How to choose the right baking stone

A few simple rules that will help you make your choice:

a stone for baking bread must necessarily have a porous structure;

the longer the baking time, the greater should be the thickness of the plate;

pastries, sweet and meat buns, cheesecakes or rolls are best baked on stones made of dense materials;

when choosing a baking stone for pizza, pay attention to models with a thickness of no more than 1-1.5 centimeters in order to reduce the heating time;

thin baking plates are ideal for baking pita bread, khachapuri, placina and other pies from unleavened or puff pastry;

ceteris paribus, give preference to porous materials;

the rectangular shape is more spacious and ergonomic;

models with angular or longitudinal legs are less susceptible to thermal shock;

before buying, measure the internal dimensions of the oven so that the stone is not too large or small.

Before buying, look at the safety certificates, it is important that the raw materials for production are environmentally friendly

Sauna Stove

“Bath” comes from the Old Slavic verb “banit” - to wash, clean with water, and “bania” means “to wash”.

Useful qualities of the bath

We have all heard many times about the benefits of the bath and its healing properties. After a bath and a sauna, the work of the kidneys is normalized, which is sometimes difficult to remove all toxins from the body, blood flow improves, due to vasodilation. High temperature and humidity relaxes the body and respiratory organs, due to which the bronchi relax, and breathing becomes deeper and more saturated. The bath contributes to the treatment of the musculoskeletal system of sciatica and joints. The question arises, which stove to choose for a bath?

Sauna stove types

Black stone stove.

This stove has been built since ancient times, when stones were laid over the hearth to cover the vault, the fall of raindrops on them led to the formation of steam, such a stove was built until the 19th century due to the simplicity of masonry, and saving materials, because. the oven does not have a chimney. Benefits of a smoke sauna The smoke and heat effectively decontaminate the steam room from bacteria and this sauna is considered to be healthier. Thanks to the fumigation of the ceiling and walls with smoke and ventilation after heating, dampness from the ceiling and walls is well ventilated from the steam room, and soot covers the steam room with a protective layer from rot and insects. The main drawback is the possibility of getting dirty with soot and a slight smell of burning in the steam room.

Benefits of a black sauna there is no smell of burning and soot from logs clean water vapor, this wood-burning stove is placed with a pipe, which increases the fire safety of the bath. The stove can store heat for up to 24 hours, and quickly heat up the stove the next day. Sauna stove with water tank

The water tank can be located both on the stove and embedded in the stove masonry, it is perfect for a bath where there are no water heaters and another source of water heating. The main disadvantage of this stove for a wood-fired sauna is that the heat capacity of the stove is deteriorating, because. most of the heat is taken to heat the water, as a result, the heater lags quickly. The stove has a furnace door in the dressing room.

Such a heater stove is perfect for the convenience of kindling the stove, and for heating a washroom or locker room, because. the furnace door is located in a separate room, and the main part of the furnace is located in the steam room. The main drawback of the sauna stove is that the heat diverges over the entire area of the bath and is not concentrated only in the steam room. The stove is a heater with a heating shield.

Designed for large areas. Such a heater stove has smoke channels, for example, Dutch or Swede stoves with a stove. Such a wood-burning stove for a bath is perfect for heating the entire area of \u200b\u200bthe bath and heating the room in the winter, because.the stove combines a conventional stove in itself. A brick sauna stove.

This stove has a stove with stones located on it. Heating comes from the stove and goes to the stones. The temperature in the sauna is in the range of 100-110 C°. And it has dry, hot air, unlike a Russian bath. The sauna stove has proven itself to be perfect for lovers of the Finnish steam room.

The main advantage of a brick sauna stove is the uniform heating of the air, unlike a metal stove. In which there is strong heating, and because of this there is no desired effect of heat. The cost of these stoves is almost the same. Russian sauna with a heater.

The Russian bath has been highly respected by our ancestors since ancient times. A stove for a Russian bath is suitable for any of the listed ones, with an open or closed heater. "Russian bath" - is a bath procedure with a heat temperature of 60 ° C and high humidity in the steam room. The alternation of bathing heat and dousing with cold water or swimming in a winter river, with rubbing snow, increases immunity and hardens the human body.

I carry out the construction of stoves, the installation and laying of a stove for a sauna heater for a wood-fired sauna, a stove for a Russian bath, a stove for a bath with a brick tank. Inexpensive sauna stoves in Moscow.

Furnace construction

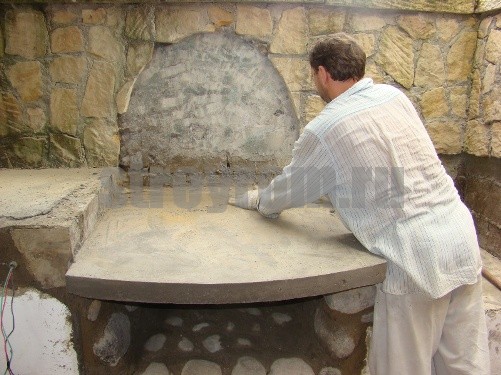

We cover the perimeter of the base of the furnace with river stone. It will serve us both as a foundation and a pantry for firewood. Then, using plywood and wooden beams, we make a frame for pouring concrete. This will be the working platform for our furnace. The size of the furnace is chosen individually, in our case it is a width of 1 meter, a height of 80 cm, a depth of 1 meter.

We put metal rods (reinforcement) with a diameter of 1 - 1.5 cm into the plywood frame. We bind the rods with each other so that we get a crate with a step of approximately 15x15 cm. We make holes along the perimeter with this step and hammer reinforcement into them.

This will give strength to the platform.

We fill it with concrete, the thickness of the pour is about 10-15 cm.

For oven interior

we use 2.5mm thick metal sheet. We reinforce the outer part of the sheet with reinforcement and iron mesh (mesh in two layers, in a checkerboard pattern). We drive metal rods into the wall along the perimeter of the sheet for stability.

For convenience, while there is no front wall, we lay out the bottom and back of the furnace inside with a stone slab of volcanic rocks or other refractory material. It holds temperature well and does not deform. We use a heat-resistant mortar for ceramic tiles.

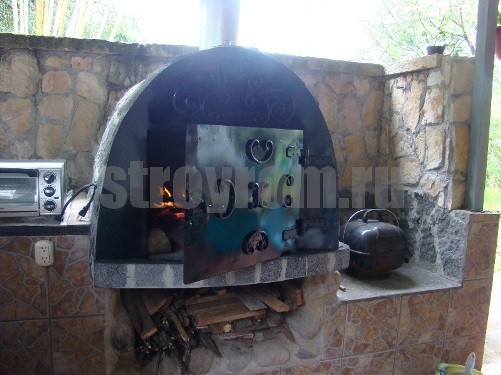

Along the edges of the sheet of the front part, we fasten, using self-tapping screws, a square metal pipe, 2x2 cm in size. We cut it in 5 cm increments, for a radius bend in the upper part, the step is reduced to 2 cm. From the same pipe we cook the frame for the front wall and doors.

The radius of the front part of the front wall should be 7-10 cm larger, since in the future this gap will be filled with a facing stone. We cut out the radius and the door opening using a jigsaw with a nail file for metal. Then welded to the frame. In the central upper part of the furnace we make a round hole with a diameter of 20-25 cm for the chimney. We make the base of the chimney from the same sheet, 2.5 mm thick. Cylindrical, 20-30 cm high. Insert the cylinder into the hole and scald in a circle.

We apply a refractory solution to the outer part of the furnace.

After complete drying, we lay a stone from volcanic rocks or other fire-resistant material.

We install the chimney. The facade is painted with refractory paint. The oven is ready for use!

Do it yourself

Do-it-yourself wardrobe bed For many people, the issue of purchasing or ordering a folding wardrobe bed is relevant. This modern technological development can very well complement the interior of your room….

Do-it-yourself brick barbecue Barbecue is essentially an outdoor oven, which is used to cook various dishes on charcoal and open fire.And, nevertheless, it is not a simple matter to build such a furnace, but ...

How to make a bed Bed made of glued laminated timber with your own hands. The bed is a very important element of any room, whether it is a bedroom for adults or children. A large comfortable bed in your bedroom is the key to good sleep and good mood throughout…

How to make a table with your own hands The best way to save money and create a beautiful interior in the country will be furniture made by yourself. The article describes a step-by-step method for making a table for ...

Installing a dishwasher Some time ago, not every consumer could afford a dishwasher. Most often they could be found in families with a high level of income. However, nothing...

Maintenance and repair of stone ovens

The easiest is to mix clay, river sand and water. The proportions will depend on the fat content of the clay. As a basis, you can take the ratio of clay and sand 1: 1. Water is added until a plastic mass is obtained. You can check the quality by rolling the ball and throwing it on the floor. If cracks appear on it, clay must be added. So that small cracks do not appear on the dried solution, salt is added to the finished mixture (300 g per bucket of solution). The learned putty is insisted for about 12 hours. and only then can it be used.

A better solution will be obtained from a mixture of two parts of sand, one part of clay, one part of lime and 0.1 part of asbestos. Lime can be replaced with cement in the same proportions. A similar putty recipe is to mix one part of gypsum and sand, two parts of lime and 0.2 parts of asbestos. Before adding to the solution, all components must be sieved, and the clay should be soaked for a day. Putty is prepared in small portions. This is especially true for a mixture using gypsum. Such a mass will be plastic in just 5 minutes. If cement is used, the working time increases to an hour. Lime is introduced into the mixture with already diluted water.

Before covering the gaps, they must be well cleaned and widened. It will not be superfluous to prime the surface. If the primer is not applied, the treated area is moistened and overwritten. To prevent cracks and cracks from reappearing, the oven can be lined with special tiles. Such a coating will preserve the integrity of the masonry for a long time. If there are a lot of gaps in the masonry, a wire tie will help save the oven.

With its help, you can strengthen the frame of the furnace. To do this, a groove about 2 cm deep is drilled in each horizontal row. A wire is laid in it around the perimeter of the furnace, fastened and pulled by twisting it. Naturally, in this case it is impossible to leave the stove unfinished, so the final stage of the repair work will be its finishing - plastering or tiling.

The stove can also smoke because of a loose firebox door or blower. Most likely, to dismantle and strengthen it, you will have to disassemble part of the masonry. But this is done as a last resort. A simpler option is to cover up the resulting cracks using a sealant. The usual clay solution will not work here.

For such repairs, it is necessary to use fireclay clay (3 parts), cement (1 part) and fine sand (10 parts). Water is added until the consistency of liquid sour cream is obtained. In the finished solution, you can add a little heat-resistant glue. Before proceeding with the putty, the surface should be well cleaned of dirt and treated with a primer. Next, a heat-resistant sealant is placed in the slots, on top of which a clay solution is applied. It is possible to heat the furnace after such a repair no earlier than a day later.

If the stove not only smokes, but also flares up poorly, remember the last time you cleaned the chimney. It is recommended to do this at least twice a year. To begin with, it is worth trying simpler options, for example, throwing a handful of rock salt into the furnace while the firewood is burning. In this way it is convenient to clean light blockages.“Salting” firewood in this way is possible not only to clean the chimney from soot, but also to prevent its formation.

Aspen firewood will also help prevent the appearance of soot cork. The temperature during their combustion is so high that the litter simply burns out. If the stove is finished with tiles and minor damage has appeared on them, you can solve the problem without dismantling the finish. Small cracks are easy enough to cover with alabaster or alabaster-chalk mortar. You can also use a mixture of crushed chalk mixed with raw egg white

It is important to monitor the condition of the furnace foundation. Any of its movements can lead to the formation of through cracks. published by econet.ru

If you have any questions on this topic, ask them to specialists and readers of our project here.