Requirements for a diesel boiler house in the house

Installing a diesel boiler in a house is a complex technical process that requires qualified assistance. When connecting, take into account the current regulatory requirements and fire safety regulations. Adjustment and maintenance are carried out using special computer software.

The organization of heating in a private house with a diesel boiler is carried out subject to the following conditions:

- The room for the boiler is chosen from technical rooms with sufficient area, lighting, ventilation.

- The placement of diesel boilers in residential country houses is carried out on a non-combustible base. Wall and floor decoration is carried out using non-combustible building materials: ceramic tiles, plaster.

- Automation - maintaining the temperature in the house is carried out automatically. Human participation in the operation of the heat generator is reduced to a minimum. Be sure to install safety automatics that turn off the operation of the boiler in the event of an emergency.

- Ventilation in the boiler room is provided through channels with natural and forced supply and air exhaust. The cross section of the ventilation duct is calculated based on triple air exchange for an hour.

- Diesel fuel storage is installed in a separate building. In the boiler room, it is allowed to store a reserve tank, with a maximum capacity of not more than 3-5 m³.

The correct installation of a diesel boiler in a residential private house is based on an understanding of work processes. The burner device creates strong noise interference, therefore, soundproof measures are carried out in the boiler room.

Additionally, a UPS and a stabilizer are installed to ensure the system's performance, even during power surges or power outages.

Advantages and disadvantages of domestic diesel fuel boilers

Reviews of diesel heating boilers for private houses and cottages indicate the same problem. A domestic consumer, if he reads the instruction manual, adjusts the operation of the boiler to his needs, violating the manufacturer's recommendations, which is the main cause of malfunctions.

The performance of boiler equipment depends on proper operation, from precisely set settings to the need for regular maintenance. If you properly heat the house with a diesel boiler, there are high rates of efficiency and heat transfer. Any violations lead to excessive fuel consumption.

The disadvantages of heaters are:

- Noisiness of boilers - as a rule, noise is not heard if the passage to the boiler room is closed by a door. It is not recommended to install a diesel boiler in the kitchen or any room adjacent to living rooms.

- Maintenance cost - you will need to regularly clean the heat exchanger and chimney from accumulated soot. When switching to another type of liquid fuel, as well as before the start of the heating season, it is necessary to adjust the burner. The best solution that allows you to save money is the conclusion of a contract for ongoing maintenance.

The advantages of boilers are considered to be low installation costs, quick commissioning, no need for permits and approvals.

The most economical boiler is one that is installed and operated in accordance with the manufacturer's recommendations. After installation and connection, a representative of the company will instruct on the use of the heat generator.

Operating experience shows that following the recommendations is the best way to extend the life of the boiler, ensure maximum heat transfer and comfortable heating of residential premises.

Calculation of power and temperature of a warm water floor

Using a propane-butane mixture

Autonomous heating of private houses with liquefied propane or its mixture with butane has not yet lost its relevance in the Russian Federation, although in recent years it has noticeably increased in price

It is all the more important to calculate the future consumption of this type of fuel for those homeowners who plan such heating. The same formula is used for the calculation, only instead of the net calorific value of natural gas, the value of the parameter for propane is set: 12.5 kW with 1 kg of fuel

The efficiency of heat generators when burning propane remains unchanged.

Below is an example calculation for the same building of 150 m², only heated with liquefied fuel. Its consumption will be:

- for 1 hour - 15 / (12.5 x 92 / 100) = 1.3 kg, per day - 31.2 kg;

- on average per day - 31.2 / 2 \u003d 15.6 kg;

- on average per month - 15.6 x 30 \u003d 468 kg.

When calculating the consumption of liquefied gas for heating a house, it must be taken into account that fuel is usually sold by volume measures: liters and cubic meters, and not by weight. This is how propane is measured when filling cylinders or a gas tank. This means that it is necessary to convert mass into volume, knowing that 1 liter of liquefied gas weighs about 0.53 kg. The result for this example will look like this:

468 / 0.53 \u003d 883 liters, or 0.88 m³, of propane will have to be burned on average per month for a building with an area of 150 m².

Given that the retail price of liquefied gas is an average of 16 rubles. for 1 liter, heating will result in a considerable amount, about 14 thousand rubles. per month for the same cottage for one and a half hundred squares. There is reason to think about how best to insulate the walls, and take other measures aimed at reducing gas consumption.

Many homeowners expect to use fuel not only for heating, but also for providing hot water

These are additional costs, they must be calculated, plus it is important to take into account the additional load on heating equipment

The thermal power required for hot water supply is easy to calculate. It is necessary to determine the required amount of water per day and use the formula:

- c is the heat capacity of water, equal to 4.187 kJ/kg °C;

- t1 — initial water temperature, °С;

- t2 is the final temperature of the heated water, °С;

- m is the amount of water consumed, kg.

As a rule, economical heating occurs up to a temperature of 55 ° C, and this must be substituted into the formula. The initial temperature is different and lies in the range of 4-10 °C. For a day, a family of 4 people needs approximately 80-100 liters for all needs, subject to economical use. It is not necessary to convert the volume into mass measures, since in the case of water they are almost the same (1 kg \u003d 1 l). It remains to substitute the obtained value QDHW in the above formula and determine the additional gas consumption for hot water.

Alternative heating of the house with diesel fuel

What could I do to make solar heating at home a little less expensive, and could use a diesel boiler as the main source of heat for the house?

The first thing I think about is using a waste oil burner. I put such a burner for testing and collect virtually free fuel, where I can - at service stations, at express oil change kiosks, and so on.

What are the disadvantages of this option? The first and most basic is the price of the burner. The cost of the burner for testing is 60,000 rubles. Which is comparable to the purchase of almost 2 tons of diesel fuel.

Secondly, working off also needs to be collected, spending gasoline and time, transporting it in cans to the house, defending it somewhere and storing it at this time.

And, thirdly, I'm not the only one so smart. More than once I have already watched comrades who collect mining at the service station and take it out for their own needs. This is exactly the same topic as with our own production of pellets. Looks like it's free. But in fact, it turns out that it is easier to heat with briquettes than to make pellets yourself from “free” sawdust.

There is, of course, also solar oil and light oil. But it also has its pitfalls. Starting from the fact that a standard burner will not be guaranteed to work on these types of fuel, and ending with the complete impossibility of obtaining this fuel in some regions.

Here the analogy with the coal-fired boiler Carborobot suggests itself. The boiler is good, no doubt. But in our region there is no fuel for it, there is no coal of the required fraction, there are no good suppliers. And to carry from somewhere - it turns out to be unrealistically expensive.

by autoruMAX » Mar 05, 2012, 06:39 pm

Good afternoon There was a problem of organizing a boiler house in the domain, you need to choose a diesel boiler for 30 kW, in pair with it, an electric boiler for 12 kW (which one is better?) A hydraulic arrow for 8 circuits - 5 for heating - a pool heat exchanger - a heated floor 1 circuit for an area of 70 mkv

the main question about a diesel boiler is which is better, which chimney is better for it? (height from the boiler room to the ridge is 14m - there is a place under the chimney - a shaft 1.5x0.7m)

how to connect boilers

in the future (in 3-4 years it is possible to switch to main gas) and increase the area from 300 to 500 mkv

water supply separately - completely on an electric boiler 300l (what a good one - so that a few tenns and spare parts if it's easy to buy)

For a diesel boiler, the most important parameter is trouble-free and so that you can, for example, buy a pair of burners and change as needed

Uv members of the forum, pliz does anyone have such a device, I want to know how much fuel it eats per day, how it works, what area it heats. I have a house of 2 floors 160 squares, lined with bricks, mp windows, maybe someone who knows which is the most economical of the well-known brands, please write here or on soap. Thanks in advance

Why did you opt for diesel equipment?

All I know is that fuel consumption is from two liters per hour and above. It would also be interesting to hear what people in the know have to say.

Uv Semyon, we don’t have mains gas and normal voltage, only liquid fuel remains, because you need to heat when there is no one at home, if there was someone all the time, you would heat with firewood

The fact is that you will need electricity in any case for the operation of automation and pumps. Simply, my personal opinion is that you can find an alternative to diesel fuel in the absence of main gas. It will be more environmentally friendly and cheaper to maintain. Unfortunately, it is impossible to write in detail here, they will consider it as advertising.

Cheaper to hire a stoker.

SemenSV, straight intrigued. Admit what there is an alternative to diesel fuel, in addition to gas and electric boilers. (firewood and coal do not count, as they require constant presence).

An alternative is wood pellets (pellets), which are produced by drying and hot pressing of woodworking rests without the use of binders. Moreover, the production of this type of fuel is mostly in Russia, and is used to a large extent in Europe, because. they have traditional energy sources are expensive. Due to their qualities, pellets are an environmentally friendly type of fuel, and the ash residue is no more than 1%.

Boilers on pellets are quite expensive, in comparison, for example, with diesel boilers - 2-2.5 times more expensive. But if you calculate the maintenance costs and fuel costs, then pellets are more profitable.

Everything that was written here was not on the rights of advertising, but only for clarification on the question asked.

What is a diesel boiler

A diesel boiler is a kind of floor structure, the base of which is made of cast iron or steel, which allows not only to supply heat through the pipe system, but also to heat the room through heat transfer from the heated walls of the boiler.

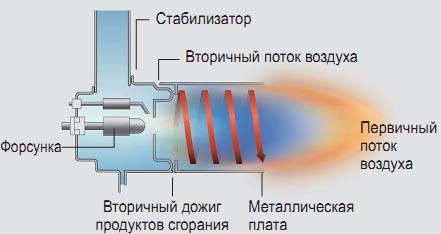

Any diesel boiler is equipped with a fan burner. which supplies and regulates the air flow supplied to the internal combustion chamber. They also distribute liquid fuel supplied to the chamber by means of a fuel pump.

The heating system of a diesel boiler is based on mixing fuel and air flows, which leads to the ignition of the first in the combustion chamber. Regular addition of the required amount of fuel allows you to maintain a continuous combustion process.

The main classification of diesel boilers is made according to the type of water heating. Diesel boilers are:

- single-circuit - serve exclusively for heating the room;

- double-circuit. equipped with a flow heater - allow you to heat the room, while heating the running water in the connected system;

- double-circuit with a built-in boiler - in addition to the main heating function, they are able to supply hot water for the whole house.

Depending on the purpose for which you are purchasing a diesel boiler, you should choose a specific model.

Double-circuit products, of course, will be more expensive, but they will provide your home with hot water, but with a limited budget, it is better to stop at conventional liquid fuel boilers.

Diesel boilers also differ in the method of traction. There are:

- boilers with natural draft - the exhaust gases are carried out through a vertical chimney;

- forced draft boilers - such models have a closed firebox, and the exhaust gases generated after fuel processing are carried out through a built-in chimney.

When choosing a boiler for your home, you should decide in advance what size the product will suit you, what shape will fit best into the interior, and, of course, choosing a model in accordance with the available budget will be an important factor.

How to choose the best diesel boiler

The advantage of choosing diesel devices is due to the fact that most models are able to work not only on diesel fuel, but also on alternative types of fuel, for example, on liquefied gas

To choose the optimal model from the numerous range of offers from leading manufacturers of heating equipment, you need to compare all the parameters.

When choosing a heating boiler, an important indicator is the type of burner used.

Therefore, it is worth paying special attention to its characteristics:

- A replacement burner costs a little more than a built-in burner, but it allows you to use not only diesel fuel, but also natural gas for heating.

- The burner is equipped with a heating system. allows significant savings in fuel consumption.

Tip: it is recommended to purchase a noise-absorbing casing for the heating system, which will reduce the noise level during the operation of the boiler.

An important parameter is the power of the boiler. It is determined from the consumption of 1 kW for every 10 squares of the area of the room. If the purpose of installing the boiler is not only heating, but also the supply of hot water, then it is better to choose a boiler with a little more power.

- This publication is devoted to the choice of a reliable sawdust boiler.

- In this material, we talk in detail about induction heating boilers.

- Read about the organization of a single-pipe heating system here.

Tip: in order for the boiler to cope with all its functional duties, its power should be slightly greater than required to heat the selected room.

The main question of interest to every buyer is the fuel consumption of the selected model. It is not at all difficult to find out this parameter; fuel consumption in kilograms per hour is equal to a tenth of the power of the burner used. Depending on this indicator, you can choose a boiler. maintenance that you can afford.

The material from which the firebox is made affects the durability of the device. A steel boiler will be more economical, but will last no more than 15 years. In turn, a cast-iron product consumes more fuel, but has a service life of at least 50 years.

Remember: the best option would be to purchase a universal boiler that can run not only on diesel fuel, but also on liquefied gas, kerosene, fuel oil. This will allow not to stop the heating process in case of running out of fuel.

Advantages and disadvantages of diesel fuel boilers

One of the most common types of equipment for individual heating systems is diesel heating boiler, which has a number benefits in front of boilers on other types of fuel, in particular:

- high power, allowing them to maintain a comfortable temperature in cottages of a large area;

- Efficiency exceeding 90% for most models;

- the possibility of installation without obtaining additional permits (as for electric or gas boilers);

- inexpensive and common fuel;

- the ability of diesel boilers to switch to gas by replacing the burner.

but diesel heating boilers not free from certain shortcomings, which include:

- the need for a container for storing diesel fuel and its increased flammability;

- the need to install the boiler in a separate room equipped with exhaust ventilation;

- the operating burner has a high noise level;

- the dependence of the boiler on the availability of electricity necessary for the rotation of the burner fan, as well as the functioning of automation systems;

- dependence of the heating system on climatic conditions, because at temperatures below +5ºС, diesel fuel becomes thick and clogs the fuel line.

General information about boilers

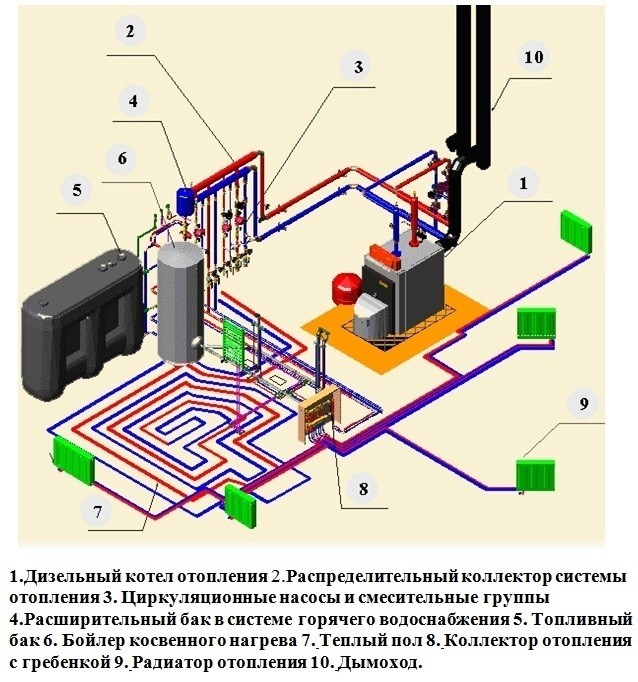

Scheme of a diesel heating boiler.

It is also important that the installation of a diesel heating boiler does not require any approvals and special permits for operation. Such a boiler works completely autonomously, without the formation of burning and dirt. To equip the boiler room, you need a small room with an exhaust hood and a container in which fuel will be stored. It must be plastic or steel. The recommended volume is 4-10 tons. The container is installed in a bunker specially equipped for this purpose. Under the bunker, you can use an isolated room. It is desirable to bury the tank in the ground.

The simplest calculation of the consumption of liquid diesel fuel is as follows: to obtain 10 kW of heat, 1 kg of high-quality diesel fuel per hour is required. Example: the area of the house is 150 square meters. meters, heating boiler capacity - 15 kW. When the heating system is operating at full capacity, one and a half kilograms of diesel fuel per hour is required. During the day, 1.5 x 24 = 36 kg of fuel will burn in the boiler.

Scheme of a diesel floor boiler.

If the unit operates at full capacity for 100 days in a year, then 36 x 100 = 3600 kg will be required. Moreover, for 100 days during the off-season, the boiler will be heated at half the design capacity, it will take 18 x 100 = 1800 kg. As a result, it turns out that during the heating season, fuel consumption will be 3600 + 1800 = 5400 kg of diesel fuel.

Diesel boilers are used to heat houses and to heat domestic water. They do not require daily care. Their service life is 25, but can reach 40-50 years. Modern devices are equipped with automated systems that simplify their use. When it becomes possible to connect to the gas supply, you do not need to purchase new equipment, it is enough to replace the burner.

Any diesel heating boilers always work according to this principle:

- when the boiler is turned on, the air blower unit and the pump are started;

- in the nozzles, an optimal pressure is created for spraying liquid fuel;

- the ignition transformer supplies the ignition voltage to the electrodes;

- the fuel ignites in the boiler, and the unit switches to autonomous operation;

- automation systems control the entire operation of the heating unit and regulate the fuel consumption in the combustion chamber.

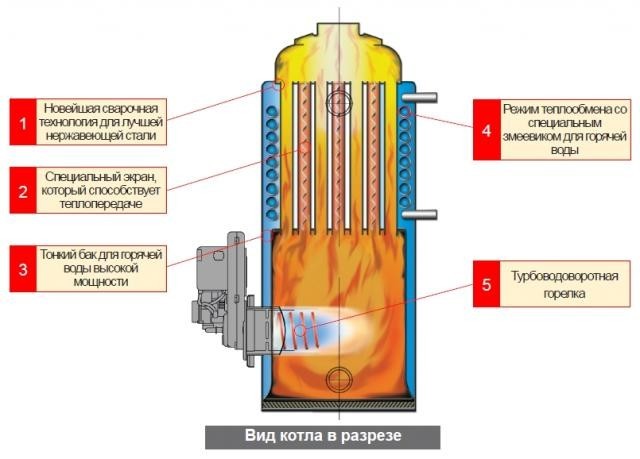

Sectional diagram of a diesel boiler.

A diesel heating unit is better to choose a double-circuit. It has a double heat exchanger. Thanks to this design, it is able to simultaneously heat the room and heat the water. The productivity of these plants reaches 95 percent. Built-in automation simplifies the process of managing them. It remains only to inspect and clean the equipment annually. To obtain water in large quantities, there are boilers with a built-in boiler.

In industrial premises, boilers are used that can operate both on diesel fuel and on fuel oil or waste oil, which is usually subject to disposal. For each type of fuel, special burners are installed. It is possible to install a universal burner that can operate on any liquid fuel.

Is a solar boiler profitable for a home

The benefits of heating a house with diesel become obvious if we consider the main advantages:

- No need for permits - the boiler room is installed in any technical room of the house. The installation itself costs the price of the strapping. For example, connecting a gas boiler must comply with strict standards. For obtaining permits and preparing project documentation, you will need to spend from 60,000 to 120,000 rubles. Additional costs will be required for the equipment of the boiler room, the connection of the gas pipeline to the house, etc. The real cost of heating is made up of not only operating costs, but also connection costs.

- Costs directly for the heating itself - the calculation of fuel consumption is carried out according to the formula, 10 kW = 1 kg of diesel fuel / hour. Accordingly, to heat a residential building of 100 m2, you will need 1 kg of diesel fuel per hour or 24 kg during the day. In a month, it will be necessary to spend already 720 kg. During the heating season, 4320-4500 kg or 5200 liters of diesel fuel will be spent.

- Additional maintenance - the principle of operation of domestic heating boilers on a solarium is associated with the use of a special burner and fuel pump. During operation, it is necessary to change the fine filter, nozzles. All this increases the cost of heating.

- Additional costs - diesel fuel is supplied to the boiler by a fuel pump, and air is forcibly supplied to the combustion chamber - all this requires connection to the mains.

A diesel boiler, in its efficiency, is inferior to a classic heat generator running on natural gas. But, given the high cost of obtaining permits and approvals, a diesel-fuel heating device is quite capable of competing with gas-fired boilers.

This is interesting: Diesel fuel boiler (video)

1 Protherm Bison 30 NL

The most reliable Country: Czech Republic Average price: 45900 rub. Rating (2019): 4.9

The diesel boiler Protherm Bizon 30 NL is the best choice for a house located far from gas pipelines. When installed, the owner will receive the most comfortable heat supply. Created with the latest developments in the production of heating equipment, the liquid fuel boiler is essentially a universal unit, and can also use main or bottled natural gas as fuel. When working with diesel raw materials, a Baltur BTL burner must be installed.

The estimated power of the unit is 27 kW, which is more than enough for housing construction with an area of about 200-220 square meters. meters. The floor structure weighs 121 kg, but at the same time it is more than compact - the boiler has dimensions of 45x38x87 (WxDxH), which allows it to be installed without problems in any utility room. With an open-type combustion chamber, the installation has a fairly good efficiency - 89%. The internal heat exchanger is provided with frost protection, and all parts of the single-circuit heater are distinguished by a high margin of safety, which allows us to speak of Protherm Bizon 30 NL as one of the most reliable among oil-fired boilers.

How to choose a liquid fuel boiler

When choosing a boiler in terms of power, they also take into account the formula according to which for heating 10 square meters. m requires 1 kW of energy. In order for the device not to operate at maximum power, its maximum indicator must exceed the theoretical calculation by 15-20%. In the case of using a double-circuit liquid fuel boiler, I add another 20% to the figure obtained for heating water.

- First of all, the advantage of a liquid fuel boiler is revealed at the design stage.When compared with gas supply, it turns out significant cost savings. To install a diesel device, it is not required to coordinate documents with numerous authorities. Approximately, up to 120,000 rubles have to be spent on obtaining permits and preparing a gas supply project. Laying a pipeline to the house and wiring will cost about the same amount.

- Owners of auto repair shops should take a closer look at liquid fuel boilers that work not only on diesel fuel, but also on used engine oil. In this case, the cost of space heating can be minimized.

- As for the cost of heating a house, the calculation of diesel fuel is performed based on a simple formula. To obtain 10 kW of heat energy, 1 kg of diesel fuel is burned per hour. To maintain heat in the house 100 sq. m. during the day you will have to stock up on 24 kg of diesel fuel. The consumption of liquid fuel per month will be about 720 kg. If the heating season lasts 7 months, then up to 5000 kg (4300-4400 l) of diesel fuel will be spent on heating.

When determining the manufacturer, experts conditionally divide all firms into several categories.

- The leading positions are occupied by such German brands of liquid fuel boilers as Viessmann Vitorondens, Buderus Logano, Vaillant iroVIT VKO. They are traditionally distinguished by excellent quality and functionality.

- Serious competition, both in price and quality, is imposed on them by heating appliances from France and Italy De Dietrich, Fondital Capri, as well as South Korean brands Kiturami and Navien.

- Relatively recently, the products of Finnish DanVex B and American EnergyLogic EL companies appeared on the domestic market. They were able to offer the domestic consumer interesting devices for high-level Russian conditions.

Attention! The above information is not a buying guide. For any advice, you should contact the experts!

Domestic boilers for diesel fuel

For domestic use, that is, for heating ordinary private houses, Korean-made Saturn devices are perfect. They differ in that they are equipped with combustion catalysts and blast burners. Of course, their power is not too large, but for an average private house it is quite enough.

Video - Diesel boilers

The devices described are equipped with special oxygen scavengers that slow down the oxidation process and, as a result, significantly extend the life of the equipment. There are also various automatic systems that simplify the operation process.