit works, but cannot provide sufficient water pressure.

You can avoid this by setting special filters. And to cope with the problem, you will have to take the pump for repair, well, or replace it with a new one. In a vibration pump, a rubber valve may wear out, which must be changed, and thereby solve the problem.

Before installing a new washing machine or dishwasher, or laying out additional pipes, calculate whether the power of the pumping station is enough for this. Some experts advise buying a pump more powerful than necessary in advance. After all, technology does not stand still, and you may want to connect an additional device that consumes water.

If the water level in the well has dropped, the water pressure will decrease significantly or completely disappear. When the water drops too much, it may be necessary to purchase a submersible pump. Buying a more powerful pump will solve most of the problems: having spent money once, you will no longer be nervous due to station malfunctions.

The principle of operation of the pumping station

The main part of the station is the pump. In principle, to provide water to a private house, you can limit yourself to an ordinary water pump, and not install a turretless one. But in this case, every time you turn on the faucet or drain the toilet, the pump will turn on. Such frequent switching on will lead to the fact that the parts will quickly become unusable and you will have to take the unit in for repair, or even purchase a new one.

To prevent this from happening, a special tank for collecting water is attached to the pump - a hydraulic accumulator. Now the pump pumps water into the tank and turns off. The water in the tank is pressurized with compressed air. When the water level drops to a critical level, the pressure drops and the pump starts, which again replenishes the water supply. The pressure in the accumulator is regulated by a special pressure switch. Thanks to the tank and the relay, the pump starts up much less frequently.

But it happens that the pump turns on too often or does not turn off at all. This happens when the pressure drops in the pumping station. The reasons for this problem can be different, here are the most basic:

- low voltage in the network;

- leakage in the system;

- weak pump power;

- air entering the pipes;

- hydroaccumulator problems.

In order to understand why the pumping station is not gaining pressure, let's look at the above causes of the problem more carefully.

Hydraulic accumulator for water supply

The accumulator is intended for closed water supply systems in the private sector and in summer cottages. The choice of this device must be taken seriously, and first you need to understand which particular model you need to choose, because each of them has its own differences and features in operation and repair.

Hydraulic accumulator device and principle of operation

Inside this apparatus there is a membrane, it divides it into two parts, one contains gas, the other contains water. Also, the accumulator is equipped with a pressure gauge for measuring pressure, and a water inlet. A pump is used to supply water. Also in the accumulator there is also an automatic device that will turn off the device if the pressure in it reaches a certain point. And when part of the water is used up, and the pressure becomes less, the same automation will restart the device.

Hydraulic accumulator, why is it needed in water supply

1. Extend pump life. 2. Prevent harm from water hammer. 3. Supports pressure. 4. Prevents breakage of both elements of the water supply system and equipment.

These devices are usually divided into vertical and horizontal, according to the method of installation.

But in any device it is very important to remove the air that has gathered in the part where water is stored in time. In vertical membrane tanks there is a special nipple that removes air

And in horizontal membrane tanks, in order to remove air, in addition to the nipple, you need to have a sewer drain and a ball valve.

If your accumulator is less than one hundred liters, what is needed to remove air:

- Disconnect the machine from the network.

- Open mixer valve.

- Empty the tank.

- Close mixer valve.

- Connect the machine to the network.

This action must be performed once a month.

Membrane tanks are blue, for cold water, as a rule, they are much safer, since the membrane is made of food grade rubber. And red, for hot water. Such a tank is not used for cold water, since the membrane is made of a different material and is not suitable for cold water supply.

It is important to know that many foreign companies produce hydraulic accumulators that may not be suitable for your water supply system, and this may adversely affect the operation of the device. How to prevent breakage

How to prevent breakage

Most often, during the operation of the accumulator, it is the rubber membrane that deteriorates. If the pressure in the system is increased or sharply reaches its maximum value, then drops sharply, and water is supplied in a small amount, and besides, the supply is often interrupted, this means that the rubber membrane has become unusable. To verify this, you need to press on the spool of the nipple to remove air. And if, after removal from the spool, water flows, then the problem is in the membrane, if the water does not go, then the problems are in the spool or in the connections.

To replace the membrane you need:

- Buy exactly the same membrane.

- Disassemble the device (the diagram is indicated in the technical documentation)

- Replace membrane

- Assemble the device.

When repairing, make sure that the edges of the membrane do not come off. In this case, you will have to redo everything.

Problems with the accumulator

Problems with the accumulator occur when:

Problems with the accumulator arise due to many reasons.

- the pressure switch is incorrectly installed (or it is faulty);

- the membrane inside the tank ruptured;

- low air pressure in the accumulator;

- leak in check valve.

If the maximum pressure in the relay is not set correctly, the pump will turn off with a delay. To fix this, slightly loosen the nut on the smaller spring. The unit will start working normally.

If the pressure switch does not work at all, it must be replaced

To understand that the relay is broken, pay attention to whether there are smudges from the fitting. In the case when the pressure in the tank is normal, and there are no smudges, the problem is in the relay

Press the air inlet if water starts dripping, i.e. the entire accumulator is filled with it. Those. there is water in the place where there should be air to provide pressure in the tank. This indicates a rupture of the rubber membrane, which must be replaced.

If the pump is turned on at night when no one is using the water, you can suspect that the check valve is leaking. In this case, the tank cannot fill up to the end, as the water flows in the opposite direction. To change the situation, you need to clean the valve.

If you have a surface pump built into your station, the cause of low pressure can also be:

- Empty suction pipe. The first start-up of such a pump can only be carried out if it is filled with water. Otherwise, the unit will not be able to work normally.

- Seized pump impeller. If you have not used the station for a long time, the impeller may turn sour (especially if the water quality leaves much to be desired). Unplug the unit from the socket and rotate the impeller by hand. If you succeeded, then after starting the station will work as expected.

- Capacitor failure. If you turned the impeller as described above, but there is no effect, you will have to spend money on purchasing a new capacitor.

If you have a deep pump installed, the breakdown may also be:

- pipe break underground: if a pipe burst between the well and the pump, then you have a lot of work to do, because you have to dig out the gust and eliminate it;

- breakdown of the unit: it may be that the pump itself has broken down - is it possible to fix it, the master must decide.

A pumping station is a very necessary thing for private houses. Its installation requires a lot of effort and financial investment. Therefore, if you have not encountered the repair of water pumps or are not confident in your abilities, let specialists diagnose and repair the station. After all, trying to repair a thing in which you do not understand the device, you can do more harm than good, and further repairs will cost even more.

After reading the article, you will be able to control the work of the masters, and not give them the opportunity to take extra money from you. If you decide to repair the pumping station with your own hands, carefully read the instructions. Let your equipment last as long as possible.

https://youtube.com/watch?v=4HTzY8JTz1c

Membrane for accumulator how to replace it in case of malfunction

The normal functionality of the home water supply system depends on the health of the accumulator. If there are malfunctions in the water supply network, it is necessary to immediately determine the cause of the malfunction and repair the equipment. Otherwise, more serious damage and irreversible failure of all equipment may occur. The most common cause of failure is the accumulator membrane. We will learn how to check, replace and diagnose the system.

How to test and troubleshoot

Most hydraulic accumulator malfunctions can be corrected independently. All reasons can be divided into several groups.

Table 1. Faults in hydraulic accumulators

Start draining water.

If at the same time air escape is observed, then the membrane has mechanical damage.

lack of compressed air in the tank.

Pumping air to the required pressure

Recommendations for the maintenance of hydraulic accumulators:

How to check the initial pressure in the tank:

- Disconnect the tank from the system.

- Drop the water.

- Connect a pressure gauge to the nipple.

- If the readings are lower than the default ones, it is necessary to pump up the pressure to the working one (with a car compressor, for example).

Membrane selection

Hydraulic accumulators distinguish between vertical and horizontal versions. Accordingly, membranes are also distinguished in various shapes and designs: cone-shaped, cylindrical, spherical, ribbed.

When replacing a unit, you should purchase a product with similar characteristics - size, volume, neck diameter, maximum temperature of the working medium, material, working pressure, etc.

Replacement cost

The membrane is an element of equipment that most often fails, because. subjected to constant compression and expansion. The cost of replacement depends on the type of tank, capacity, type of membrane, manufacturer.

If the water supply system is operated continuously, it is advisable to purchase a more expensive membrane that can withstand more cycles of operation.

The cost of models of imported manufacturers reaches half the cost of the accumulator itself. At the same time, the nominal service life of products is several times higher than cheaper ones.

Membrane replacement

With minimal skills in working with plumbing equipment, replacing the membrane on the hydraulic tank is not difficult. By following the correct procedure, replacing a node takes a minimum amount of time:

- Disconnecting the tank from the water supply.

- Remove excess air pressure with a nipple.

- Drain the water from the container.

- Remove the pressure gauge, freeing up space for the diaphragm to exit.

- Remove non-working part.

- Install a new membrane, fix the pressure gauge.

- Pump up pressure 0.2 less than the lower pressure of the pump switch.

- Install back.

After that, it is necessary to check the operability of the water supply. To do this, it is necessary to fill the system with water and control the operation of the tank.

Repair or how to glue

The membrane can be repaired by vulcanization. This method can extend its life by several weeks - until a serviceable product is purchased and installed. But any repairs are a temporary measure and in any case you will have to buy a new one.

Hydraulic accumulator without membrane

In addition to typical factory-made hydraulic tanks, you can make such a device yourself. A hydraulic accumulator without a membrane is an ordinary water tank. It is the membrane that helps maintain the pressure in the system. It is much easier to buy an inexpensive ready-made accumulator.

In order to build a hydraulic accumulator yourself, the following materials are needed:

- tank (capacity) with a volume of at least 30 l,

- stop valve,

- ball valve,

- half inch faucet,

- fasteners (washers and nuts),

- sealant (sealant),

- rubber pads,

- nipple,

- fittings (tee, chervernik).

- Make holes in the container (on the lid and bottom, on the side).

- Install a half-inch valve in the upper hole (on the cover), seal the connection with gaskets and sealant, fix with washers.

- Attach a tee to the faucet.

- Fix a ¾ shut-off valve in the lower hole, on which put a tee.

- Install a ball valve on the side hole.

A malfunctioning accumulator can affect the operation of the entire water supply system. By applying the tips and methods described in the article, it is easy to troubleshoot your home plumbing system. Timely prevention can prevent serious breakdowns and premature failure of hydraulic tanks and the entire system as a whole.