The principle of operation of the Vaillant condensing boiler

The Vaillant condensing boiler uses modern energy-saving technologies. It has been observed that in traditional (atmospheric) heating equipment, a large amount of heat simply goes into the chimney.

The Vailant condensing boiler has a heat exchanger that allows you to accumulate the energy of the exhaust products of combustion. Heat is removed by provoking condensate, steam droplets heated to the “dew point”.

The coolant temperature does not exceed 60°C. Therefore, condensing heat generators are recommended to be connected to low-temperature heating systems. Smoke removal takes place in a forced way, through a horizontal coaxial chimney. As a coolant, it is forbidden to use antifreeze.

The operation of the boiler is controlled by sensitive automation, controlled by a microprocessor controller. Fifth generation boilers are equipped with weather-dependent temperature sensors that send a signal to the control unit to correct the selected operating mode.

If necessary, to increase the capacity, a cascade connection to a single network of up to five units of heating equipment is allowed. All settings are made via the main control unit, one of the connected boilers.

Gas boiler automation

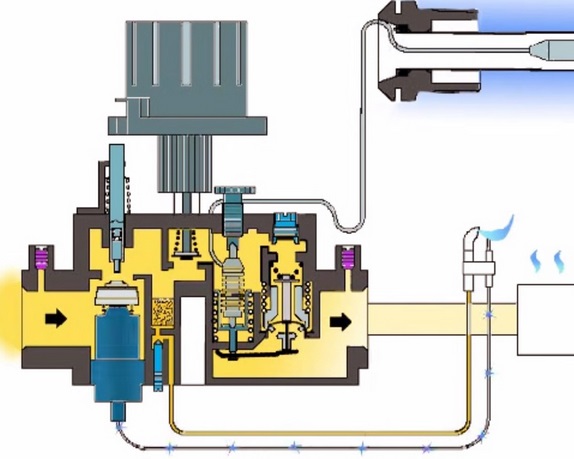

In budget configurations of boilers, the burner control functions are performed by an automatic gas valve, combined in one unit with a thermostat. A simpler principle of operation of the gas boiler thermostat is used, in which the gas valve actuator is connected to the thermostat rod. The stem moves under the influence of a thermocouple connected to it by a capillary tube. The movement of the rod is limited by the handle, which sets the desired temperature on the boiler.

Thermocouples are of two types. The first uses the principle of an expanding liquid placed in a closed space of the body. When the thermocouple is heated, the liquid begins to expand and through the capillary tube act on the thermostatic stem. Another principle of operation of the thermocouple of gas boilers is based on the following phenomenon: if the joint of two different metals is heated, then a small voltage appears on the wires soldered to these metals, up to 50 mV. In this case, the gas valve drive is equipped with an electromagnet, which turns off when the thermocouple cools down and shuts off the gas. The diagram of the automatic valve is shown in the figure.

Diagram of an automatic valve

When ignited using a piezoelectric element, the principle of operation of the gas boiler automation is as follows:

- The adjusting wheel is pressed by hand, while gas is supplied to the igniter.

- With the other hand, the piezo ignition button is pressed, a spark jumps on the igniter and it ignites.

- The wheel is held for 10-30 seconds. This is necessary so that the thermocouple heats up and fixes the gas valve in the open position.

- The wheel is released and rotated to the desired position. Gas is supplied to the main burner and it is ignited from the igniter.

- When the gas is suddenly turned off, the gas burner and the igniter go out. It takes a few seconds for the thermocouple to cool down and release the gas valve actuator, which immediately shuts off the gas.

This is the simplest security automation that does not require an electrical connection. However, it is inertial, that is, for its operation, it takes time for the thermocouple to heat up or cool down. However, in accordance with regulatory documents, this automation should be on every boiler, since it is reliable and does not require electricity.The electronic elements and sensors controlled by the controller are deprived of inertia, but still they can only be used in conjunction with basic automation.

How does a double-circuit gas boiler work

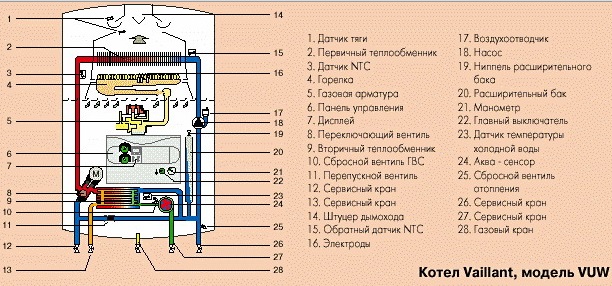

The base of any boiler is the body, it can be round or rectangular. The combustion chamber is located inside, outside its walls are covered with heat-insulating material. In the lower part there is a gas burner with an igniter.

In the upper part there is a main heat exchanger made of cast iron or heat-resistant steel, through which the coolant flows. The secondary heat exchanger for providing domestic hot water is located outside the combustion chamber. An automatic element is placed in front of the burner, which includes a gas valve and a thermostatic regulator with a heating sensor (thermocouple).

A three-way valve is used to distribute the coolant flows and mix in the circuit. The general arrangement of a double-circuit gas boiler can be considered using the example of a wall-mounted gas unit with an open chamber of the German-made VAILLANT brand.

In addition to the main equipment, high-tech gas boilers are equipped with a circulation pump, a fan for forced air supply and an expansion tank. In the most expensive trim levels, there is a second expansion tank for hot water or a built-in boiler.

The flame of a gas burner heats the main heat exchanger, a coolant circulates in it with the help of a pump, this is the principle of operation of a gas boiler. The coolant temperature is measured by a sensor and maintained at a certain level by an electronic control unit. It happens like this:

- The coolant circulates in a small circle through the main heat exchanger, a three-way valve and a pump.

- The temperature sensor detects the heating of the water to a certain value and transmits an impulse to the control unit, which commands the three-way valve electric drive.

- The three-way valve begins to open the coolant flow from the outside, from the system, mixing it with heated water. The more it heats up, the more the valve opens the external flow. Thus, the outlet temperature is always constant.

- When the temperature of all the water in the system reaches the set value, the electronic control unit acts on the gas valve and it shuts off the fuel supply, the burner turns off. The flame remains only on the igniter.

- As soon as the coolant cools down, the controller gives a command and opens the gas valve, after which the burner is automatically ignited from the igniter.

Distinctive features

But all of the above can be found in other brands. So what's the point of buying these particular boilers? It's all about several features of the equipment produced by Vailent:

- High build quality. It is he who owes the price of the goods. Nothing will hold together or fall apart during installation, as in Chinese handicrafts, and the name of the company is known to the whole world, because the brand is over 100 years old. The experience of Vaillent engineers is difficult to overestimate, which is why their products are famous for their high level of safety, because there is nothing more important in gas boilers.

- Often "German technology" is just a marketing ploy, and not all goods produced in Germany are worthy of praise. But it is thanks to companies like Vaillent that users still appreciate European quality.

- Diverse product range. Having one quality standard, the company manages to produce cheap wall-mounted and expensive floor double-circuit gas boilers. Thus, you can choose what you need specifically in your case.

- The high efficiency of all boilers, one of the highest on the market, is combined with the German safety standard.

You should not idealize the equipment of any manufacturer and forget about such a thing as "factory marriage". No matter how many good reviews you hear about the company, you may come across exactly that unsuccessful boiler. Fortunately, the guarantee allows you to quickly exchange goods.

To avoid additional problems, choose the right store for the purchase. After all, you have to pay a lot of money for the quality of Vaillent, and you absolutely don’t want to spend an annual salary on something that may not work at all. Also, do not be afraid to check with the sellers whether their store is an official distributor of equipment or a reseller. But this can be understood on your own, because in the second case, prices are 10-20 percent higher.

Description of the Vaillant floor boiler

It is not the first year that Vaillant floor-standing gas boilers conquer the market, and all thanks to the high quality of products. The most popular product of the company are double-circuit devices, their advantage lies in the fact that they are capable of delivering more power, providing heat from two floors or more.

However, it is definitely worth making an extension or a separate boiler room for such a boiler, because it is forbidden to place devices with a power of more than 60 kW in the kitchen according to fire safety rules. But if there is no desire to spend additional resources on rebuilding a new building, the company also has a number of wall-mounted heaters - from 24 to 34 kW with a capacity.

To understand why it is worth paying a little more for a brand, let's look at the characteristics that the Vaillant atmovit gas floor-standing boiler produces.

Subtleties of repair of heating boilers Vailant

It should be understood that often the need for repair arises for two reasons: violation of the rules of installation and operation. If the gas equipment is set incorrectly, the gas valve with the engine is the first to fail. The ignition electrodes are at some risk, especially if the fuel mixture does not meet the manufacturer's requirements. In this "situation" even electronic components can break - by the way, they cost a lot of money.

If there is a problem, Vaillant will definitely inform the user about it. For this, a special LCD screen is provided, on which errors F28 and F29 will appear.

Upon receipt of such a signal, we recommend that you drop everything and make an immediate, full-fledged diagnosis of all equipment. It is desirable that it be performed by qualified specialists. In addition to repairing the boiler, they will also clear its memory to prevent a repeat failure.

In general, many owners of Vaillant and other heating devices make the same mistake in the event of a breakdown. They begin to randomly change components. However, in reality, it turns out that it was necessary to look for the true cause, and not try to correct the consequences of the breakdown.

- Problem 1: The equipment has completely failed. Sometimes this happens at the beginning of operation, when the user or unfortunate masters incorrectly connect the phase and zero. The accumulated air in the system can create a serious barrier to starting the mechanism. Take this into account during operation.

- Problem 2: Burner flame is low. This problem is global, as evidenced by numerous "cries for help" on forums and thematic sites. This happens if the minimum natural gas pressure in the system is set incorrectly. It also does not hurt to check if the diode bridge is working together with the valve. The problem is solved by the correct setting of the technique. All recommendations can be found in the manual or instructions that come with all Vailant cats.

By the way, low pressure can cause the burner to go out immediately after starting. If you are faced with this situation, do not panic. It will be enough to set the pressure at the level of five mbar.

- Problem 3. The water temperature in the system is too high or too low. You can fix the problem by adjusting the indicators. But if the modulation mode stops functioning, the valve and the board are most likely faulty.

- Problem 4: The filter is clogged. This is usually due to poor water quality. Fighting this problem in Russia is practically useless.

Mounting Features

Installation of double-circuit boilers should always be carried out with caution. Do not forget that the case heats up just like water

Accordingly, it is worth worrying about the refractory wall and its coating. And it is best not to place flammable objects near the boiler at all.

And leave half a meter on the sides and a meter in front around the case so that you can easily service the device if necessary. With branded boilers, it is much easier to get permission to connect to the gas main, but if you do not follow all the safety precautions, then even the most expensive device will be lying around in the garage without use.

Specifications

You can argue about the superiority of double-circuit and single-circuit boilers for a long time, but it all depends solely on the volumes that need to be heated. The company has several series, for various purposes, but they all have in common:

- Highly economical gas consumption. The efficiency of the boilers is approaching record levels, with a difference of 5 percent, depending on the model chosen.

- There are also series with mechanical and digital control. It is not worth mentioning that the second variety is more reliable, but makes you dependent on electricity, and in the event of a power outage on the site, you can freeze in your own house.

- The speed of water heating is standard, it is difficult to speed up this process in any way, and almost all double-circuit boilers of the middle price category give the same indicators.

- Additional purification of combustion products. Someone will consider this unnecessary, but those who have ever dealt with a clogged chimney will immediately understand why such functionality is needed. In fact, this saves the user from unnecessary headaches.

- The user immediately has access to control of all systems, without the need to climb into the hardware of the boiler and change something. The PRO series also has an electronic display and remote control capability.

- The screen displays absolutely everything. If an error occurs, it will issue its code and decryption, allowing the user to quickly find the cause of the breakdown.

The consumer is provided with a standard choice, from wall-mounted versions with 24 and 34 kW power, to floor-standing versions, the power of which is 2-3 times greater. Such a solution allows you to operate the company's equipment in all premises, from small apartments to multi-storey private houses. You do not need to abandon your favorite brand because of the scarcity of the product range.

In addition to the standard circulation pump with expansion tanks, you will find many safety features in the boiler, which is extremely important. Someone will consider such pedantry to be unnecessary and only overpriced, but in fact it is better to play it safe, especially if you want to hang an autonomous heating system right in the living room

But the price segment varies greatly. The quality of the equipment allows you to take second-hand boilers, but it is better to choose a series of a maximum of 2 years ago so that there are no problems. A new device will cost you from 60 to 150 thousand rubles, depending on the series and configuration. Here everyone makes an individual choice, because it is unlikely that you will need a powerful floor-standing boiler in an apartment or a weak wall-mounted boiler in a two-story house.

The main thing is not to forget that, even after calculating the required power for the specific dimensions of the building, it is better to add 10 kW on top as a reserve. Otherwise, you will encounter "cold zones" in the pipes, and the room temperature will constantly change within 5 degrees.