6 Calculation of economic damage associated with failures of heating networks

General economic damage,

ANDyi

= ANDy1

+andy2

+andbonds

,

where Iy1

— losses of thermal energy in pipelines associated with coolant leaks (lost profits), thousand rubles/year;

ANDy2

— compensation for losses to consumers of thermal energy, thousand rubles/year;

ANDbonds

— expenses for unscheduled repairs of heating network equipment, thousand rubles/year.

2.6 1 Heat losses in pipelines, thousand rubles/year

ANDy1

= Qsweat

* Cte

where Qsweat

— the amount of lost thermal energy associated with failures of the heating network, Gcal per year;

Cte

— price of 1 Gcal of heat supplied to the consumer, rub/Gcal;

Qsweat.open

= qsweati

*l i

*ni

* Tfeces i

where qsweati

— the specific number of heat energy leakages for a given failure mode of the heating system, Gcal/rm-day-unit of the failure type, is determined according to the data in Table 4;

ni

- the number of failures of the heating network of a given nature, is determined by the results of processing statistical data;

Tcal i

- the time elapsed from the moment the failure was detected to its elimination, days;

li

- the length of the replaced section of the heating network when the failure is eliminated, running meters.

Table 2.6.1 Calculation of Qsweat

for each failure mode

| The nature of the failure | qsweat | n | Tfeces | l | Qsweat |

| Fistula | 0,05 | 34 | 6 | 0,4 | 4,08 |

| pipe rupture | 0,279 | 14 | 5 | 5 | 97,65 |

| Weld rupture | 0,015 | 14 | 5 | 3 | 3,15 |

| Damage to the stuffing box compensator | 0,005 | 10 | 3 | 0,1 | 0,015 |

| Valve failure | 0,001 | 9 | 3 | 0,2 | 0,0054 |

Qsweat

= 104.9 Gcal/year

Cte

\u003d 227.04 rubles / Gcal

ANDy1

= 227.04 * 104.9 = 23816.5 rubles / year

ANDy1

=0.0238165 million rubles/year

2.6.2 Compensation for losses to heat consumers

Compensation for losses to consumers for undersupply or reduction of coolant parameters is determined in accordance with the terms of commercial contracts between the energy supply organization and the consumer of thermal energy, million rubles / year,

ANDy2

= Cgreat dane

*Qsweat

. open

.

where Cgreat dane

— the contractual price of industrial damage per 1 Gcal of unsupplied heat energy, thousand rubles/Gcal.

Cgreat dane

= 227.64 rubles / year

ANDy2

= ANDy1

=0.0238165 million rubles/year

2.6.3 Costs for unscheduled equipment repairs

This item includes the costs of detecting a leak, earthworks, direct repairs (installation of patches, welding, etc.) and does not include the cost of construction and installation work related to the replacement of heating network equipment.

ANDbonds

= ECrem i

*n i

*l i

Where is C rem i

— specific cost of repair work to eliminate water leaks in heating networks with a given failure mode, thousand rubles/linear meter;

ni

- the number of failures of the heating network of a given nature;

li

- the length of the replaced section of the heating system, running meters.

Table 2.6.3 Calculation of ANDbonds

for each failure mode

| The nature of the failure | n | l | C rem | ANDbonds |

| Fistula | 34 | 0,5 | 0,9 | 15,3 |

| pipe rupture | 14 | 4 | 0,5 | 28 |

| Weld rupture | 14 | 3 | 0,5 | 21 |

| Damage to the stuffing box compensator | 10 | 0,3 | 0,5 | 1,5 |

| Valve failure | 9 | 0,3 | 0,5 | 1,35 |

ANDbonds

= 67.15 thousand rubles / year

ANDyi

=0.0238165 + 0.0238165 + 0.06715= 0.114783 million rubles/year

General operating costs, thousand rubles / year,

ANDthe ex

= ANDsign

+andlane

+andsn

+andam

+andrem

+andyi

ANDthe ex

= 5.85 +10.95679013 + 5.321122 + 3.332 + 7.981683 + 0.114783 = 33.556378 million rubles/year

Disclosure obligation

According to Decree of the Government of the Russian Federation No. 570 dated July 5, 2013, heat supply organizations are required to disclose information about their activities on the Committee's website in the form of UIAS templates. To do this, it is necessary to download and send the completed templates in the EIAS system within the following terms:

one-time (or within 10 days from the date of changes) - information about the organization (JKH.OPEN.INFO.ORG);

within 10 days from the date of filing an application for setting tariffs (JKH.OPEN.INFO.REQUEST);

within 30 calendar days from the date of adoption of the order on setting tariffs (JKH.OPEN.INFO.PRICE);

within 30 calendar days from the date of submission of the balance sheet to the Federal Tax Service, but no later than April 30 (for organizations that do not submit the annual balance sheet to the tax authorities (JKH.OPEN.INFO.BALANCE);

within 30 calendar days after the end of the quarter (except for MSW operators) (JKH.OPEN.INFO.QUARTER).

If there have been changes in the disclosed information, information about these changes shall be published in the same sources in which the relevant information was originally published within 10 calendar days from the date of the information change.

In addition, heat supply organizations, as part of the disclosure of information, are obliged to publish the following information on their official website on the Internet:

- Until March 1 annually - On the conditions under which the supply of goods (rendering of services), as well as information on contracts concluded in accordance with Parts 2.1 and 2.2 of Article 8 of the Federal Law "On Heat Supply";

— Quarterly, before the 10th day of the month following the reporting quarter — On the decommissioning of thermal energy sources, heating networks; On the grounds for suspension, restriction and termination of the mode of consumption of thermal energy in the cases provided for in paragraphs 70 and 76 of the Rules for organizing heat supply in the Russian Federation.

Full information about the information disclosure standards and the procedure for their implementation is available on the Committee's website in the "Other Information" section - the "Information Disclosure" subsection (or the "Information Disclosure" banner).

Regulation 2018 in the field of heat supply

Information Letter of the Tariff Regulation Committee of the Volgograd Region dated March 23, 2017 No. 31-06-08/643

Sample statement on the choice of the method of regulation Sample statement on the adjustment Sample statement on the establishment of tariffs Reports on the results of work on the regulated type of activityList of documents for correcting long-term Calculation of tariffs for heat energy Calculation tables when choosing an indexation method

Instructions for filling out economic justification forms Long-term tariff Economic justification

transcript

1

2 Calculation of useful supply of heat carrier Appendix 4.2 p.p. Indicators (thousand m³) Period (plan for 2015) including total water steam Heat carrier production, total, 690, .465 25.124 including: -CHP 25 MW and more CHP less than 25 MW. 690, .465 25.124 — boiler electric boilers Purchased heat carrier Consumption of heat carrier for household needs. 2.212 2, Coolant supply to the network (clause 1+clause 2-clause 3). 688, ,253 25, Regulatory losses in the transfer of coolant. 170, , Volume of returned coolant Useful supply of coolant to consumers (p.4 - p.5.-p.6). 518, .892 25.124

3 Annex 5.2 Calculation of operating (controllable) costs for each year of the long-term period for water coolant Parameters for calculating costs Unit of measurement Long-term period Consumer price index for the billing period (CPI) 1.047 1.047 assets (IAC) the number of conventional units related to c.u. 1443, , ,113 to assets required for activities 3.2 installed thermal capacity of a heat source 4 Cost elasticity coefficient for asset growth (K el ) 5 Operating (controlled) Gcal/h thousand rubles

4 Appendix 5.2 Calculation of operating (controllable) costs for each year of the long-term period for steam coolant Cost calculation parameters Unit of measurement Long-term period Consumer price index for the billing period (CPI) 1.047 1.047 assets (IAC) the number of conventional units related to c.u. 1443, , ,113 to assets required for activities 3.2 installed thermal capacity of a heat source 4 Cost elasticity coefficient for asset growth (K el ) 5 Operating (controlled) Gcal/h thousand rubles

5 Appendix 5.9 Calculation of the required gross revenue by indexing the established tariffs for water coolant Expense year i0 to year i0 + 1 to year i1 to n 1 Operating (controlled) Uncontrolled Costs for the acquisition (production) of energy resources,cold water and heat carrier 4 Profit 5 Results of activities before the transition to price (tariff) regulation based on long-term parameters 6 Adjustment to take into account the deviation of the actual values of tariff calculation parameters from the values taken into account when setting tariffs 7 Adjustment taking into account the reliability and quality of goods sold (services rendered), subject to accounting in the RGR 8 Adjustment of the RGR in connection with a change (non-fulfillment) of the investment program 9 Adjustment subject to accounting in the RGR and taking into account the deviation of the actual indicators of energy saving and energy efficiency increase from the established planned (calculated) indicators and the deviation of the terms of the program implementation in the field of energy saving and energy efficiency improvement from the established deadlines for the implementation of such a program 10 TOTAL required gross revenue 11 Commodity revenue

6 Appendix 5.9 Calculation of the required gross revenue by indexing the established tariffs for the heat carrier steam Name of consumption year i0 to year i0 + 1 to year i1 to n 1 Operating (controlled) Non-controlled Performance results before the transition to price (tariff) regulation based on long-term parameters 6 Adjustment to take into account the deviation of the actual values of tariff calculation parameters from the values taken into account when setting tariffs 7 Adjustment taking into account the reliability and quality of goods sold (rendered services), subject to accounting in the NGR 8 Adjustment of the NRV in connection with the change (failure) of the investment program 10 TOTAL required gross revenue 11 Commodity revenue

2 We calculate the annual payroll fund for two additionally hired operators in connection with the expansion of the boiler house

|

№ |

Name |

unit of measurement |

Value |

|

1 |

Worker Fund |

Hour |

1986 |

|

2 |

Medium rank |

5 |

|

|

3 |

Average tariff |

rub./hour |

45 |

|

4 |

Quantity |

people |

2 |

|

5 |

Number of people |

people hour |

3972 |

|

6 |

Number of people |

people hour |

1324 |

|

7 |

Quantity |

people hour |

87,384 |

|

8 |

Number of people |

people hour |

130 |

|

9 |

payroll fund |

rub. |

178740 |

|

10 |

Award for |

rub. |

71496 |

|

11 |

Additional pay for work |

rub. |

23832 |

|

12 |

Additional pay for work |

rub. |

1966,14 |

|

13 |

Surcharge for |

rub. |

2925 |

|

14 |

Total core |

rub. |

278959,14 |

|

15 |

Additional |

rub. |

27895,914 |

|

16 |

annual fund |

rub. |

306855,054 |

|

17 |

annual fund |

rub. |

352883,312 |

|

18 |

Average monthly |

rub. |

14703,47 |

|

Expenses |

7.

Deductions for social needs, rub./year.

Sn =

Szp ·

Tsv, rub./year

Szp - costs for

payment

basic salary,

rub./year;

Tsv - Tariff

insurance rates, %

|

№ |

Names |

unit of measurement |

Value |

|

1 |

Deductions |

rub. |

77634,32 |

|

2 |

Deductions |

rub. |

10233,61 |

|

3 |

Deductions |

rub. |

17997,04 |

|

4 |

Deductions |

rub. |

705,76 |

|

Total: |

rub. |

106570,73 |

8.

Costs

maintenance and operation of equipment,

rub./year:

We accept the standard

for this article 10% of the purchase price

equipment

rub./year

rub./year

9.

Depreciation deductions, rub./year

(According to

regulation on accounting "Accounting

fixed assets" PBU

6/01)

|

№ |

Name |

Estimated |

Notes |

||

|

initial |

norm |

Sum |

|||

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

Hot water boiler |

2480 |

10 |

248 |

OKOF code 14 2897030 |

|

Total: |

2480 |

10 |

248 |

10.

Property tax expenses

rub./year:

Property tax

is 2.2% of the cost of equipment

rub./year

rub./year

10.

Expenses for other needs

rub./year:

This

item includes expenses not included

in other items (including costs

for repairs and maintenance).

,

,

rub./year,

thousand

thousand

rub./year

11.

Full cost of annual volume

thermal energy production,

thousand rubles/year:

,

,

rub./year

|

№ |

Articles |

Designation |

Sum, |

|

1 |

Expenses |

Sm |

45,9 |

|

2 |

Expenses |

ST |

9685,36 |

|

3 |

Expenses |

Se |

1038,28 |

|

4 |

Expenses |

Sv |

242,21 |

|

5 |

Salary |

Szp |

352,88 |

|

6 |

Deductions |

Sw |

106,57 |

|

7 |

depreciation |

Sam |

248 |

|

8 |

RSEO |

Srseo |

248 |

|

9 |

Expenses |

Stax |

54,56 |

|

10 |

Other |

Spr |

1202,17 |

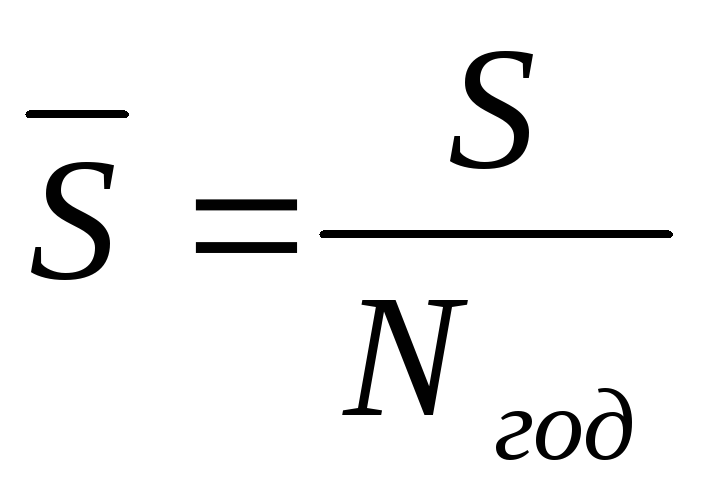

12.

Total unit cost of production

thermal energy, rub./year:

RUB/GJ,

where

GJ/year

GJ/year

– total annual heat supply

consumers.

RUB/GJ, (481.81

RUB/GJ, (481.81

RUB/Gcal)

To determine the main development trend, the values of empirical levels are depicted on the graph y f t.

The change in the number of failures of heat networks for the proposed period of time, depending on the nature of the failure, is taken as a dynamic series. Empirical levels of the series are smoothed by the moving average method. The smoothed levels are plotted on the chart.

Failure Mode - Pipe Burst

Failure Mode - Weld Break

Failure mode - Damage to the stuffing box compensator

Failure mode - valve failure

1.2 DERIVATION OF THE TREND EQUATION

The graphic representation of the smoothed levels clearly shows the main trend in the number of failures of heat networks for various reasons.

The next stage of work is to obtain a generalized statistical assessment of the trend by the method of analytical alignment.

The main development trend yt

as a function of time:

yti

= f(ti

).

Determination of theoretical (calculated) levels yti

is produced on the basis of an adequate mathematical model, which most accurately reflects the main trend of the dynamics series - the number of heating system failures for this reason.

The selection of a mathematical function is based on determining the type of development of an economic phenomenon in time.

When the trend type is set, it is necessary to calculate the optimal values of the trend parameters based on the actual levels, i.e. get the values of the coefficients of the equation. Based on the requirements of the least squares method (LSM), a system of normal equations is compiled, solving which, we calculate the trend parameters.

For a linear trend, the normal MKT equations have the form:

n*a + b*St i

= Sy i

a*St i

+ b*St2i

= S yi

*ti

where yi

are the levels of the initial series of dynamics;

ti

– numbers of periods or moments of time;

Normal MKT equations for a trend in the form of a 2nd order parabola:

n*a + b*Sti

+ c*Sti2

= Syi

a*Sti

+ b*Sti2

+ c*Sti3

= Syi

*ti

a*Sti2

+ b*Sti3

+ c*Sti4

= Syi

*ti2

where yi

– levels of a series of dynamics;

ti

– numbers of periods or moments of time;

a, b, c are the constants of the equations.

Table 1.2.1 Formation of data for the derivation of the trend equation - the nature of the failure of the fistula

| fistula | Yi | moving average (3 years) | Ti | Yi*Ti | Ti*Ti | Yi*Ti 2 | Ti 3 | Ti 4 | Ti 2 |

| 1991 | 25 | — | 1 | 25 | 1 | 25 | 1 | 1 | 1 |

| 1992 | 31 | 30,33333333 | 2 | 62 | 4 | 124 | 8 | 16 | 4 |

| 1993 | 35 | 31,66666667 | 3 | 105 | 9 | 315 | 27 | 81 | 9 |

| 1994 | 29 | 31,66666667 | 4 | 116 | 16 | 464 | 64 | 256 | 16 |

| 1995 | 31 | 30 | 5 | 155 | 25 | 775 | 125 | 625 | 25 |

| 1996 | 30 | 32,66666667 | 6 | 180 | 36 | 1080 | 216 | 1296 | 36 |

| 1997 | 37 | 33,33333333 | 7 | 259 | 49 | 1813 | 343 | 2401 | 49 |

| 1998 | 33 | 34,33333333 | 8 | 264 | 64 | 2112 | 512 | 4096 | 64 |

| 1999 | 33 | 33,66666667 | 9 | 297 | 81 | 2673 | 729 | 6561 | 81 |

| 2000 | 35 | — | 10 | 350 | 100 | 3500 | 1000 | 10000 | 100 |

| total | 319 | 257,6666667 | 55 | 1813 | 385 | 12881 | 3025 | 25333 | 385 |

For a linear trend:

10*a +55*b = 319; a = 28;

55*a + 385*b = 1813; b = 0.71;

y \u003d 28 + 0.71 * t;

For a trend in the form of a second-order parabola:

10*a + 55*b + 385*c = 319; a = 26.02;

55*a + 385*b + 3025*c = 1813; b = 1.7;

385*a + 3025*b + 25333*c = 12881; c = -0.09;

y = 26.02 + 1.7*t -0.09*t2

;

| pipe rupture | Yi | slip cf. for 3 years | Ti | Yi*Ti | Ti*Ti | Yi*Ti 2 | Ti 3 | Ti 4 | Ti 2 |

| 1991 | 12 | 1 | 12 | 1 | 12 | 1 | 1 | 1 | |

| 1992 | 8 | 10 | 2 | 16 | 4 | 32 | 8 | 16 | 4 |

| 1993 | 10 | 9,666667 | 3 | 30 | 9 | 90 | 27 | 81 | 9 |

| 1994 | 11 | 11,33333 | 4 | 44 | 16 | 176 | 64 | 256 | 16 |

| 1995 | 13 | 11,33333 | 5 | 65 | 25 | 325 | 125 | 625 | 25 |

| 1996 | 10 | 11,66667 | 6 | 60 | 36 | 360 | 216 | 1296 | 36 |

| 1997 | 12 | 11,33333 | 7 | 84 | 49 | 588 | 343 | 2401 | 49 |

| 1998 | 12 | 13 | 8 | 96 | 64 | 768 | 512 | 4096 | 64 |

| 1999 | 15 | 12,66667 | 9 | 135 | 81 | 1215 | 729 | 6561 | 81 |

| 2000 | 11 | 10 | 110 | 100 | 1100 | 1000 | 10000 | 100 | |

| total | 114 | 91 | 55 | 652 | 385 | 4666 | 3025 | 25333 | 385 |

For a linear trend:

y \u003d 9.75 + 0.3 * t;

For a trend in the form of a second-order parabola:

y = 9.82 + 0.26*t + 0.004*t2

;

Table 1.2.3 Formation of data for the derivation of the trend equation - the nature of the failure weld rupture.

| seam rupture | Yi | cf. rolling for 3 years | Ti | Yi*Ti | Ti*Ti | Yi*Ti 2 | Ti 3 | Ti 4 | Ti 2 |

| 1991 | 10 | 1 | 10 | 1 | 10 | 1 | 1 | 1 | |

| 1992 | 6 | 7,666667 | 2 | 12 | 4 | 24 | 8 | 16 | 4 |

| 1993 | 7 | 6,666667 | 3 | 21 | 9 | 63 | 27 | 81 | 9 |

| 1994 | 7 | 8,333333 | 4 | 28 | 16 | 112 | 64 | 256 | 16 |

| 1995 | 11 | 9 | 5 | 55 | 25 | 275 | 125 | 625 | 25 |

| 1996 | 9 | 10,33333 | 6 | 54 | 36 | 324 | 216 | 1296 | 36 |

| 1997 | 11 | 11,66667 | 7 | 77 | 49 | 539 | 343 | 2401 | 49 |

| 1998 | 15 | 12 | 8 | 120 | 64 | 960 | 512 | 4096 | 64 |

| 1999 | 10 | 12,33333 | 9 | 90 | 81 | 810 | 729 | 6561 | 81 |

| 2000 | 12 | 10 | 120 | 100 | 1200 | 1000 | 10000 | 100 | |

| total | 98 | 78 | 55 | 587 | 385 | 4317 | 3025 | 25333 | 385 |

For a linear trend:

y \u003d 6.61 + 0.58 * t;

For a trend in the form of a second-order parabola:

y = 7.27+ 0.25*t + 0.03*t2

;

| S/c | Yi | avg moving for 3 years | Ti | Yi*Ti | Ti*Ti | Yi*Ti 2 | Ti 3 | Ti 4 | Ti 2 |

| 1991 | 7 | 1 | 7 | 1 | 7 | 1 | 1 | 1 | |

| 1992 | 12 | 9,666667 | 2 | 24 | 4 | 48 | 8 | 16 | 4 |

| 1993 | 10 | 11 | 3 | 30 | 9 | 90 | 27 | 81 | 9 |

| 1994 | 11 | 12 | 4 | 44 | 16 | 176 | 64 | 256 | 16 |

| 1995 | 15 | 12,66667 | 5 | 75 | 25 | 375 | 125 | 625 | 25 |

| 1996 | 12 | 13 | 6 | 72 | 36 | 432 | 216 | 1296 | 36 |

| 1997 | 12 | 10,33333 | 7 | 84 | 49 | 588 | 343 | 2401 | 49 |

| 1998 | 7 | 9,666667 | 8 | 56 | 64 | 448 | 512 | 4096 | 64 |

| 1999 | 10 | 10 | 9 | 90 | 81 | 810 | 729 | 6561 | 81 |

| 2000 | 13 | 10 | 130 | 100 | 1300 | 1000 | 10000 | 100 | |

| total | 109 | 88,33333 | 55 | 612 | 385 | 4274 | 3025 | 25333 | 385 |

y = 9.69 + 0.22*t;

For a trend in the form of a second-order parabola:

y \u003d 7.66 + 1.36 * t - 0.11 * t2

;