Do-it-yourself material recycling

If you want to know exactly how foam can be recycled, then we suggest that you consider a step-by-step instruction. All you need is a sufficient amount of foam and a crusher. Then you can get foam granules and use them for your own purposes. If you do not have your own foam crusher, then you can make it yourself. After all, factory models have a very high price.

Here's what you need to have a new useful tool on your farm:

- sewer PVC pipe, 50 mm in diameter;

- tape measure and marker;

- saw blade for metal;

- a wooden beam that would fit inside the pipe;

- metal screws;

- screwdriver and drill;

- metal studs with bolts;

- Chipboard or plywood to create a box.

With this set of tools and materials, you can create a working foam crusher. With its help, sheets or others will turn into crumbs. The mechanism is based on a moving part with teeth, which crush the foam into granules. And thanks to the container or box, the material is easier to direct towards the rotating mechanism. You will learn exactly how to create a crusher from this video.

So, when the crusher is ready, you can get to work. Here's what to do:

- Choose a suitable location. Alternatively, choose a garage, warehouse, pantry or barn.

- Install the crusher, taking care of the container under it, where the crumb will fall. It can be a bucket, a bag or a wooden box.

- Styrofoam sheets are easy to crush. But as for curly products, it is better to break them into pieces in advance with your hands.

- Now it remains to turn on our home-made unit and gradually process the raw materials.

Thanks to this technology, most of the granules will remain intact. And this means that they will, after all, do a better job of doing their job. You just need to be careful, as the foam is electrified and very light.

It is important to make sure that there are no drafts in the room, otherwise you will have to remove everything from the floor later. Now the foam can be collected in bags and used immediately or stored until it waits in the wings

Note!

If you melt the styrofoam with acetone, it can be used in liquid form as an adhesive. Although the mixture can not be called safe

Materials for manufacturing

Since there are several types of such material, respectively, it is made from various raw materials. The most popular today are products from:

- polystyrene;

- polyurethane;

- polyvinyl chloride;

- polyethylene.

Let us consider in more detail the preparation of each of these types of foam:

- Polystyrene foam is made from polymers of styrene. This substance has minimal strength and can be easily dissolved with gasoline or acetone. This type of foam is formed by gas filling styrene granules. Also, the procedure for obtaining such substances involves the use of additional substances that improve the structure or color the product itself.

- Polyurethane foam has good technical characteristics, which depend on the procedure for obtaining such a substance. Polyurethane polymers are very often used in various industries. The structure of the foam from such substances can be different (rigid or elastic), which is obtained from certain types of this raw material. This material is obtained by foaming with the help of special gases.

To obtain polyvinyl chloride foam, they resort to heating the raw material and its subsequent foaming under the influence of various gaseous substances. To obtain a material with initial characteristics, the resulting mixture is pressed.

The mechanical properties of the foam are also regulated with the help of special substances that are added during its production.

Polyethylene is used as a raw material for the preparation of such products. Styrofoam from it turns out soft and almost colorless.

Such products are used as wrappers for packaging various sanitary ware and household appliances. Such material is also obtained under the influence of gases that penetrate into the pores of polyethylene.

Styrofoam is popular as a heater, and therefore it is often used to insulate the facades of houses.

How to make foam look in the video:

All stages of foam plastic production technology are considered. The equipment required for the manufacture of this material is listed. Recommendations are given that you should definitely read before buying.

Many of us have met expanded polystyrene more than once, tried it by touch, made something from it, used it in construction, for home improvement. However, not everyone knows what the foam manufacturing technology is, what are its features.

Oddly enough, but in the production of this material there is nothing super complicated. And it is noteworthy that now quite a lot of low-quality polystyrene foam has appeared on the market, which is made without taking into account the relevant norms and rules.

Some craftsmen manage to create a small production line even in an ordinary garage. Yes, don't be surprised.

And this must be taken into account when buying - not all Vasya Pupkins strictly adhere to the prescribed technological standards. And what are the standards in the garage?

Raw materials and technology

Polystyrene foam is made from special expandable polystyrene foam. Its cost largely depends on the manufacturer and fraction. The price of raw materials for the production of foam plastic ranges from $ 2 per 25 kg.

When purchasing polystyrene foam, pay special attention to its quality. Domestic raw materials can be bought at a low price, but this may adversely affect the quality of the finished product

Imported polystyrene foam allows you to get high-quality material with a small amount of marriage. Recently, the main raw materials are purchased from China.

Pay attention to the quality of polystyrene, as well as the duration of its storage. The older the raw material, the longer the foaming process will take and the more difficult it is to achieve the density of the foamed granule

What is needed for the production of expanded polystyrene?

- Raw materials (foaming polystyrene foam);

- Steam (temperature about 110 degrees);

- Electricity (voltage 980 W);

- Cold water;

- Equipment.

Production technology

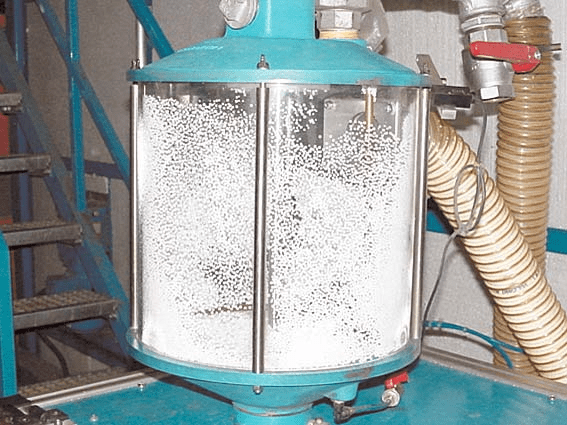

When the feed material enters the pre-expander, the granules inflate and turn into balls. If necessary, this process is repeated. After foaming, the granules increase in volume. This foam production technology is used for the manufacture of material of low strength.

Related videos

Related videos

Using recycled styrofoam

Construction is a process that requires large investments. And if you have foam, then it will definitely find its application at a construction site. For example, styrofoam chips can be used as filler for site depressions and bumps. It is clear that they cannot level the road, but a path or other unevenness is easy. Recycled polystyrene foam can be filled with a well, a hole of different diameters or a cavity.

Note!

For many years, the material will not change and will be preserved in the form and form in which it was left. It perfectly absorbs and thaws moisture.

Therefore, metal containers with polystyrene foam are not so susceptible to corrosion.

As for the construction business, recycled polystyrene foam is used to create lightweight bricks. Its structure is such that among the people it is called perforated.Even lightweight concrete has appeared, which, according to experts, is no less durable than ordinary concrete. This polystyrene biton is an excellent building material. It consists of Portland cement, directly foam plastic granules, water and an air-entraining additive. Sometimes sand is added to the mixture.

Another area of use is design. Designers are very fond of foam and use it in a variety of ways. It is used to decorate walls, create pots, planters or similar accessories. Garden figurines or coasters look very nice. They are created by pouring into molds and heating them. You can find a variety of options for what to make from polystyrene at home.

How Styrofoam is Made

We previously said. Remember that this material consists of numerous cells filled with air. This means that the manufacturing process must include foaming of the material.

And there is: the foaming process is one of the most important in the production of expanded polystyrene

.

However, this is not all.

Consider:

Stages of foam manufacturing technology

The process usually includes:

Now in more detail:

1. Foaming.

During this process, the raw material is placed in a special container (foaming agent), where under the action of pressure (a steam generator is used), the granules increase by about 20-50 times. The operation is performed within 5 minutes. When the granules reach the required size, the operator turns off the steam generator and unloads the foam from the tank.

2. Drying of the obtained granules.

At this stage, the main goal is to remove excess moisture remaining on the granules. This is done with the help of hot air - it is directed from the bottom up. In this case, for better drying, the granules are shaken. This process also takes a short time - about 5 minutes.

3. Stabilization (tracking).

The granules are placed in bunkers, where the aging process takes place. The duration of the process is 4 ... 12 hours (depending on the ambient temperature, the size of the granules).

Important note

: Styrofoam manufacturing technology may exclude the 2nd stage (drying). In this case, stabilization (tracking) will last longer - up to 24 hours

4. Baking.

This step in foam production is often referred to as molding. The bottom line is to connect the previously obtained granules. To do this, they are placed in a special form, after which, under pressure and under the influence of high temperature of water vapor, the process of sintering the granules takes place. Lasts approximately 10 minutes.

5. Maturation (aging).

The goal is to rid the resulting expanded polystyrene sheets of excess moisture, as well as the remaining internal stresses. To do this, the sheets are placed in a free place of the production workshop for several days. In some cases, maturation can take up to 30 days.

6. Cutting.

The manufactured blocks of foam are placed on a special machine, on which the blocks are cut into sheets of the appropriate thickness, length, and width. This manufacturing process is carried out using nichrome strings heated to a certain temperature. Accordingly, both horizontal and vertical cutting of blocks is carried out.

This is how foam is made.

Of course, after the listed 6 stages, 7th stage - processing the remaining scraps

. As a result, they are mixed with other granules, which will then be subjected to the same processes - sintering, curing ...

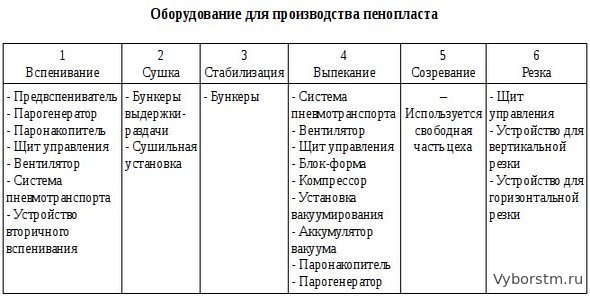

The equipment that is used in the production of expanded polystyrene is shown in the form of a table:

The foam making process

This material is made from expanded polystyrene, by foaming it. Almost 98% of it consists of gas. There are 6 stages of creating foam in an industrial environment:

Let's consider each of the stages.To begin with, the raw materials are poured into the foaming agent, after which the steam generator forms a pressure at which the granules begin to increase from 20 to 50 times. The entire foaming process takes 5 minutes. Upon reaching the desired size, the raw material is unloaded for drying. It is needed so that excess moisture on the granules evaporates. Everything happens due to hot air directed from the bottom up. Drying and shaking are performed for about 5 minutes.

Further, the raw materials are moved to bunkers, where they are aged for 4-12 hours. After that, the foam is formed or baked. The main task is to connect all the granules, creating a slab or other desired element. To do this, they are poured into a mold and succumbed to pressure under high temperature from steam. Baking lasts 10 minutes. Next, the finished foam must be aged to get rid of moisture and tension inside. Sometimes maturation lasts a whole month. At the end of this stage, the block is installed on the machine, which cuts the material, forming it. The machine has nichrome strings that heat up and easily cut foam.

In addition, the processing of polystyrene foam is also carried out at the production site. After all, when creating, pieces remain. Here they are being processed. Why recycle material at all?

Foam production at home

First you need to purchase raw materials - foaming polystyrene. Expandable polystyrene is a product of the chemical industry

When buying it, you should pay attention to the warranty storage lines. The rule applies here - the “older” the expandable polystyrene granules are, the longer the foaming process takes and the more difficult it is to obtain the required density

It should immediately focus the attention of readers of this article on the fact that making small amounts of foam plastic at home is, to put it mildly, unprofitable. If, according to the conditions, insulating plates or baguettes are required, which the building materials market is filled with, it is much easier and cheaper to buy them and not fool your head

But for enthusiasts who specialize in the manufacture of exclusive author's products (like handmade craftsmanship), the technology is useful - making foam at home

, which will be described below. Since this material is perfectly glued, it is possible to invent and invent complex products from segments that have different shapes and sections.

What can foam molds be made from?

Various materials can be used as the material for making foam molds, from ceramics to wood. Molds made of steel or tin-casting molds serve for a long time.

You can also use heat resistant plastic. If, however, you decide to use silicone culinary molds as molds for foam plastic, they must be strengthened with alabaster or gypsum - just pour a suitable container with alabaster or gypsum mortar and dip the mold into it along the very edges. It is quite difficult to weld the finished product to the mold, as well as to glue the foam to other surfaces.

Manufacturing technology and processing of foam at home

The technology for the production of foam at home involves two-stage steaming of the feedstock. In this case, all kinds of household appliances can be used as a source of steam: a steam mop or a Karcher type washing machine with a steam generation function.

The amount of steam produced by these devices will be quite enough for the production of small products that fit on the palms of the hands. As a rule, these products are used for interior decoration.

The first stripping of polystyrene foam can be organized in an ordinary metal bucket.Fill it with 20% (1/5) of the volume with expandable polystyrene granules, immerse the hose from the steam generator into the thickness of the granules and start the device in a circular motion and process the granules with steam.

After a certain period of time, the granules will increase in size and fill the bucket to the very top. Now it is necessary to distribute the primary processed raw materials into molds and steam them until the granules stick together.

Now you don’t need to mix them, just lower the hose to the bottom of the mold and turn on the steam generator. Thus, you will get a kind of gap for which you can attach the foam and easily remove it from the mold.

It should be borne in mind that the thinner and more embossed the product, the smaller the diameter of the primary granules should be (after the first foaming-steaming). And the larger they are, the lighter and more fragile the finished product.

The production of building materials has always brought a good income. This also applies to foam. Today, this material is in great demand in the domestic market.

If you decide to open your own business and make a good fortune, pay attention to the business plan for the production of foam. To implement this idea, you will not need a large start-up capital, as, for example, in the case of, so any novice entrepreneur can do this business.

Polyfoam manufacturing technology directly affects the quality

As we said above, now the market is filled with a considerable amount of low-quality material. It can be produced in garages, some storage facilities.

But the main problem is not where the material is made (although the environment also affects quality), the main problem is not following all the rules for making foam.

What deviations from the correct production of polystyrene foam can be?

The most diverse - starting from poor-quality granulation and ending with poor, inaccurate cutting of foam blocks into sheets.

Some smart people do not carry out stabilization as such, aging at all. For them, only the speed of production of polystyrene foam is important.

Because of this, they get worse:

- it can be fragile, fragile,

- granules may not be well connected to each other,

- density may be uneven.

It can also be due to poor quality, faulty equipment that was used during production - foamers, dryers, compressors, steam generators, etc.

And further important point

: with poor manufacturing technology, the foam may have a sharp, unpleasant odor. The following picture is possible: they brought brand new sheets of expanded polystyrene home, put them in a garage or other room, and ... soon they heard that the room was filled with some kind of pungent, unpleasant smell.

This is very bad. This means that the foam still “floats” in full, releasing harmful substances. It is especially dangerous when such low-grade material is piled up in residential areas.

Location

In order to choose the right geographical location of the enterprise, it is necessary to conduct a thorough market research. The most favorable for doing business are those regions in which the supply of this product does not fully cover the demand. In such a place, you can safely launch your commercial project.

Do not forget to clearly work out and include in the business plan the ways of selling the finished material. This is a very important point, on which the profitability of your enterprise largely depends. In addition, the seasonality of the business should be taken into account. In a period when demand for products is falling, you can switch to the production of foam products. This will allow you to provide a stable year-round income.

The main consumer of foam -. Each of them already cooperates with other manufacturers

You need to attract their attention to your product with low prices, but at the same time with good quality. To ensure stable sales of products, it is necessary to find regular wholesale buyers, for example, and conclude contracts with them

Recycling why and how

If we talk about large-scale production, then the goal is clear - there is a lot of waste, and this is additional funds. And what about us, ordinary users? The thing is that over the years there is more and more material in the house. It takes up space and accumulates more. It is not recommended to burn it, as it emits harmful substances, and throwing it away is also not an option.

So it turns out that the correct and effective solution is to recycle or do it yourself. Such recycling of polystyrene will help to use it for another purpose and get rid of excess garbage at home.

To do it yourself, it is important:

- determined for the purpose of processing and creating foam;

- choose the best place where you can bring everything to life;

- will determine the method of influencing foam plastic waste.

Many stop at using foam as a packaging material. It is problematic to store it ready-made, but grinding will help solve the problem. To do recycling, you need a foam crusher.

There are several ways to recycle or dispose of Styrofoam:

Some may ask: why do I need crushed foam? It can be used not only for transportation, but also as a heat-insulating material. Let's see where else it comes in handy.

Conclusions on the manufacture of foam

- The technology is quite simple, but requires mandatory compliance with all prescribed rules and regulations.

- Material (which outwardly will be similar to high-quality) can be obtained even with significant deviations from the rules of production. And this is used by "handicraft" firms (bad people).

So: buy only products from reliable, trusted manufacturers (who monitor quality)

. Check that sellers have the appropriate quality certificates.

Now you know how polystyrene is made, you know the main features of manufacturing technology and which material should be preferred. Good luck!