Expert answers

Peter Semiletov:

I do not quite agree with the author of the previous answer. As a stove-maker with 18 years of experience, I explain that the solution is prepared taking into account the fat content of the clay. Yes, 1/2 (1-clay 2-sand) is average, but it’s easier to determine visually. If you type the finished mortar on the trowel, you discard the mortar with a slight movement and lumps and strips remain on the trowel; the mortar is ready. by definition, it does not tolerate a sharp temperature drop and your furnace will collapse like a colossus of Rhodes. The most reliable thing is to invite a professional - although not cheap, but for sure, there will be someone to show if something goes wrong

ityth:

How to prepare a mortar for laying the oven?

The brickwork of the actual stove or fireplace is carried out on a clay-sand mortar. Two or three days before the start of work, the clay must be soaked by pouring water in a ratio of 1:2 for dry clay or 1:1 for wet clay. Periodically, the solution is stirred, if necessary, adding water, until a homogeneous pulp of the consistency of liquid sour cream is obtained. It should be borne in mind that the fatter the clay, the longer it must be soaked. You can additionally increase the density of the solution by including cement in its composition at the rate of 1 (cement): 9 (sand).

- there are many more recipes

Rost:

Inside they put on clay and outside on c. n. solution!

a normal solution .. needed .. each stove-maker has his own .... I won’t tell mine ... no need

Nikolay Todorov:

Depending on the brick, the mortar is also selected (usually this is the ratio of clay and sand within 1:1 or 1:2, depending on the fat content of the clay). Refractory brick laying is carried out on a solution of refractory clay mixed in a 1: 1 ratio with finely ground chamotte. Now the markets are on sale-ordinary claychamotte clay can also be obtained from Gzhel. Sand is preferably mountainous, but not always available, therefore it is better with grains no more than 1 mm

Tatyana Makarova:

The kiln mixture is used for red brick laying of industrial and domestic stoves and fireplaces, with a working temperature of up to 850°C.

INSTRUCTIONS FOR USE: Before laying, the brick must be soaked in water. Then a small amount of refractory mixture (1-2 bags) is taken and poured into a container. Constantly stirring the mixture, water is added in small parts. The consistency of the clay mortar should be such that when laying a brick, it can easily be squeezed out under the weight of the brick itself and under a light pressure on it by hand.

The seam of the clay mortar should have a thickness of 3-5 mm - the thinner the seam, the stronger the masonry. The hardened solution of the furnace mixture in the masonry has a degree of expansion when heated, equivalent to red (furnace) brick, which will avoid cracks in the masonry during the operation of the furnaces. One bag of mix is enough to lay an average of 35-40 bricks.

Weight 25 ± 0.2 kg. TU 1523-002-0148977766-2006

Composition of the mixture: 1. Clay red natural according to the normative document of the deposit. 2. quartz sand according to GOST 22551-77 3. molding sand according to GOST 2138-91

Products are not included in the range of products and services subject to mandatory certification and declaration of conformity.

During storage, the mixture is not afraid of moisture. The storage period is not limited.

Anton Glyzin:

if the clay is well soaked, then you can! the main thing is that there are no lumps of clay left!

P.S. The stove may need love, but if this stove is in some kind of boiler room and is huge, then no love and hands will be enough for it.

ALEX***:

Why not???

Oleg:

Not desirable. The oven is like a daughter. Love is needed. :)

Truculentus:

If it does not contradict the inner worldview, then it is possible.

Roman Gudymenko:

If the mixer is new and perfectly clean, at least knead the dough in it for Easter cakes :) :) :) !

valentin melnichuk:

I did but I messed up decently and there are a lot of lumps. Then I drilled the blades and twisted a few steel wires, made such a grid, if you understand me, it turned out well. I just didn’t have a way out, I needed large volumes, not for stoves.

Andrey Volkov:

Buy a dry fireclay mix and don't worry. Everything is muddled with a mixer - there the consumption is not so big to stir up in a concrete mixer. Yes, and clay for manual kneading needs to be soaked and also picked it up in the right place

::p:::w:::i:::o:::::::::::$:::e::

You can, of course, mix as much as you need and leave it at least for a year, a year later I remembered, came, added water, stirred it again and work, it’s, e-my, clay!)

Yura:

and even very convenient, I plan it myself

Best Answers

Captain Nemo:

Ideally, clay mortar and brick are almost the same in composition and are able to withstand heating over 1000 degrees. Professional stove-setters determine the quality of clay for mortar by touch and perform laying with a joint thickness of 3-4 mm. With thicker seams, the clay between the bricks does not withstand high temperatures and crumbles, cracks form into which air is sucked in, which means that traction deteriorates, fuel consumption increases and there is a danger of carbon monoxide escaping into the living space.

The golden rule of furnace work is that the less clay in the furnace masonry, the higher its quality.

One of the basic rules of the stove-maker, inherited from the ancestors: the less clay, the better the quality of the masonry. And yet, clay is the most noble building material, since it gives the right to make mistakes. If the cement mortar masonry cannot be disassembled without loss, then the clay mortar masonry is disassembled easily and without waste. During repair work, brick and facing material laid on clay mortar can always be preserved.

There is an opinion that the strength of the clay solution can be increased with the help of various additives. For example: for 10 kg of clay - 100-150 g of table salt or 1 kg of cement.

However, our great-grandfathers hardly used cement, and their stoves stood for a hundred or more years.

If the components are correctly selected, the clay solution does not require any additives, and all kinds of recommendations are just a safety net.

The masonry mortar should be plastic, moderately greasy, or, as they say, normal. The greasy solution, drying, decreases in volume and cracks. Skinny doesn't give enough strength. Clays for the preparation of the solution are of different fat content or plasticity. There are deposits of clay, from which a solution of normal fat content is prepared without the addition of sand. Sometimes you have to mix two or three clays taken from different places, and strictly dose them.

First they are mixed dry, then closed with water. If the clays turn out to be fatter, then sand is added to them, the amount of which can vary from 0.5 to 5 parts by volume. The most common ratio of clay and sand in the finished solution is 1:1 or 1:2. The amount of water is approximately 1/4 of the volume of clay. Fatty clays will require more sand, which should be fine-grained and free of impurities. The sand is preliminarily sifted through a fine sieve with 1.5 × 1.5 mm clear cells, at least. Very thin clays have to be elutriated, removing excess sand from them. sbani /files/pechi_glina

sergey kurguzov:

in general, when laying the furnace, you need to do everything by sight of the clay, you don’t need sand, you need it to be sifted, and when lining, you need to add salt

Sergey Semyonov:

it is not necessary to add cement - for an arch or vault, yes. but it is better to lay walls without cement. choose the ratio of sand to clay by touch. because the clay can also be different - the resulting composition should not be too loose (fluid) and not too greasy (viscous and prone to cracks), the criterion is such that the furnace joint should be 3-4mm.if you can’t get such a thin seam, the clay is greasy and more sand is tedious

Ways

Purification of water from clay suspension takes place at the first stages of water treatment. Methods and forms of purification, as well as the types of equipment used, will depend on the initial quality of the water based on its analysis data. The more water is contaminated with clay, the more purification steps it goes through.

So, water purification from clay includes:

- settling - the initial stage of water treatment, allowing large and heavy clay particles to settle to the bottom;

- the use of a hydrocyclone is a method of water purification from mechanical impurities that do not settle; operates on the principle of a centrifuge, when large particles are concentrated near the walls of the device, and purified water is collected in the central part;

- straining - a method of water purification by passing through a special membrane, the pores of which are smaller than the particles of pollution that are captured;

- filtration through filters-clarifiers - similar in action to filtering;

- coagulation - the addition of special substances to water that contribute to the coarsening of suspended particles, which can subsequently be removed by filtration;

- film filtration - a method in which the filter material is covered with a film of clay suspension, including even very small particles.

Each of these methods is usually used in combination with others, since they are all stages of the same process.

Goals

If water is planned to be used in everyday life, especially for drinking and cooking, cleaning from clay is necessary. It allows:

- reduce turbidity - even in small concentrations, clay suspension reduces the transparency of water and makes it undrinkable;

- soften water and remove impurities from it - water containing dissolved clay, in terms of hardness, as a rule, does not meet the requirements of GOST “Drinking Water”, and is also often unsuitable for domestic needs;

- Eliminate odor - drinking water, according to regulatory documents, should not have any foreign odors.

- disinfect water at the initial stage of purification, since clay suspension often contains dangerous microorganisms, algae, protozoa and other biological objects.

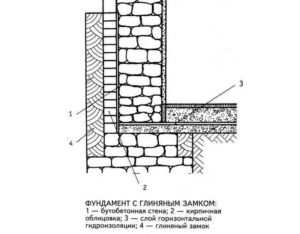

Why do you need a clay castle around the foundation

The design of the clay castle itself performs several functions:

- Protection of the foundation from moisture.

- Additional dense cushion for the sole of the base.

- Reducing the pressure of ground and melt water on the walls of the foundation.

This material has a few other nice features:

- fat content, which allows not to use additional materials in the area of \u200b\u200bthe sole for isolation from moisture;

- the density of the dried substance does not allow the foundation to crack or crumble;

- ease of use, implying any amount of material to use for the castle.

But for all its splendor, clay also has some not very pleasant sides:

- Short-lived protection - after 5-6 years, the castle should be redone, removing the previous layer.

- Not always good quality - due to sand impurities, the clay becomes less oily and freezes heavily, losing its properties.

- Low waterproofing of vertical surfaces - additional waterproofing is required for the external and internal walls of the foundation.

It is worth knowing that the closer the groundwater approaches the foundations, the more short-lived the castle will be. Therefore, to drain water from foundations, drainage is often performed around the entire perimeter near the base of the house.

How to breed and with what to mix fireclay clay step by step diagram

Step 1: We insist the powder on the water

To prepare a solution of fireclay clay for plaster, we will need a pack of fireclay powder. Pour the powder into a container, slowly adding water until the powder is completely covered with water. Before diluting the final solution, fireclay clay must be infused for at least three days.

Step 2: Making the final batch

After we have endured the necessary time, stir the resulting mixture again, if necessary, adding a little bit of quartz and water, if necessary. If the solution comes out liquid, you can sprinkle more powder, dilute it too saturated with an additional amount of water. By its own consistency, the ready-to-use mortar should resemble sour cream - with such a density, it will not flow from the surface and will adhere perfectly to the wall surface.

Of course, you can also buy a composition for instant mixing - it does not need to be infused for three days, but it is also expensive. In any case, repair PVA glue must be added to the acquired composition; it will not be superfluous to strengthen this type of solution with crushed fiberglass. For plastering with such a solution, great knowledge is not needed - just prepare large and small spatulas in advance and apply the solution equally to the surface.

Step 3: Prepare the Surface

Based on the reduced plastic parameters of fireclay, it is imperative that the surface that you want to plaster be provided with a mesh, and to fix the coupling, go through an excellent primer mixture. Because the conversation is very often about plastering fireplaces and stoves, the primer mixture must also be heat-resistant, and the mesh must be iron. In such a case, you compensate for the flexibility of fireclay and achieve the highest fire resistance of the plaster.

How to prepare material for work

Clay of any color is suitable for performing insulation work. The main thing is that she should have as little sand as possible in herself. It is better to take clay that gets wet for a very long time. This is a criterion for small impurities of sand in it.

The best option is to prepare the material in the fall, six months before future use. For clay, it is necessary to allocate a certain place where it will be subject to frost, precipitation and other weather conditions. So in autumn and spring, the wind will be able to weed out sand from the upper layer. And frost in winter will add strength and durability to the material through freeze and thaw cycles.

In the spring, immediately before use, 3-4 days before use, the clay should be poured with water and covered with a film. Let it become a homogeneous viscous material. Then it will be easier to lay and compact it. Yes, and her performance will improve.

Some owners prefer to make a clay mass 1-2 days before use. It's not essential. But it is better to let the clay brew to the required condition.